- Offer Profile

End-to-end warehouse design for complex distribution challenges

FORTNA is an end-to-end design-build firm, delivering transformative, data-driven distribution solutions to the world’s leading brands. We empower our clients with the design and delivery of intelligent solutions that optimize performance, address disruption and increase profitability.

Warehouse automation solutions for complex distribution challenges

FORTNA develops the optimal solution for your business challenges. Our unique approach allows us to identify and select best-fit technologies that meet your business requirements.

By Function

Whether your business wrestles with e-Commerce fulfillment and returns, omnichannel commerce or the complexities of local micro-fulfillment, our solutions improve performance today.

Central Hub/Last Mile Depot

The Central Hub/Last Mile Depot model helps optimize distribution to reduce your shipping costs

By centralizing the storage and transportation of inventory in a central facility from which goods are distributed to multiple regional warehouses when required, the Central Hub/Last Mile Depot model optimizes truck loading and thus, transportation, as orders are consolidated and dispatched with routes optimized to decrease shipping costs.

- Achieve faster delivery speeds and cost efficiencies

- Enable two-day, one-day, and even same-day delivery

- Efficiently allocate staff and resources to meet increasing order volumes

- Save time and increase your bottom line

- Provide a superior customer experience

- Reduce emissions and achieve sustainability goals

Reduce last mile delivery challenges to improve performance and drive profitability

FORTNA’s central hub and last mile depot solutions allow companies to fast-track same-day deliveries by streamlining the final piece of your shipping and delivery process.

By arming your distribution operations with a central warehouse that’s used to catering various destinations – whether that’s customers, stores or other smaller warehouses – central hub and last mile depot solutions play an important part in supply chain strategy, helping you minimize your overall transportation costs.

Achieve unprecedented benefits from the Central Hub/Last Mile Depot model

By integrating the FORTNA Central Hub/Last Mile Depot model into your distribution operations, you can help your warehouse improve transportation productivity and simplify the shipping process, all while boosting your inventory traceability and achieving efficient inventory control. The result: lower transportation costs and a superior delivery experience for customers.

Cross-Docking and Returns

How cross-docking helps enable a smarter, more efficient returns process

The promise of a simple, fast and efficient returns process is now critical to the happiness of the e-Commerce customer, especially when purchasing goods online without the opportunity to see, touch, try on and experience products in a physical storefront. But for distribution centers and warehouses focused on optimizing every square foot of available space, the prospect of organizing this wave of returns can significantly impact productivity and overall efficiency.

A cross-docking solution with built-in quality assurance checks aids in overall customer satisfaction by allowing warehouse staff to sort and distribute items as ordered, rather than having to dedicate large amounts of space in the warehouse to storing products in bulk to be placed in storage.

Cross-docking provides greater flexibility and efficiency in managing the flow of returns and provides warehouses with a better system for balancing both incoming goods for distribution and products being returned by customers.

Contain costs, leverage labor and increase efficiencies with cross-docking solutions

FORTNA applies a lean supply chain model to cross-docking to simplify the extremely complex operation of working with inventory that is coming in, being sorted and simultaneously directed to various destinations to minimize costs, leverage labor and increase efficiencies.

- Faster shipping and receiving times

- Leverage labor

- Efficient inventory management

- Enable high inventory turnover

- Leverage distribution center as a sorting facility

Shift to e-Commerce requires returns processing solutions

Companies have an increasingly large returns problem. Since e-Commerce purchases are returned at a much higher rate than in-store purchases, as e-Commerce grows, so will the average rate of returns. How you address this challenge impacts profitability. It’s time to think about handling returns with the same level of efficiency as your fulfillment operation.

Rapid deployment of returned merchandise to saleable inventory is essential. Returns can be a strategic differentiator and increase customer satisfaction and loyalty.

Process returns with speed, accuracy and efficiency

- Rapidly redeploy returned merchandise to saleable inventory: Returns represent a significant opportunity to increase sales and reduce inventory and working capital. Reclaim space in the DC currently occupied by the growing number of returns.

- Increase customer satisfaction and loyalty: Today’s consumers consider return policies before making a purchase. Your return policy can be a differentiator. Respond to customers’ expectations for fast and easy returns.

- Free up labor for revenue-generating activity: Optimize returns processing for profitability with automation and intelligent software. New solutions are available to simplify the returns process and minimize reverse logistics cycle time.

e-Commerce Fulfillment

FORTNA solves complex e-Commerce fulfillment challenges

e-Commerce demand continues to experience exponential growth, creating new distribution challenges for companies to navigate. FORTNA designs and delivers solutions to address:

- Changing order profiles and channels creating additional complexity

- Labor challenges driving up costs, limiting availability and requiring additional measures to keep workers safe

- Growing number of returns, driven by growth

- Customer expectations for accuracy and fast and free delivery

- Efficient inventory deployment despite hard-to-predict peaks, seasonal demand and customer preferences

- Endless aisle selection driving SKU proliferation

Improve agility and efficiency in e-Commerce operations

- Improve business flexibility and continuity: Flexibility to pivot based on shifting business landscape and changing order profiles. Optimize e-Commerce operations with best-fit technologies and intelligent software.

- Efficient operations to meet and exceed customer expectations: Amazon has raised the bar for fast and accurate order fulfillment. Customers expect immediate availability of inventory regardless of where it sits in the network. Your operations must be designed for responsiveness.

- Address demand with efficient use of inventory: Leverage inventory to fulfill orders from the most advantageous node in the network resulting in the ability to better address ever-changing levels of demand.

High-density Storage

Where online demand meets flexible fulfillment operations

FORTNA enables order fulfillment operations close to your customer. The flexible, scalable AutoStore fulfillment solution maximizes capacity and performance so you can:

- Improve order fulfillment speed and accuracy

- Solve for shifting customer demand

- Optimize for profitable fulfillment

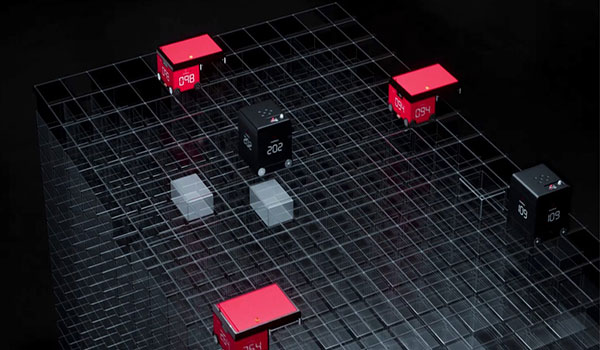

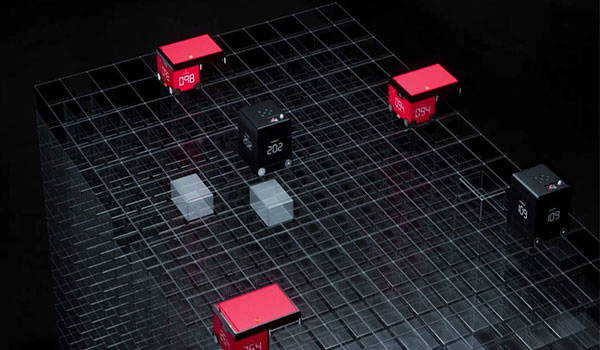

High-density storage with AutoStore picking robots

AutoStore offers a high-density storage solution to increase the speed, accuracy and responsiveness to dynamically changing e-Commerce demand. At FORTNA, we begin with your business requirements and apply our proprietary Distribution Optimization Framework to design a data-driven solution with AutoStore and our intelligent software. The result is fast and accurate order fulfillment and a realized competitive advantage. AutoStore fulfillment solutions are ideal for operations with:

- Each picking operations

- Low- and mid-velocity SKUs

- Small items or cases

- Limited or odd-shaped space

- Large or fast-growing number of SKUs

- Order profiles with few line items

- Merchandise requiring secure storage

AutoStore is the ultimate order fulfillment solution. It combines the highest storage density of any goods-to-person solution, with a high throughput technology, making it a perfect fit for order fulfillment from large warehouses to small urban stores and backrooms.

- Sustainable: The energy-efficient robots utilize regenerative technology and can run on solar power alone. Ten robots use less energy than a vacuum.

- Relentless: The B1 supports true 24/7 operations with technology that allows a robot to switch out its battery rather than spend time on a charging station.

- Space Optimized: With high-density storage, AutoStore can increase storage capacity 4X within the same footprint and take advantage of even the smallest space available.

- Scalable: Expand the system as your business grows by adding more robots, more workstations or adding storage locations, without disrupting ongoing operations.

- Secure: The compact design and fully enclosed grid allow products to be securely stored, authorizing access only at the time an order is processed.

- Reliable: AutoStore solutions are modular so individual components can be switched out for repair without impacting uptime of the rest of the system.

Scalability and flexibility to support growth

- Lower operating expenses, including labor: Reduce labor requirements and related costs with automated solutions for case and pallet picking operations in ambient, chilled and frozen environments.

- Improve inventory accuracy with real-time data: Leverage intelligent software to provide data and analytics for real-time decision making.

- Maximize space utilization in multi-temp environments: Take advantage of vertical building cube to maximize real estate footprint with scalability and flexibility to support future growth.

Micro-fulfillment

Fueling fast, accurate, local fulfillment with automated micro-fulfillment solutions

Micro-fulfillment offers one solution to increase the speed, agility and responsiveness to dynamically changing e-Commerce demand. At FORTNA, we begin with your business requirements and apply our Optimization Science™ to deliver a data-driven design that includes best-fit technologies and intelligent software.

Where online demand meets hyper-local fulfillment

FORTNA places order fulfillment operations close to your customer.

- Improve order fulfillment speed and accuracy

- Solve for shifting customer demand

- Optimize profitable order fulfillment

Omnichannel Fulfillment

Omnichannel fulfillment solutions & integration services

Order fulfillment requirements will continue to change at a rapid pace. Omnichannel consumers expect fast, flexible order fulfillment, anytime, anywhere, adding complexity and additional strain on distribution operations. FORTNA can help transform omnichannel fulfillment operations to handle increasing requirements for speed, accuracy and flexibility.

FORTNA designs and delivers solutions that accelerate omnichannel fulfillment capabilities by:

- Improving business agility

Flexibility to pivot based on shifting business landscape and changing order profiles, FORTNA will optimize operations across channels with best-fit technologies and intelligent software.

- Increasing responsiveness

Amazon has raised the bar for fast and accurate order fulfillment. Customers expect immediate availability of inventory regardless of where it sits in the network. FORTNA will help design your omnichannel operations for responsiveness.

- Maximizing inventory efficiency

Leverage a single pool of inventory for the optimal fulfillment location and method. FORTNA solutions are designed to locate inventory and fulfill orders from the most advantageous node in the network, resulting in reduced inventory and working capital.

Leveraging omnichannel operations for increased business resilience

FORTNA helps companies transform distribution for increased resilience and agility by:

- Driving increased flexibility and agility in their networks

- Digitizing operations for increased visibility to real-time data and insights

- Developing new capabilities and leveraging technologies to increase competitive advantage

- Improving business agility

Packing and Shipping

Packing and shipping solutions for resilience and profitability

e-Commerce has drastically changed consumers’ expectations for the time it takes to pack and ship a product directly to the customer’s homes. Higher order volumes coupled with turnover-prone labor force facilities to use software technology, such as FORTNA OptiSlot DC™ and best-fit solutions designed to maximize system utilization to meet the higher demand of order fulfillment. FORTNA can help efficiently organize, pick and sort products to minimize downtime and efficiently get products out of a facility.

Improve online fulfillment speed, capacity and inventory productivity

Facilities utilize shipping and packing technologies, such as FORTNA OptiSlot DC™, to meet the higher demand for shorter e-Commerce delivery times.

- Improve last mile cost, speed and reliability

- Increase inventory turnover and productivity

- Increase network capacity and balance peak volume

Seven benefits of ship from store fulfillment:

- Increase capacity across the network

- Inventory productivity

- Last mile delivery speed and reliability

- Transportation savings

- Higher margins due to fewer markdowns

- Handle excess volume during peak

- Most of all, RESILIENCE

Slotting

Eliminate congestion and elevate item retrieval with slotting solutions

When items need to be moved due to changes in product demand, seasonal or promotional activities, failure to keep up with these fluctuations can cause a degradation in fulfillment performance and a waste of location capacity. Warehouses can benefit from reduced labor expenses, controlled replenishment, reduction in partial order shipments and improved space utilization with advanced slotting software.

Gain rapid ROI with advanced slotting solutions

FORTNA helps you optimize your warehouse operations to meet fluctuations in e-Commerce demand.

- Improve productivity by decreasing fulfillment time

- Increase space capacity with smart pallet building

- Reduce breakage with advanced software analysis

Optimizing operations with slotting solutions

Here are the telltale signs that indicate your DC would be a good candidate for automating the receiving and picking operations with slotting:

- Pick path congestion

- Forklifts consistently picking from top levels

- Popular items in hard-to-reach areas

- Shipping staff consistently rebuilding pallets

- Open air slots in prime picking area

- Pickers waiting on products

- Dust on products in prime picking areas

- High breakage rates

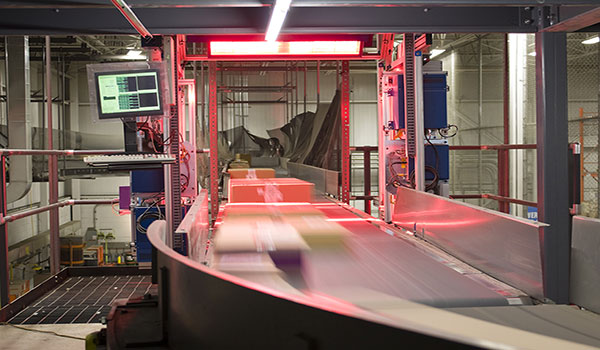

Sortation

Move a broad range of products and packaging to the right places at the right time

Sortation is essential for supply chain systems to run smoothly with the rise in labor shortages, SKU variability and e-Commerce distribution demands. FORTNA offers a broad range of conveyor and sortation solutions that can create a more responsive operation to effectively handle high volumes of cases or totes with speed, accuracy and high throughput.

FORTNA oversees all aspects of conveyor and sortation systems in-house, handling design, engineering, installation, fabrication, software and controls to bring together all elements of a complete, tightly integrated solution. This expertise optimizes product flow and makes the most of limited floor space and labor in greenfield and brownfield projects.

Optimize your supply chain, increase throughput and adapt to changing volumes

As the pressure increases on distribution operations to perform at or exceed expectations, the demand for higher order volumes and shorter processing times continues to grow. To adjust to this changing reality, companies need to implement smarter and more efficient sortation solutions to sort large quantities of inventory contained in a wide variety of package sizes and types. FORTNA provides comprehensive and unique sortation systems designed to streamline your sortation process for optimized results with minimized operations costs.

Benefits of sortation systems

- Increase throughput and capacity

- Reduce labor costs through automation

- Support future growth with scalable and modular designs

- Improve operational control

- Shorten processing times

- Minimize the cost per case and item sorted

- Maximize operational effectiveness

By Technology

We identify and select technologies that uniquely meet your business requirements. The result is a comprehensive, flexible solution that delivers the promised business results.

AGVs and AMRs

Reduce labor needs with AGVs and AMRs

In a labor-constrained market, reducing excess walking or travel is the lynchpin to more efficient operations.

Autonomous Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) can move freely around obstacles, allowing for the movement and transportation of materials without the need for additional labor or permanent conveyor systems. That enables increased productivity, reduced labor costs and damage and scalability to support growing operations.

FORTNA works with top AMR and AGV manufacturers across a variety of different solution types to design flexible, scalable, and modular operations that meet your business requirements.

Flexible. Safe. Reliable. Precise.

AGV and AMR units can be integrated seamlessly within even low-density environments and low-volume, high-complexity sorting applications. These solutions are available in a wide variety of configurations and can carry heavier payloads with greater flexibility and safety than previous generations of these technologies.

AGVs offer a wide array of compatible interfaces to work with existing equipment and facility design, while AMRs are focused on transportation use cases based on eliminating wasted travel, driving higher productivity and lowering overall fulfillment costs:

- "Meet Me Robots" travel to meet a worker to perform a specific task like picking or replenishment.

- "Follow Me Robots" reduce ergonomic and physical strain on workers by transporting goods alongside their human counterparts as they pick or replenish shelves.

- "Mobile Rack Robots" bring inventory to workstations optimized for the most efficient picking or replenishment.

- "Mobile Sortation Robots" offer greater flexibility without the need for fixed conveyor and sortation systems.

We take a unique approach to identify best-fit technologies

The FORTNA Distribution Optimization Framework leans into your data and our proprietary processes, tools, and algorithms to design and deliver solutions using best-fit mobile solutions.

We work with a deep bench of partners, but our unique approach allows for a truly innovative and holistic design that leverages best-in-class technologies, without bias toward any manufacturer or supplier. We can help you select appropriate technologies and work collaboratively with the chosen supplier to optimize your solution for exemplary business results.

Powered by an intelligent warehouse execution system

FORTNA WES™ intelligent software optimizes the design and allows you to leverage artificial intelligence and machine learning capabilities for compounded gains in efficiency and insights. This unique software platform makes it possible to integrate solutions from virtually any type of equipment and swap out technologies without having to make expensive and time-consuming updates to your existing systems.

Automated Storage/Retrieval Systems (AS/RS)

Optimize space and efficiency with automated storage and retrieval systems

High-volume distribution centers need high-density pallet-based storage and retrieval systems for the best use of space and increased speed, accuracy and efficiency. Pallet-based AS/RS can also serve as the backbone of an automated reserve area in a fulfillment center.

FORTNA works with top manufacturers of pallet-based AS/RS, automated deep-lane pallet shuttle systems and robotic solutions to design scalable and modular operations that meet your business requirements.

High capacity, throughput and performance

Automated storage and retrieval systems are ideal for increasing operational performance without increasing your building footprint. Inventory accuracy and reduced shrinkage make these ideal solutions for high-volume inventory. The optimized flow of material and just-in-time replenishment eliminates unnecessary inventory, reducing your total cost. Today’s solutions also work well in ambient, chilled or freezer environments and are ideal for a variety of industry segments and applications for manufacturing and distribution.

Unique approach to identify best-fit technologies

The FORTNA Distribution Optimization Framework™ leans into your data and our proprietary processes, tools and algorithms to design and deliver solutions using best-fit mobile solutions. We work with a deep bench of partners, but our unique approach allows for a truly innovative and holistic design that leverages best-in-class technologies, without bias toward any manufacturer or supplier. We can help you select appropriate technologies and work collaboratively with the chosen supplier to optimize your solution for exemplary business results.

Powered by an intelligent warehouse execution system

FORTNA WES™ intelligent software optimizes the design and allows you to leverage artificial intelligence and machine learning capabilities for compounded gains in efficiency and insights. This unique software platform makes it possible to integrate solutions from virtually any type of equipment and swap out technologies without having to make expensive and time-consuming updates to your existing systems.

AutoStore Fulfillment Systems: Powered by FORTNA

High-Density Storage with AutoStore Picking Robots

AutoStore offers a high-density storage solution to increase the speed, accuracy, and responsiveness to dynamically changing e-Commerce demand. At FORTNA, we begin with your business requirements and apply our proprietary Distribution Optimization Framework to design a data-driven solution with AutoStore and our intelligent software. The end result is fast and accurate order fulfillment and a realized competitive advantage.

FORTNA enables order fulfillment operations close to your customer. The flexible, scalable AutoStore fulfillment solution maximizes capacity and performance so you can:

- Improve Order Fulfillment Speed & Accuracy

- Solve for Shifting Customer Demand

- Optimize for Profitable Fulfillment

AutoStore Fulfillment Solutions Are Ideal for Operations with:

- Each picking operations

- Large or fast-growing number of SKUs

- Low/mid velocity SKUs

- Order profiles with few line items

- Small items or cases

- Merchandise requiring secure storage

- Limited or odd-shaped space

Conveyor Systems

Warehouse conveyor systems for speed and accuracy

In the face of increasing SKU variety and throughput demands, conveyor systems must be flexible and durable to sustain the critical functions of the supply chain. At FORTNA, we specialize in designing, manufacturing and integrating roller- and belt-driven conveyor and singulation solutions that are customized to meet the unique requirements of your operation, ensuring that downstream automated processes operate efficiently.

Cost-effective and high-throughput convey and sort solutions

One of the most pressing challenges in modern operations is the need to save space while maintaining productivity. Our conveyor systems are designed to have a space-efficient footprint, while still allowing for future expansion as your business grows. We recognize that minimizing downtime is crucial, so all our systems are engineered with ease of maintenance in mind.

We deliver bespoke conveyor and singulation solutions for a wide range of operations

Our bi-directional conveyor design provides an added layer of flexibility, enabling your line to handle both inbound and outbound operations with equal efficiency. We leverage our deep industry expertise and years of experience to help you achieve your throughput and quality goals across a wide range of operations from greenfield projects to retrofits. Our solutions are optimized for the efficient, singulated flow of cartons, polybags, totes and pallets and are tailored to meet the specific demands of your business.

- Automate repetitive movements to increase reliability and efficiency

- Protect products and reduce loss with intelligent product movement

- Reduce manual labor by minimizing walking and carrying

- Support and enhance automation with seamless system integration

Conveyance technologies for more efficient product transport

Our conveyance technologies are versatile, and designed to handle a variety of product sizes, weights and shapes to help you increase productivity and maximize efficiency in your distribution process.

- Vertical conveyor

- Belt conveyor

- Accumulation conveyor

- Empty corrugate conveyor

- Pallet conveyor

- Spiral inclines/declines

- Case and package conveyor

- MDR (motor-driven roller) conveyor

- Flexible conveyor

- Telescoping conveyor

- Plastic belt conveyor

Goods-to-Person (GTP)

Goods-to-person automation technology for increased productivity

High-volume e-Commerce fulfillment operations need high-density storage and retrieval systems for the best use of space and increased speed, accuracy and efficiency. Advances in goods-to-person automation coupled with the streamlining of operational requirements have advanced micro-fulfillment capabilities.

High capacity. High throughput. High performance.

Goods-to-person solutions are ideal for increasing operational performance without increasing your building footprint. Inventory accuracy and reduced shrinkage make these the ideal solution for high-value inventory. The optimized flow of material and just-in-time replenishment eliminates unnecessary inventory, reducing your total cost. Today’s solutions also work well in chilled or freezer environments and are ideal for a variety of industry segments and applications, such as e-Commerce and omnichannel facilities and parts management.

Picking

Automated warehouse picking technologies

The shift to a higher volume of e-Commerce orders is driving the need for responsive operations that are built to reduce labor while increasing accuracy and high throughput. Combining the proprietary algorithms of FORTNA WES™ with several key order picking and packing technologies make it possible for high volume operations to meet growing demand with greater efficiency.

FORTNA works with leading equipment manufacturers to design flexible, scalable and reliable operations that meet your business requirements.

Responsive. Fast. Accurate.

FORTNA will help integrate with your existing systems and/or help you leverage newer automation technologies for an operation that is responsive to fluctuations in demand.

- Autobag/Polybag

- Pick-to-Light

- RF handheld scanners and mobile devices

- Carton-erector

- Print and Apply

- Smart Cart

- Mobile Cart

- Put-to-Light

- Voice-directed

Robotics

Flexible, scalable, modular robotic order fulfillment systems

Labor cost, availability and safety are challenging for even the most efficient operations. Robotic solutions deliver the speed, accuracy and efficiency to fulfill a broad range of operational requirements for distribution centers. FORTNA experts will partner with your business to engineer flexible, scalable and modular solutions that meet your unique business needs.

FORTNA Robotics combines the cutting-edge technology and agility of a startup with the industry and application knowledge of an experienced integrator. This approach delivers cutting-edge robotics that fit established material handling processes and work seamlessly as part of large, integrated systems.

FORTNA’s commitment to research and development works to apply the latest advances in vision, sensing and gripping technologies to expand the capability of automation to handle increasingly complex tasks. From singulating items in preparation for sorter induction to unloading at the receiving dock and more, FORTNA provides innovative robotics ready to address challenges facing your business.

Technologies

- Robotic singulation and induction (RSAI): Identify, pick and place individual items from bulk flow, to produce a properly oriented, single-file stream of packages for downstream automated sortation systems.

- Dual robot each picking from totes: Take advantage of two six-axis robots working in tandem with a variety of end effectors to maximize picking efficiency and boost output in a variety of order fulfillment applications.

- Multi-pick robotic end effector: Pick over 30 items at a time and fill several orders simultaneously, a strong fit for applications with large amounts of multi-item orders to fulfill.

Innovative. Efficient. Robust.

The optimal robotic technologies are incorporated into innovative designs for a robust solution that meets and exceeds performance expectations. FORTNA robotic solutions increase productivity and efficiency while lowering overall costs.

Popular applications include each picking and e-Commerce packing. Robotic picking arms, sophisticated end-of-arm effectors, advanced vision systems, sensors and automatic shut off all work together to handle a wide variety of SKUs and ensure safe collaboration with human workers.

Software

Intelligent automated warehouse software for complex distribution challenges

Intelligent software is essential to optimizing operations for maximum efficiency, reliability and flexibility. FORTNA WES™ is the leading warehouse execution system in the market. With an equipment and supplier agnostic approach to software, FORTNA designs and implements innovative and high-performance solutions for clients to power their operations with fast and accurate order fulfillment.

Warehouse automation software to power optimal performance

In addition to our FORTNA WES™ offering, our unique design approach allows us to identify and select additional technologies that uniquely meet your business requirements. The result is a comprehensive, flexible solution that delivers the promised business results.

By Industry

Our robust experience enables us to develop solutions for those unique industry challenges and cross-pollinate best-in-class strategies and solutions.

Aftermarket Parts

Distribution solutions for aftermarket parts

Rapid digitization requires supply chain efficiency

Parts suppliers must balance distribution costs and resources to manage high inventory levels and a rapid shift to e-Commerce order fulfillment with more expensive single-unit shipments. Some of the industry’s biggest challenges include:

- e–Commerce order fulfillment speed and accuracy

- SKU proliferation fueled by advancing technologies

- Slow moving parts inventory for older vehicles

- Increased competition for price-sensitive customers

- Global product sourcing and supply chain

FORTNA applies a data science approach with an operator’s perspective to ensure innovative design and optimal material and information flow supported by a justifiable business case.

- Data-Driven: Scientifically proven proprietary modeling tools and algorithms allow FORTNA to design for maximum efficiency and outcomes.

- Holistic Approach: FORTNA designs solutions with a holistic perspective, considering upstream/downstream impacts on the entire operation and network.

- Best-fit Technology: At FORTNA, we identify and select appropriate and best-fit technologies to optimize the solution.

Consumer Packaged Goods

Shift to omnichannel distribution demands an evolution in supply chain

Consumer Goods companies must rethink their supply chain strategies and operations to remain competitive and rapidly respond to changing customer demands. Some of the industry’s biggest challenges include:

- Changing order profiles from wholesale to direct to consumer model

- Rapidly changing retailer expectations for more frequent orders

- SKU proliferation due to consumer demand for product variety

- Intense price competition

- Globalized supply chain

- Creating a green, sustainable supply chain

Electronics

Ever-changing product lifecycle requires supply chain efficiency

Electronics distributors are experiencing a shift in customer demand for unprecedented order fulfillment responsiveness and speed. Some of the industry’s biggest challenges include:

- Globalized manufacturing

- Changes in order sizes and complexity

- SKU proliferation

- High inventory levels to store older products

- Tariff-sensitive and long-distance supply chain

- High return rate

Food and Beverage

Changing consumer behaviors driving demand for agility and new fulfillment models

The food and beverage industry continues to undergo fundamental shifts in operations. Enabling e-Commerce and the handling of pieces, cases, layers and pallets while adapting to spikes in demand are key challenges for food and beverage distributors. Additional challenges include:

- Shift to digital, resulting in new fulfillment models

- Each, case, less than full and mixed case pallet picking

- Changing consumer tastes, driving SKU proliferation

- Safety and product tracking regulations

- Multi-temperature environments

- Inventory replenishment of essential items

- Labor challenges driving up costs, limiting availability and requiring additional measures to keep workers safe

Grocery

Changing consumer behaviors driving demand for agility and speed

The grocery industry has undergone a fundamental shift. Enabling omnichannel capabilities, including curbside pick-up and home delivery, and micro-fulfillment strategies are critical as grocers navigate challenges that include:

- Shift to digital, resulting in new fulfillment models

- Fulfillment speed and accuracy expectations set by Amazon and other major online retailers

- Multi-temperature environments to prevent spoilage

- Complexity of handling fresh products

- Inventory replenishment of essential items

- Labor challenges driving up costs, limiting availability and requiring additional measures to keep workers safe

Industrial Distribution

Digital order fulfillment requires distribution speed and accuracy

Industrial product companies are challenged to meet their customers’ demands for a wide variety of SKUs to be delivered when and where they are urgently needed. Some of the industry’s biggest challenges include:

- Demand for same-day or next-day order delivery

- Increased competition for price-sensitive customers

- High SKU count with many slower moving products in inventory

- High return rate

- Creating a green, sustainable supply chain

Life Sciences

Market regulations and customer demands are driving new business requirements for healthcare, medical device, pharmaceutical and life sciences distributors. Faced with the complexity of controlled inventory and multi-temperature storage, companies must also navigate increasing labor challenges that make it difficult to meet service and cost expectations predictably. FORTNA can help improve efficiency so leaders can meet performance goals with existing human and capital resources.

New challenges add complexity for life science distributors

In a complex distribution landscape, healthcare, hospital, pharmaceutical, medical supply and medical device distributors must navigate challenges that include:

- Limited labor availability, rising costs, high turnover, increasing absenteeism and additional measures required to keep workers safe

- New challengers, putting pressure on costs and service expectations and driving the need to enable and enhance omnichannel capabilities

- Rigorous product safety and regulations, including track and trace requirements from the Drug Supply Chain Security Act (DSCSA) and Falsified Medicines Directive (FMD)

- Multi-temperature storage environments and cold chain/temperature-controlled transportation

- Global mergers, acquisitions and market consolidation that continues to blur lines between sectors

Parcel

At FORTNA, our team of parcel experts boasts extensive industry experience and specialized expertise in managing projects of varying sizes and throughput requirements. Our tailored solutions cater to the needs of a diverse clientele ranging from regional service providers to large-scale global logistics corporations.

Move more packages to more places, faster than ever

With FORTNA’s cutting-edge designs, parcel handling systems can move seamlessly and reliably through sorters, scales and scanners, meeting the demands of even the most challenging workflows. We provide ongoing Lifecycle Performance Services to ensure maximum system longevity and sustained high performance, even during critical peak periods.

We offer state-of-the-art technology and innovative strategies to customize automated systems with the necessary equipment, software and workflows to optimize site-specific requirements. Our parcel handling solutions have been meticulously designed to ensure optimal operational efficiency for a wide range of packaging materials including polybags, corrugated boxes and soft pack mailers.

Retail and Apparel

Shift to digital drives demand for enhanced omnichannel capabilities

Retail has experienced unprecedented disruption in the last few years. Omnichannel capabilities, including ship from store, micro-fulfillment and dark stores, are front and center as retailers and general merchandisers navigate challenges that include:

- Shift to digital, resulting in new order profiles and complexity

- Customer expectations for a seamless experience across channels

- Faster order-to-delivery cycle times and enabling click and collect capabilities

- Endless aisle selection driving SKU proliferation

- Growing number of returns, driven by e-Commerce growth

- Efficient inventory deployment to anticipate and meet seasonal demand

- Labor challenges driving up costs, limiting availability and requiring additional measures to keep workers safe

Third Party Logistics

Unprecedented growth in e-Commerce demands agility and responsiveness

Third party logistics providers are facing seismic growth in e-Commerce order fulfillment from customers who demand access to higher inventory levels, additional services and same-day or next-day delivery. Some of the industry’s biggest challenges include:

- Global competition: finding new and retaining existing customers

- On-going disruption driving the need for contingency planning and risk management strategies

- Extended value-added services such as kitting, reverse logistics and transportation consulting

- Fluctuating inventory levels and seasonal demand

- Integrating labor-saving picking technologies

- High cost of labor, shortages and reliability issues