HOVMAND

Videos

Loading the player ...

- Offer Profile

-

Experience the Value of Working with Hovmand

We make material handling more efficient and improve the daily work life

Hovmand is the world-leading manufacturer of mobile, battery-powered lifters. For nearly 50 years, we have been improving efficiency and working conditions in the area of material handling. Our innovative lifting solutions help customers all over the world improve ergonomics and create more productive workflows.

We are driven by a desire to help our customers achieve their goals and develop the most innovative products to ensure that all organisations are equipped with solutions to create a safe and efficient work life. We are firm believers that no person should ever have to experience health problems because of material handling.

Product Portfolio

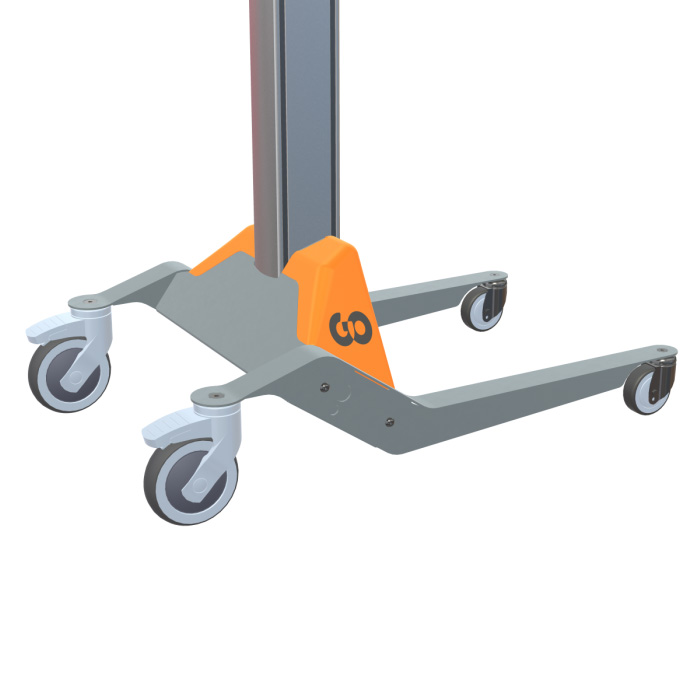

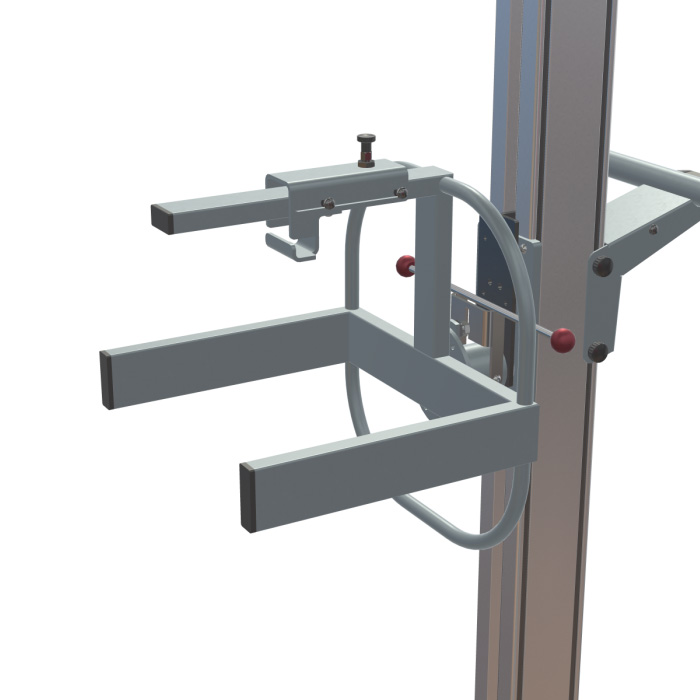

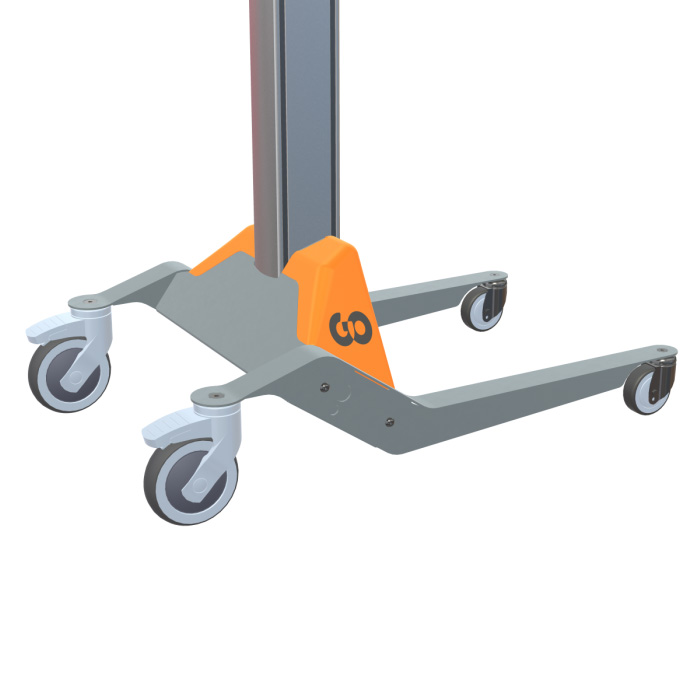

GO Series: The Cost-Effective Solution in Material Handling

- With its innovative design, the GO series makes lifting look easy. The lifters and corresponding lifting tools allow you to move liquids and smaller objects without strain or complications.

Multipurpose Lifter

- Looking for a simple and versatile lifting solution? GO is a multipurpose lifter made to solve a wide variety of everyday lifting problems. The lifter can be used across all types of industries and situations where you need to lift and move something on a platform – the opportunities are, therefore, almost endless.

The GO lifter allows you to place any type of object on the platform and move it from A to B at just the right height. This makes GO the ideal lifting aid in, for example, stores, libraries, offices and supermarkets or anywhere you wish to improve material handling in a simple manner.

Affordable Ergonomics

- At Hovmand, we are proud market leaders of sophisticated and advanced lifting solutions that enhance the daily work life of employees all over the world. With the GO lifter, we wish to make ergonomic tools even more accessible, and we have, therefore, developed an extremely affordable all-in-one lifter, ready to help you improve workflows from day one.

On top of being ergonomic, the GO lifter also comes with several features to ensure safe use. These features include a soft-start function for precise positioning of the platform, a safety clutch and overload protection to guarantee ergonomic and safe working conditions. With the GO lifter we have made the perfect cost-effective solution for more efficient material handling.

Go Series Products

GO Box 435x379-75s W (GO)

-

Lifting capacity

Max. 70 kg (~154 lb.)

Lifting height (stroke)

120 - 1505 mm (~5-59 in.)

Application:

A versatile lifter for a wide range of objects such as boxes, crates, stacks of paper, folders, and more.This Lifter Bundle includes:

- Mast: GO

- Leg: Box 435x379-75s

- Tool: W (GO)

GO Box-435x379-75s Plastic Can Tipper - Small

- Lifting capacity

Max. 60 kg (~132 lb.)

Lifting height (stroke)

Max. 1600 mm (~63 in.)

Application

Lift, tip, and transfer liquids in jerrycans and plastic cans to other containers with this three-in-one device.

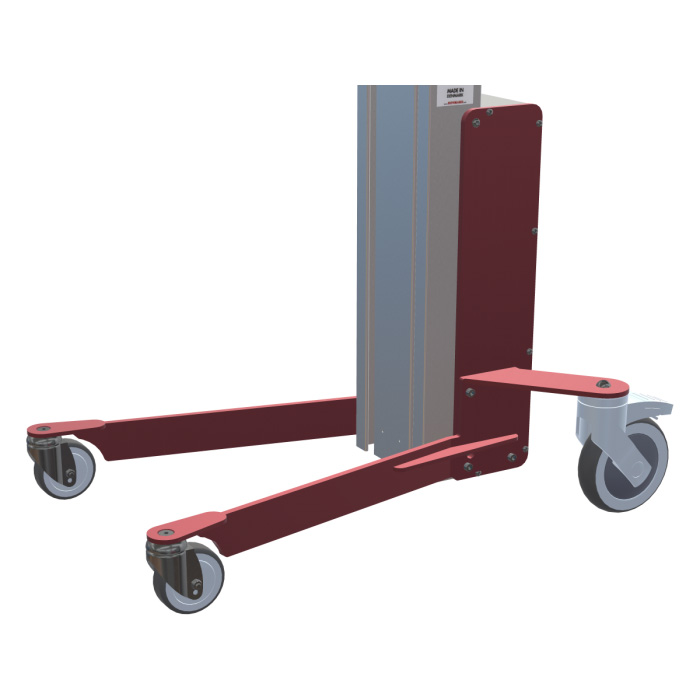

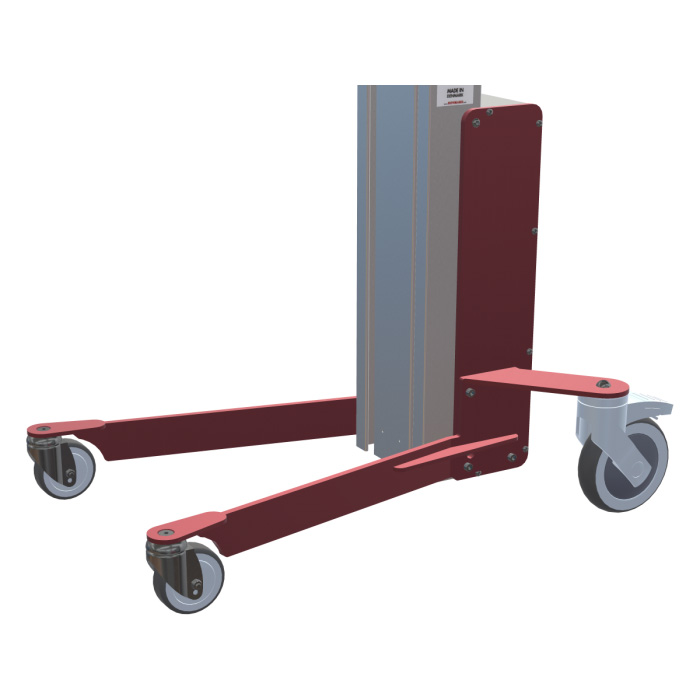

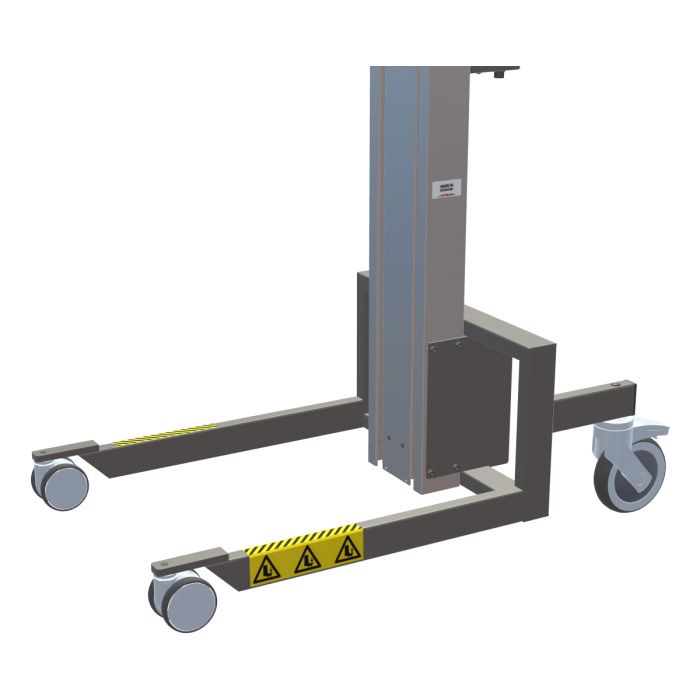

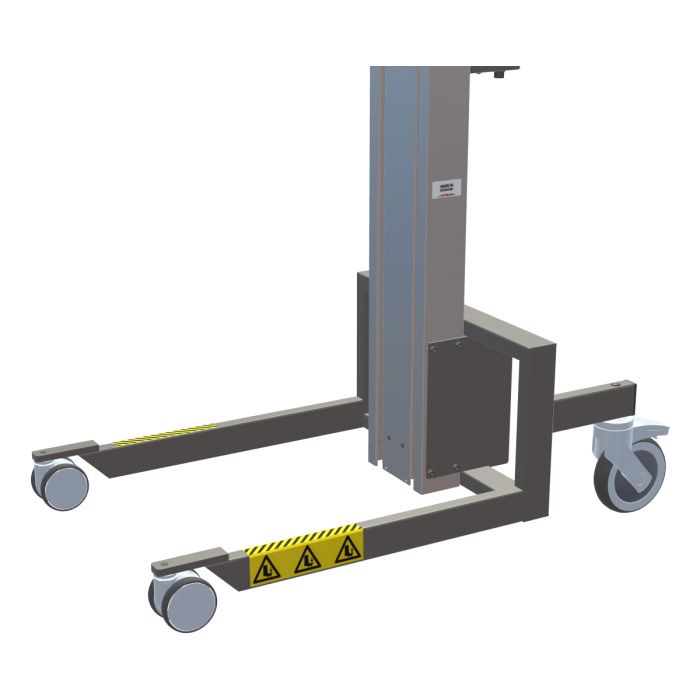

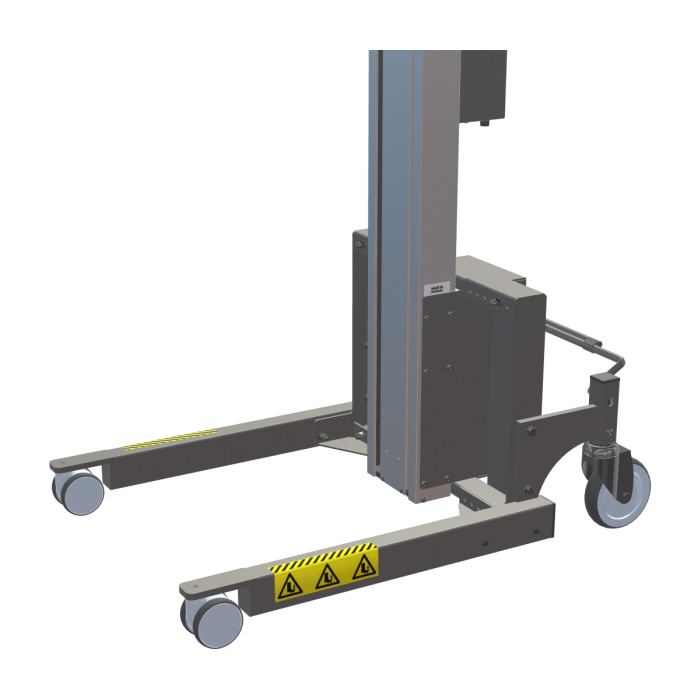

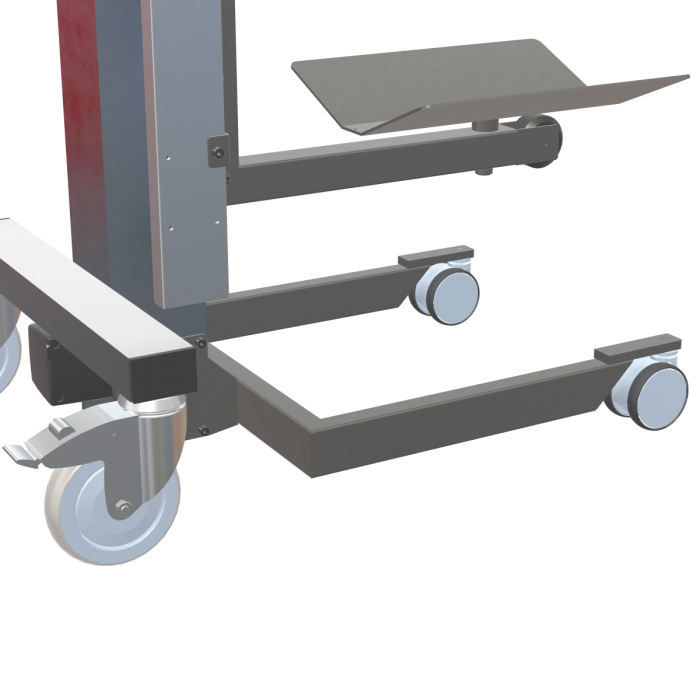

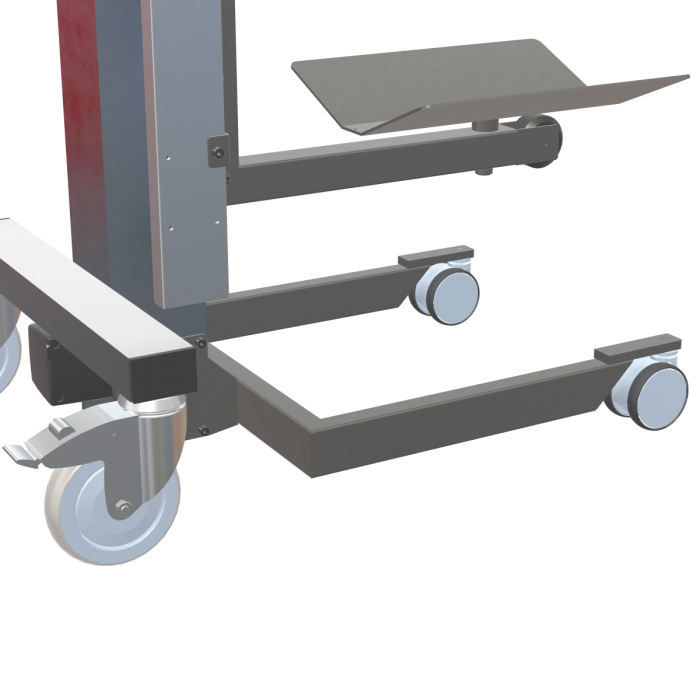

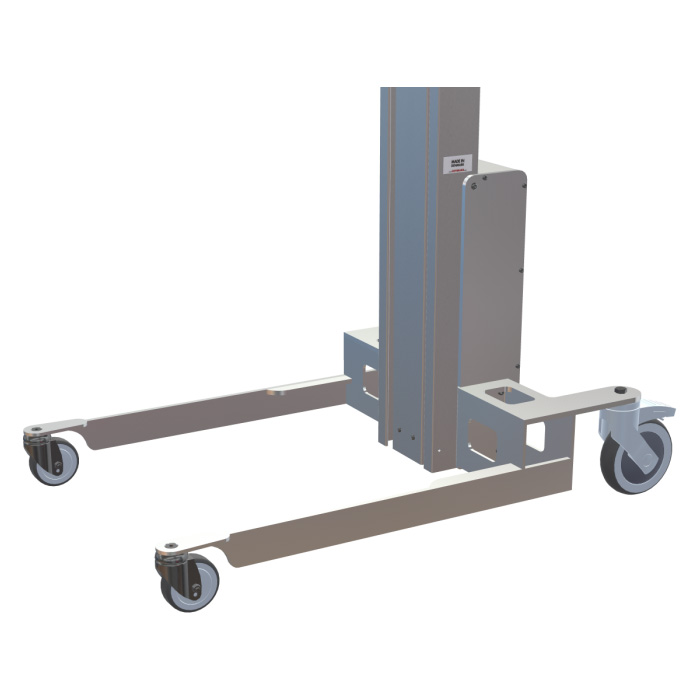

Impact series: Multi-purpose lifters for versatile material handling.

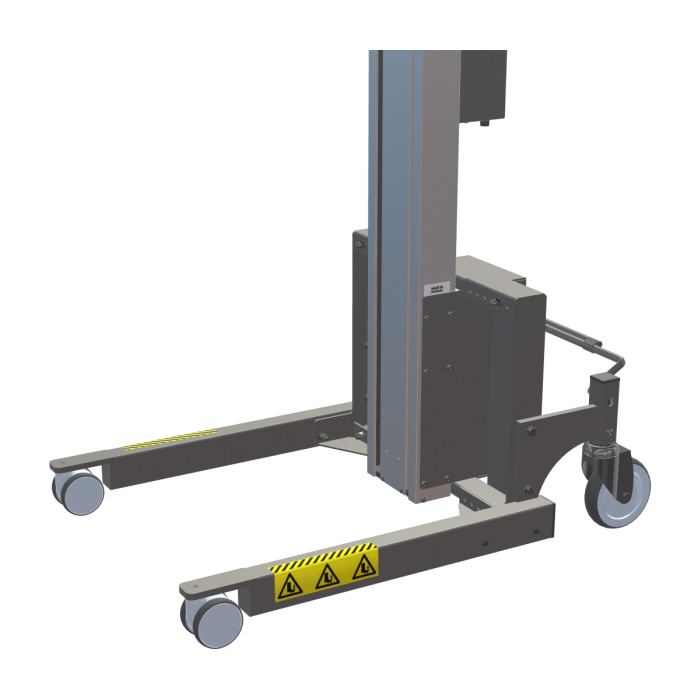

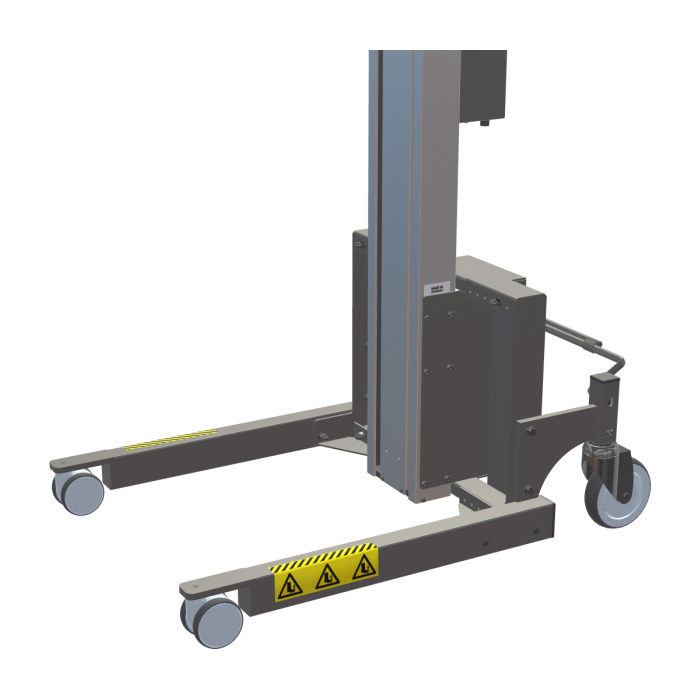

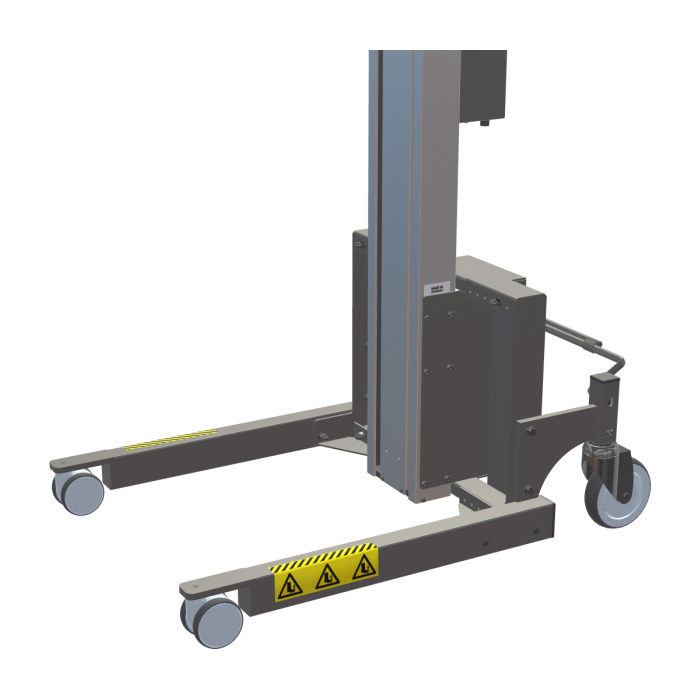

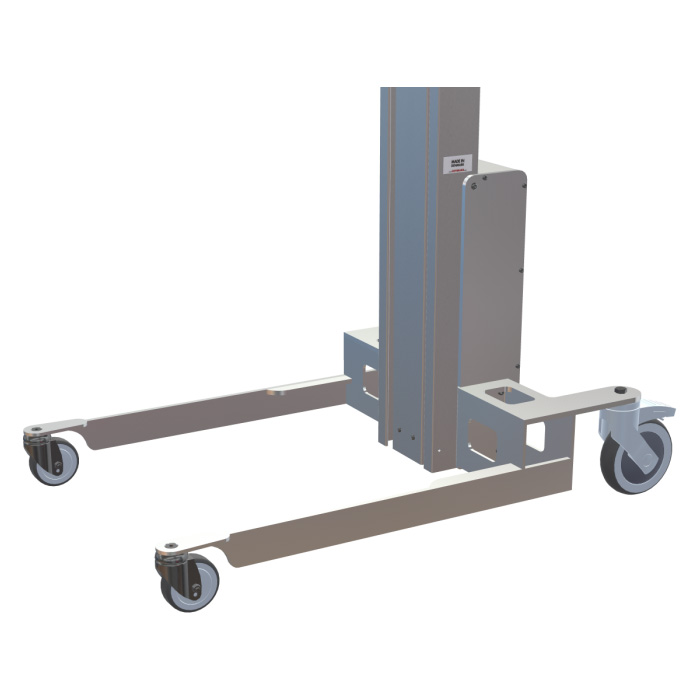

- Our most versatile and customisable lifter series, featuring a highly resilient yet lightweight design, fit for numerous industries.

Highly Customisable

- Our Impact lifters are a game changer when it comes to material handling. We can help ensure the correct lifting technique of almost all types of materials and goods ranging from drums, reels and crates to buckets, canisters and bowls.

Regardless of your industry and lifting need, the possibilities for customising an Impact lifter are almost endless. Our modular system allows you to combine legs, mast height, lifting capacity and a wide range of applications to create a lifter that makes your work processes more efficient and ergonomically safe.

Resilient yet Lightweight

- Made of aluminium and steel, and with a sleek, streamlined design, our Impact lifters are extremely resilient, while also being surprisingly lightweight and easy to manoeuvre. Designed for maximum daily use, the Impact lifters effortlessly move, lift and transport objects weighing up to 200 kilos (~441 lb.)

In daily life, our material handling lifters are made to withstand sudden force and minor collisions, and you will be happy to find that they require very little maintenance. For increased safety, all our lifters are equipped with overload protection, a safety clutch and a soft start function for easy operation.

Impact Series Products

Impact 70

-

INCREDIBLY VERSATILE.

The battery-powered IMPACT 70 lifter is incredibly versatile. With its wide range of applications, it makes work processes more efficient, ergonomic and safe across many industries. It effortlessly moves, lifts and transports goods weighing up to 70 kg. Its "Commander" push-button control unit is easy to understand and can be operated from any position.

For increased safety, the IMPACT 70 is additionally equipped with overload protection and safety clutch, and you can combine it with four different leg types, three mast heights and more than 15 different tools.

Lifting capacity

Max. 70 kg (~154 lb.)

Lifting height (stroke)

Max. 1685 mm (~66 in.)

Application:

Impact 70 can lift and handle crates, boxes, sacks, Euro stacking containers, reels, and more.

Impact 80

INCREDIBLY QUIET.

The IMPACT 80 is designed to lift and move a wide range of different objects, including rolls, boxes, cartons and crates with a total weight of up to 80 kg. The particular feature out this lifter is that it works almost silently. In order to enable even more prolonged use, it has a built-in charger and battery indicator.

One for (almost) everything: thanks to its quick-change adapter, you can use a wide variety of tools with just one lifter, allowing flexible deployment at the workplace. This makes your daily work processes even more efficient and cost-effective.

Lifting capacity

Max. 80 kg (~176 lb.)

Lifting height (stroke)

1242 - 1642 mm (~49-65 in.)

Application

Impact 80 is a reliable lifter, fit for moving crates, boxes, sacks, Euro stacking containers, reels, buckets, small drums, and more.

Impact 90

-

VERY FAST AND RESILIENT.

The IMPACT 90 is not only the fastest lifter in this product range, it is also one of the most resilient. Designed for maximum daily use, it effortlessly moves, lifts and transports objects weighing up to 90 kg. The lifting speed easy to regulate by means of a handy remote control. To protect your employees and colleagues, the IMPACT 90 has overload protection, a safety clutch, shielding for all moving parts and a battery indicator for better planning capability. Configure the fastest Impact lifter according to your needs with a versatile selection of lifters, trolleys and mast heights. Lifting capacity

Max. 90 kg (~198 lb.)

Lifting height (stroke)

1242 - 2042 mm (~49-80 in.)

Application

Impact 90 is the fastest lifter on the market and can handle crates, boxes, sacks, Euro stacking containers, reels, buckets, small drums, and more.

Impact 130

-

EXTREMELY POWERFUL.

If there's something heavy to lift somewhere, the IMPACT 130 is certainly a reliable help. The IMPACT 130 is a powerful lifter that easily lifts loads of up to 130 kg for a variety of lifting tasks. Not for nothing is it the most popular lifter in our entire product range  and a great support in day-to-day work and manufacturing processes.

For added protection and comfort, the IMPACT 130 is equipped with overload protection, a safety clutch and a soft start function for easy operation. For more specific requirements, the IMPACT 130 can be customised with a choice of five mast heights, different leg types and different wheels.

Lifting capacity

Max. 130 kg (~287 lb.)

Lifting height (stroke)

1242 - 2771 mm (~49-109 in.)

Application

Impact 130 is a powerful lifter, highly suitable for lifting crates, boxes, sacks, Euro stacking containers, reels, buckets, small drums, jerrycans, and more.

Impact 200

ENDURING AND RELIABLE.

When the going gets tough, the IMPACT 200 is the most reliable and durable lifter. This is because it effortlessly copes with of up to 200 kg total weight. And with amazing stamina, too. Thanks to its exchangeable batteries, it can work 24 hours a day for you without loss of power. We have designed a range of electrical and manual tools for really heavy tasks, and you can configure these as required. You can easily move rolls or drums by remote control for example, according to your choice. This not only makes your processes more fluid, it also gives you a whole new level of flexibility in terms of the efficiency of your existing production processes. In addition, you can choose the right mast height, undercarriage and platform to suit your operations.

Lifting capacity

Max. 200 kg (~441 lb.)

Lifting height (stroke)

1232 - 2041 mm (~49-80 in.)

Application

Impact 200 is designed to do the hard work and is able to lift crates, boxes, sacks, Euro stacking containers, reels, buckets, drums, and more.

Compact

STRONG AND SPECIALISED.

When it comes to handling large and heavy paper, cardboard and plastic reels, COMPACT is the right choice. The smallest battery-operated lifter on the market features a combined boom with wheel for easy lifting of rolls up to 100 kg and a rotating V-block for special reels with axle up to 60 kg. A cost-effective alternative for those who like to keep things simple. This ensures your reels are transported safely from A to B and all the way to the packaging machine (perhaps better: further processing machine?).

Our COMPACT lifter is a simple, self-explanatory lifting solution, specially developed for the printing and packaging industry. And it's so simple: pick up the reel on the boom or the V-block, run to the machine, apply the brakes and then comfortably push the roll from the boom or V-block into the machine. Lifting capacity

Max. 100 kg (~221 lb.)

Lifting height (stroke):

825 - 1325 mm (~32-52 in.)

Application

Compact is the market’s smallest battery-driven lifter, perfect for handling reels.

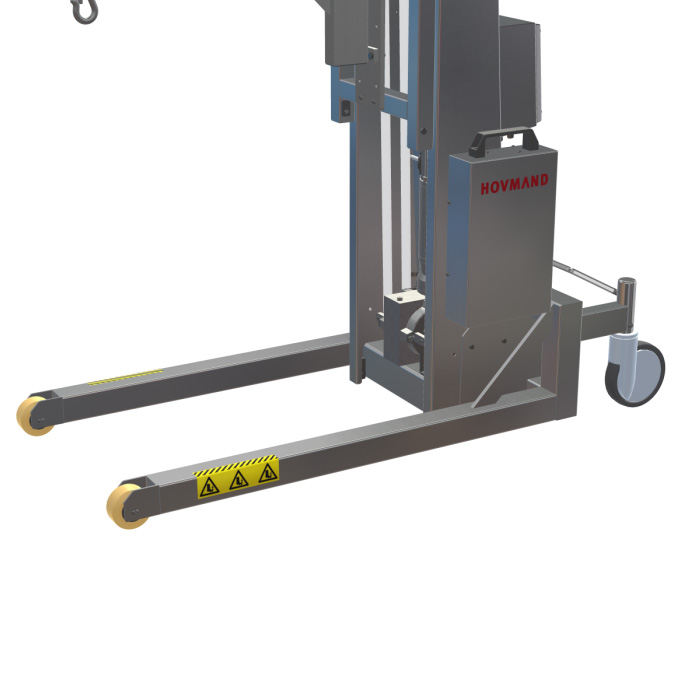

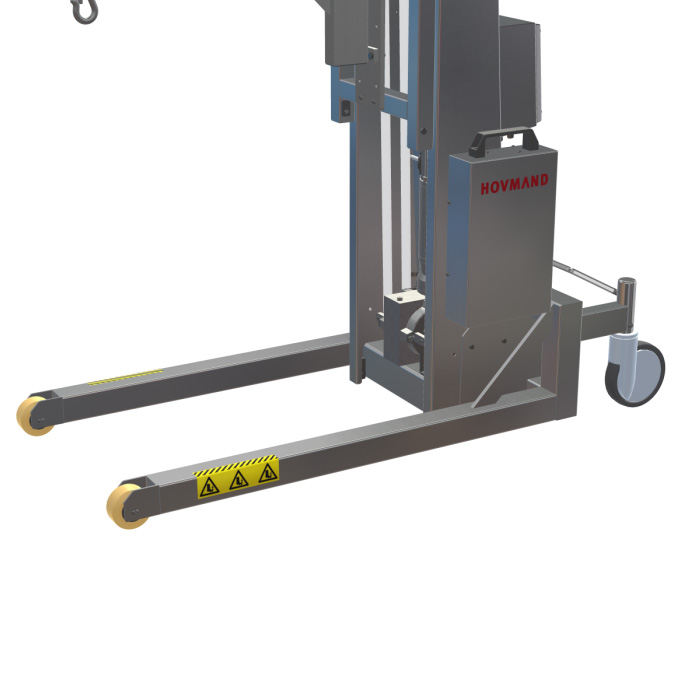

INOX Series: Stainless Steel Lifting Equipment

- Made from 100% electropolished stainless steel and with our largest lifting capacity of up to 300 kg (~661 lb.), the INOX series is your perfect lifting aid in hygienic environments.

Hygienic Design

- Our stainless steel lifter is your perfect aid in sensitive work areas that have rigorous standards in terms of hygiene and the cleaning of equipment (IP66). Designed and manufactured to GMP standards, our stainless steel lifters meet all requirements when it comes to handling and transporting sensitive goods in hygienic areas.

The INOX lifter and its corresponding lifting tools are made of 100% electropolished stainless steel, which makes the material particularly easy to clean. The hygienic, waterproof design provides optimum protection from germ or dust adhesion and is even resistant to aggressive cleaning agents.

Adaptable and Safe

- With an INOX stainless lifter by your side, you are more than equipped to move, handle and lift almost all types of materials and goods. The INOX range offers our largest lifting capacity of up to 300 kilos (~661 lb.), and with all our lifters built on a modular platform, you can adapt any lifter to fit precisely to your manufacturing process.

When working in areas with strict hygienic requirements, safety standards must also be kept in place to guarantee correct material handling. For enhanced safety in demanding environments, our lifters are made with overload protection, a safety coupling, various shields for all moving parts and an accurate battery charge indicator to ensure better production planning.

INOX Series Products

- Inox lifters offer robustness and easy cleaning, perfect for strict hygiene environments.

Customisable with a high lifting capacity, they ensure safe, ergonomic material handling while resisting aggressive cleaning agents. Ideal for tasks like filling containers, rotating drums, lifting sacks, tilting buckets, and more.

Impox 70

-

PARTICULARLY LIGHT AND ELEGANT.

The IMPOX 70 is the perfect choice where handling has to be just right. This is because it is made of an optimum combination of aluminium and stainless steel. The chassis and handles are rust-free (electropolished) and all tools are made of stainless steel, while the plastic control unit for lifting and lowering and the wheels of the lifter are antistatic (ESD) as standard.

All tools and components are approved for the food industry. This light and almost elegant lifter is ideal for use in the food and kitchen sectors, being able to easily move containers and meat crates with a total weight of up to 70 kg from A to B as required.

Lifting capacity

Max. 70 kg (~154 lb.)

Lifting height (stroke)

977 - 1672 mm (~39-66 in.)

Application

The lightweight IMPOX 70 is ideal for the food industry as it easily moves and lifts containers, crates, and boxes.

INOX 90

-

EXTREMELY MANOEUVRABLE AND RELIABLE.

The INOX 90 is your perfect aid in sensitive work areas that have rigorous standards in terms of hygiene and the cleaning of production equipment (IP 66). With a capacity of up to 90 kg total weight, this stainless steel minilift reliably lifts, moves and transports goods from A to B in your containers. The properties of the INOX 90 are crucial for a smooth manufacturing process  especially in the production of food, cosmetics and medicine.

Overload protection, a safety coupling, various shields for all moving parts and an accurate charge indicator also contribute to enhanced safety. The INOX 90 has electropolished surfaces and all tools are made of pure stainless steel. You can adjust its speed to two different levels by remote control. Lifting capacity

Max. 90 kg (~198 lb.)

Lifting height (stroke)

956 - 1651 mm (~38-65 in.)

Application:

With tools made of pure stainless steel, INOX 90 is great for handling crates, boxes, and reels in sensitive work areas.

INOX 200

-

POWERFUL, HYGIENIC AND WATERPROOF.

Made of electropolished stainless steel, the INOX 200 handles loads of up to 200 kg. It was specially developed for industries with rigorous requirements in terms of cleanliness and hygiene (IP66) and is therefore frequently used in the pharmaceutical and food industries.

The model can be equipped with electric or manual tools, for example to move reels, Euro stacking containers or barrels  depending on the lifting task in question. All tools for the INOX 200 are made of pure stainless steel.Lifting capacity

Max. 200 kg (~441 lb.)

Lifting height (stroke)

1228 - 2028 mm (~48-80 in.)

ApplicationINOX 200 can be used with both electric and manual equipment to move reels, boxes, drums, and more.

E300

-

POWERFUL WITH EXCELLENT PROPERTIES.

When it comes to hygiene, the stainless steel lifter meets the rigorous requirements of food, cosmetics, chemical and pharmaceutical production (IP66). This is due to its elaborately electropolished surface finish that permits only minimal particle adhesion. Thanks to numerous manual and electric lifters, the E300 can be used for a wide range of applications, including handling drums, tubs and vessels up to a height of 2.35 metres.

For example, it can be used as an efficient reel lifter with a boom or roller grab, as a drum tipper or for stacking crates using a fork. The E300 lifter makes it possible to grip, lift, turn and tip very heavy loads of up to 300 kg. The E300 is also equipped as standard with a removable battery unit and antistatic ESD wheels to prevent discharge. Lifting capacity

Max. 300 kg (~661 lb.)

Lifting height (stroke)

1300 - 1650 mm (~51-65 in.)

Application

Made of pure stainless steel, E300 is designed to lift heavy buckets, drums, and boxes in hygienic, industrial areas.

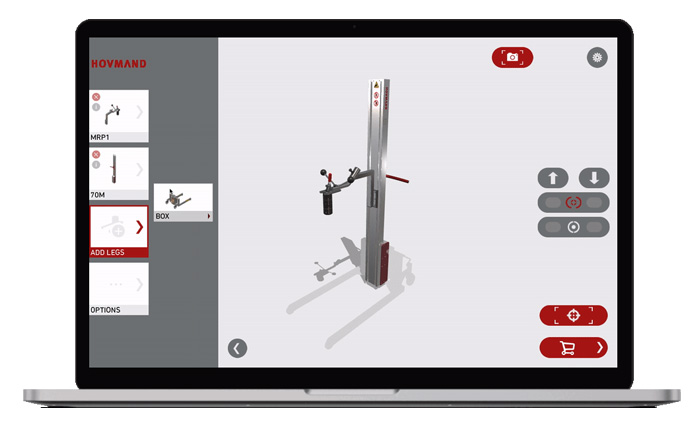

Design your own lifter

- At the touch of a fingertip, Hovmand’s Virtual Engineering app ensures you get the right solution, no matter your industry or desired application. With endless possibilities for configuration, no challenge is too great. Get started now.

Experience Our Virtual Engineering App

- We are constantly on the move. Just like our customers and partners. Always on the lookout for even better and simpler solutions to make your work processes easier. In our almost 50 years of company history, we have gone from dealing sack trucks to becoming the global market leader of mobile lifting solutions. In this video, showing our latest innovation – the Hovmand Virtual Engineering app – our CEO Søren Hovmand explains how we are using digitalisation to bring value to our customers in a completely new way.

How to Design a Lifting Solution Discover the perfect lifting solutions for retail, industry or logistics. Our flexible modular system enables us to put together a solution that is individually configured to your specific challenge. We use a wide range of leg types, mast heights and applications depending on what, where and how high you need to lift the object.

Our products are designed to provide the right lifter for every industry, situation and lifting need. With our Virtual Engineering app, we can customise the right solution for you at the touch of a fingertip or the click of a mouse. And you can see your product right away in 3D in your own environment – thanks to augmented reality technology.

Lifters for All Industries

- Hovmand supplies lifters to companies in sectors such as food, beverage, pharma, chemistry and industrial production. For industries with strict hygienic requirements, we offer electropolished lifters to meet the high demands for sterility and easy cleaning.

Food and Beverage

- Hygienic Lifting Equipment for Food and Beverage Industries

Enhanced Safety and Hygiene in the Production Process When manufacturing food and beverages, manual operations, such as heavy lifting and transporting of unwieldy objects, often pose a fundamental risk to safety, efficiency and sanitation. An issue that cannot be overlooked, as product quality relies highly on sound production processes that comply with the industry’s demanding hygiene requirements.

With a Hovmand lifting solution, the problem is removed, and you can easily optimise an entire process chain. Our battery-powered lifters are manufactured according to GMP standards and offered in stainless steel with a waterproof design, fit for easy cleaning. Whether you need to transport and combine raw materials and ingredients, pack finished products or prepare them for shipping – our lifters function as your perfect aid.

Heavy Lifting in Kitchens and Bakeries

- Professional kitchens and bakeries use large instruments and quantities of ingredients that foster material handling. In particular, the transport and manoeuvring of mixer bowls often presents as a complicated task. This is because mixer bowls need to be lifted, shifted, tipped and emptied several times every day. More so, mixer bowls come in many sizes and weight classes, making the lifting of these instruments a health hazard or even impossible.

At Hovmand, we have developed a number of lifters fit for the challenge and with assured ergonomic gains to be experienced. Maybe, you are looking for a simple solution to ease lifting between workstations, bring items to the table edge and place bowls right on the tabletop.

Or perhaps, you are looking for a seamless way to get a hold of a mixer bowl, lift it, shift it around, position it at a suitable height, rotate the bowl and pour the contents into a pan or the dough onto the table. Our lifters are fit for these very purposes, bowls (between 30 and 200 litres) easily ‘snap lock’ to the lifting arms and are held securely in place during moving.

Once the work is done, you can take the bowl directly to the sink where you can wash it or place it in the dishwasher. For selected lifters, we also offer a platform attachment that allows you to lift and carry cardboard and plastic boxes, pans, sacks, bowls and roasting dishes. In other words, we ensure you gain a suitable lifting aid that meets your needs and brings your material handling to the next level.

Moving Buckets and Reels in Dairy Production

- Within dairy production, multiple processes necessitate lifting and moving of objects and materials. For example, jerrycans and buckets must be transported throughout warehouses and storage areas. Also, the many fragile or liquid substances, handled in dairy plants, require packaging and wrapping with stretch film.

This promotes a substantial amount of reel handling. Reels often pose as heavy and unwieldly, making their moving, lifting and placement onto packaging machines a problematic activity, taking a high toll on employees’ backs and ultimately leading to low efficiency.

Do you recognise these challenges? And are you looking to optimise workflows, while also securing the health of employees? Then look no further. We supply lifters for multiple applications within dairy production. In storage areas, one of our smaller lifters (Impact 70 or Impox 70) with an attached platform, is an ideal solution, suitable for moving objects such as buckets.

We also have experience in designing and supplying custom-made solutions for unique dairy containers and offer lifters with squeeze, turn and rotating functions for easy emptying of jerrycans. The latter activity often takes place within the actual production, why lifters are made of 100% electropolished stainless steel. Last but not least, we have multiple solutions and tools that transform handling of reels from a complex to an effortless task.

Material Handling in Meat Production

- Production of meat is a craftsmanship, perfected throughout numerous centuries. Therefore, modern trade has become a demanding task that requires a number of activities, among others, revolving around material handling. On a daily basis, heavy boxes containing processed or raw meat need to be lifted and moved between workstations and onto pallets or shelving racks.

Likewise, sacks containing up to 50 litres (of e.g., salt) must be transported and unloaded. And if the meat plant also takes on the packaging, then heavy plastic reels must be placed onto the packaging machine. All activities that put strain on the individual worker and eventually slow down the speed of production. In realisation of this challenge, an increased focus on occupational health and safety has characterised the meat business in recent years. Maybe your company is next?

We offer lifting solutions to mitigate the risks associated with manual handling of cardboard and other odd size boxes as well as sacks. Our lifters and attached platform or fork tools, make moving and manoeuvring of meat and other raw materials an ergonomically safe activity.

For packing, we offer solutions with multiple tool types to ensure reels weighing up to 200 kg (~441 lb.) are properly lifted and can be shifted onto the relevant packaging machine. If any of the lifting activities take place in cleanrooms, our solutions are also provided in a stainless steel and hygienic design, ensuring protection from germ or dust adhesion as well as resistance to water and aggressive cleaning agents

Handling Reels and Sacks in Breweries

- Recent years’ rising demand for craft beer and other beverage products has created a surge in the number of breweries and microbreweries found on a global scale. A positive indication for the segment’s profitability. But with rising demand also comes new requirements for productivity and efficiency that simultaneously must comply with the wellbeing of workers.

In large breweries, this can be a difficult balance and task, when multiple reels of wrapping-film and labels need to be moved throughout production and onto machines many times each day. Similarly, microbreweries often face repetitive lifting of sacks containing raw materials such as malt, sugar and flavouring agents. At Hovmand, we aim to remove these lifting challenges for good.

Our lifters always ensure ergonomic material handling and with a broad array of tools and applications, no problem is too difficult. To ease the moving and manipulation of reels, we offer multiple powerful lifters, capable of handling up to 200 kg (~441 lb.) and with attachments that facilitate capture, shifting, turning and horizontal tipping.

Our modular design guarantees that each solution is tailored to your individual workflow and can be supplied in stainless steel, based on wants or requirements. This also applies to our smaller lifters. So, if you are looking to move raw materials, without putting strain on employees then do not hesitate to contact us.

Industrial Production

- Lifting Solutions for Industrial Production

Increase Safety and Productivity with the Right Equipment

Wherever there is a production facility, there is also a wide variety of materials that need to be lifted, moved and transported. Boxes, reels, drums and objects of all shapes and sizes can be found in manufacturing processes, and for employees, material handling is often a repetitive task that can pose an everyday safety risk and turn into health problems over time.

To guarantee maximum protection and eliminate long-term physical consequences, Hovmand lifters are the ideal solution for lifting and transporting goods throughout the entire production. With the right industrial lifting solution, you are just one step away from obtaining an optimum work environment with effective and safe material handling.

Say Goodbye to Manually Lifting Boxes

- A production area without a crate or box is a rare sight. From the materials are received and assembled to the finished products are shipped off, crates and boxes play an important role. Often, boxes are delivered in large numbers on pallets from where they are distributed to different parts of the assembly line.

Crates and boxes are, therefore, a practical solution when it comes to material handling, but they can get very heavy for employees, who typically have to lift them manually. Consequently, the task may lead to decreased productivity.

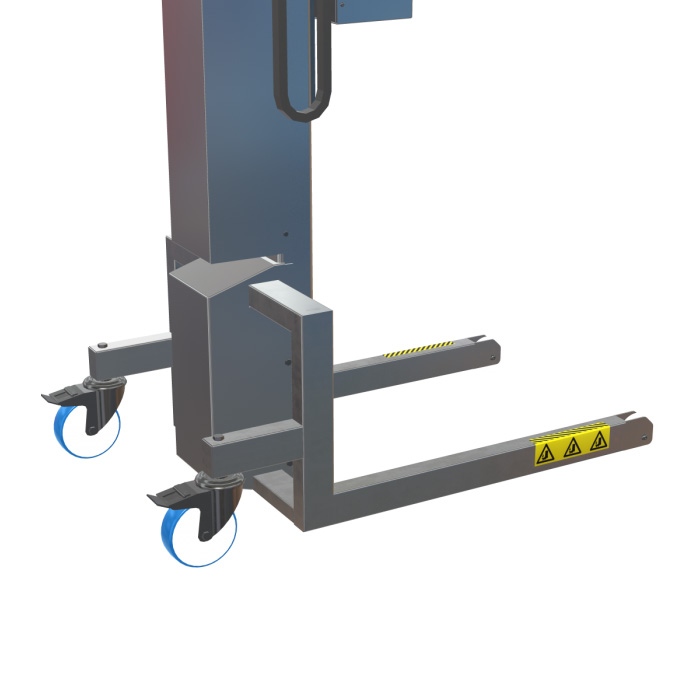

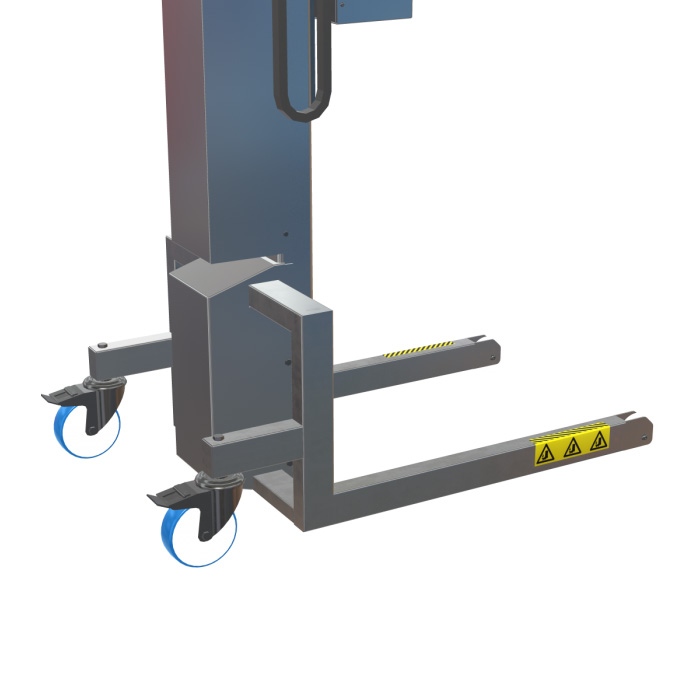

With a Hovmand lifter, the boxes are effectively transported from storage areas to the working station where they can easily be positioned at an ergonomically correct height. We offer a broad range of fork tools developed to fit the most widely used boxes in industrial production.

In case you need help handling many different types of boxes, we also have more flexible fork tools. By using a Hovmand lifting solution, you get a more efficient production process as a lifter can move several boxes at once. This relieves the employees, who in turn will be less prone to accidents.

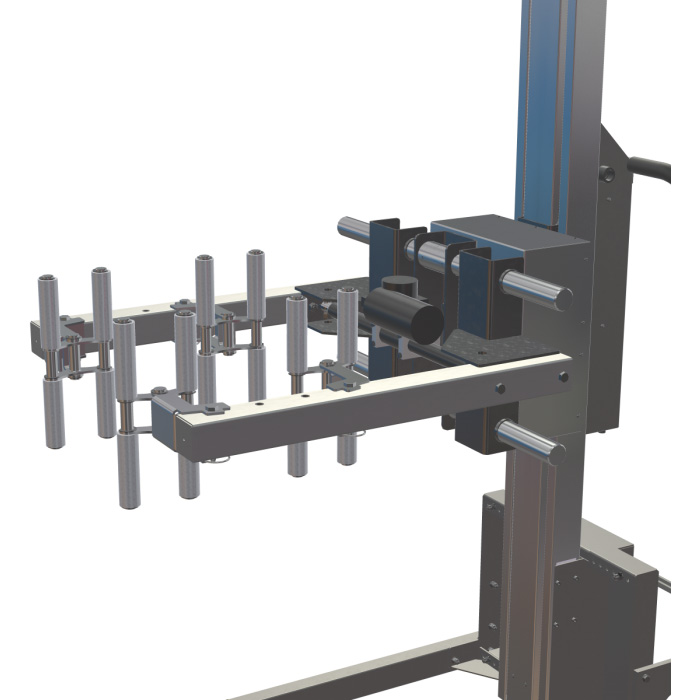

Moving Machine Parts and Other Irregularly Shaped Items

- Material handling in the manufacturing industry involves much more than crates, boxes, buckets and other common, stackable objects. In fact, many production processes also rely on lifting and moving machine parts such as press moulds, filling pipes and motors – in essence, machine parts that need to be mounted onto a larger machine.

Other irregularly shaped items may also be found in production facilities, including windows, wooden boards or other bulky and heavy objects that are nearly impossible to move and position ergonomically.

The lightweight and easily manoeuvrable Hovmand lifter is an ideal aid when it comes to assembling a variety of parts in an effective manner. Combined with our wide range of customisable tools, we can always find a solution for you regardless of the item you need to lift or move.

Our flexible, configurable tools such as the vacuum pump or crane arm are highly versatile solutions that can help you create better ergonomics and workflows.

Precise and Easy Handling of Drums

- Drums are practical and versatile, which may explain why they are so often used in industrial production. The drums are used to store a wide variety of raw materials and ingredients, including oil, chemicals and detergents. Generally speaking, drums are the preferred type of storage application whenever the raw materials are of liquid form. The advantages of drums for material handling are many, but when they have to be moved, rotated and emptied, the task puts stressful pressure on the body.

With a customised Hovmand lifter, you can remove the physical strain on employees, while ensuring safer and more precise handling of drums. Our drum lifter effortlessly grabs onto the drum with its gripping tool, and the lifting and tipping process is easily controlled via a remote control, ensuring safe and effective working conditions. The lifting solution can be used with all types of drums and our modular system can be adapted to any production facility.

For improved handling of drums in the manufacturing industry, we recommend that you look at our Impact series and its compatible tools.

Pharma and Chemistry

- Lifting Solutions for Pharma and Chemistry

Improve Ergonomics and Safety with GMP-Regulated Lifting Solutions The production of pharmaceutical products and chemicals is characterized by extremely rigorous hygiene standards. The regulations apply to the production, filling process and packaging to ensure the best possible products for consumers, while also protecting the health and safety of employees handling dangerous goods.

Mechanical aids used in GMP-regulated areas must also comply with the high standards of hygiene and quality. Our broad range of stainless-steel lifters and their corresponding tools can help lift, transport and fill most types of applications in the pharmaceutical and chemical industry, and are carefully designed to be used in cleanrooms or potentially explosive areas. They are manufactured to GMP standards to prevent contamination and ensure guaranteed reproducible product quality. Continue reading to learn more about the challenges specific to the pharmaceutical and chemical industries, and how we can help you minimise physical strain and maximise employee safety.

Customised Material Handling for All Types of Drums

- In both pharmaceutical and chemical production processes, various types of drums and containers are used to store different kinds of powder. These powders are transported from storage areas to production facilities where they are used to manufacture a range of products. While being practical storage solutions, drums are difficult to handle as they come in a variety of shapes and thicknesses.

At Hovmand, we specialise in handling a wide range of drums, so whether your drums are made of steel, fiber or plastic, our innovative solutions help lift, transport and rotate them electrically and securely. Thanks to our flexible modular system, we can easily customise the lifter to fit your material handling needs. In case your drum or container has unusual or unique dimensions, we can even design a one-of-a-kind lifter for you.

If you need help handling drums and other containers within pharmaceutical or chemical industries, we recommend that you take a look at our INOX series and compatible tools.

Moving Sacks and Bags in Pharma and Chemical Plants

- When producing pharmaceutical and chemical products, large amounts of powder and granules frequently come in the form of sacks and bags that need to be filled into larger containers or mixing machines. A process that often takes place above shoulder level, why lifting of lightweight fosters poor ergonomic work conditions.

With a Hovmand lifting aid and platform tool, sacks and bags can be effortlessly positioned and lifted to the desired height, ensuring that emptying is conducted quickly, ergonomically and safely. And to accommodate that this pharmaceutical and chemical process often takes place in cleanrooms, our solutions and tools are provided in stainless steel and a hygienic design.

If you also wish to handle sacks and bags (weighing up to 130 kg/ ~287 lb.) in storage areas, our Impact series and platform mounted with rollers is fit for this very same purpose.

Handling Canisters and Buckets

- Liquid substances often provided in buckets, jerrycans and other types of containers, are a typical part of the pharmaceutical and chemical industries. However, handling such materials is not an easy task. For example, emptying buckets in funnels positioned above shoulder level or tilting and decanting jerrycans at different heights put employees at risk and creates a need for specialised tools.

At Hovmand, we offer tailored solutions in powder-coated and stainless steel, perfectly compatible with the pharmaceutical and chemical industries’ environments. Our lifters can move both 25 and 60 litre canisters, enabling easy pick-up from storage and following transport to mixing machines, where lifting and emptying can take place – seamlessly, securely and efficiently.

Lifting Equipment for All Applications

- Lifters for Easy Transport and Precise Filling

During the manufacturing process, granulates, fluids or bulk materials often have to be transported from the warehouse to the production in buckets or small drums and then filled into other containers. Drums and buckets come in many sizes and are incredibly useful, able to lift, move and store a variety of materials, including hazardous substances. This makes drums and buckets fit for versatile applications, but also places high demands on the employees to handle them safely and precisely.

At Hovmand we offer customised solutions for companies that need to lift heavy drums and buckets. We have worked for many years to create the best material handling solution for companies. We can, therefore, guarantee that using our lifters for handling drums and buckets will not only create a more efficient workflow but also improve staff health, while creating more streamlined operations and leading to more efficient handling of your drums and buckets. Crates and Boxes

- Effortless Lifting of Crates and boxes

Many production processes and logistics systems involve crates, boxes and containers that have to be moved from A to B. Since both the goods and the available space are usually too small for large and heavy forklift trucks, manual transport is often the only option. However, handling even lightweight crates can overstress

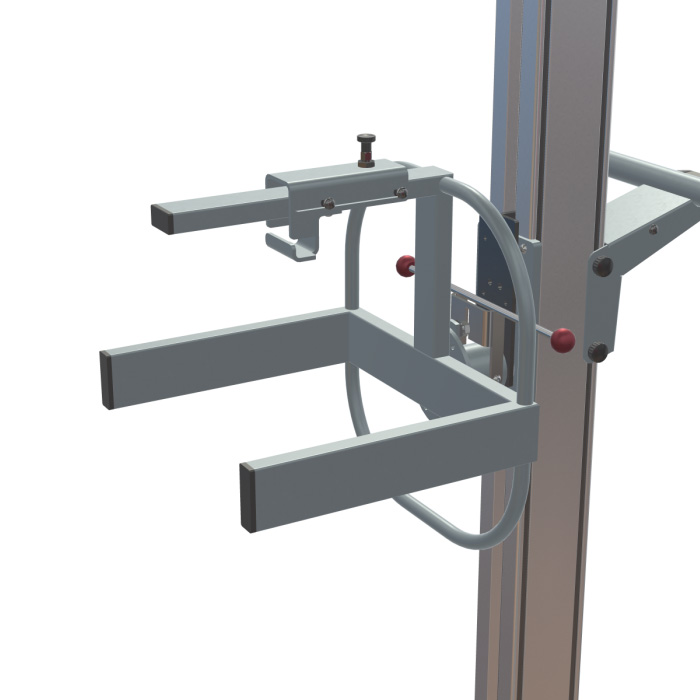

How to Handle a Plastic Box?

- Many logistics systems use stacking boxes of different types as an integrated part of merchandise management. With a fork tool, numerous plastic boxes can be handled easily and efficiently. The fork tool is utilized in combination with boxes that feature an edge around their top surface or grooves along their sides, creating space for the instrument to get ahold. Whether you are looking to lift a single plastic box or stack several boxes, the tool gets the job done. By placing the fork prongs around the box, the edges and grooves work to your advantage and enable a tight grip, for secure handling.

We offer different types of forks in our assortment of tools, all fitting with a wide selection of boxes. For example, our G1 fork is a safe choice due to its versatile application and perfect compatibility with nearly all standard box sizes. You can see it in live-action in our first video above.

If you handle boxes with unique measurements, we have fork tools that offer the possibility for width adaptation. This type of tool is also well-suited for moving and lifting boxes of various sizes. See for yourself in the second video above.

Is it Possible to Lift a KLT Box?

- A number of boxes do not have rims or grooves surrounding their surfaces, complicating compatibility with lifting solutions. Particularly, this type of box is prominent within internal logistics, where many processes are automated, and boxes are moved around by means of assembly lines. However, boxes still have to be moved and lifted beyond the automated processes and this often creates unforeseen challenges that put employees at risk of permanent discomfort, accidents and musculoskeletal disorders.

To overcome the challenge, we have created our KLT-fork with prongs that slide into the depressions, on the side of the box. The lifting device tightly grips hold of the box, ensuring safe handling without putting a strain on workers’ health.

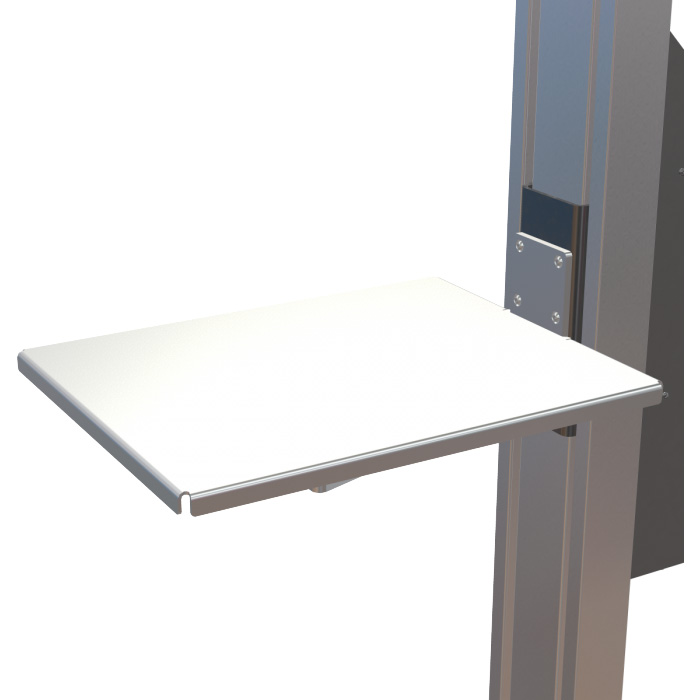

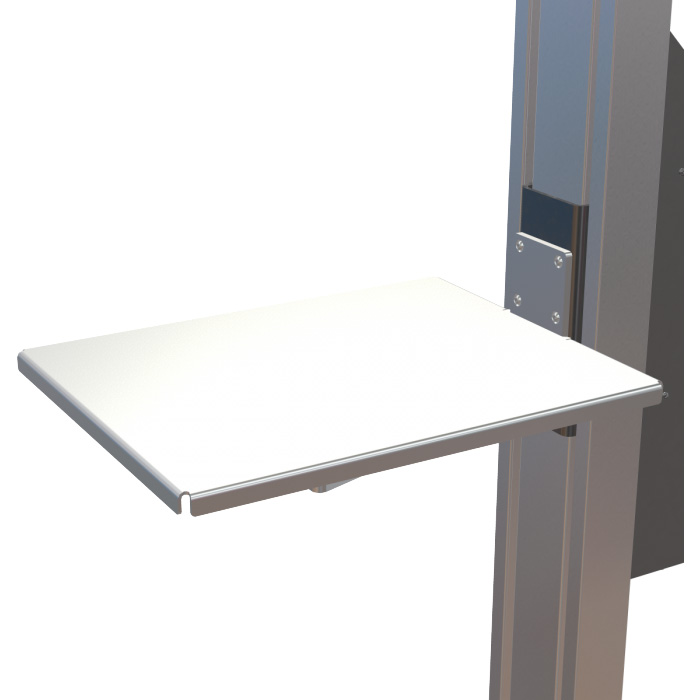

Handling Cardboard and Other Odd Size Boxes

- Boxes come in a myriad of sizes and many different materials. Some are designed to be easy to grip and lift, while others pose as more challenging to move, tilt and empty. Moreover, boxes can be made from cardboard, have rims and grooves or feature handles. Sometimes many different sizes and types are even processed in the same workflow, setting additional requirements for the lifting tools which aid in handling the boxes and maintaining employee health.

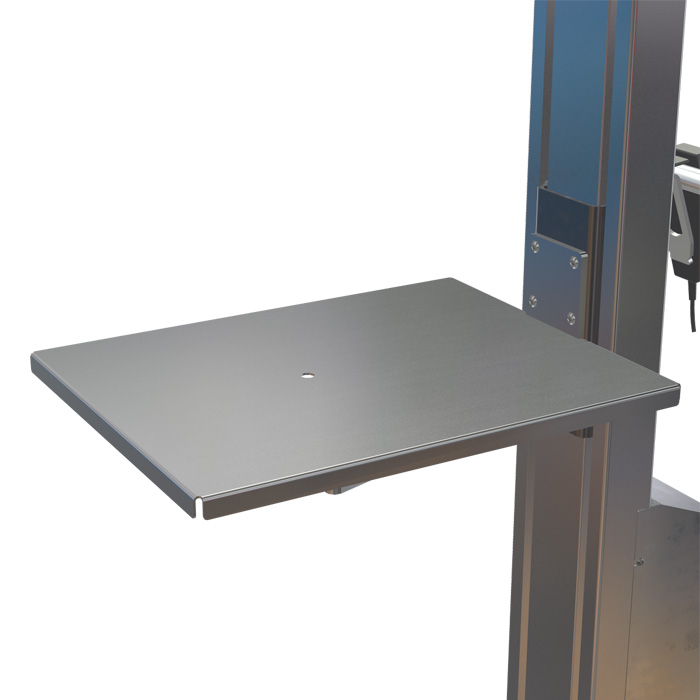

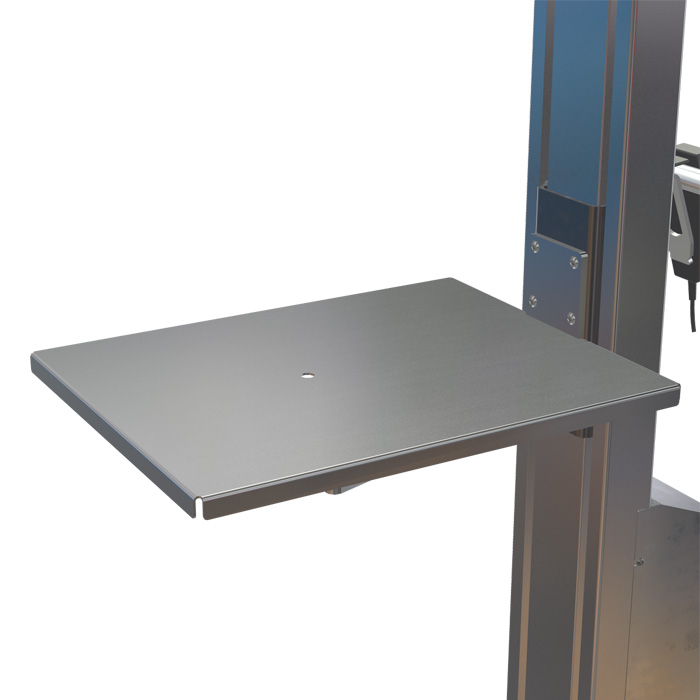

Luckily, Hovmand is a specialist in the field of material handling, offering solutions equipped to overcome nearly all challenges. For example, boxes that cannot be lifted with a fork tool can be handled with a platform. Powered by a remote control unit, the platform is easily positioned at the right height, enabling boxes to be pushed from positions such as shelves, and onto the platform or vice versa.

Our platforms are offered in different materials, including aluminum, stainless steel, plastic (approved for the food industry) and wood. Also, they are available in sizes up to 600x600 mm (~24x24 in.) and if needed, we can even provide them on a larger scale.

If the box is large or heavy, the platform can be mounted with rollers in front and/or on the side so loading and unloading becomes easy.

Lifters for Handling Drums and Buckets

- Lifting Solutions for Pharma and Chemistry

Improve Ergonomics and Safety with GMP-Regulated Lifting Solutions The production of pharmaceutical products and chemicals is characterized by extremely rigorous hygiene standards. The regulations apply to the production, filling process and packaging to ensure the best possible products for consumers, while also protecting the health and safety of employees handling dangerous goods.

Mechanical aids used in GMP-regulated areas must also comply with the high standards of hygiene and quality. Our broad range of stainless-steel lifters and their corresponding tools can help lift, transport and fill most types of applications in the pharmaceutical and chemical industry, and are carefully designed to be used in cleanrooms or potentially explosive areas. They are manufactured to GMP standards to prevent contamination and ensure guaranteed reproducible product quality. Continue reading to learn more about the challenges specific to the pharmaceutical and chemical industries, and how we can help you minimise physical strain and maximise employee safety.

Grab, Lift and Rotate Drums

- Drums come in a variety of heights, diameters and weights, but with the common denominator that they all need to be moved and emptied. Some drums have handles, but the vast majority are very challenging if not impossible to grab, lift and pour. To make matters worse, drums are made of various materials, including metal, plastic, cardboard and fiber, which further complicates the handling process. Overall, this sets high requirements for the equipment needed to handle drums.

To assist in the moving of drums, Hovmand has created a number of solutions that easily grab, lift and rotate drums. Our electric drum lifters safely pick up drums and precisely tilt them at varying speeds depending on your need. To ensure a firm grip of the drum no matter the weight, material or diameter, we have developed a wide selection of grippers, lifting column loads and chassis. In other words, we can design the perfect drum lifter to best suit your needs.

How to Empty a Plastic Bucket

- In production and logistics, a lot of materials are delivered in plastic buckets. In some instances, the contents of the buckets need to be emptied into a tub or poured into a pot or a funnel. Sometimes the funnel in question may be situated unusually high or the buckets may contain harmful materials, making it important to handle the buckets with the utmost care.

When handling plastic buckets, we have a variety of solutions that can be suited to all types of buckets regardless of their size, design or weight. For smaller buckets, we recommend using a lifter with an attached platform, while buckets with handles are easily moved using a crane arm, which can be equipped with different slings, ropes or straps. Watch the middle video above to see our different solutions for grabbing, turning and emptying buckets.

Safely Decant Jerrycans

- Chemicals, soap, beverages and much more are delivered in small and large jerrycans. The smaller jerrycans, weighing under 10 kg (~22 lb.), are usually manageable but as soon as the jerrycans get heavier, carrying, transporting and emptying them becomes a challenge. Not only does the weight put a strain on the body, but tilting and decanting jerrycans at different heights puts employees in unhealthy positions that call for the use of specialised tools.

With the right manual lifting equipment, a single employee can decant jerrycans safely and efficiently without endangering their health. At Hovmand, we have developed the mobile jerrycan refilling aid, which is a three-in-one solution for carrying, transporting and precisely refilling canisters into other containers. The jerrycan refilling aid is available in two versions: the cost-effective GO Jerrycan version with a volume of 15-25 litres as well as the canister refilling aid based on our Impact series.

Lifting Equipment for Reels

-

Lifting Reels Made Easy

Today, many types of materials are supplied as reels. Something that fosters numerous reel sorts, including foil for wrapping and material for packaging foods, paper manuals, print and more. Moreover, reels can be both short and long, have small or large diameters and vary extensively in weight. And finally, the reel material can have different thicknesses, price classes and degrees of vulnerability.

The countless combination options make handling reels a complicated task that requires various types of equipment, when lifting, moving and tilting takes place. To overcome the hurdle and ensure that employees are kept safe from physical strain, we have created a number of solutions – ranging from simple to large and more automated.

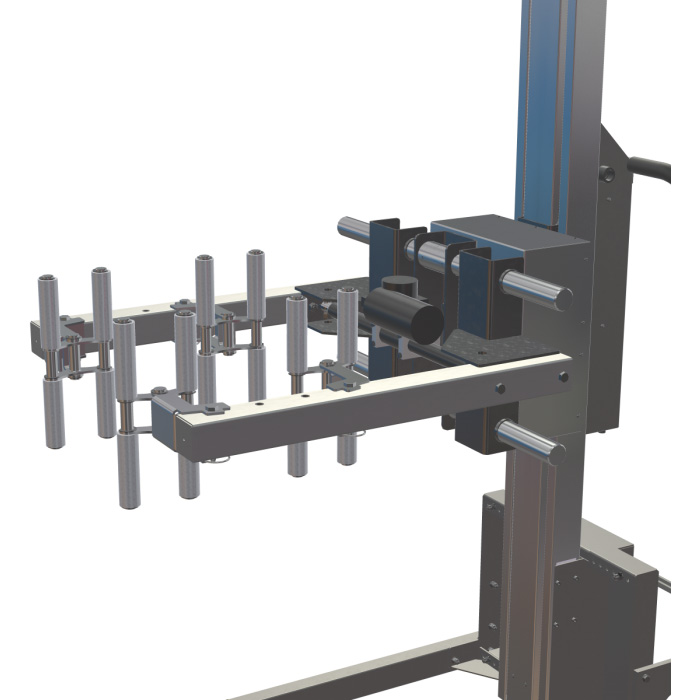

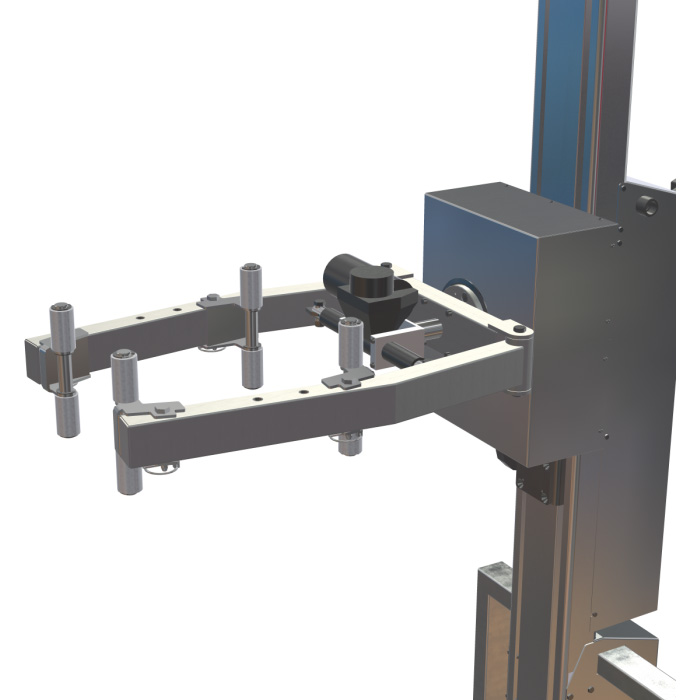

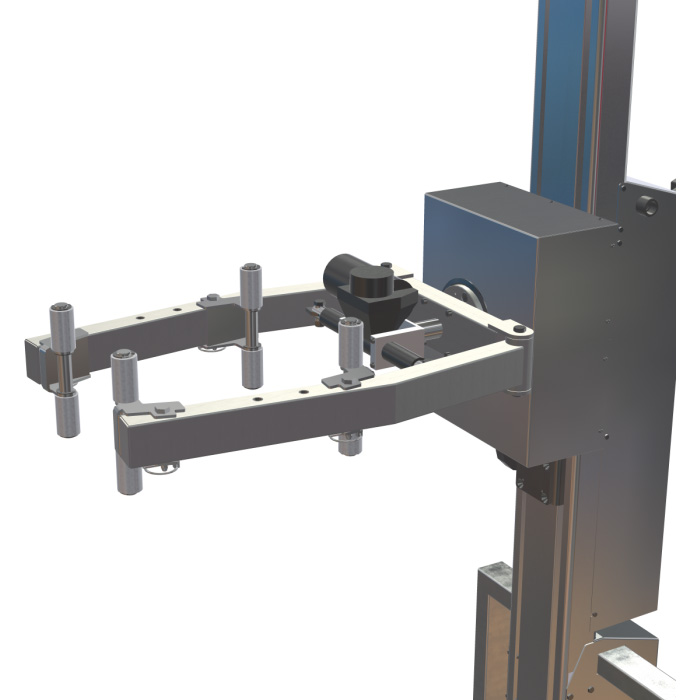

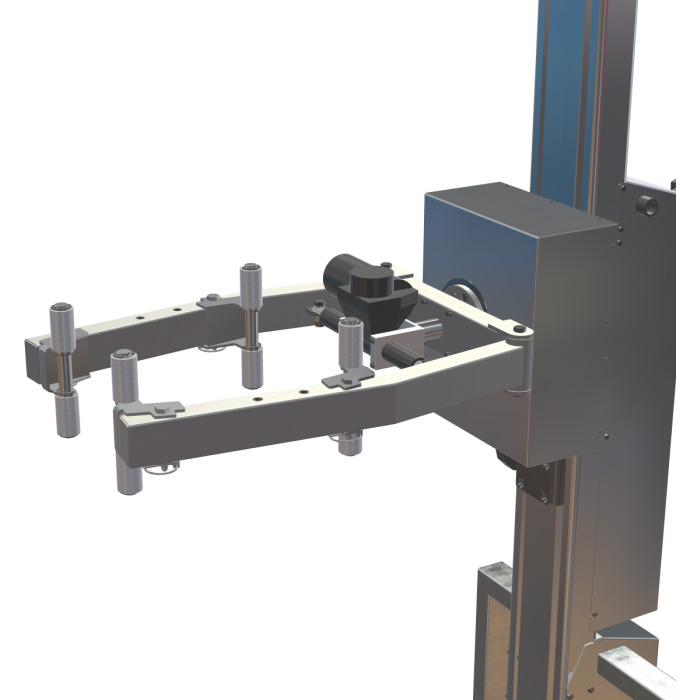

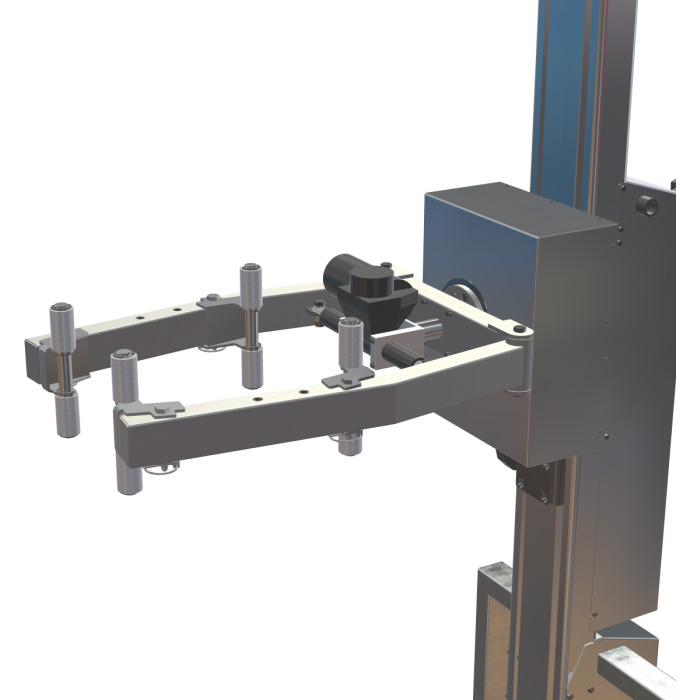

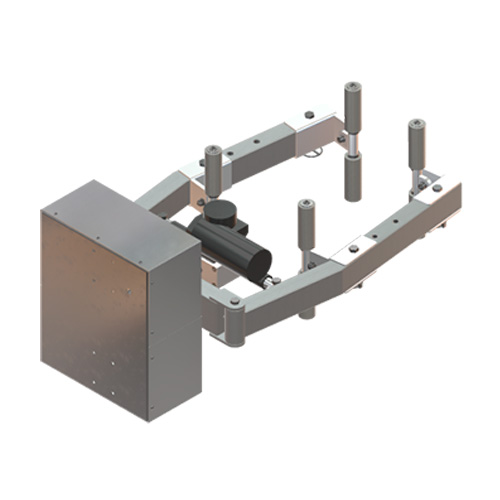

Our Most Popular Solution: The Reel Manipulator

- How do you get ahold of reels that are placed very close to a pallet and in several layers? And even if this is managed, how is it then possible to turn the reel from vertical to horizontal to facilitate mounting onto a packaging machine? All without physical strain or damaging the reel? This is one of the most widespread challenges when handling heavy reels.

Fortunately, we have created an innovative lifting device called a ‘Real Manipulator’. The tool grips the reel by the core, ensuring it is firmly held and can be moved. Following this, the reel can easily be rotated for correct positioning and attachment onto machines. Most of our reel manipulators can even be swung from side to side, enabling swift lifting from pallets, without having to push the reels around.

We supply our reel manipulators in three different versions – one mechanical and two electrical. The mechanical version is quick and easy to use and can handle reels weighing up to 80 kg (~176 lb.), while the electrical versions are suitable for larger reels, weighing up to 200 kg (~441 lb.).

The Simple and Flexible Solution: Boom and V-Block

- In some cases, reels must be mounted above shoulder level, while others have to be mounted below knee height. Similarly, you may work with multiple types of reels. In this case, some reels may need to be attached to a fixed boom (resembling a spear) and others installed by way of a loose boom placed in the core of the reel, and then onto a packaging machine. For this type of task, our “Boom – V-block” is a practical and versatile solution.

For simpler lifting tasks, we can recommend booms and double booms that are available in different sizes and versions. A boom is placed in the core of the reel, which can then be lifted, while a double boom lifts under the reel.

If you need to handle different reels, an adjustable boom is a perfect solution. Here the width between the two booms can be adjusted to suit your various reels.

Can You Grab the Outside of a Reel?

- What can you do when the reel material is very smooth, or the reel needs to be placed in a complicated position? In short, what if gripping the core of a reel is impossible? Luckily the answer is simple; you can grip the outside of the reel.

Our ‘Grip and Turn’ tools provide the perfect solution to the task. The handling equipment grips the outside of the reel, holding it in place for easy lifting and subsequent rotation into position. We offer several sizes of Grip and Turn tools, depending on the task, and with a lifting capacity of up to 250 kg (~551 lb.).

Depending on your reel, our tools can even be fitted with different grippers. This allows for a secure grip on the reel and at the same time ensures that the reel is not damaged.