- Offer Profile

-

ATIS Srl. designs and manufactures pneumatic industrial manipulators of reputable and safe mechanical engineering characteristics.

The complete range of ATIS pneumatic manipulators, deployable in every production section of diversified industries, are designed and manufactured to meet customers’ specific requirements and enhance the values of resources at customers’ disposal.

R&D team at our design and engineering department is incessantly working on new ideas and solutions, and thanks to new materials and state of the art technologies we can meet the most stringent requests of the handling applications.

ATIS manipulators special features are:

- Easy maneuverability of loads

- Maximum Precision

- Total safety

- Productivity growth

- Avoidance of damage to products

- Bespoke solutions

ATISMIRUS

-

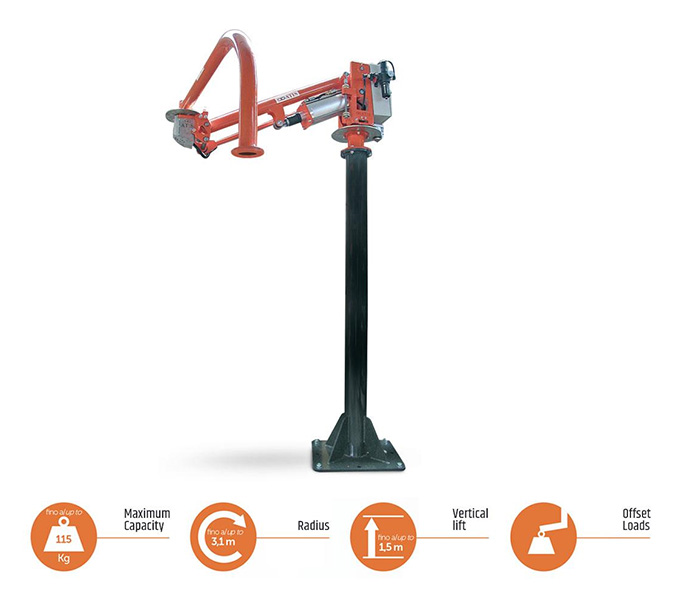

ATISMIRUS – an articulated rigid arms pneumatic manipulator with parallelogram for vertical movements, designed for maximum precision in load handling. It is most suitable for handling offset loads in every direction without hindrance, but with ease and precision.

It could be fitted with tailored gripping tools, designed to meet the customer's specific requirements. The customized tools come with either manual or pneumatically powered movements that allows execution of load handling cycles.

ATISMIRUS series is appropriately defined to meet clients requirements, suit the chosen tooling head and render load handling easy for operators to carry out.

From the onset, we paid attention to the workers' needs; our engineering team made load handling easier and operator-friendly features of the system became the priority. Technical specifications of the product to handle are fundamental elements that are taken into account by our engineering personnel.

ATISMIRUS pneumatic industrial manipulators with parallelogram are available in different configurations such as:

- Fix to floor base-plate column mounted

- Auto-stable base plate column mounted

- Fixed overhead

- Overhead trolley mounted on tracks

ATISMIRUS pneumatic industrial manipulators do not require an electrical power supply, but only 5-7 bar (73 to 116 psi) of compressed air. This implies that installation time very short and setting-up of the working area is simple and easy.

ATISMIRUS 80

-

ATISMIRUS 80, pneumatic manipulator, the smallest one of the rigid arms category.

Pneumatic manipulator with swivel rigid arms, the smallest of its category. Developed for handling light products even special-shaped, is ideal for sustained workloads.

Lightness, precision and agility are the main features of this manipulator. It can be configured with custom-made gripping tools, designed and studied according to specific customer's needs: pneumatic grabs, suction cups, special hooks and many more.

- swivel rigid arms

- handling light products

- lightness

- precision

- speed

- completed with customized equipment

ATISMIRUS 100

-

ATISMIRUS 100 configuration overhead or column.

Pneumatic rigid arm manipulator with swivel arms, the right compromise between capacity and agility. The right choice for handling medium weights and gives its best adapting to many common working situations.

Thanks to the completion with a specific gripping tool it gives the opportunity to handle even offset products in any direction without big effort.

- swivel rigid arms

- movement of rather heavy loads

- handling top-heavy products

ATISMIRUS 200

-

Pneumatic manipulator with swivel-rigid arms, it has a higher capacity than the ATISMIRUS 100. Developed with the same technical and structural features, is equipped with an additional pneumatic cylinder to obtain higher power and bigger audiences.

This manipulator can also be set up with a customized gripping tool to meet the customer's needs.

- swivel rigid arms

- equipped with additional pneumatic cylinder

- completed with custom gripping system

ATISMIRUS 300

-

This pneumatic manipulator with articulated rigid arms is the perfect solution for heavier weights. It's developed for increased performances and capacities, but at the same time, it guarantees the highest accuracy and ergonomics, even in the most challenging conditions.

Reliability and safety with bulky and heavy loads make this model the right choice for heavy industry, while our technical experience completes it with customized gripping tools to comply with customer's requirements.

- swivel rigid arms

- solution for higher loads

- precision and ergonomics

- reliability

- safety

ATISMIRUS 500

-

This pneumatic rigid arm manipulator with swivel arms is the evolution of the previous model with higher capacity. An enhanced cylinder and improved technical and structural features allow to handle heavier loads and to achieve longer radiuses.

There are lots of customization choices with gripping tools developed according to customer's requests, and the higher capacity allows even more personalizations' options.

- swivel rigid arms

- studied for maximum loads

- precision and ergonomics

- reliability

- safety

ATISACER

-

ATISACER – A series of pneumatic manipulators with steel cable actionable by pneumatic power.

They can be equipped with customised gripping tools, designed to meet the specific customer needs. The bespoke gripping tools come with either manual or pneumatically powered movements that allows execution of load handling work cycle.

They are designed taking into account load capacity, working radius and suitable gripping tool, to ensure an easy load handling for the operator.

Each gripping tool is unique and represents the company’s philosophy of adaptation to customer’s requests.

ATISACER pneumatic industrial manipulators are available in different configurations such as:

- Fix to floor base-plate column mounted

- Auto-stable base plate column mounted

- Fixed overhead

- Overhead trolley mounted on tracks

ATISACER pneumatic industrial manipulator runs on compressed air of 5-7 bar (73-116 psi).

ATISACER 55

-

ATISACER 55 - standard hook tooling

Like all ATISACER manipulators, ATISACER 55 is equipped with a double wire rope transmission system combined with a pneumatic cylinder.

ATISACER 55 is the smallest of the family, light and easy to handle for loads up to 50 kg (110 lbs); it allows to handle many kinds of products safely and easy, thanks to the special gripping tools that can be integrated.

To guarantee most safety, ATISACER 55 works with double rope and comes with load and no-load balancing system. The operator acts directly on the product or the tool, with high precision and without effort.

If needed, ATISACER 55 can be equipped with a "sensitive" handle, which allows operating on variable weight products just acting on it.

This manipulator can also be installed on a column, both fixed on the floor and transportable self-standing base, or overhead fixed or on rails.

- rope guided vertical stroke

- appropriately sized according to the load

- each machine is unique

ATISACER 80

-

ATISACER manipulators, provided with rope vertical movement, allow handling of loads in any direction without ties, easily and accurate.

ATISACER 80 is the newest member of the ATISACER family, provided with a double rope system and a pneumatic cylinder. It completes the range of ATIS' rope system manipulators.

The manipulators pneumatic system allows balanced movements, both with and without load. Integrated with standard hooks or with special gripping tools ATISACER gives its best in small and constricted working areas.

The manipulator is provided with certified accumulation tank to allow the operator to carry out the handling process in case the main air supply fails. It's furthermore provided with double safety ropes. It mounts double braking pads on the main axle and the medium joint as well.

ATISACER 80 turns out to be very easy to handle, lightweight and quick-moving.

- swivel arms

- double rope guided vertical stroke

- appropriately sized according to the load

ATISACER 150

-

ATISACER manipulators, provided with rope vertical movement, allow handling of loads in any direction without ties, easily and accurate.

ATISACER 150 is the biggest of the ATISACER family, provided with a rope system and pneumatic cylinder. The manipulators pneumatic system allows balanced movements, both with and without load. Integrated with standard hooks or with special gripping tools, ATISACER gives its best in small and constricted working areas.

The manipulator is provided with certified accumulation tank to allow the operator to carry out the handling process in case the main air supply fails. It's furthermore provided with double safety ropes. It mounts double braking pads on the main axle and medium joint as well.

ATISACER 150 turns out very easy to handle, lightweight and quick-moving.

- swivel arms

- double rope guided vertical stroke

- appropriately sized according to the load

More products

ATISLINEAR

-

ATISLINEAR manipulators are able to handle load s in both vertical and horizontal orientations, thanks to the forceful vertical movement and attachment, with the aid of steel plate flange, to trolley mounted on overhead tracks.

ATISLINEAR manipulators are compact and ideal for applications in all restricted working areas.

Thorough study and analysis of manipulator, during design stage, coupled with our design engineers years of experience brought about this exceptionally sensitive manipulator capable of formidable efficiency in any onerous condition.

ATISLINEAR manipulators can be supplied with bespoke gripping tool, designed to meet the customer's specific requirements. The bespoke gripping tool comes with either manual or pneumatically powered movements that allows execution of load handling cycle.

- rigid vertical movement

- attach to the trolley on tracks through connecting flange

- compact manipulator

ATISFERAX

-

ATISFERAX – lever-actionable manipulators with vertical movement and the ability to handle loads extremely well and precisely in any direction.

These are extraordinarily lightweight manipulators, with minimum resistance to change of movements, undoubtedly optimise the most extreme cycle time requirement and notably reduce the stresses on operators.

ATISFERAX is a unique manipulator of its kind, one of many INNOVATIONS by ATIS in this area:

- as a result of our experience

- as a result of the desire to always propose the best solutions to our customers

- as a result of continuous R&D

ATISFERAX manipulators can be equipped with tailored gripping tools, designed to meet specific requirements. The bespoke gripping component comes with either manual or pneumatically powered movements that allow the execution of load handling cycle.

ATISFERAX manipulators are available in different configurations such as:

- lever actionable vertical movement

- extraordinary lightweight manipulators

- reduced resistance to change of movements

Solutions

Bottles

Containers

Food industry

Household appliances

Packaging

Radiators

Rolls

Sanitary

Window frames

Gripping Systems

Hook tooling

The hook gripping system can simply be our standard hook, and it is often, but not only, fitted on our ATISacer balanced rope manipulators. The shaped hook tool is a simple and essential gripping system that adapts well when handling various types of products, from cans or drums of paint, to packs of cardboard and much more. Our technical department will develop the required shape of the gripper in order to handle the product in complete safety and with maximum ease. The integration of the pneumatic hook balancer in the production cycle will be fast and the ATIS manipulator will become an irreplaceable ally for the operator in carrying out his job.

Suction Tooling

The suction tooling adopted and integrated into ATIS pneumatic manipulators has multiple applications in different sectors of various industries. These pneumatic toolings are capable of lifting and moving many and diversified products such as sheet metal, boxes, glass sheets, bottles and more. Suction tooling could be designed in many ways. It can be tooling with a single suction cup or multiple suction cups because the choice is dictated by the size, weight and shape of the product to handle. The suction tooling frames are designed considering the customer's request. The suction retainers on the frame can be fixed or adjustable to cover various shapes and dimensions of the product to handle. Certain feature such as inclination and rotation, for flipping product upside down, can be integrated into the tooling. The rotation and inclination capability could be either manual or pneumatic, while a continuous 360º rotation is also attainable with our suction tooling. All gripping tools integrated to our pneumatic manipulators are thoroughly analysed, designed and equipped with the best safety systems available on today's market.

Magnet tooling

-

The magnets, either manual or pneumatic, also known as integrated magnets, can be integrated into all ATIS pneumatic manipulators:

- ATISmirus series, the articulated rigid arms manipulators with parallelograms.

- ATISacer series, the articulated rigid arms manipulators with double wire cables.

- ATISlinear series, the vertical sliding manipulators and compact.

- ATISferax series, the lever actionable pneumatic manipulators.

The magnet tooling can as well be integrated into numerous other solutions available at ATIS.

Once the choice of tooling fell on using a magnet as the best solution for handling customer's product, it will be our engineering design department that will evaluate and design suitable magnet tooling to be integrated to the manipulator.

More than one magnet can be used for an application, for example, a long steel pipe or large steel coil will need more than one magnet to lift it at the same time.

The magnets and the pneumatics, inclusive of the necessary push-button control, will all be integrated into the tooling.

Mechanical gripping tooling

-

When aren't required specific movements, a not complicated work cycle is involved (like simply gripping and releasing the product) and in any other case where hook manipulator cannot be a good fit, we can supply pneumatic manipulators with mechanical grippers, i.e. pneumatic manipulators with a mechanical pantograph.

The mechanical grippers are always developed to adapt to the product handled and with attention to the smallest details, adapting to the shape of the product.

Crates, trees, boxes, foodstuffs and many other products can be lifted and moved effortlessly, thanks to this gripping system.

Pneumatic gripper tooling

-

For all the more particular applications and where there is the need to rotate, tilt and/or grip the product in specific points with assembly references and many other details, the solution is to use an ATIS manipulator with pneumatic grippers.

The gripping system with pneumatic grippers is extensive and ranges from the simplest grippers for gripping the outside diameter of a drum or a reel, or the sides of boxes or crates, or it can be deployed to grip internal diameters of various shapes and dimension, up to the more complex grippers also equipped with automation for assembling the components in accurate and defined positions.

Thanks to the extensive experience and knowledge of the sector, ATIS develops gripping systems that are functional, long-lasting, safe, reliable and ergonomic.

SERVICES

-

We assure all our customers total professional technical support at short notice.

Our pneumatic industrial manipulators require minimum or no maintenance to operate smoothly and assure no interference or interruptions to customers production lines.

If following the instructions and the guidelines given by our technical personnel during installation and as reported in the manual, minimum maintenance is necessary for the perfect effectiveness of our manipulators and maintenance interventions could be avoided.

There's constant technical personnel available to provide either technical assistance over the telephone or pay a site visit to resolve technical issues such as:

- Execution of installation

- Commissioning of series of ATIS manipulators

- Special maintenance tasks

- Supply and fixing of wearable parts

- Any other maintenance service as required

Rigorous testing

-

All ATIS pneumatic industrial manipulators are supplied with gripping tools, specifically designed to meet customers' load handling requirements.

The bespoke approach to design helps us to find the most suitable solution to load handling problems and this is one of the focal points on which our manipulator design principle is based.

The attention and flexibility in our approach to the specific load handling needs of customers were born out of the extensive experience, within the industry, that spans over thirty years and acquisition of necessary innovative technologies.

All starts from our open attitude to dialogue and total collaboration with customers, from the design stage of each project to the final assembly/buy off stage. The below summarises the process steps in use at ATIS:

- Meeting and initial conversation with customers

- Assessment of customer's handling requirements relative to work cycles

- Development of concept, generation of first design and issuance of technical drawings

- Revision and approval of technical drawings

- Manufacturing stage

- Equipment testing and buy-off

- Equipment Delivery

Bespoke gripping systems

-

All ATIS pneumatic industrial manipulators are supplied with gripping tools, specifically designed to meet customers' load handling requirements.

The bespoke approach to design helps us to find the most suitable solution to load handling problems and this is one of the focal points on which our manipulator design principle is based.

The attention and flexibility in our approach to the specific load handling needs of customers were born out of the extensive experience, within the industry, that spans over thirty years and acquisition of necessary innovative technologies.

All starts from our open attitude to dialogue and total collaboration with customers, from the design stage of each project to the final assembly/buy off stage. The below summarises the process steps in use at ATIS:

- Meeting and initial conversation with customers

- Assessment of customer's handling requirements relative to work cycles

- Development of concept, generation of first design and issuance of technical drawings

- Revision and approval of technical drawings

- Manufacturing stage

- Equipment testing and buy-off

- Equipment Delivery

Technical Assistance

-

We assure all our customers total professional technical support at short notice.

Our pneumatic industrial manipulators require minimum or no maintenance to operate smoothly and assure no interference or interruptions to customers production lines.

If following the instructions and the guidelines given by our technical personnel during installation and as reported in the manual, minimum maintenance is necessary for the perfect effectiveness of our manipulators and maintenance interventions could be avoided.

There's constant technical personnel available to provide either technical assistance over the telephone or pay a site visit to resolve technical issues such as:

- Execution of installation

- Commissioning of series of ATIS manipulators

- Special maintenance tasks

- Supply and fixing of wearable parts

- Any other maintenance service as required