- Offer Profile

-

Leading the Mobile Robotics era

Over 35 years of experience in delivering technological solutionsASTI Mobile Robotics, transforming the future together, is an international group of mobile robotics companies. Its engineering team analyses, designs, manufactures, deploys and maintains AGV-based intralogistics systems used to move materials and products from one location to another within plants.

Offering the market’s widest range of automated guided vehicles (AGVs), ASTI Mobile Robotics Group has been awarded Europe's leading mobile robotics manufacturer for the fourth consecutive year. The company is an expert in industrial connectivity and mobile robotics data analytics.

Mouse line

-

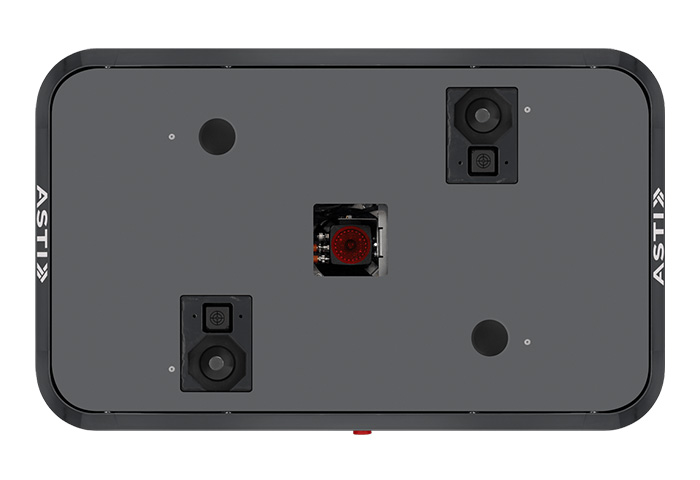

New cutting-edge generation

The Mouse range is the perfect automation solution. Validated rigorously for performance and safety, they are the 24/7 workhorses of intralogistics towing applications. Now our range offers a new generation that incorporates enhanced functional features, keeping the essence of our well known Mouse robots: more compact, agile and connected. Mouse line

-

Featured by its easiness and proven performance, our AGVs enable easier optimal performance which leads to high productivity and lower operating costs in your intralogistics operations.

Our Mouse robots provide an easy to install, easy to operate and easy to maintain solution. Our new evolution 2.0 also integrates the latest navigation technologies, faster charging systems and increased load capacity offering further functions.

PARAMETERS- Towing capacity: 350N - 2000N

- Dimensions (LxWxH): 1700 x 520 x 385 - 2104 x 500 x 230

- Movement: Unidirectional/Bidirectional

- Speed range mm/sec: From 35 to 2000

- Navigation: Magnetic/SLAM

- Battery: Gel/Lithium

- Charging system: Online charging / Manual battery interchange

Application- Assembly & subassembly

Flexible production lines to facilitate the addition and removal of stations and smooth adaptation to changes. - Kitting

Preparation of kits of related items that are supplied to the production line at the same time. They speed up manufacturing or picking processes. - Robot cells

Bidirectional communication with robot cells for safe operations and precise transport. Collaborative solution for production processes.

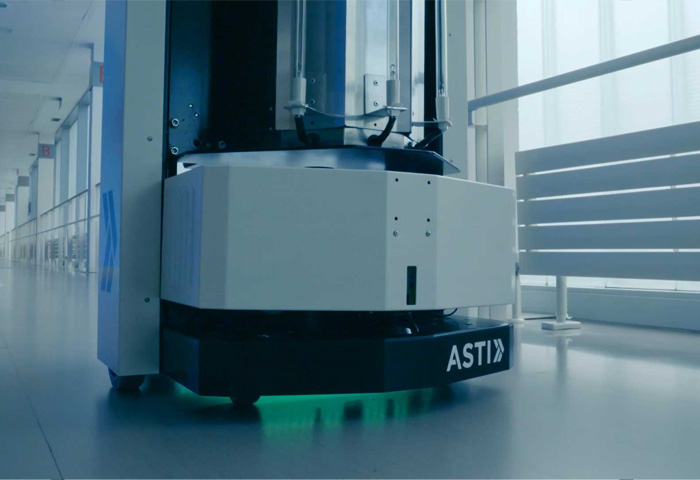

Tractor line

High performance

With minimum dimensions, large capacity and great manoeuvrability, our Tractor range is a strong, easy, safe and flexible solution for logistics trains over long distances both in indoor and outdoor environments.Tractor line

-

Known for their robustness and strength, our AGVs are able to transport several trolleys at the same time, which leads to high productivity and lower operating costs in your intralogistics operations.

These robots offer a user-friendly, easy to install and low maintenance solution. Equipped with the latest technologies such as SLAM navigation and 4G communication, they can integrate different functions according to the customized needs of your intralogistics.

PARAMETERS- Towing capacity: Up to 10 TN

- Dimensions (LxWxH): 1221 x 695 x 762 - 1424 x 980 x 880

- Environment: Indoor / Outdoor

- Speed range mm/sec: From 35 to 2000

- Navigation: Magnetic/SLAM

- Battery: Lead acid / Lithium / Gel

- Charging system: Online charging / Manual battery interchange

Application- Milk run

Logistic trains that transport several loads at the same time over long distances. Our Tractor AGVs are able to overcome slopes. - Horizontal

transport

Transport of loads with precise, automatic and safe loading and unloading of the good by means of conveyors - Outdoor

Safe delivery of goods between buildings. They work outdoor, coexisting with cars and trucks if necessary

Platform line

Platform line <1000 kg

Fast and efficient

Excellent manoeuvrability, thanks to its compact design and omnidirectional and turn on spot technology, our Platform line for up to 1000 kg can perform longitudinal and transversal movements, enabling greater agility and efficiency in your intralogistics goods movements.

This innovative range of robots is designed to meet your business needs in operational flexibility, responsiveness, peak demands, productivity and safety, delivering racks, carriers, boxes or hanging garments in confined spaces and narrow aisles.

With smart navigation technology combined with software intelligence, this ASTI AGVs range can perform multi-origin and multi-destination operations to meet the high demand of your logistics processes.

PARAMETERS- Payload: 350/600 kg

- Dimensions (LxWxH): 1052 x 660 x 352 / 1202 x 780 x 352

- Lifting table: 120 mm stroke

- Movement: Multidirectional

- Speed range mm/sec: From 50 to 2000

- Navigation: QR Codes / SLAM

- Battery: Lithium

- Charging system: Online charging

Application- Picking & Putaway

Rack delivery from the storage area to the picking stations where the operator performs the picking (picks products that will be part of the orders) or put away (fills racks with multi SKU). - Kitting

Kit preparation of related items that are supplied at the same time. They speed up manufacturing or picking processes. - Multi SKU management

Total control of a huge number of different SKUs in real time, allowing full traceability of goods in every stage: from storage to shipment.

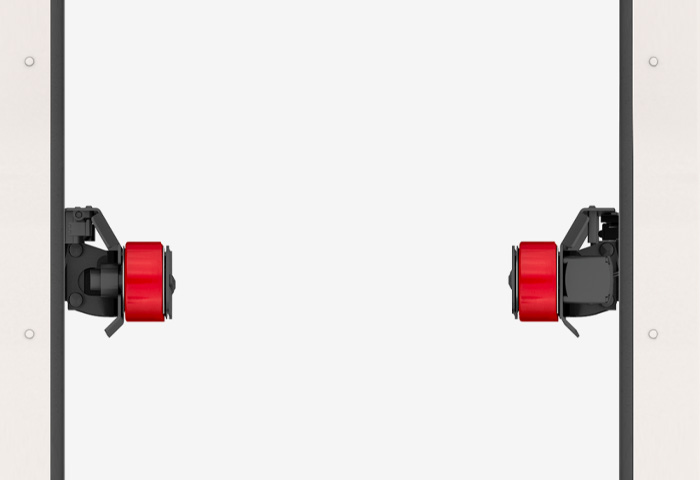

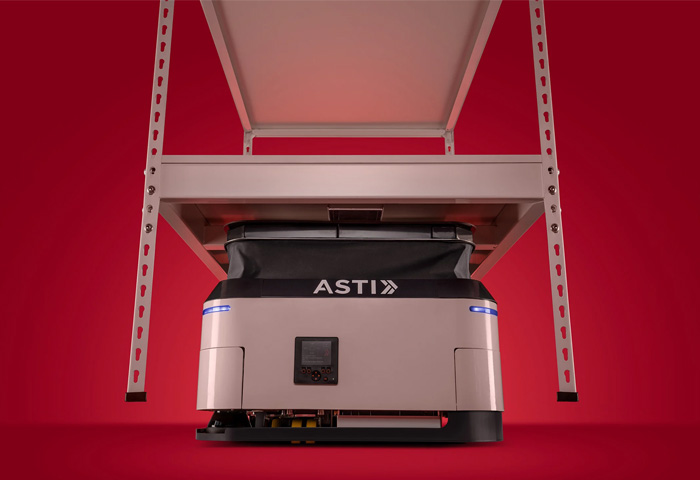

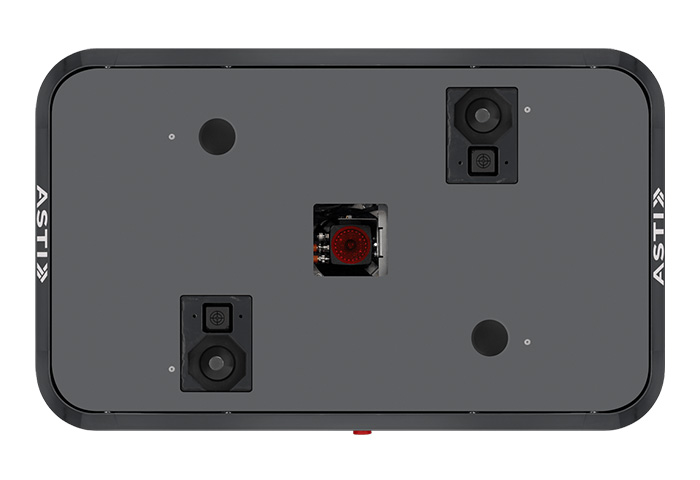

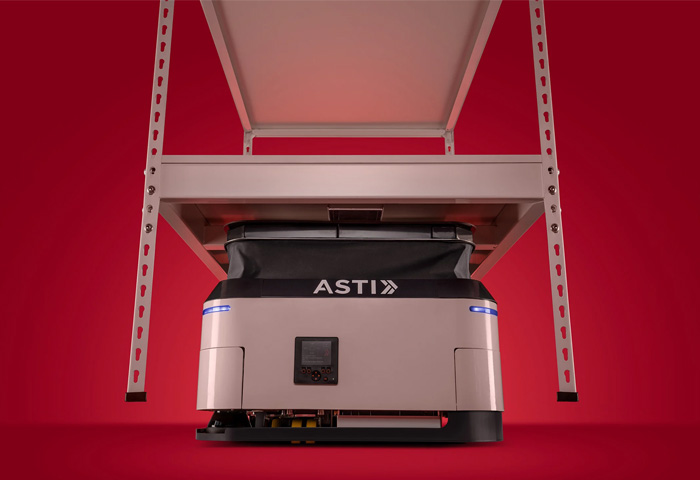

Platform line >1000 kg

-

Flexible and modular

Adaptable to any industrial sector, our Platform range for more than 1000 kg combines omnidirectional move capabilities with very low height profile and high payload, which provides multipurpose application possibilities in all internal logistics.

Equipped with the latest ASTI technologies, this model is easily configurable based on customer needs. It can integrate different handling systems, such as a conveyor or a lift table.

Optimize your intralogistics and manufacturing flows with our smart and reliable platform AGV. Safe interactions with operators and connected elements of the plant for a collaborative working environment.

PARAMETERS- Payload: Up to 2 TN

- Dimensions (LxWxH): 2200 x 850 x 300 / 1850 x 1065 x 300

- Handling system: Lift table (200 mm stroke) / Conveyor (roller or chain conveyor) (optional)

- Movement: Multidirectional

- Speed range mm/sec: From 35 to 2000

- Navigation: Magnetic / QR Codes / SLAM / Hybrid

- Battery: Lead Crystal / Lithium

- Charging system: External charger / Online charging system / Inductive charging system

Application- Assembly & subassembly

Flexible production lines to facilitate the addition and removal of stations and smooth adaptation to changes. - Robot cells

Bidirectional communication with robot cells for safe operations and precise transport. Collaborative solution for production processes. - Line

operations

Drop off & pick up on conveyor of raw materials, finished products and WIP products. Also empty pallet feeding and interfacing with wrappers, labellers, palletizers and automated warehouses.

Forklift line

Reliable and efficient

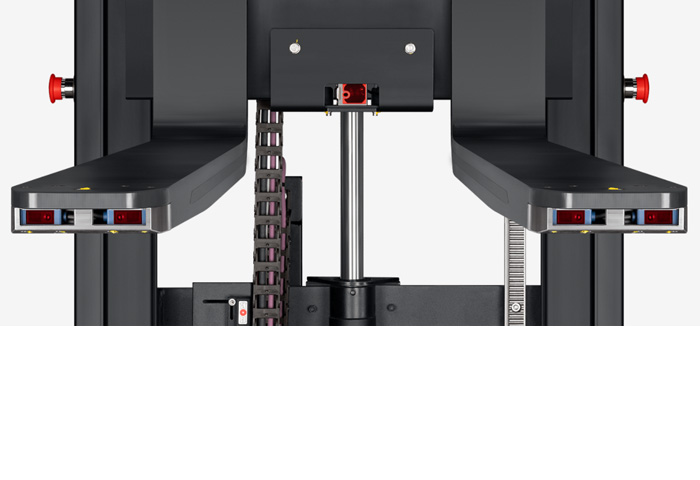

High quality mobile robots to improve your productivity and competitiveness. Characterised by its versatility and scalability, our Forklift range provides powerful performance in palletised loads handling. Robust and compact solution for an agile transport and unlimited combinations of loads and applications.Forklift line

-

Increase your storage efficiency and reduce costs and risks. Its counterbalanced or stacker mechanics make this multifunctional range of vehicles a powerful solution to transport pallets and containers with great stability.

Forklift AGVs for industrial environments guarantee an automatic, safe and flexible solution, coexisting with humans and manual trucks if necessary. Our new evolution CB 2.0 also integrates better turning radius and higher load capacity and lifting height, offering further functions.

PARAMETERS- Mechanical design: Stacker / Counterbalanced

- Dimensions (LxWxH): 2236 x 1041 x 2326 / 2863 x 1150 x 2840

- Service weight capacity(kg): 1200 - 2000

- Standard lifting height(mm): Multidirectional

- Navigation: Magnetic / QR Codes / SLAM / Hybrid

- Battery: Lead Crystal / Lithium

- Charging system: External charger / Online charging system / Inductive charging system

Application- Reception & Shipment

Load handling from reception bays to storage areas and vice versa, from the warehouse to the shipping bays in ground level lines. Additional operations can include scanning barcodes and weighing the load. - Line

operations

Drop off & pick up on conveyor or at ground level of raw materials, finished products and WIP products. Also empty pallet feeding and interfacing with wrappers, labellers, palletizers. - Vertical operations

Pick up and drop off from racks, automatic warehouses, stacking and destacking of pallets and block storage.

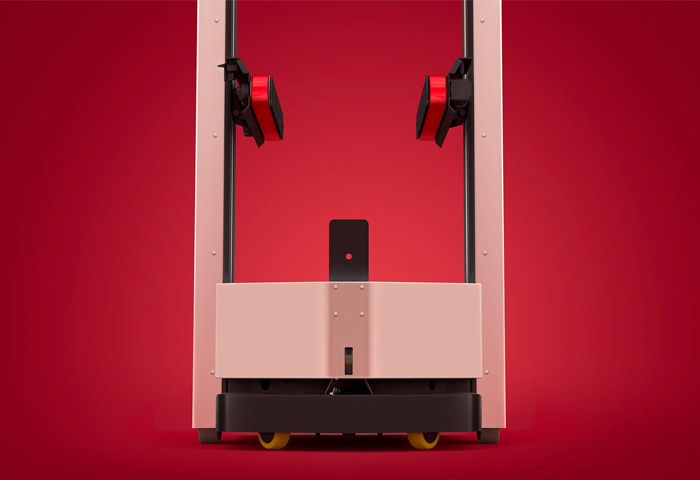

Boxmover line

Advanced technology for light loads

Optimize workplace, workflows, and cost with our proANT AGVs for a high quality and reliable automation solution. Unlike traditional AGVs, proANT uses cutting edge technologies and advanced SLAM navigation that allows total flexibility, dynamic planning, quick installation and safe interaction with operators and changing environments.Boxmover line

-

Our proANTs can be configured with different handling systems to facilitate the integration in your existing transfer stations without the need for any changes to the infrastructure, fences or special routes to operate.

proANT keeps track of your process flow and optimization in real time using advanced smart connectivity and remote data traceability to simplify information analysis, predict maintenance and enhance rapid decision making.

PARAMETERS- Payload: 50 - 200 kg

- Dimensions (LxWxH): 740 x 662 x 1550 / 1020 x 940 x 1943

- Movement: Unidirectional

- Speed range mm/sec: From 300 to 1200

- Environment: Indoor

- Transfer height: Customized fixed height

- Navigation: SLAM (Natural navigation/Free navigation)

- Battery: Lithium-ion

- Charging system: Online charging

Application- Picking & Putaway

Rack delivery from the storage area to the picking stations where the operator performs the picking (picks products that will be part of the orders) or put away (fills racks with multi SKU). - Kitting

Kit preparation of related items that are supplied at the same time. They speed up manufacturing or picking processes. - Multi SKU management

Total control of a huge number of different SKUs in real time, allowing full traceability of goods in every stage: from storage to shipment.

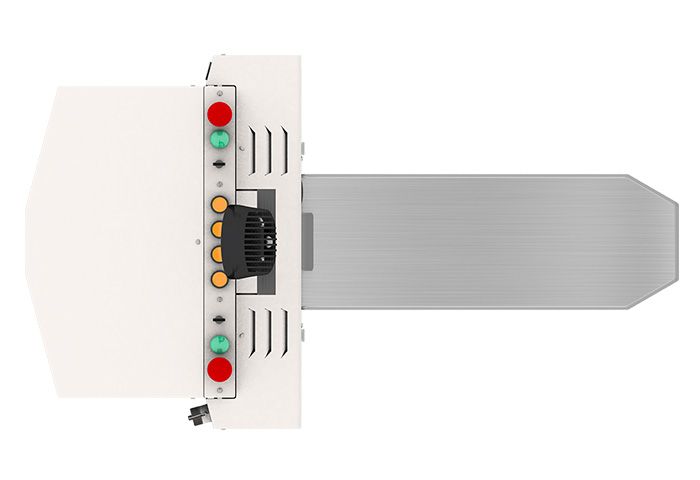

Disinfection line

ZENZOE Robot: Most competitive and efficient disinfection solution

ZENZOE Robot, with German-Spanish technology, disinfects based on well-proven Ultraviolet Germicidal Irradiation (UVGI) principle and can deactivate most of the germs including SARS-COV-19 up to 99,99% disinfection efficiency.ZENZOE ROBOT

-

ENZOE family: Efficient COVID-19 removal in the shortest possible time

This disinfection solutions are based on German-Spanish technology, whose wavelengths and UV-C intensity are the most appropriate to provide efficient COVID-19 removal in the shortest possible time. Ultraviolet radiation, far from other chemical products such as ozone, is not only an environmentally friendly solution, but it is also non-toxic, so there is no waiting time for the disinfected facility to be used again. The ZENZOE family of products has three manual versions (ZENZOE Easy, Pro, Plus) and a robotic version (ZENZOE Robot).

PARAMETERS- Configuration:4 UV-C Lamps

- UV-C at 100h (W): 192

- Dimension (LxWxH): 740 x 662 x 1.970 mm

- Working Voltage: 24V (dc)

- Environment: Indoor application

- Safety: Emergency stop, safety sensors

- Speed:1,2 m / sec

- Battery charging time: 60 minutes

- Disinfection time: 6-8 minutes / 25 m² room

- Autonomy: 2,5 ~ 2,7 hours

- Navigation: SLAM / Free navigation

- Connectivity: 4G or WiFi

Application- Healthcare

- Industrial

- Commercial

Industries

Our experience, technology and know-how at the service of your industry

Automotive

- The complete solution for OEMs & Tier 1 to make the most of their competitiveness.

Ecommerce & Retail

- Overcome the industry challenges with AGV systems suitable for multi-SKU management.

Food & Beverage

- Connect your intralogistics operations from production to shipment improving your quality control.

Pharma & Beauty

- Industry 4.0 applied to pharmaceutical industry needs in compliance with standards.

Manufacturing

- Agile and dynamic transports to gain productivity and quality in your processes.

Metals & Machinery

- Damage free loads and optimal use of space with our AGVs systems for intensive use.

Logistics

- Highly integrated systems that exceed your expectations for material handling.

Aerospace

- Wide variety of proposals that ensures full control of your goods, quality and safety.

More industries

- Gain your competitive edge and operational efficiency.

Industries

INDUSTRY 4.0

-

ASTI Mobile Robotics is an expert in industrial processes, connectivity and customer support

We supply one of the enabling technologies of Industry 4.0 by designing, manufacturing, install and maintaining connected products. We offer services of connectivity and integration with users, predictive maintenance and performance analysis, with more knowledge of plant performance, making multi-site comparisons, analysing applications based on shifts... Our mobile robots are not only the company's system, transporting goods from one place to another, but at the same time they are your nervous system because they transmit information. They collect data and move it. With all the information they generate, in what we call the 'Facebook of machines or our Cloud', we can extract a lot of value. All our mobile robots have an on-board PC, a lot of sensors, and it's like a walking loT chip, which is constantly collecting information.

SAFETY SYSTEMS

-

At ASTI Mobile Robotics, people come first

Automated guided vehicles are collaborative robots that move safely within industrial means, coexisting with humans and manual trucks. At ASTI Mobile Robotics, people come first, therefore we ensure that all our products meet with the most strictest safety regulations.

NAVIGATION SYSTEM

-

Precise, reliable and flexible navigation systems

Our different technologies can be used for vehicle location and navigation throughout the facilites layout.

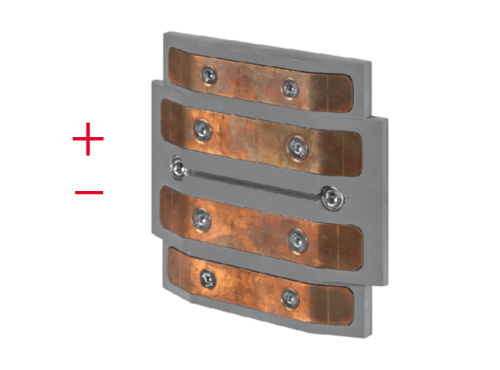

BATTERY AND CHARGING SYSTEMS

-

Our full range of energy systems

Provides an efficient charging strategy and powerful batteries to ensure the autonomy our AGVs need to operate.

COMMUNICATION SYSTEMS

-

Making the AGVs dance at the pace of your facilities through our IT system

ASTI Mobile Robotics is an expert in industrial connectivity. Our systems allow us to connect our vehicle fleets with the rest of our clients systems, production lines, terminals and management systems. The IT system is divided into different modules which are responsible for performing all orders , regulate the priority of the AGVs movements and manage bidirectional communication with all plant elements and customer management systems.

CONNECTED SYSTEMS

-

Discover our ASTI Connected Services

Connectivity can take your factory to another level, optimising operations and processes and facilitating decision making. Through real-time communication and by monitoring every vehicle of each unit or system, within the value chain. Real-time alerts, monitoring and diagnosis, remote software updates and customisable dashboards.