- Offer Profile

-

Hangcha Group was founded in 1956. 66 years later, Hangcha Group continues to manufacture reliable material handling equipment. Quality and innovation are two of the reasons that Hangcha Group is ranked 8th globally in sales of material handling equipment, distributes to over 180 different countries, and employs over 5,400 people.

Now, we can offer a complete fleet of material handling equipment, from 1-48t internal combustion counterbalance forklift, 0.6-48t electric forklift trucks, warehouse equipment, 3-6t side loader, empty container handler, reach stacker, AGV and much more. Our annual production capacity is more than 400,000 units thanks to the intelligent manufacturing factory. In 2021, more than 247 000 new Hangcha units were sold worldwide

LITHIUM E-TRUCKS

E-Trucks

XE Series Electric Forklift Truck With Lithium Power 1.5-3.8t

- Load Capacity: 2,000~3,800kg

- Lift Height: 0~7000mm

- Drive Types: Li-Ion

Independently developed by Hangcha on the basis of decades of deep understanding of electric forklifts and internal combustion forklifts, the dedicated XH series high voltage lithium battery forklifts are a new series of electric counterweight forklifts with a new energy vehicle voltage platform and a pioneered special structure that represents a breakthrough over the traditional design concept. Representing a redefinition of electric forklifts in terms of efficiency, power, reliability, etc., this series of electric forklift models will supersede the internal combustion forklifts.

XE Series Electric Forklift Truck With Lithium Power 4.0-5.0t

- Load Capcity: 4,000~5,000kg

- Lift Height: 0~7000mm

- Drive Types: Li-Ion

XE series standard lithium battery forklifts are quality products that are developed on the basis of the advantages of the dedicated lithium battery forklift structure and the permanent magnet synchronous motor technology. Inheriting the family design of electric forklifts, some key parts can also be used for internal combustion forklifts.

XE Series Electric Forklift Truck With Lithium Power 6.0-10t

- Load Capcity: 6,000~10,000kg

- Lift Height: 0~7000mm

- Drive Types: Li-Ion

While inheriting the family design of electric forklifts, some key parts are universal with internal combustion trucks. The whole truck has been optimized in terms of performance, ergonomics, reliability, maintenance, outdoor working ability, and load capacity to meet the needs of customers for internal combustion forklift usage scenarios.

XH Series High-Voltage Lithium Battery Forklift 2.0-3.8t

- 2,000~3,800kg Load Capacity

- 0~7000mm Lift Height

- Li-Ion Drive Types

Independently developed by Hangcha on the basis of decades of deep understanding of electric forklifts and internal combustion forklifts, the dedicated XH series high voltage lithium battery forklifts are a new series of electric counterweight forklifts.

Exterior

With the inherited exterior design of the dedicated XC lithium battery forklift and a smooth and sturdy profile, the whole vehicle is impact, elegant, stylish, sturdy and powerful.Advancement

oth the drive and operating systems are vehicle-grade permanent magnet synchronization systems, equipped with a high-speed ratio gearbox with a driving speed, upslope degree and acceleration performance rival that of internal combustion vehicles, and the environmental performance better than that of internal combustion vehicles.Safety

The cover of the vehicle is designed to be sealed to the water resistance level of IPX4. All the motor, electronic controls and high-voltage components reach the dust and water resistance level of IP67, a high protection level adequate to withstand harsh operating environments and ensure safety and reliability.

XH Series High-Voltage Lithium Battery Forklift 4.0-5.0t

- 4,000~5,000kg Load Capacity

- 0~7000mm Lift Height

- Li-Ion Drive Types

Independently developed by Hangcha on the basis of decades of deep understanding of electric forklifts and internal combustion forklifts, the dedicated XC series heavy-duty lithium battery forklifts are a new series of electric counterweight forklifts with a new energy vehicle voltage platform and a pioneered special structure that represents a breakthrough over the traditional design concept.

Comfort

The enlarged brake pedal and appropriate regenerative braking function can effectively reduce the driver’s fatigue.Advancement

The vehicle’s 309V high-voltage platform is equipped with a long-lasting large-capacity lithium battery, which is powerful, efficient and energy-saving, adopts a super-fast charging technology that enables a short charging time, and is compatible with the automobile charging pile to enable more convenient charging.Safety

The cover of the vehicle is designed to be sealed to the water resistance level of IPX4. All the motor, electronic controls and high-voltage components reach the dust and water resistance level of IP67, a high protection level adequate to withstand harsh operating environments and ensure safety and reliability.Maintainability

The water tank lid can be removed quickly and easily without a tool to enable a large operating area for cleaning and maintenance.

XH Series Heavy-Duty High-Voltage Lithium Battery Forklift 4.0-5.0t

- 4,000~5,000kg Load Capacity

- 0~7000mm Lift Height

- Li-Ion Drive Types

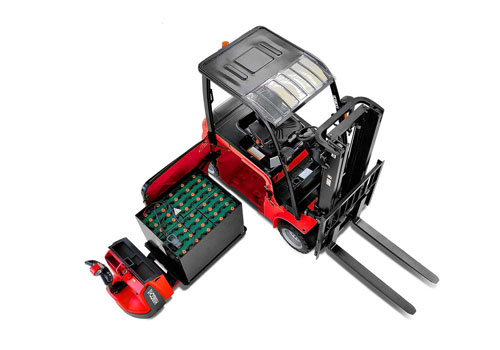

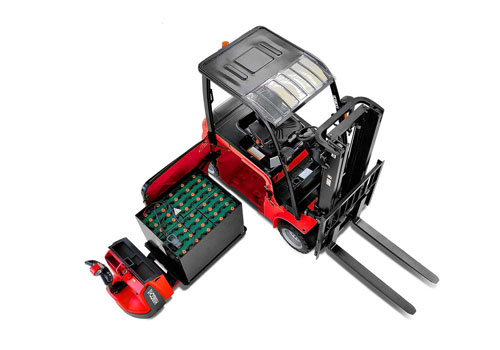

The XH series heavy-duty high-voltage lithium battery special forklift inherits the advantages of the XH heavy-duty series and adopts the CATL standard box. This tonnage industry is the one that uses a dual-water cooling system for the motor and battery. It has super heat dissipation performance and can meet 24h non-stop operation.

Appearance

With the inherited classic exterior design of the dedicated XC lithium battery forklift and a smooth and sturdy profile, the whole vehicle is compact, elegant, stylish and sturdy.Safe and Reliable

The cover of the vehicle is designed to be sealed to the water resistance level of IPX4 for the body. All the motor, electronic controls and high-voltage components reach the dust and water resistance level of IP67, a high protection level adequate to withstand harsh operating environments and ensure safety and reliability.Strong Adaptability

The drive axle, steering axle and tires of internal combustion forklifts can meet the demand of high-intensity operating conditions of internal combustion forklifts. It meets all-weather operating conditions and is usable under severe operating conditions such as cold storage, heavy rains and waterlogged roads.Convenient Maintenance

The vehicle with ergonomic design, a wide view and a large operating space makes it easier for drivers to operate; The multi-functional color screen instrument is designed to have graphic interfaces; three SPE speed gears are selectable to adapt to different operating conditions; interfaces can be switched between English and Chinese to meet the demands of customers at home and abroad.

XH Series High-Voltage Lithium Battery Forklift 6.0-10t

- 6,000~10,000kg Load Capacity

- 0~7000mm Lift Height

- Li-Ion Drive Types

Independently developed by Hangcha on the basis of decades of deep understanding of electric forklifts and internal combustion forklifts, the dedicated XH series heavy-duty high-voltage lithium battery forklifts are a new series of products with a new energy vehicle voltage platform and a pioneered special structure that represents a breakthrough over the traditional design concept.

Ultra-long Battery Life

The vehicle uses an overall controller to control the traction motor controller assembly and the driving motor controller assembly to form a highly independent, light-weighted, efficient and intelligent drive system.Internal Combustion Condition

Both the drive and operating systems are vehicle-grade permanent magnet synchronization systems. Equipped with a high speed ratio gearbox, the driving speed, upslope degree and acceleration performance surpass that of internal combustion vehicles.Easily Maintainable

The water tank lid can be removed quickly and easily without a tool to enable a large operating area for cleaning and maintenance.Safety

The cover of the vehicle is designed to be sealed to the water resistance level of IPX4 for the body. All the motor, electronic controls and high-voltage components reach the dust and water resistance level of IP67, a high protection level adequate to withstand harsh operating environments and ensure safety and reliability.

XH Series Heavy-Duty High-Voltage Lithium Battery Forklift 6.0-10t

- 6,000~10,000kg Load Capacity

- 0~7000mm Lift Height

- Li-Ion Drive Types

Independently developed by Hangcha on the basis of decades of a deep understanding of electric forklifts and internal combustion forklifts, the dedicated XH series heavy-duty high-voltage lithium battery forklifts are a new series of products with a new energy vehicle voltage platform, a water-cooling lithium battery, as well as a pioneered special structure that represents a breakthrough over the traditional design concept.

Strong Adaptability

The drive axle, steering axle and tires of internal combustion forklifts can meet the demand of high-intensity operating conditions of internal combustion forklifts. It meets all-weather operating conditions and is usable under severe operating conditions such as cold storage, heavy rains and waterlogged roads.Ultra-long Battery Life

With a 309V high-voltage platform and vehicle-grade permanent magnet synchronization system, the vehicle boasts of a smaller current, very low heat loss and more energy-efficient; The vehicle uses an overall controller to control the traction motor controller assembly to form a highly independent, user-friendly and intelligent drive system.Safe and Reliable

The cover of the vehicle is designed to be sealed to the water resistance level of IPX4 for the body. All the motor, electronic controls and high-voltage components reach the dust and water resistance level of IP67, a high protection level adequate to withstand harsh operating environments and ensure safety and reliability.Convenient Maintenance

The vehicle with ergonomic design, a wide view and a large operating space makes it easier for drivers to operate; The multi-functional color screen instrument is designed to have graphic interfaces; three SPE speed gears are selectable to adapt to different operating conditions; interfaces can be switched between English and Chinese to meet the demands of customers at home and abroad;

XA Series 3.0-3.5t Electric Forklift Truck With Lithium Power

- Load Capcity: 3,000~3,500kg

- Lift Height: 0~5000mm

- Drive Types: Li-Ion

XA series four-point light-duty lithium battery forklift are qualityguaranteed cost-efficient new products with a redesigned internal structure, which inherit the classic exterior design of Hangcha’s A series products and are applicable to light-duty operation scenes.

XA II Series 3.0-3.8t Electric Forklift Truck With Lithium Power

- Load Capcity: 3,000~3,800kg

- Lift Height: 0~6000mm

- Drive Types: Li-Ion

XA II series 4W light-duty lithium battery forklift are quality-guaranteed cost-efficient new products with a redesigned internal structure, which inherit the classic exterior design of Hangcha’s A series products and are applicable to light-duty operation scenes.

XA III Series Electric Forklift Truck with Lithium Power

- Load Capcity: 2,000~3,800kg

- Lift Height: 0~7000mm

- Drive Types: Li-Ion

XA series four-pivot lithium battery forklifts are a new generation of products developed by Hangzhou. The design concept is to inherit the appearance of "Leiting" series products while improving the performance of the products, expanding the optional battery capacity, optimizing the internal structure, and adopting a series of mature components, which can meet the requirements of more complex and high-intensity work.

XC Series Electric Forklift with Li-Ion Power 1.5~3.5t

- 1,500~3,500kg Load Capacity

- 0~7000mm Lift Height

- Li-Ion Drive Types

The XC series new energy electric forklifts, covering range from 1.5t to 3.5t, is a series of products with new chassis launched by HANGCHA.

Advantages

An ultra-high power AC pump motor is used. The system has high efficiency, complete protection functions, built-in speed and temperature sensors, and greatly improved reliability and life.

Comfort

Owing to the low center of gravity and good stability, the driver feels comfortable during turning.

Safety

The optional OPS system can disable the lowering when the driver leaves the seat and enable high safety.

Maintenance

Internal Components Protected with Fully-sealed Hood, controllers, motors electrical components, etc. are sealed from dust and water.

Main Accessories

The truck has passed the CE certification.

XC Series Electric Forklift with Li-Ion Power 2.0~3.5t (Light Duty)

- 2,000~3,500kg Load Capacity

- 0~7000mm Lift Height

- Li-Ion Drive Types

The XC series new energy electric forklifts, covering range from 2.0t to 3.5t, is a series of products with new chassis launched by HANGCHA.

Advantages

The ultra-high power AC traction motor has a bridge structure.

Safety

The handbrake can be optionally equipped with an alarm buzzer to prompt the driver to pull up the handbrake before leaving the truck.

Maintenance

Internal Components Protected with Fully-sealed Hood, controllers, motors electrical components, etc. are sealed from dust and water.

Main Accessories

The truck has passed the CE certification.

XC Series 4-W Electric Forklift Truck With Lithium Power 6.0

- Load Capcity: 6,000~10,000kg

- Lift Height: 0~7000mm

- Drive Types: Li-Ion

XC series lithium battery forklifts 6-10t are brand new products on the basis of Hangzhou forklift's “lithium battery special structure”, and offer two platforms, the classic “AC Asynchronous” and the leading “permanent magnet synchronous”. Following the family design of electric forklifts, they are optimized mainly on the overall performance, ergonomics, reliability, maintenance, outdoor operation ability and load capacity in a bid to meet customers’ use scenarios of traditional electric forklifts.

XC series electric forklift with Li-Ion power 1.5~3.5t

- Load Capcity: 1,500~3,500kg

- Lift Height: 0~7000mm

- Drive Types: Li-Ion

The XC series new energy electric forklifts, covering range from 1.5t to 3.5t, is a series of products with new chassis launched by HANGCHA.

A series Dual Drive Electric Forklift(Li-Ion)

- Load Capcity: 2,000~3,500kg

- Lift Height: 0~6500mm

- Drive Types: Li-Ion

A series 4.0-4.99t (Li-Ion)

- Load Capcity: 4,000~4,990kg

- Lift Height: 0~6000mm

- Drive Types: Li-Ion

A Series High Capacity Electric Forklift Truck

- Load Capcity: 12,000~16,000kg

- Lift Height: 0~6500mm

- Drive Types: Li-Ion

The new A series (12-16 ton) electric counterbalanced forklift continues the style of the original A series electric forklift, with the addition of lithium battery models to meet various market demands. The climbing performance and lifting speed are higher than the original A series electric forklift, and the degree of localization of key components of the whole truck is higher. By adopting domestically produced and mature components, it provides customers with a more cost-effective and diversified product.

AE series 1.5-3.5t (Li-Ion)

- Load Capcity: 1,500~3,500kg

- Lift Height: 0~7000mm

- Drive Types: Li-Ion

Independently developed by Hangcha on the basis of more than 30 years of electric forklift research and development and accumulated manufacturing technology, the AE series electric forklifts are a new series of high-efficiency and energy-saving electric counterweight forklifts with a new structure that represents a breakthrough over the traditional design concept. The research and development of control and power systems are innovated and the product exterior, ergonomics, reliability, maintenance and other aspects are optimized, so that the performance of the vehicle is greatly improved.

X series 0.6-1.0t(Li-Ion)

- Load Capcity: 600~1,000kg

- Lift Height: 0~4500mm

- Drive Types: Li-Ion

Hangcha’s X series 0.6-1.0t 3W electric forklifts are a new series of high-efficiency, energy-saving small-tonnage electric counterbalanced forklifts with a new structure that represents a breakthrough over the traditional design concept. With a compact structure, small turning radius and light weight and high maneuverability, the truck is widely used in narrow operation places, e.g., used for handling between floors, to and from elevators or in warehouses, supermarkets, workshops, etc.

X Series 1.3-1.5t

- Load Capcity: 1,300~1,500kg

- Lift Height: 0~4500mm

- Drive Types: Li-Ion

Hangcha’s X series 1.3-1.5t three-point electric forklifts are a new series of high-efficiency, energy-saving electric counterweight forklifts with a new structure that represents a breakthrough over the traditional design concept. With a compact structure, small turning radius and light weight and high maneuverability, the vehicle is widely used in narrow operation places, e.g., warehouses, supermarkets, workshops, etc.

XC Series Electric Forklift with Li-Ion Power 4.0~5.0t

- 4,000~5,000kg Load Capacity

- 0~7000mm Lift Height

- Li-Ion Drive Types

XC series 4-5t new energy electric forklifts have tonnage extended on the basis of Hangcha Group's dedicated XC series 1-3.5t lithium battery vehicles. The whole series covers dedicated lithium battery models dedicatedly developed according to the characteristics of lithium batteries.

Advantages

An ultra-high power AC pump motor is used. The system has high efficiency, complete protection functions, built-in speed and temperature sensors, and greatly improved reliability and life.

Comfort

Owing to the low center of gravity and good stability, the driver feels comfortable during turning.

Safety

The optional descending lock function can disable the descending function when the driver leaves the seat and enable high safety.

Maintenance

The drive motor of a high protection level is dustproof and waterproof and highly reliable.

Main Accessories

The emergency cut-off switch equipped for the standard configuration complies with EU regulations.

X series 1.0-3.5t (Li-Ion)

- 1,000~3,500kg Load Capacity

- 0~7000mm Lift Height

- Li-Ion Drive Types

The X series 1.0- to 3.5-ton forklift trucks are new-generation products by independent research and development based on former products of HANGCHA, with an overall upgrade in appearance molding, performance efficiency, comfort, safety and maintainability.

Appearance

Appearance design methods of new concepts, streamlined surface modeling, flexible and smooth lines, elegant and decent.

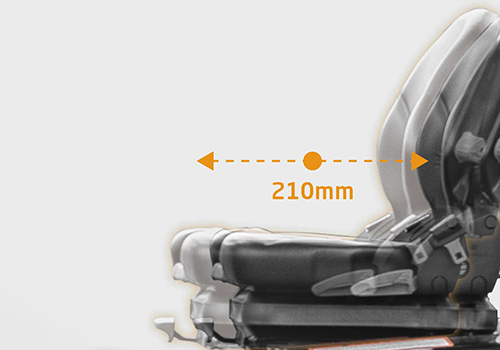

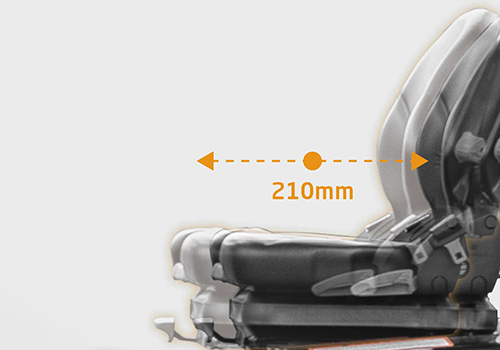

Comfort

Designed based on ergonomics, the longer wheelbase provides larger space for legs. The diameter of steering wheel has been decreased to 300mm. Seats can be adjusted forward and backward for operators to choose the best driving position.

Safety

LED front lights and combined lights provide better view to operators under any circumstance.

Maintainability

Brake fluid can be added when the shield cover and oiler cover are opened.

Advancement

AC controllers realize computer control in travelling, turning, lifting, inclining and other movements.

X series 4.0-5.0t (Li-Ion )

- 4,000~4,990kg Load Capacity

- 0~7000mm Lift Height

- Li-Ion Drive Types

Stability

The drive motor is arranged in parallel, the battery is placed at the bottom of the vehicle frame, the wheelbase and rear wheel pitch are increased, the swing point of the steering axle is raised, and the distance between the front of the fork and the front axle is reduced, to enable excellent stability.

Comfort

In accordance with the ergonomically design, the wheelbase is increased to enable enlarged leg space. The radius of the hand wheel is reduced to 300mm and the seat can be adjusted backwards and forwards, so that the operator can choose the best driving position.

Safety

The optimized design of the wide-view mast, wide-view overhead guard and low dashboard enables a broader view of the operator and higher safety.

Advancement

The high-frequency MOSFET integrated controller ensures smooth and accurate driving and lifting control, and has excellent speed regulation performance, good performance of electronic control matching the motor, functions of regenerative braking, reverse braking and anti-sliding on ramps, etc., and high safety and reliability.

Maintainability

The fully opened hood quite facilitates the maintenance of the battery, oil pump motor and electric control assembly.

XC Series 3-Wheel Electric Forklift Truck with Lithium Power

- 1,300~2,000kg Load Capacity

- 0~6500mm Lift Height

- Li-Ion Drive Types

Covering models with a tonnage of 1.3t, 1.5t, 1.6t, 1.8t and 2.0t respectively, the new XC series three-point new energy electric forklifts are HANGCHA’s dedicated-purpose battery forklifts subsequent to the XC series four-point dedicated-purpose battery forklifts.

Excellent Ergonomic Design

The truck has a large operation space more than 50% larger than that of the traditional three-point electric truck. The enlarged brake pedal and appropriate regenerative braking function can effectively reduce the driver’s fatigue.Easy Operations and Maintenance

With the fully sealed hood and side plates, all major components including the electrically controlled components, motor, electrical components, etc. are sealed from dust and water. Vulnerable parts and key parts are arranged reasonably to facilitate maintenance and repair.Advancement

The high-frequency MOSFET integrated controller ensures smooth and accurate driving and lifting control, and has excellent speed regulation performance, good performance of electronic control matching the motor, functions of regenerative braking, reverse braking and anti-sliding on ramps, etc., and high safety and reliability.Main Accessories

The main electrical components such as the motor controller, contactor, power plug, emergency cut-off switch, dashboard, accelerator, are all products of well-known foreign brands.Comfort

The intelligent sensing enables buered descending. When the fork is 100 - 60mm away from the ground, the descending will automatically slow down, so that the goods and pallet will not hit the ground.

A Series 1.3-2.0 (Li-Ion)

- 1,300~2,000kg Load Capacity

- 0~6500mm Lift Height

- Li-Ion Drive Types

Comfort

Both the steering column and seat can be adjusted easily, every operator can find the best driving position.Safety

Emergency switch is standard specification which meets the Euro safety regulation.Maintainability

Front dual separated driving motors can realize the wheels forward or backward independently, the small turning radius is suitable for narrow channel; Imported reducer, high power driving motor provides a reliable and strong performance.Maintenance

Full opened battery cover is easy for battery service and changing.

Pallet Trucks

A series Mini range pallet truck II

- Load Capcity: 1,500kg

- Lift Height: 0~120mm

- Drive Types: Lead Acid Battery

The A series pallet truck mini range Ⅱ has been engineered to be both powerful and flexible to meet the requirements of many demanding applications. Whether it’s supermarket work, delivery service, stock replenishment or heavy manufacturing, the A series pallet truck mini range Ⅱ has the strength and durability to minimise your total cost of ownership.

A series Mini range pallet truck III

- Load Capcity: 1,500kg

- Lift Height: 0~120mm

- Drive Types: Lead Acid Battery

The A series pallet truck mini range III has been engineered to be both powerful and flexible to meet the requirements of many demanding applications. Whether it’s supermarket work, delivery service, stock replenishment or heavy manufacturing, the A series pallet truck mini range III has the strength and durability to minimise your total cost of ownership.

A Series Mini Pallet Truck

- Load Capcity: 2,000kg

- Lift Height: 0~120mm

- Drive Types: Lead Acid Battery

The A Series 2.0t Mini Pallet Truck is a new product developed by Hangcha for warehouse and logistics applications. With the state-of-the-art permanent magnet brushless drive technology, and the 48V system, features advanced performance, comfortable operation, safety and reliability, and low maintenance cost, and is an ideal vehicle for loading, unloading, and handling palletized goods in warehouses, supermarkets, workshops and homes.

A Series Pallet Truck With High Lift 2.0t

- Load Capcity: 2,000kg

- Lift Height: 0~550mm

- Drive Types: Lead Acid Battery

The A series pallet with high lift is a pedestrian pallet truck which can also be used for order picking and light stacking operations. In addition to the support arm lift the load can be raised to an overall height of 675 mm via a simplex mast contained in the battery compartment. This height adjustment is really appreciated when order picking, restocking shelves in retail stores or assembly line activities in manufacturing industries.

A series Hi range pallet truck

- Load Capcity: 2,000-3,000kg

- Lift Height: 0~125mm

- Drive Types: Lead Acid Battery

A series rider pallet truck

- Load Capcity: 2,000-3,000kg

- Lift Height: 0~125mm

- Drive Types: Lead Acid Battery

Pallet Stackers

A series Basic range pallet stacker

-

- 1,200~1,600kg Load Capacity

- 0~4500mm Lift Height

- Lead Acid Battery

A series High Range Pedestrian Pallet Stacker With Initial Lift

-

- 1,200~1,600kg Load Capacity

- 0~5500mm Lift Height

- Lead Acid Battery

The A series pedestrian stacker is a new product developed for warehouse and logistics applications. With the latest AC control technology, it features excellent performance, easy operation, safety and reliability, and low maintenance cost, and is an ideal vehicle for loading, unloading, and handling palletized goods in warehouse, supermarket, and workshop.The lithium battery forklift is equipped with the c-series forklift special lithium battery cell and module jointly developed by HANGCHA and CATL, standard power distribution heating function.

A series Mini range pallet stacker

-

- 1,000~1,200kg Load Capacity

- 0~2000mm Lift Height

- Lead Acid Battery

A series mini range pallet stacker (double column)

-

- 1,000~1,200kg Load Capacity

- 0~3600mm Lift Height

- Lead Acid Battery

The A series mini range pallet stacker (double column) has been engineered to be both powerful and flexible to meet the requirements of many demanding applications. Whether it’s supermarket work, delivery service, stock replenishment or heavy manufacturing, it has the strength and durability to minimise your total cost of ownership.

A series Hi range pallet stacker

-

- 1,200~2000kg Load Capacity

- 0~5500mm Lift Height

- Lead Acid Battery

A Series Double-column Pallet Stackers Mini Range II

-

- 1,200~1,600kg Load Capacity

- 0~4500mm Lift Height

- Lead Acid Battery

The A series 1.2t/1.5t mini stackers is a new generation of products designed by Hangcha for warehousing and logistics applications. Using the latest permanent magnet drive technology and with advanced performance, comfortable, safe and reliable operations and low costs, the products are ideal tools for loading, unloading and handling palletized goods in warehouses, supermarkets, workshops and homes.

A Series Mini Range Pallet Stacker With Initial Lift 1.0-1.2t

- The A series mini range pallet stacker with initial lift is a new product developed by Hangcha for warehousing and logistics applications. It has a compact body, and can be operated easily and is suitable for operation in narrow aisles. It can carry out double pallet handling through leg lifting and is ideal for loading in warehouses, supermarkets, and workshops.

A series electric counterbalanced stacker

- Is widely used in pallet stacking, wherever support arm stacker truck cannot operate close pallet and lower pallet. Applied the latest AC drive technology, advanced performance, comfort, safe, reliable, low maintenance cost, easy to operate, and economical to buy is the ideal solution for warehouses, supermarkets, workshop loading/unloading and handling pallets of cargos.

A series high range stand-on pallet stacker with initial lift

- The A Series Pallet Stacker Truck is a new product developed for warehouse and logistics applications. With the latest AC control technology, it features excellent performance, easy operation, safety and reliability, and low maintenance cost, and is an ideal vehicle for loading, unloading, and handling palletized goods in warehouse, supermarket, and workshop. The A series pallet stacker with initial lift offers better reachability with its lifting arms.

A series high range stand-on pallet stacker with reach fork

- The A series pallet stacker with reach fork moves goods forward and backward with a scissor fork extension system. It acts as a counterbalanced stacker when its fork is extended, which can handle non-standard pallets, enclosed pallets, and enclosed shelves easily; and acts as a straddle stacker when its fork is retracted, which can operate flexibly in narrow passage.

A series high range stand-on pallet stacker with mast move

- The truck combines benefits of regular stacker and counterbalanced stacker. It can be used for non-standard pallets, enclosed pallets, and enclose shelves. The mast can be retracted into truck body, which reduces passage width required for operation significantly, and the stacker is an ideal vehicle for operation in narrow passage. Cutting-edge AC control technology applied for the truck offers excellent performance, comfortable operation, safety and reliability, and low maintenance cost.

WS Series Electric Pedestrian Stacker

-

- 1,500kg Load Capacity

- 0~3500mm Lift Height

- Lead Acid Battery Drive Types

Reach Trucks

A Series Premium Version Reach Truck

- 1200~2000kg Load Capacity

- 0~13000mm Lift Height

- Li-Ion Drive Types

After several years of design, development, and manufacturing, Hangcha launched a new product lately –the A Series Premium Version Reach Truck: CQD12/14/16/20-AD2H. This truck is mainly used in multi-level warehouse. CQD20-AD2H rated load capacity is 2 tons, maximum lifting height is 12.5m, and the load capacity can reach 1100kg at the maximum lifting height. Its technical parameters and configuration are close to that of similar products of international manufacturers including Crown, Linde, Jungheinrich, and Hyster. This product (A series premium version reach truck) together with standard reach truck constitute the entire family of A Series reach truck of Hangcha. These products supplement with each other in rated tonnage, cover different prices together, and can satisfy different demands in prices, functions, and configuration from various users.

A Series Stand-on Reach Truck 1.5-1.8t Li-Ion

- 1,200~2,200kg Load Capacity

- 0~12500mm Lift Height

- Li-Ion Drive Types

The A series stand-on reach truck is a new-generation product developed by our company in response to different market needs. The truck has comfortable ergonomics, wide operating vision and a stable control system.

Safety

An optimal four-link suspension mechanism forces the drive wheel and the auxiliary wheels, thereby reducing slipping of the drive wheel.

Comfort

Optimal ergonomic design. the steering wheel, operating lever and accelerator are positioned at the best distance to the driver, making the operation lighter more comfortable.

Reliability

The Curtis controller and CAN-bus communication provide safe and reliable.

Maintenance

Traction and lifting system are all adopt maintenance-free AC motor.

A Series Stand-on Reach Truck 1.5-1.8t

- The A series stand-on reach truck is a new-generation product developed by our company in response to different market needs. The truck has comfortable ergonomics, wide operating vision and a stable control system.

A Series Stand-on Reach Truck 2.0-2.5t

- The new A series 2.0-2.5t standing driving forward-moving type is a new product developed by the company for different market needs. The ergonomically-designed comfortable vehicle has wide operating vision and a stable control system, and is further optimized and improved in terms of configuration, parameter, performance, safety, cost, etc., making this product comparable to foreign brands and have obvious advantages when compared with other similar domestic products.

Order Pickers

A Series Medium Level Order Picker 1.0t

- Load Capacity: 1,000kg

- Lift Height: 0~4500mm

- Drive Types: Lead Acid Battery

The A series medium level order picker is a type of high-end truck of warehouse equipment. The truck features complete safety protection system, excellent ergonomic design, and cutting-edge control system. With reliability, stability, comfort, safety, and excellent performance, it is suitable for order picking operations for low and medium-level automatic storage & retrieval system with height below 5m.

A Series High-lift Order Picker 1.2t

- Load Capcity: 1,200kg

- Lift Height: 0~9500mm

- Drive Types: Lead Acid Battery

The A Series high-lift order picker, a high-end warehouse equipment, provides a comprehensive safety protection system, excellent ergonomics design and advanced control system. Being reliable and stable, comfortable and safe, and along with excellent performance, it is a perfect option for cargo picking in stereoscopic warehouse that is 5m to 10m high.

Low-level order picker

- Load Capcity: 2,500kg

- Lift Height: 0~125mm

- Drive Types: Lead Acid Battery

A series low-level order picker is mainly applied in long-distance trans portation among the production lines. Low operator platform for frequent and effortless entry and exit. Thanks to the standing design, it can greatly improve the efficiency of operations. Furthermore, for indoor application, the electric drive system is environmental friendly within the workshop. Therefore, this product is a good partner of automobile manufacturing, logistics companies, warehouses and other places, fields which has broad application prospects.

Tow Tractors

X Series Electric Platform Truck 1.0-5.0t

- The X series electric platform truck is a new series of products independently developed by Hangcha. With exterior design, safety, reliability, advancement and comfort, etc. reaching the level of the world's advanced brands and featuring high speed, high efficiency and high safety, it is an ideal choice for the short- and medium-distance goods handling at railway stations, vehicle companies, etc.

A Series 3.0-5.0t Electric Tow Tractor

- HANGCHA A series 3.0-5.0t electric tow tractor is mainly applied in short-distance transportation among the production lines. Low operator platform for frequent and effortless entry and exit. Thanks to the standing design, it can greatly improve the efficiency of operations. Furthermore, for indoor application, the electric drive system is environmental friendly within the workshop. Therefore, this product is a good partner of automobile manufacturing, logistics companies, warehouses and other places, fields which has broad application prospects.

A Series Electric Tow Tractor 2.0-6.0t

- As for A series of tractors, the advanced AC drive control technology is adopted for the complete tractor. The tractor has excellent performance, can be operated comfortably, is safe and reliable, has low maintenance cost and is the high-efficiency tool for resolving material transport among different zones for the workshops, flow lines and large factories.

X Series Electric Tow Tractor 6.0-10t

- Load Capcity: 6,000~10,000kg

- Drive Types: Lead Acid Battery

X Series Electric Tow Tractor 20-40t

- Load Capcity: 20,000~40,000kg

- Drive Types: Lead Acid Battery

X Series Internal Combustion Tractor 2.0-3.0t

- Load Capcity: 2,000~3,000kg

- Drive Types: Diesel

Representing the design concept of safety, reliability, comfort and environmental protection, the X series 2–3 ton internal combustion tractor has been completely improved in safety, comfort and reliability through a new design and the performance of the vehicle has been greatly improved compared with the prior products.

X Series Internal Combustion Tractor 3.5-8.0t

- Load Capcity: 3,500~8,000kg

- Drive Types: Diesel

AERIAL PLATFORMS

Vertical Mast Lift

- 0~210kg Load Capacity

- 0~11220mm Lift Height

- Lead Acid Battery Drive Types

The HANGCHA HV110D is a jib machine that offers outreach capability to get virtually any job done. A 130° rotating jib and 345° non-continuous hydraulic turntable allows for exceptional range of motion and precise positioning. These capabilities combined with the efficient electric drive motors and a low machine weight make the HANGCHA HV110D lift the solution for hard-to-reach jobsite needs. It has the characteristics of compact body size, small turning radius, good handling performance and strong endurance. It is mainly used in warehouse, exhibition hall, aircraft maintenance, mechanical equipment installation, equipment maintenance and other fields.

Anti-overturning system

When the machine raises, this system will open automatically, to protect the machine from overturning while walking at un-leveling ground.

Safety

Alloy steel axis, to make sure the safety, reliable and efficient.

Internal charger

You can charge the battery directly, do not need to remove it from machine.

The working scope

It can go to the working area rapidly trough lifting, lowering, traveling forward and backward, turret turning, etc.

Self-leveling sensor

When the degree is more than 2.5°, it will alarm.

The proportional control system

Control the speed of traveling, lifting and turret turning as you need.

Articulation Boom Lift

- 230~250kg Load Capacity

- 0~5600mm Lift Height

- Lead Acid Battery Drive Types

The working height can perfectly adapt to the needs of building working.

Mini Size

The compact size makes the machine gets into the elevator with free access.

Light Weight

The weight is very light, which can meet the load limit of elevator and better protect the ground.

Large Capacity

Though the self-weight is light , it has a large capacity, the machine can allow two peoples working together.

High Efficiency

Equipped with efficient fully electrified DC drive system, more durable.

Low Failure Rate

Simple and clear system, drawer structure, easier maintenance, lower use cost.

High Rewarding

Transport and procurement costs are lower, and rental prices are comparable to regular models.

Green Environment Protection

Electric drive walking system, zero emission, low noise, more suitable for indoor use.

Mini Self-propelled Scissor Lifts (Electric Motor Drive)

- 230~250kg Load Capcity

- 0~5600mm Lift Height

- Lead Acid Battery Dirve Types

The working height can perfectly adapt to the needs of building working.

Mini Size

The compact size makes the machine gets into the elevator with free access.

Light Weight

The weight is very light, which can meet the load limit of elevator and better protect the ground.

Large Capacity

Though the self-weight is light , it has a large capacity, the machine can allow two peoples working together.

High Efficiency

Equipped with efficient fully electrified DC drive system, more durable.

Low Failure Rate

Simple and clear system, drawer structure, easier maintenance, lower use cost.

High Rewarding

Transport and procurement costs are lower, and rental prices are comparable to regular models.

Green Environment Protection

Electric drive walking system, zero emission, low noise, more suitable for indoor use.

Self-propelled Electric Scissor Lifts

- 230~450kg Load Capacity

- 0~13700mm Lift Height

- Lead Acid Battery Drive Types

HANGCHA self-propelled electric scissor lifts are the high efficient, safe and ideal solution for modern industry. Ideal for maneuvering in tight Spaces, they're excellent for indoor and outdoor application, all the functions, lifting, lowing, steering, forward and backward are under operator's control. Easy maintenance and service after opening the battery cover, all key parts are easy access. With low noise level, and high reliability, HANGCHA self-propelled electric scissor lifts are always your best partner.

Application

Stations, dock, airport, power station, gym, big company ect.

Characteristics

The proportional control system: Control the speed Of Traveling and lifting as you need. Extension deck: You can reach the working place by the Extended platform. Safety: Alloy steel axis, to make sure the safety, reliable and efficient.

XB Series Pallet Truck With Scissor lift

- 500~2,000kg Load Capacity

- 0~2000mm Lift Height

- Lead Acid Battery Drive Types

High structural strength

High strength rectangular tube, Self-lubricating nylon slider, long service life and stable performance.

High performance

Permanent magnet motor, One-piece hydraulic power pack, colloidal maintenance-free battery, high performance,stable and efficient.

Reliability

Side support system, one-way throttle valve on lifting hydraulic cylinder, Waterproof connector, safety and reliability in performance.

Safety

Three emergency braking functions, emergency reverse button on Joystick, electronic lift limit, ensure the safety of personnel and cargo.

Maintenance convenience

The battery is removed from the side of chassis, One piece plastic cover, easy to maintaining.

Diesel Articulated Boom Lift

- 0~230kg Load Capacity

- 16700~22000mm Lift Height

- Lead Acid Battery Drive Types

High structural strength

High strength rectangular tube, Self-lubricating nylon slider, long service life and stable performance.

High performance

Permanent magnet motor, One-piece hydraulic power pack, colloidal maintenance-free battery, high performance,stable and efficient.

Reliability

Side support system, one-way throttle valve on lifting hydraulic cylinder, Waterproof connector, safety and reliability in performance.

Safety

Three emergency braking functions, emergency reverse button on Joystick, electronic lift limit, ensure the safety of personnel and cargo.

Maintenance convenience

The battery is removed from the side of chassis, One piece plastic cover, easy to maintaining.

A Series Storage Assist Vehicle

- Load Capcity: 150~227kg

- Lift Height: 5600~14000mm

- Drive Types: Lead Acid Battery

It has the characteristics of compact body size, small turning radius, good handling performance and strong endurance. It is mainly used in warehouse, exhibition hall, aircraft maintenance, mechanical equipment installation, equipment maintenance and other fields.

E-TRUCKS

3 wheel Forklift Truck

X Series 0.6-1.0t

- 600~1,000kg Load Capacity

- 0~4500mm Lift Height

- Lead Acid Battery Drive Types

Hangcha’s X series 0.6-1.0t 3W electric forklifts are a new series of high-efficiency, energy-saving small-tonnage electric counterbalanced forklifts with a new structure that represents a breakthrough over the traditional design concept. With a compact structure, small turning radius and light weight and high maneuverability, the truck is widely used in narrow operation places, e.g., used for handling between floors, to and from elevators or in warehouses, supermarkets, workshops, etc.

Appearance

The whole truck is small and flexible, adopting a combination of straight lines and streamlined curved surfaces, with a simple appearance and strong strength.

Comfort

Excellent ergonomic design and large operation space provide the operator with more comfort, and satisfy the operator’s needs for long-term and high-intensity operations. Safety

The emergency power-off switch complies with European safety standards.

Advancement

Full AC motors, precise speed control, maintenance-free , temperature monitoring.

A Series 1.3-2.0t

- 1,300~2,000kg Load Capacity

- 0~6500mm Lift Height

- Lead Acid Battery Drive Types

Comfort

Both the steering column and seat can be adjusted easily, every operator can find the best driving position.

Stability

Sinking type battery layout provides good stability especially during cornering.

Safety

Emergency switch is standard specification which meets the Euro safety regulation.

Maintenance

Full opened battery cover is easy for battery service and changing.

A Series 1.5t

- 1,500kg Load Capacity

- 0~6500mm Lift Height

- Lead Acid Battery Drive Types

A series 1.5t rear-wheel driving three pivot electric forklift truck is very suitable for operating in limited space, with small turning radius, which is the ideal forklift truck in store, supermarket and warehouse, etc.

Ergonomic

State-of-the-art design makes a clear footwell with wellplaced pedals which give plenty of room for large feet space and help the driver's comfort working.

Reliability

AC motor is the simple brushless motor, less maintenance and better suitability for wet and explosive conditions.

Side battery change

24V battery is ideal for two or three shifts requirements, and side battery change is a perfect option to change the batteries quickly.

4 Wheel Forklift Truck

A Series 1.0-3.5t (Four Wheel)

- 1,000~3,500kg Load Capacity

- 0~6500mm Lift Height

- Lead Acid Battery Drive Types

Stability

Advanced parallel layout of drive motor and lower located battery up to chassis bottom provide good stability to the truck.

Comfortable

New designed wide view mast provides better forward view ability.

Advanced

Multi functions big LED dashboard provides running hours, battery power, and self diagnosis functions, and with high accuracy even in bad environment.

Service Ability

CE certificate is available.

A series 2.5-3.5t (Four Wheel, High-Performance)

- 2,500~3,500kg Load Capcity

- 0~7500mm Lift Height

- Lead Acid Battery Dirve Types

New A series of high-performance electric forklift whichcovers from 2. 5t to 3. 5t,is the key promoting product of Hangcha in 2015. lt is based on the already available for A series electric forklift, mainly to meet the requirements of efficiency first, fast lifting and driving speed, high capacity battery, excellent ergonomic, easy operation and operating safety.

Main parts

Motor controllers, connectors, power plug, emergency switch, dashboard, accelerator are all applied world famous brands, ensure the reliability of good performance and provide easy service. Emergency switch is standard specification which meets the Euro safety regulation.There is overloading protection for eletronics and hydraulic system.The whole truck meets CE certificate.

Excellent Ergonomic

New Big LED dashboard is easy to see, with comprehensiveindicator lights,and provides friendly human-computer interaction.The operator can monitor the truck operation at a glance.

Easy operating and maintenance

The key controllers are all sealed in the counterweight, dust and water free.Selfcooling traveling motor with lP20 protection has good reliability. Protection grade of the whole forklift is IPX3.

Safety

Suspension seat use high-class Grammer MSG65, which has the OPS function of locking forklift truck' s forward/backward, mast' s lifting/lowing, tilting and side shifting etc. Parking brake with buzzer, which means when parking brake is released at Key off position, the buzzer is operated. Steering wheel, armrest and reversing handle are all equipped with horn button, which can warn surrounders. PIN code access system with 99 passwords can be set, provides easy management.

A Series Dual Drive Electric Forklift

- 2,000~3,500kg Load Capacity

- 0~6500mm Lift Height

- Lead Acid Battery Drive Types

Maneuverability

Driven by two motors independently, the front wheels can rotate forwards and backwards with a small turning radius and have good maneuverability. An imported reduction gearbox is provided. The high-power drive motors provide strong and reliable driving force.

High Efficiency

A high-power oil pump motor is used. The large-displacement silent gear pumps improve the lifting speed and operation efficiency.

Comfortable

New designed wide view mast provides better forward view ability.

Advanced

High frequency MOSFET controller provides accurate control of traveling, lifting, and better adjustable performance, and better matches the motor. Regenerative braking, reverse current braking and anti-slide on slop function guarantee the operation safety.

A series 4.0-4.99t (Four Wheel)

- 4,000~4,990kg Load Capcity

- 0~6000mm Lift Height

- Lead Acid Battery Dirve Types

Stability

The internationally advanced parallel arrangement is adopted for traction motor, and the battery is sunken to chassis, resulting in lower gravity center and better stability of entire truck.

Comfort

The adjustable, small-diameter steering wheel with tilt designed based on ergonomics offers good hand feeling, and the seat can also be adjusted forward and backward, which can provide best driving position for the operator.

High performance

Soft landing system lowers descending speed automatically when fork reaches the height range of 100-60mm from the ground, so as to reduce vibration of the entire truck, and provide effective protection for goods.

Maintenance

Fully-openable cover enables easy maintenance of battery.

A Series 12-16t (Four Wheel)

- 12,000~16,000kg Load Capacity

- 0~6500mm Lift Height

- Lead Acid Battery Drive Types

The electric forklift truck, with key parts of associated products from world-renowned manufacturers, features excellent performance, reliability and durability, high safety, as well as elegant, steady, simple but bright appearance. The product can be applied for a wide range of purposes, and is suitable for various working conditions including indoor and outdoor spaces.

Hydraulic System

The system is equipped with electro-hydraulic proportional sectional valve of world-renowned brand, silent gear pump, pilot electric control handle, and AC oil pump motor. The load sensing hydraulic system reduces continuous load on oil pump motor; the remote electric control operating mode is simple, easy, and flexible. Several hydraulic pressure detection points are added to simplify maintenance and service work.

Mast System

The duplex mast has increased width, higher resistance to torsion, and broader view; oil circuit with dual governing valves features higher safety. Hydraulic fork width adjustment is a standard configuration.

Braking System

The system is equipped with Poclain hydraulic brake valve, multi-plate wet travel brake and spring action, and hydraulic release caliper disc parking brake system.

Steering System

The system is equipped with horizontally placed oil cylinder steering axle of single dual-action oil cylinder, features fully hydraulic power steering, steering priority, with load sensing function, and can realize easy steering.

A series 14-16t (Four Wheel)

- 14,000~16,000kg Load Capacity

- 0~6500mm Lift Height

- Lead Acid Battery Drive Types

The electric forklift truck, with key parts of associated products from world-renowned manufacturers, features excellent performance, reliability and durability, high safety, as well as elegant, steady, simple but bright appearance. The product can be applied for a wide range of purposes, and is suitable for various working conditions including indoor and outdoor spaces.

Hydraulic System

The system is equipped with electro-hydraulic proportional sectional valve of world-renowned brand, silent gear pump, pilot electric control handle, and AC oil pump motor. The load sensing hydraulic system reduces continuous load on oil pump motor; the remote electric control operating mode is simple, easy, and flexible. Several hydraulic pressure detection points are added to simplify maintenance and service work.

Mast System

The duplex mast has increased width, higher resistance to torsion, and broader view; oil circuit with dual governing valves features higher safety. Hydraulic fork width adjustment is a standard configuration.

Braking System

The system is equipped with Poclain hydraulic brake valve, multi-plate wet travel brake and spring action, and hydraulic release caliper disc parking brake system.

Steering System

The system is equipped with horizontally placed oil cylinder steering axle of single dual-action oil cylinder, features fully hydraulic power steering, steering priority, with load sensing function, and can realize easy steering.

Electric System

The full AC controller of state of the art in the world is adopted, achieving electronic control for traveling, lifting, braking, and steering actions of the forklift. It features smooth and accurate control, superior speed regulation performance, with regenerative braking, reverse braking, and anti-slipping on slope and other functions, enabling more effiective operation, higher safety and comfort. The MMI instrument of world-leading brand is adopted, with large screen LCD battery indication, timing, failure self-diagnosis, and mode selection, and accurate display even in severe environment. The LED lighting system is adopted for energy saving.

AE Series 1.5-3.5t (Four Wheel)

- 1,500~3,500kg Load Capacity

- 0~7000mm Lift Height

- Lead Acid Battery Drive Types

Independently developed by Hangcha on the basis of more than 30 years of electric forklift research and development and accumulated manufacturing technology, the AE series electric forklifts are a new series of high-efficiency and energy-saving electric counterweight forklifts with a new structure that represents a breakthrough over the traditional design concept. The research and development of control and power systems are innovated and the product exterior, ergonomics, reliability, maintenance and other aspects are optimized, so that the performance of the vehicle is greatly improved.

Appearance

With a profile formed by a combination of straight lines and streamlined curved surfaces, the truck is compact and maneuverable and has simple and sturdy appearance.

Comfort

The cover is sealed with a good effiect of rain resistance.

Safety

The optional lowering lock function can improve the safety greatly when the driver leaves the seat.

Maintenance

The front-opening hood design makes charging and maintenance easier.

Advancement

The controller, oil tank and pump motor are all placed at the front to enable small pipeline length and less energy loss.

X series 1.0-3.5t (Four Wheel)

- 1,000~3,500kg Load Capacity

- 0~7000mm Lift Height

- Lead Acid Battery Drive Types

Independently developed by Hangcha on the basis of more than 30 years of electric forklift research and development and accumulated manufacturing technology, the AE series electric forklifts are a new series of high-efficiency and energy-saving electric counterweight forklifts with a new structure that represents a breakthrough over the traditional design concept. The research and development of control and power systems are innovated and the product exterior, ergonomics, reliability, maintenance and other aspects are optimized, so that the performance of the vehicle is greatly improved.

Appearance

With a profile formed by a combination of straight lines and streamlined curved surfaces, the truck is compact and maneuverable and has simple and sturdy appearance.

Comfort

The cover is sealed with a good effect of rain resistance.

Safety

The optional lowering lock function can improve the safety greatly when the driver leaves the seat.

Maintenance

The front-opening hood design makes charging and maintenance easier.

Advancement

The controller, oil tank and pump motor are all placed at the front to enable small pipeline length and less energy loss.

X Series 4.0-5.0t (Four Wheel)

- 4,000~4,990kg Load Capacity

- 0~7000mm Lift Height

- Lead Acid Battery Drive Types

Stability

The drive motor is arranged in parallel, the battery is placed at the bottom of the vehicle frame, the wheelbase and rear wheel pitch are increased, the swing point of the steering axle is raised, and the distance between the front of the fork and the front axle is reduced, to enable excellent stability.Comfort

In accordance with the ergonomically design, the wheelbase is increased to enable enlarged leg space. The radius of the hand wheel is reduced to 300mm and the seat can be adjusted backwards and forwards, so that the operator can choose the best driving position.Advancement

The high-frequency MOSFET integrated controller ensures smooth and accurate driving and lifting control, and has excellent speed regulation performance, good performance of electronic control matching the motor, functions of regenerative braking, reverse braking and anti-sliding on ramps, etc., and high safety and reliability.Safety

The optimized design of the wide-view mast, wide-view overhead guard and low dashboard enables a broader view of the operator and higher safety.

Maintainability

The fully opened hood quite facilitates the maintenance of the battery, oil pump motor and electric control assembly.

X Series 6.0-10t (Four Wheel)

- 6,000~10,000kg Load Capacity

- 6000mm Lift Height

- Lead Acid Battery Drive Types

Stability

Small-diameter solid tires, front and rear battery sets and other technologies are used to enable excellent stability of the vehicle.Comfort

The inclination angle of the ergonomically designed hand wheel is adjustable and the seat can be adjusted 150mm forwards and backwards, so that the operator can choose the best driving position.Safety

The optimized design of the wide-view mast, wide-view overhead guard and low dashboard enables a broader view of the operator and higher safety.Maintainability

The innovative two-door structure with one door, respectively, on the left and right sides of the forklift easily facilitates the maintenance of the motor, oil pump and electric control of the forklift and enables good resistance to dust and water.Advancement

The high-frequency MOSFET integrated controller ensures smooth and accurate driving and lifting control, and has excellent speed regulation performance, good performance of electronic control matching the motor, functions of regenerative braking, reverse braking and anti-sliding on ramps, etc. and high safety and reliability.

IC - TRUCKS

A Series IC Forklift Truck

A series 1.0-3.8t Internal Combustion Counterbalanced Forklift Truck

- 1,000~3,800kg Load Capacity

- 0~6000mm Lift Height

- Diesel Drive Types

Appearance

Based on around 10 years Nissan technology applied on HC trucks, and HANGCHA own R and H series, the new A series is fully own researched truck. The improved new outline, safety, comfortability, and reliability, all these provide better performance to the trucks.

Comfortable

The same ergonomic technology as R series has been adopted. The smaller steering wheel, extra space for foot and operator space, wider forward visibility, all these improve operator's comfort and release operator's fatigue.

Safety

Thanks to the long wheelbase design, the longitudinal stability of whole truck is improved, the residual load capacity at same height is improved greatly. At the same time, it prolongs the working life time of steering tire by reducing the rear axle load.

Reliability

The aluminum ribbon-tubular radiator with large capacity and the optimized cooling system fu rather enhance the heat dissipation capability of the whole truck to ensure the reliability of the engine.

Outline

Applied the advanced outline designing method, the truck is designed with stream, sporty outline, and thanks to the new design, all the exposed parts are metal made. which is firm and reliable.

A series 4.0-5.0t Internal Combustion Counterbalanced Forklift Truck

- 4,000~5,000kg Load Capacity

- 0~7000mm Lift Height

- Diesel Drive Types

Appearance

With the newest appearance design method, the whole forklift has smooth profile lines, presents the dynamic effect, and meets the newest appearance design fashion.

Comfortability

With the man-machine engineering technology same to that for R series, the space for legs and boarding is larger, the operating vision is extended. The operating comfortability is greatly improved, and the fatigue strength of the operator is reduced.

Safety

With the long axle base design, the whole forklift has better longitudinal stability. At the same lifting height, compared with the original forklifts, the lifting capacity is improved by great degree. Meanwhile, the rear axle load is reduced, and the life of the steering tyres is extended.

Reliability

With the thicker rear leg of the overhead guard, the engine air admission quantity is increased, the air admission resistance is reduced. The engine can conduct more sufficient combustion, and the engine life is extended.

A series 5.0-7.0t Internal Combustion Counterbalanced Forklift Truck

- 5,000~7,000kg Load Capacity

- 0~7000mm Lift Height

- Diesel Drive Types

The A series is a novel series of internal combustion counterweight forklifts, which is independently developed by Hangcha by learning Japanese Nissan’s technologies and on the basis of the prior products. Through comprehensive optimization of the exterior design, safety, comfort and reliability, the performance of the vehicle has been greatly improved in comparison with the prior products.

Appearance

With the latest exterior design method used, the vehicle has a smooth vivid profile following the latest exterior design trend.

Comfortable

Advanced ergonomic technology, an integral engine hood, a steering wheel of a smaller size and an enlarged space for the pedaling foot are used to significantly improve the operation comfort and reduce the operator’s fatigue.

Safety

The center of gravity of the vehicle moves backward to enable the higher longitudinal stability and high-position operation stability of the vehicle.

Reliable

The large-capacity aluminum plate-fin heat dissipater has optimized heat dissipation channels. The integrated transmission oil and engine coolant heat dissipater and intercooler provide a good heat dissipation capacity.

A series 8.0-10t Internal Combustion Counterbalanced Forklift Truck

- 8,000~10,000kg Load Capacity

- 0~7000mm Lift Height

- Diesel Drive Types

The A series is a novel series of internal combustion counterweight forklifts, which is independently developed by Hangcha by learning Japanese Nissan’s technologies and on the basis of the prior products. Through comprehensive optimization of the exterior design, safety, comfort and reliability, the performance of the vehicle has been greatly improved in comparison with the prior products.

Appearance

With a new exterior design method used, the vehicle has a smooth vivid profile following the up-to-date exterior design trend. The vehicle is compact in appearance, and the exposed parts are robust and reliable metal parts.

Comfort

Advanced ergonomic technology, an integral engine hood, a steering wheel of a smaller size and an enlarged space for the pedaling foot are used to significantly improve the operation comfort and reduce the operator’s fatigue.

Safety

The center of gravity of the vehicle moves backward to enable the higher longitudinal stability and high-position operation stability of the vehicle.

Reliable

The large-capacity aluminum plate-fin heat dissipaters are used as the hydraulic oil, transmission oil, engine coolant heat dissipaters, and the intercooler. These dissipate heat well.

A2 Series Internal Combustion Forklift

- 1,500~3,800kg Load Capacity

- 0~7000mm Lift Height

- Diesel Drive Types

New Design

Inherit the exterior design of Hangcha’s A products and integrate innovation in classic style, thus the vehicle has a smooth vivid profile and a sturdy design. The newly designed semi-enclosed instrument console make the entire forklift look compact and stylish.Safety and Reliability

The vehicle has an optimized layout design, reduced front overhang, lowered center of gravity and improved stability of the entire forklift. The new channel steel, ultra-wide-view mast and lowered dashboard in the cab broaden the front view of the driver significantly. Profiled steel overhead guard features high strength with good sealing of the cab.Comfort and Convenience

Standard seat with an adjustable backrest has good packaging and anti-slip design, enabling a more comfortable driving and sitting experience. The low-angle accelerator pedal reduces the driver’s fatigue. Integrated light combination switch makes the operation more convenient.

A Series 12-16t Internal Combustion Counterbalanced Forklift Truck

- 12,000~16,000kg Load Capacity

- 6500mm Lift Height

- Diesel Drive Types

Exterior and Performance

The upper surfaces of the large locked toolbox and counterweight on the left and right sides of the vehicle body are designed to be fully flat to enable a large storage space.Reliability

The high-power plate-fin heat dissipater and independent hydraulic oil heat dissipater have been subjected to heat balance test verified under two kinds of operating conditions - typical operating conditions and no-load maximum-speed long-distance driving conditions, to ensure the normal operations of the system under various operating conditions.A Simple and Efficient Hydraulic System

The fully hydraulic load sensing steering system makes steering easier and more flexible. Two pumps are used to enable merging and less pressure loss and energy consumption..Maintenance

With the LCD instruments to display the relevant information of the vehicle which emit an alarm for an engine fault, the running status of the vehicle can be monitored and fault queries can be performed to facilitate problem analysis.

X Series IC Forklift Truck

X series 1.5-3.8t Internal Combustion Counterbalanced Forklift Truck

- 1,500~3,800kg Load Capacity

- 0~7000mm Lift Height

- Diesel Drive Types

The X series is the new series of internal combustion counterbalance forklift truck developed by Hangcha independently, adopting the world advanced technologies based on the original products. Through the comprehensive upgrading of appearance molding, energy conservation, environmental friendly, comfort, security and reliability, it will become the world-class forklift truck which can meet your overall demands.

Comfort

Adopt the new-type of box iron. Increase the inside width of inner mast and the spacing between lifting cylinders. The lowering of instruments in the cabin will greatly increase the forward visibility; The rear visibility will also be greatly improved through the optimization design of counterweight.

Reliability

2.0~3.8t roller bearing on the steering axle king pin adopts large size tapered roller bearing (TRB), larger steering cylinder and bumper block assemblies on the top, which can prolong the service life of bearing and highly improve the reliability of steering axle.

Maintenance The enlarged opening angle of hood and increase of left and right hood side plates can provide you with convenient and rapid maintenance mode.

X series 5.0-10t Internal Combustion Counterbalanced Forklift Truck

- 5,000~10,000kg Load Capacity

- 0~7000mm Lift Height

- Diesel Drive Types

The X series is the new series of internal combustion counterbalance forklift truck developed by Hangcha independently, adopting the world advanced technologies based on the original products. Through the comprehensive upgrading of appearance molding, energy conservation, environmental protection, comfort, security and reliability, it will become the world-class forklift truck which can meet your overall demands.

Reliability

The radiator adopts aluminous plate-fin radiator with better performance and higher structural strength. Impendent oil radiator, optimized oil and water heat dissipation channel and double ventilation holes on counterweight can greatly improve cooling efficiency and reliability of overloaded operation and ensure reliable operation of the engine.

Intelligentized management system (option)

Reserved plug of extending function of Intelligent module is on the wire bundles that makes truck management more convenient and rapid.

Energy conservation and environmental protection

The whole truck adopts LED lights as shiner and new-type panoramic retroreflector to ensure energy conservation and power saving as well as greatly improve the performance and service life of luminaires at the same time.

X series Diesel Forklift Truck For Work In Container

- 5,000~10,000kg Load Capacity

- 0~3600mm Lift Height

- Diesel Drive Types

Vehicle warranty period

The warranty period is prolonged to 2 years or 4000 hours (except for vulnerable parts), where the expiring period will prevail.

Vehicle features

The vehicle is designed to have a sturdy exterior with novel streamlined curved surfaces and a prominent and innovative inside. With a free duplex mast for the standard configuration and optional masts of multiple specifications for inside-container operations, the highly-adaptable vehicle has a low height and a narrow body appropriate to inside-container operations and meets the other requirements for operations in low and narrow environments.

Vehicle-mounted video system

The 8.5-10t vehicle is equipped with a front and rear cameras–equipped with a vehicle-mounted video system for the standard configuration to broaden the front and rear operating views.

LCD instruments with clear display

The newly developed LCD instruments have more comprehensive functions and more stable performance and can completely display important information such as the running status of the vehicle, engine failure, etc., so that the operator can more clearly know the status of the vehicle and the maintenance becomes easier.

New-generation integrated electrical box

A new-generation integrated electrical box with reasonable layout is used, which can be maintained and repaired easily and has better waterproof performance.

The vehicle can operate inside a container

The vehicle has a low height and a narrow body appropriate to inside-container operations and meets the other requirements for operations in low and narrow environments.

X series 12t Internal Combustion Counterbalanced Forklift Truck

- 12,000kg Load Capacity

- 0~6500mm Lift Height

- Diesel Drive Types

The X series is the new series of internal combustion counterbalance forklift truck developed by Hangcha independently, adopting the world advanced technologies based on the original products. Through the comprehensive upgrading of appearance molding, energy conservation, environmental protection, comfort, security and reliability, it will become the world-class forklift truck which can meet your overall demands.

Energy conservation and environmental protection

The whole truck adopts LED lights as shiner and new-type panoramic retroreflector to ensure energy conservation and power saving as well as greatly improve the performance and service life of luminaires at the same time.

Fully improved reliability and security

The radiator adopts aluminous plate-fin radiator with better performance and higher structural strength. Impendent oil radiator, optimized oil and water heat dissipation channel and double ventilation holes on counterweight can greatly improve cooling efficiency and reliability of overloaded operation and ensure reliable operation of the engine.

Maintenance

The enlarged opening angle of hood and increase of left and right hood side plates can provide you with convenient and rapid maintenance mode.

Comfort

Adopt the new-type of box iron. Increase the inside width of inner mast and the spacing between lifting cylinders. The lowering of instruments in the driving cab will greatly increase the forward visibility; The rear visibility will also be greatly improved through the optimization design of counterweight.

X Series IC Forklift Truck For Work In Stone Industry

- 5,500kg Load Capacity

- 0~7000mm Lift Height

- Diesel Drive Types

The Yuchai common rail engine has strong power and low fuel consumption

High torque at low speeds, good performance of acceleration at medium and high speeds. Bosch’s non-road special common rail system has good oil adaptability. A long oil change interval enables a low use cost.A special gearbox of a domestically renowned brand

The customized 16t special gearbox has a large capacity, high efficiency and good traction performance. The PTO outputs high torque and can be matched with a large-displacement gear pump. The electronic steering provided for the standard configuration makes operations easier.Domestic heavy-duty caliper drive axle

The caliper brake provides fully hydraulic power braking and large braking force. The integrally-cast axle housing has good strength. With a main gearbox for heavy-duty trucks, mature and reliable. The input shaft cable-type central parking brake is simple and reliable and can be operated easily.Easy Maintenance

The wide-open hood, water tank lid, left and right hood side panels, and front bottom panel can be removed easily. A cloud smart module provided for the standard configuration enables remote control and diagnosis.

Sideloader Forklift

- Load Capcity: 3,000~6,000kg

- Lift Height: 3600mm

- Drive Types: Diesel

The side forklift is a special type of industrial vehicle. The main difference between it and the general counterbalanced front forklift is that the working device of the side fork is installed on the side of the vehicle body. In addition to being able to lift and tilt, it can also extend and Income.

XF Series IC Forklift Truck

XF series 1.0-3.5t Internal Combustion Counterbalanced

- Load Capcity: 1,000~3,500kg

- Lift Height: 0~7000mm

- Drive Types: Diesel

XF2 Series IC Counterbalanced Trucks

- Load Capcity: 1,500~3,500kg

- Lift Height: 0~7000mm

- Drive Types: Diesel

XF2 Series IC Counterbalanced Trucks

- 1,500~3,500kg Load Capacity

- 0~7000mm Lift Height

- Diesel Drive Types

Appearance

A vivid and sturdy exterior inheriting the classic design, embodying innovative ideas, and bringing a strong high-tech impact.All-round visibility

Optimized design provides outstanding visibility in all directions.Comfortable

The fully-suspended gearbox, fully-suspended overhead guard, and fully-suspended seat realize three-stage vibration reduction to reduce vibration of the vehicle.Reliable

A wet axle is developed and used to significantly improve the reliability of the braking system and force transmission structural parts. (Wet brake, custom high-strength bolts, wheel side planetary reducer).Electrical system

The new-generation high-efficiency energy-saving novel combination LED lighting system is energy-saving, while the performance and service life of the lights are significantly improved.

XF series 4.0-5.5t Internal Combustion Counterbalanced Forklift Truck

- 4,000~5,500kg Load Capacity

- 0~7000mm Lift Height

- Diesel Drive Types

Reliability

XF series features rugged design, stamped frame and engine hood, stamped instrument panel and head guard, heavy profile rail mast combine to provide excellent rigidity, which ensures outstanding reliability even in heavy-duty work.Productivity

The new Dynamic load sensing hydraulic steering system contributes to reduce loss of hydraulic and improve energy efficiency.

Comfortable

The new automobile-style light/turn-signal lever and forward-reverse lever are ergonomically designed and arranged to improve comfort and productivity. The new, relocated easy-to-see LCD meter lets the operator check on all aspects of operational status at a glance.

Safety

A throttling device is adopted to avoid the mast being out of control even some pipes are broken.

XF series 5.0-7.0t Internal Combustion Counterbalanced Forklift Truck

- 5,000~7,000kg Load Capacity

- 0~7000mm Lift Height

- Diesel Drive Types

Comfortable