SK LASER

Videos

Loading the player ...

- Offer Profile

- SK Laser, based in Wiesbaden, is a manufacturer of laser systems for 2D and 3D laser engraving and laser marking for all plastics and metals since 2005. It is a strongly growing, owner-managed company of the laser industry. With our successful laser machine, the workstation 1, the company has established itself on the market and keeps a large number of very satisfied customers inland and abroad.

Product Portfolio

KOLLTRONIC® LASER MACHINES - MADE IN GERMANY

-

SK Laser GmbH offers industry-specific solutions for permanent laser marking and laser engraving of products, components or entire assemblies.

We build your laser system according to your needs. Whether complete solutions or integrated marking laser, SK Laser provides a tailor-made laser systems of different technology for precise results in all areas in application

The Kolltronic ® F-series

-

The Kolltronic ® fiber laser engraves and marks both plastics, as well as metals in shades from white to black as surface engraving, depth engraving or annealing.

It is equally suitable for color change, as well as the color or material removal on plastics.

This allows you to mark a wide range of materials and objects such as screws, tools, labels and much more clean and dry, resistant to chemicals and light as wells as smearproof.

The fiber laser ist available in the power stages 10, 20, 30, 50, 75 and 100 watts. As a laser class 1, system we offer our workstation 1, which is particularly suited for the production of small series. For flexible workpiece processing with frequently changing objects an open laser (class 4) is the best choice.

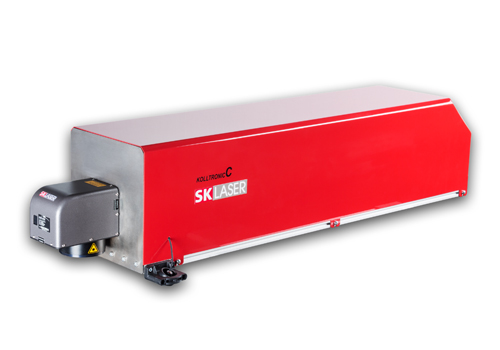

The Kolltronic ® C-series

-

The Kolltronic ® C-series is especially good for laser marking on organic materials. This includes plastics, wood, paper, cardboard, textils and plexiglass.

The more powerful CO2-laser allows you to cut wood and plastics up to 20 millimeters.

Our Kolltronic ® CO2-lasers are available with an output power from 30 to 200 watts.

The Workstation 1

-

The Workstation 1 is our basic model on which everything is based. It can be expanded and equipped very flexible. We supply the machine according to our customers requirements, so you have a variaty of variants.

Larger versions in XL and XXL, tunnels for long parts, semi-automatic laser systems with drawer or turntable, also the possibility of crane loading for products weighing 200 kg, axis traversing systems and camera systems can be installed in the laser machine according to customer requirements. Everything is available up to the fully automatic laser machine.

The workstation can be supplied with different laser types and different laser powers.

Special construction

-

Besides the workstation 1, SK LASER offers special machines and complete solutions, which are precisely designed to your reqiurements.

This allows a variety of variants for your laser system. From tunnels for long workpieces, to semi-automatic systems with turn-tables, camera systems and axis displacement systems, to fully automated laser systems.

We also manufacture work desks, cabinets and machine housings made of aluminum, according to your wishes.

3D Laser engraving

-

3D LASER ENGRAVING SYSTEM FOR DEPTH ENGRAVING OF STEEL

The low-cost alternative for 3D depth engraving in tools and mold making and all other applications in deep engraving.

With the KOLLTRONIC® 3D laser engraving machine, finally there is a low-cost solution for depth engraving in metal available.

The processing of 3D objects takes place via a standard software with a variety of import possibilities, stl files are only mentioned here as an example. Laying and filling is done without complicated calculation or programming at the push of a button.

The 3D laser systems engrave 3D objects with high precision. In addition, these 3D laser systems can be used for a wide range of 3D laser tasks. They characterize a wide variety of products such as

screws, tools, labels and plastics, non-contact, clean and dry, durable, chemical, light-resistant and wipe-resistant. The result: excellent, safe readability with the eye and with digital reading devices.

The direct manual entry of labeling contents on the device is just as possible as the computer-controlled communication with networks in the fully automatic production. Modern, open interface concepts give possibilities and freedom and are open to future communication in the line.

There are no restrictions on the labeling format (choice of fonts, codes, etc.). KOLLTRONIC systems precisely match the product to be applied.

THE SOFTWARE

-

The intuitive software is exactly what you need in today's industry. Texts, barcodes, signs, circles, lines an reactangles are drawing elements which can be generated with one click. Variable data such as time, shift or item numbers can be quickly and securely set up without programming skills. Logos and pictures can be imported, the most important being here: dxf, dwg, plt, wmf, jpg, bmw and many others.

Other special shapes, such as circular inscriptions, are also set up in a single click in a selection menu. There is also the possibility to laser-engrave several parts that are located in a device or on a tablet. Fot this there is a matrix function, in which the user only needs to enter the number of rows and columns and the distance between.

CUSTOMIZED SOLUTIONS

-

fiber lasers, CO2 lasers, YAG-lasers and green lasers

We build laser open laser systems, laser workstations (class 1) and fully automatic lines

The SK Laser GmbH offers branch-specific solutions for permanent laser marking and laser engraving on procudts, components or entire assemblies. We build your laser according to your needs. We supply open laser stations as well as closed in laser protection class 1. Of course we provide the system for installation into your production line with connection via RS232 or Profibus. If you are looking for a fully automatic system with feeding, positioning, laserstation and discharge, then you are right with us!

If you want to replace the laser installed in your production line or handling system, the Kolltronic ® lasers are the first choice.

If you would like to repair a part, ask our specialists. We react quickly and flexibly.

We also repair laser machines from other manufacturers. All laser engraving e.g. YAG lasers, CO2 lasers or other lasers.

Application

LASER MARKING

-

With our Kolltronic ® laser system marking is possible on almost all metals and plastics (fiber laser), as well as organic materials ( CO2 laser).

In this process the upper cover layer of the material is removed and a recess, the engraving, occurs.

The engraving is smear and water resistant.

ANNEALING

- On metals, a color change can be achieved by heating the material. The oxidation process takes place on the surface so that the material surface remains flat and is not removed. Depending on the temperature and material, this oxide layer can not only precipitate black but also colored.

COLOR CHANGE

-

Carbon oxidizes when plastics are heated, resulting in a foam layer. Depending on the color of the plastic, this color is either light or dark.

This application is only possible with plastics.

COLOR/MATERIAL REMOVAL

-

On lacquered or coated materials, laser marking can be achieved by means of targeted color or material removal, in which the color of the underlying material becomes visible.

This is used, for example, in the automotive industry to manufacture rear-illuminated operating elements.