- Offer Profile

- Crown is one of the world’s largest material handling companies with a reputation for award-winning product design, advanced engineering and technology, and superior after-sales service. Crown’s business philosophy utilises vertically integrated processes to design, manufacture and distribute forward-thinking, innovative solutions that improve customers’ productivity and operating efficiency. Crown produces a broad range of forklifts, batteries and chargers, as well as automation solutions and fleet management technologies, and warehouse solutions products and design services.

Electric Counterbalance Forklifts

-

Raising the Bar for Reliability

On the dock or in an aisle, Crown’s electric counterbalance forklift trucks can meet your rugged real-world challenges with power, productivity and performance while providing the efficiency and safety of electric operation.

SC Series

- Electric Counterbalance Forklift, 3-Wheel (48 V)

- Capacity: Up to 2000 kg

- Lift Height: 7490 mm

The SC Series Forklift Provides More Value and Versatility

This Crown forklift delivers the power, manoeuvrability and dependability to satisfy the demands of both the application and the operator. Attention to detail, advanced engineering, a solid foundation and task-focused ergonomics – that’s the ideal balance you find on the SC Series.

You can choose from 3- and 4-wheel models with capacities from 1.3 to 2.0 tons.

Legendary Robustness

You can see it in the smallest detail because we engineer our forklift trucks for exceptional reliability.

- Nested I-beam masts to minimise longitudinal, lateral and torsional flexibility.

- Integrated side-shift featuring a carriage that shields the cylinders and helps prevent hydraulic oil leaks.

- Crown-designed and built electric motors with the highest thermal rating in the industry.

- Symmetrical box frame construction to eliminate frame distortion caused by impacts of the forklift.

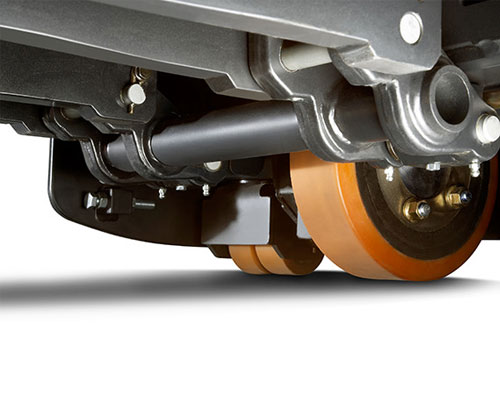

- Rugged steer axles feature heavy-duty tapered roller bearings to withstand the stress of rough surfaces and dock boards.

- Nested I-beam masts to minimise longitudinal, lateral and torsional flexibility.

FC Series

- Electric Counterbalance Forklift, 4-Wheel (48 V)

- Capacity: Up to 3000 kg

- Lift Height: 7925 mm

The FC Forklift Truck Delivers Productivity with Every Move

The Crown FC Series forklift truck features an ideal combination of productivity and power. Exceptional manoeuvrability and a range of capacities enable the FC Series to meet even more of your material handling needs.

Performance that Adds Up

Thanks to fast acceleration and travel speeds the FC Series forklift truck delivers outstanding performance.

The hydraulic system provides high lift, tilt and lower speeds, resulting in increased productivity. The dual traction motors allow for excellent acceleration and torque, as well as reliable traction in slippery conditions.

Combined with Crown’s Intrinsic Stability System, the Access 1 2 3 operating system monitors and communicates real-time information to support forklift efficiency, safety and reliability.

C-B Series

- Electric Counterbalance Forklifts, 4-Wheel (80 V)

- Capacity: Up to 3500 kg

- Lift Height: 6010 mm

Forklifts Energised to Excel Indoors and Out

Reduce your carbon footprint with Crown’s C-B Series. With capacities from 2.5 to 5.0 tons, these electric forklifts offer the strength and stability often associated with IC lift trucks. Energised with 80 volts of clean, efficient electric power, the C-B Series can perform a variety of demanding tasks in both indoor and outdoor applications with ease.

In tough warehousing, manufacturing and distribution applications, the C-B Series can boost your productivity with powerful performance, manoeuvrability, stability, and energy efficiency.

The dual traction motors deliver smooth and responsive acceleration as well as reliable traction in slippery conditions. The forklifts feature power steering, a small turning radius and regenerative, electrically assisted braking.

Economic, standard, or high productivity? With three different operating modes you can choose your preferred level of energy efficiency. A turtle mode can be activated in delicate environments to reduce travel speed without impacting the lift speed.

To enhance operator efficiency, a range of intelligent operator assistance systems is available, such as operator sensing system, mast lowering interlock and tilt lockout, speed reduction in turns, electronic parking brake and unlimited ramp hold.

RC Series

- Stand-up Electric Counterbalance Forklift, 3-Wheel (36 V)

- Capacity: Up to 1800 kg

- Lift Height: 7010 mm

One Forklift, Multiple Solutions

When you're looking for one forklift that can handle a wide variety of tasks, whether it's dock work, transport or replenishment and retrieval in the aisle, the RC Series provides a compact, manoeuvrable solution with exceptional ergonomics, comfort and ride control.

Rock-Solid Performance

Crown’s proactive Intrinsic Stability System addresses the potential causes of lift truck instability, enabling operators to perform tasks with confidence.

- Hydraulic, travel, cornering and ramp speeds are all monitored and controlled as a system to help avoid unsafe operation.

- A tilt interlock limits tilt at higher lift levels that could result in tip-overs of the stand-up forklift.

- To further boost operator confidence, the RC Series packs a stability-enhancing counterweight into a compact, space-saving design.

IC Counterbalance Forklifts

-

Power and Flexibility

Crown diesel and LPG forklifts provide the right combination of strength, durability, operator comfort, and application flexibility to handle your rough outdoor environments.

C-D Series

- Diesel Forklifts

- Capacity: Up to 3500 kg

- Lift Height: 8250 mm

The C-D Series Diesel Forklifts are Built to go the Distance

The Crown C-D Series diesel forklifts deliver power, reliability, operator comfort, and serviceability to conquer the tasks of rugged outdoor environments. The powerful turbo diesel engines offer fuel-efficient performance and comply with the latest exhaust emission regulations (EU Stage 5).

The IC forklifts are available with load capacities from 2.0 to 5.5 tons.

Do you operate under extreme conditions? The C-D Series diesel forklifts are designed to excel on rugged terrain as well as in extremely dusty, humid, hot, or cold outdoor applications. They provide the right combination of strength, reliability, and application flexibility to help boost your productivity in many challenging industries such as recycling, chemical, building materials, or metal processing.

From features that protect critical components in extremely harsh environments to carriage options that handle various load types, these IC forklifts can be optimised to fit the requirements of your operation.

Economic, standard, or high productivity? With three different operating modes you can choose your preferred level of energy efficiency. A turtle mode can be activated in delicate environments to reduce travel speed without impacting the lift speed.

C-G Series

- Gas Forklifts, LPG

- Capacity: Up to 3500 kg

- Lift Height: 6010 mm

C-G Series LPG Forklifts are Reliable and Versatile

The Crown C-G Series gas forklifts are designed to withstand the rigours of heavy-duty use in rugged applications. Dependable LPG engines deliver powerful, fuel-efficient performance – compliant with the latest exhaust emission regulations (EU Stage 5).

The LPG forklifts are available with load capacities from 2.0 to 5.5 tons.

Do you operate under extreme conditions? The C-G Series gas forklifts are designed to excel on rugged terrain as well as in extremely dusty, humid, hot, or cold outdoor applications. They provide the right combination of strength, reliability, and application flexibility to help boost your productivity in many challenging industries such as recycling, chemical, building materials, or metal processing.

Powerful and dependable LPG engines provide high torque at low engine speeds for applications requiring ramp loading and unloading, fast lift speeds, or heavy hydraulic flow.

Economic or standard? With two different operating modes you can choose your preferred level of energy efficiency.

C-G Series

- C-G Series LPG Forklifts are Reliable and Versatile

The Crown C-G Series gas forklifts are designed to withstand the rigours of heavy-duty use in rugged applications. Dependable LPG engines deliver powerful, fuel-efficient performance – compliant with the latest exhaust emission regulations (EU Stage 5).

The LPG forklifts are available with load capacities from 2.0 to 5.5 tons.

Very Narrow Aisle Trucks

Engineered for Performance

Crown offers VNA trucks in two configurations, offering the speeds, capacities, energy efficiency and lift heights to match your exact needs, providing operators with the tools and confidence to perform at the highest levels.VNA Turret Truck TSP Series

-

Purpose-Built for Elevated Results

Crown builds each VNA truck to fit the specific requirements of your application.

With advanced technology, exceptional travel, lift and lower speeds, load capacities and lift heights - supported by an industry-leading, heavy-duty mast - the new TSP Series enables you to achieve sustained high-performance results.

Smarter System, Longer Uptime

VNA trucks are important investments for the productivity of your operation.

Optimum uptime and performance are critical. That's why the TSP Series offers a combination of robust construction and advanced technology to deliver the serviceability and reliability required for success.

- Heavy-duty steel frame and covers

- Separate electronics and hydraulic systems

- Wireless software downloads

- Easy-to-adjust settings

- Step-by-step calibration instructions

- Gena analyser to view inputs and outputs of individual system components

- Easy-access covers, panels, and skirt door

Reach Trucks

Reaching New Heights in Productivity

Crown reach trucks offer a range of available features and capabilities from breakthrough connectivity with Crown's Gena operating system to outstanding mast stability, cycle times, visibility and energy savings.ESR Series

- Capacity: Up to 2000 kg

- Lift Height: Up to 14205 mm

Real Performance is Within Reach

The ESR 1000 reach truck with Xpress Lower technology doubles lowering speed to improve cycle time and increase productivity while regenerative lowering reduces energy consumption.

Built-in connectivity provided by the Gena operating system provides operators, managers and service engineers with a connected, data-rich environment that's more human, personalised and interactive.

Work Smarter and Faster at Height

On an ESR reach truck, operators work with skill and precision at any height without compromising productivity. ESR 1000 and ESR 5200 models feature various combinations of advanced hydraulics and motors, programmable features, intuitive displays, one-touch controls and camera options that all work together to raise performance.- The ESR 1000's optional Xpress Lower technology lets you double lowering speeds, resulting in substantial savings in time and money.

- The optional Auto Height Select feature available for the ESR 1000 automatically stops the forks at programmed rack heights to avoid product, rack and truck damage while improving throughput.

- The Tilt Position Assist option available on all ESR models compensates for mast and carriage deflection and automatically levels forks relative to the ground for more precise positioning.

Order Pickers

Taking Performance to the Next Level

Crown can optimise your order-picking process – both on the ground and at the highest elevations. Superior driving performance and stability, industry-leading ergonomics and a significant number of features allow operators to work productively and confidently.

LP Series

- Faster Access Begins Here

In picking operations, easy access is key. That’s where the Crown LP Series mid-level order picker excels with blended control operation, advanced ergonomics and reliability that pay for years to come.

QuickPick remote

- Optimise the Order Picking Process

Crown’s QuickPick Remote is a game-changing innovation in low-level order picking – a fast-paced, physically demanding job. The technology automates tasks that simplify workflow —saving time, reducing risk and increasing productivity.

In traditional order picking applications, operators constantly return to the compartment to move the truck forward. With QuickPick Remote, operators maintain a smooth workflow pattern, focusing less on positioning the truck and more on the task of picking.

Low-Level Order Picker GPC Series

- Capacity: Up to 2700 kg

- Lift Height: Up to 960 mm

The GPC Order Picker is a Productivity Centre for Your Warehouse

Crown’s GPC Series order picker focuses on the entire picking process whatever the job. These trucks enhance productivity, application versatility and ergonomics as well as reliability for long-term performance and ROI.

The GPC Order Picker Delivers Efficiency at Every Pick

The GPC Series provides superior driving performance along with fatigue-reducing comfort for increased operator productivity.

And since studies have shown, that 90 percent of the typical picking cycle is performed off the truck, Crown engineers and designers created a comprehensive range of options and accessories to fit the exact requirements of each application and to reduce and simplify operator movements on and off the order picker.

Move Picking to a Higher Level

The GPC Series offers a complete line of order pickers to meet any application challenge, including taller, heavier loads and second-level picking.

An optional fold-down step provides a practical way to extend operator reach. The GPC Series also includes a platform-lift option to position operators for easier second-level picking.

Order picker models with high-lift forks provide ergonomic and productivity advantages. Forks can be lowered or raised to minimise operator lifting and bending for steadier picks and reduced fatigue.

Engineered for Reliable Performance

The GPC Series order picker features a robust, reliable design that can stand up to the harsh environment of order fulfillment.

Crown applies advanced technology to order picking with AC motors, Crown’s exclusive Access 1 2 3 Comprehensive System Control, e-GEN braking and electronic steering to enhance safe performance and productivity.

Order Picker with Mast MPC Series

- Capacity: Up to 1200 kg

- Lift Height: Up to 4300 mm

With the MPC Order Picker the Exception is Now Standard

You could buy four different forklift trucks for order picking, stacking, replenishment and pallet transport or you could invest in one truck that does it all – the MPC Series order picker with mast.

Application Versatility

The MPC Series owes its versatility to a high-lift mast and counterbalance design. Whether you are working close to machinery, handling 4-way pallets, manoeuvring in congested areas or filling a rack - this order picker with mast can handle it all.

Ergonomic, Smooth, Safe

Crown engineers designed the MPC order picker with outstanding visibility, manoeuvrability and control. A low step height simplifies on/off tasks.

Smooth, responsive acceleration and braking as well as the ergonomic full-suspension platform give operators more confidence for safer operation.

Plus there’s solid-steel protection all around.

The MPC Order Picker is Engineered for Reliable Performance

The MPC order picker with mast features a robust, reliable design that can stand up to the most intensive use.

We’ve combined the chassis of our award winning low-level order picker with an I-beam mast and rugged ISO Class 2A fork carriage for strength and flexibility.

Strong performance and low energy consumption is achieved through Crown’s exclusive Access 1 2 3 Comprehensive System Control, AC motors, e-GEN braking system and electronic steering.

With Crown’s vertically integrated manufacturing and aftermarket services, total cost of ownership can be substantially lower over time.

Mid-Level Order Picker LP Series

- Capacity: Up to 1000 kg

- Lift Height: Up to 2440 mm

Faster Access Begins Here

In picking operations, easy access is key. That’s where the Crown LP Series mid-level order picker excels with blended control operation, advanced ergonomics and reliability that pay for years to come.

Crown's Mid-Level Order Picker Enables Constant Movement

The Crown LP Series mid-level order picker delivers performance advantages through diagonal travel for free ranging operations and automatic speed adjustment features.

In addition, intuitive, blended controls for lift, traction and steering make the most of speed while ensuring precise control.

Build Shift-Long Confidence

In fast-paced picking work, operator confidence is critical. When operators trust an order picker to perform the way they intend, they accomplish more.

First, the LP mid-level order picker fosters shift-long confidence with a well-designed operator compartment where everything is well within reach.

Crown engineers and designers added AC traction and AC steering to this series for lower effort steering, smoother overall performance and more confident load handling.

High-Level Order Picker SP Series

- Voltage: 24 or 48 volts

- Capacity: Up to 1250 kg Lift Height: Up to 10210 mm

Discover the Visibility Advantage

Crown's SP Series man-up forklifts are designed to help busy order pickers efficiently handle a variety of tasks in dynamic, high-density environments.

For long-term performance, the SP Series offers a powerful visibility advantage, industry-leading speeds, an operator-focused design, advanced technology options and a comprehensive approach to uptime.

The SP Series takes order-picking productivity to the next level by focusing on the combined performance of lift truck and operator during picking tasks.

Efficiency is critical and Crown's high-level order pickers deliver outstanding raise/lower and travel speeds with an intuitive blending of truck functions, helping to exceed throughput goals.

The stability at height and OnTrac anti-slip traction control enhance operator confidence during truck positioning, allowing the operator to focus on the picking task.

The spacious operator compartment allows operators a wide range of movement with access to a broad pick face - for smooth movement of product to the lift truck and transition to the next picking task.

Order Picker Work Assist Vehicle WAV Series

- Operator Platform Capacity: Up to 135 kg

- Load Tray Capacity: Up to 90 kg

- Load Deck Capacity: Up to 115 kg

- Lift Height: Up to 2995 mm

The Mobility Revolution

The Wave, Crown's Work Assist Vehicle, is a revolutionary order picker that delivers significant savings through enhanced productivity, application versatility and safety.

Do Twice the Work

The Wave order picker is a revolutionary, mobile productivity tool that allows one person to safely and efficiently accomplish the work of two while travelling twice as fast as the average walking speed.- Reach working heights of up to 5 metres

- Travel up to 8 km/h with travel speed based on lift height

- Simultaneously travel and elevate for smoother, more efficient workflows

- Manoeuvre through tight aisles and doorways as narrow as 80 cm

The Wave Order Picker Provides Safety with Every Turn

The Wave's built-in system of protection and control starts the moment the operator turns the key switch. Crown's Access 1 2 3 System coordinates a functional display, manages lift/lower operations and controls travel speeds, steering and braking.

The order picker's four-point safety system provides enhanced operator control and safety.

Productivity that Pays for Itself

Experience a world without the risks of traditional ladders – employee falls and injuries, expenses of lost time and productivity, and expensive product damage.

Many customers report a complete return on investment within one year of purchase of the Wave order picker.

Order Picking Technology

- Automate workflow to increase productivity by up to 25%

Go Remote to Improve Productivity with Less Effort

Crown’s exclusive QuickPick Remote technology boosts order-picking productivity up to 25 percent.

Optimise the Order Picking Process

Crown’s QuickPick Remote is a game-changing innovation in low-level order picking – a fast-paced, physically demanding job. The technology automates tasks that simplify workflow — saving time, reducing risk and increasing productivity.

In traditional order picking applications, operators constantly return to the compartment to move the truck forward. With QuickPick Remote, operators maintain a smooth workflow pattern, focusing less on positioning the truck and more on the task of picking.- Lessen operator joint stress and fatigue

reduce steps by up to 50 percent - Promote safety

reduce operator accidents and injuries - Reduce damage

fewer impacts on product and racking - Increase operator productivity

pick more orders in less time

Revolutionise Your Workflow and Save Time

Increase operator productivity by leveraging a truck that allows the operator to maintain a consistent rhythm and pace, making the most of every second in the picking process.

A typical order picker steps on the operator platform approximately 1,200 times each shift. QuickPick Remote eliminates up to 70 percent of this activity. With the simple press of a button on the wireless remote, the order picker remotely advances the lift truck to the next pick location, allowing the operator to minimise steps and remain in the optimal pick position. Long-term testing shows that productivity between first and last pick of the day increased by 10 percent on average with gains within the aisle of up to 25 percent.

Stackers

- Control You Can Count On

At Crown, safety and efficiency are built into the design of every stacker. Our full line of operator-friendly stackers offers extraordinary manoeuvrability and application flexibility.

Stackers WF Series

- Capacity: Up to 1200 kg

- Lift Height: Up to 4400 mm

The Economical and Efficient Stacker

Crown’s WF Series stacker contributes time and cost savings while delivering flexibility that makes it one of the most in-demand in the warehouse. Now, you can save space and organise products for faster access while giving your employees a quicker, safer way to lift, carry or transport heavy or bulky loads.

Flexibility and Versatility

The Crown WF Series stacker serves as a dependable workhorse for a variety of applications, especially where space is limited. The compact design operates in crowded aisles and tight work areas, and offers load capacities of up to 1200 kg.

Move with Ease

In crowded aisles and tight spaces, the WF Series’ fork-over design lets your employees move with ease and efficiently handle Euro pallets and other open-bottom containers. With a narrow turning radius and Crown’s exclusive X10 Handle, operators experience precise control.

The low-profile power unit, clear mast design with nested rails and the efficient routing of hydraulic hoses all contribute to clear visibility even while working with elevated loads or moving products. In fact, this stacker offers unmatched visibility all around; forward, upward and both sides.

The WF Stacker is Powerfully Safe

The WF Series balances operator power and safety – helping operators manoeuvre and position loads in tight, congested spaces with less effort. In addition, the stacker features a centre-mounted tiller, which positions the operator at a constant distance from the drive unit during both right and left turns.

Stackers ES Series

- Capacity: Up to 1600 kg

- Lift Height: Up to 5400 mm

ES Stackers Offer Precision and Strength in Small Spaces

The Crown ES Series stackers deliver powerful performance, responsive control, excellent manoeuvrability and visibility so operators can work safely and productively in small spaces.

Robust and Powerful

With the ES Series, strength is apparent on the inside and out. The stackers' components and structures are engineered for maximum power and endurance.

The drive unit features a Crown-built AC traction motor and heavy-duty cast iron gearbox to handle the heaviest loads. A formed steel tiller arm with die-cast aluminum control handle ensures long life in the toughest environments.

The rugged power unit features a thick steel skirt and removable steel covers. The mast features nested I-beam construction and thick steel cross bars.

Superior Handling and Performance Responsive traction control, the narrow chassis and optional electronic steering simplify manoeuvring the stackers in confined spaces, even with heavy loads. Precise proportional lift and lower functions optimise load handling at heights up to 5.4 metres.

The brake-override function allows operation in the creep speed mode with the handle position nearly vertical for precise manoeuvring.

The innovative X10 Handle includes a rabbit/turtle switch for two levels of programmable travel performance so operators can quickly select the setting that matches their experience level or specific task.

Platform Stackers ET Series

- Capacity: Up to 1600 kg

- Lift Height: Up to 5400 mm

ET Stackers are Built for Real World Challenges

The Crown ET Series is engineered for harsh and less-than-perfect conditions. The platform stackers are built to be rugged, precise and powerful. Put them to the test and you’ll find robust performance, simplified use and excellent control.

More than Lifting

Maximise stacking productivity with features that give operators more control for real-world stacking functions.

Crown's ET Series excels at positioning the truck to improve stacking efficiency. This is achieved through proportional lift/lower feature, sturdy mast, rigid chassis, superior visibility, and the centre-mounted tiller.

The ETi platform stackers with initial lift add a flexibility advantage by providing higher ground clearance for better handling on inclines and uneven surfaces and to avoid product shifting and unsafe transport conditions. Robust initial lift load arms stand up to the severe pounding caused by uneven floors, dock boards and rough surfaces. They also enable double pallet handling.

Rugged and Nimble

The platform stackers’ large Crown-built AC traction motor and a low-noise cast iron gearbox provide reliable power to handle heavy loads.

Nested I-beam rails and thick steel cross bars contribute to a rugged and stable stacker mast with high residual capacities. The reinforced 8 mm thick steel chassis and die-cast aluminum control handle hold up under the toughest conditions.

Crown’s e-GEN braking system uses the power of the high-torque traction motor to improve overall braking performance while virtually eliminating brake maintenance.

Double Stackers DS Series / DT Series

- Capacity: Up to 2000 kg

- Lift Height: Up to 2600 mm

- Platform: None, Folding or Fixed

Pick up the Pace with Crown Double Stackers

Crown offers a range of model variations to meet your double-stacking requirements – from medium-duty retail environments to high-density stock-to-dock applications. Crown's double stacker series combine the abilities of a heavy-duty stacker with the flexibility of a pallet truck, plus the capacity to transport two 1000 kg pallets.

Flexibility Pays

In terms of productivity, control, durability and versatility, Crown's DS and DT Series far exceed typical expectations for double stacker pallet trucks. With double-deck lorries, the advantages stack up even further. You can save shipping costs, valuable dock and floor space while increasing throughput.

The double stacker series are available in five configurations offering travel speeds of up to 12.5 km/h.- Two models without platform are available for dedicated pedestrian use in medium- to heavy-duty applications.

- The folding-platform configuration with folding side restraints offers the flexibility of switching between rider and pedestrian mode.

- The fixed-platform configuration with side entry and backrest is especially useful for transport and order picking.

- The fixed-platform configuration with rear entry and comfortable operator compartment is ideal for high traffic areas

Double up Throughput in Retail

The new DS pedestrian double stacker helps you master the challenges associated with narrow aisles and confined stockrooms in retail and wholesale environments. It is perfect for pallet handling, transport, shelf-replenishment and unloading double-deck lorries in congested spaces.

The DS Series offers superior manoeuvrability and ergonomics thanks to its compact size, small turning radius, low-mounted X10 Handle and optional fork lift switches on both sides of the mast. At the same time, it features class-leading levels of stability, residual capacity, robustness and reliability.

For additional benefits in retail applications, the double stacker is available with optional V-Force Lithium-Ion Compact Batteries and integrated on-board charger, providing longer runtimes and allowing easy opportunity charging.

Straddle Stackers ST/SX Series

- Capacity: Up to1350 kg

- Lift Height: Up to 4250 mm

Optimised Space and Efficiency with Crown Straddle Stackers

Crown ST/SX Series straddle stackers offer a safe, productive and cost effective solution when you need to maximise your storage space and improve efficiency.

Exceptional Utility

Experience more efficiency and utility all-around with the ST/SX Series straddle stackers. Stacking capabilities save space and time, order picking becomes more manageable and efficient. Use it as a portable work station, load and unload trucks from the ground and simplify maintenance tasks.

When compared with counterbalance forklifts, Crown straddle stackers allow you to stack more products in the same size room, which translates into more usable space while optimising selectivity.

ST/SX Straddle Stackers Offer a Clear View All Around

Operators using the ST/SX Series straddle stackers benefit from exceptional visibility, allowing them to quickly and confidently manoeuvre in tight spaces and position loads on the floor or while elevated.

The low-profile power unit and clear mast design provide excellent fork-tip visibility on the ground and while working with elevated loads.

Take Control

You need exceptional control to meet the challenges of efficiently moving and storing product in limited space. The innovative controls and compact design of the ST/SX straddle stackers enable operators to manoeuvre with ease.

The exclusive Crown X10 Handle with its uniquely designed handgrip, thumbwheel and raise/lower buttons, simplifies operation and enhances comfort. The brake-override feature enables the straddle stackers to turn in an area almost as small as their own footprint while the handle remains within the geometry of the trucks.

Operators can quickly and conveniently choose from two levels of programmable performance to match their own skill level or the particular application needs.

SH/SHR/SHC Series

- Heavy-Duty Stackers Navigate with Ease

The Crown SH, SHR and SHC Series combine the operational benefits of pedestrian stackers with the power and flexibility to handle non-standard loads. The small footprint and extended load capacities enable operators to quickly and easily manoeuvre and position heavy loads in tight, congested areas.

Pallet Trucks

The Ultimate Gain in Productivity

From hand pallet trucks to electric rider pallet trucks, Crown offers a lift truck model for every pallet-handling application. Innovative design and solid construction ensure long-lasting value and versatility.

Hand Pallet Truck PTH-Series

- Capacity: Up to 2300 kg

- Lift Height: Up to 800 mm

A Hand Pallet Truck with Exceptional Long-Term Value

Hand pallet trucks should be durable, not disposable. Therefore, the Crown PTH Series offers superior quality, serviceability and durability that exceed the toughest application needs.

Durability that stands the Test of Time

The PTH Series hand pallet truck features solid construction and generous use of steel – especially at critical stress points – to deliver long-lasting performance.

Its durability is enhanced by a reinforced handle, strong C-channel forks made of thick steel, cross braces and steel forgings on lift link arms and box-style push rods.

In addition, the PTH Series uses galvanised pins and shafts for corrosion protection and hard chrome pistons to minimise rust.

Designed to Perform

The PTH Series hand pallet truck is designed for smooth and quiet operation and easy handling so operators experience less fatigue and work more efficiently.

Extra Comfort and Functionality

The PTH Series includes a manual and a powered scissor lift model, which offer productivity-enhancing options; they can be used as:- hand pallet trucks,

- storage tables or

- workbenches

The lifting forks rise up to 800 mm, which saves the operator unnecessary bending, heavy lifting and increases efficiency in repetitive handling operations.

Pallet Truck WP Series

- Capacity: Up to 2000 kg

- Lift Height: up to 750 mm

Application-Focused Design

Crown's application-focused design makes it easy to find the pallet truck that matches your workforce, levels of usage, facility layout and shipping needs.

The WP Series – including the compact WP 3010 model – meets the requirements of many demanding applications. Whether it's dock work, delivery service, in-store retail or heavy manufacturing, Crown’s WP Series allows you to select the best pallet truck for your business.

Built Rugged. Guaranteed Tough.

Pallet trucks are defined by more than a capacity rating. The WP Series holds up under tough conditions offering reliability, robustness, load stability and powerful performance.- Durable Steel Covers

The valuable internal components of the pallet truck are protected by reinforced steel covers. - Optimised Steel Chassis and Fork

Crown has the confidence to include a 5-year warranty on the steel structure of the chassis and fork assembly. - Robust X10 Handle

All WP pallet truck models feature a robust aluminium alloy control handle and steel tiller arm. - Stability System

Some models feature dual lift cylinders coupled with a heavy-duty torsion bar to eliminate chassis twist when handling offset or tall loads.

Fit for Travel

Whether it's inbound or outbound, the WP Series gives you a pallet truck to handle each point-of-delivery challenge. It improves productivity, performance and throughput on and around lorries and helps operators work safely and efficiently.- Compact size and tight turning radius for superior manoeuvrability

- Short headlength for transport on fully loaded lorries

- Easy-to-use controls for operations staff and lorry drivers

- Various sizes of load backrests for greater load stability

- Low overall height for easy fit in under-lorry storage boxes

Operational Advantages for Retail

Moving and positioning loads quickly and safely in confined storage spaces and narrow aisles with minimal disruption to shoppers is a constant challenge for retail that the WP Series answers. A compact design and smooth, intuitive controls are just a few of the in-store benefits you'll find.

Crown offers a range of pallet truck models, features and options to help you in any retail application, ranging from small shops to supermarkets to large DIY centres.

Platform Pallet Truck WT Series

- Capacity: Up to 2500 kg

- Platform: Folding or Fixed

This Pallet Truck is Built to Perform

When you face intense pallet truck conditions and high throughput demands, Crown has the answer. The WT Series has what it takes for both truck and operator to excel: robust engineering, best-in-class durability, task efficiency and comfort.

The WT Series platform pallet truck offers the widest model variation available including four platform configurations, capacities of up to 2.5 tons and electronic steering.

Demanding Job

Built for the extreme, the WT Series platform pallet truck features a cast-steel reinforced chassis, up to 12 mm thick covers, die-castaluminium handle and the toughest side restraints available.

An advanced suspension significantly reduces shock to the chassis, platform and truck components. The sealed drive unit suspension requires no adjustment for drive tyre wear. Trucks with electric steering include the Active Traction system with innovative hydraulics that adjust the pressure on the traction tyre depending on loading conditions for faster travel speeds and better traction on ramps.

One Smooth Ride

Operators encounter numerous challenges that slow them down; jolts from dock boards, unstable footing, narrow spaces, strenuous steering and heavy loads. The WT Series platform pallet truck addresses these challenges with the FlexRide folding platform suspension which reduces shock transfer to the operator by more than 80%.

Independent testing has confirmed that the ultimate operator suspension is the WT Series’ weight-adjustable FlexRide, optional on rear-entry fixed platforms, which fine-tunes the suspension for the operator’s body.

Excellent fork tip visibility, superior tiller positioning and a folding platform all contribute to more comfort and safety.

This Platform Pallet Truck offers Lasting Value

Crown builds long-term value into all of its trucks and the WT platform pallet truck is no exception.

Extended service intervals on the Crown WT Series drive more uptime and savings. What’s more, when maintenance or service is required, castor and load wheels are easily replaced and both side panels on the power unit open easily for fast access to internal components.

With Crown’s vertically integrated manufacturing and aftermarket services, total cost of ownership can be substantially lower over time.

Ride-on Pallet Truck RT Series

- Capacity: Up to 2000 kg

Run Fast, Run Strong with the RT Ride-On Pallet Truck

The RT Series ride-on pallet truck is engineered to make a huge difference in manoeuvrability, responsiveness, reliability and safety. Both the sit-down and stand-up models deliver fast, strong transporting performance with the comfort operators need to run day after day.

Designed for Operator Success

Like all Crown forklift trucks, ergonomics play an important role in design for optimum operator productivity. The RT Series is another proof point of this value.

The RT stand-up pallet truck provides best-in-class ride comfort with a suspended floorboard, wrap-around soft foam lean pad and a choice of right or left-hand steering.

For long-distance, high-throughput applications, the RT sit-down pallet truck features a full-suspension seat as well as a height-adjustable floorboard. Its higher seating position provides better visibility all around.

Higher Performance, Safely

Crown AC motors offer powerful acceleration and 12.5 km/h travel speed.

Operators benefit from electronic steering for improved responsiveness and manoeuvrability. Speed control in curves safely delivers top driving performance.

The ride-on pallet truck features standard pallet entry and exit rollers allowing the load arms to traverse pallet bottom boards whether the pallet is empty or full.

The patented entry bar switch deactivates travel if the operator places a foot outside the truck perimeter.

WT Series

- Herausragende Leistung und einzigartiger Komfort

Wenn Sie einen Gabelhubwagen für intensivste Einsatzbedingungen und höchste Umschlagleistung benötigen, hat Crown die passende Antwort. Die WT Serie bringt alles mit, was für eine herausragende Leistung von Fahrzeug und Bediener notwendig ist: eine robuste Konstruktion, überragende Langlebigkeit, hohe Betriebseffizienz und hervorragenden Bedienkomfort.

Die WT Serie bietet die größte Modellvielfalt auf dem Markt, einschließlich vier verschiedener Plattformkonfigurationen, Tragfähigkeiten bis zu 2,5 Tonnen und elektrischer Lenkung.

Tow Tractors

Power to Pull You Through the Toughest Tasks

Innovative technology and heavy-duty construction are the cornerstones of Crown’s tow tractors, offering proven pulling power and control for manufacturing, warehouse and distribution centre applications.Tow Tractor TC Series

- Capacity: Up to 3000 kg

The Crown Tow Tractor was Engineered for Performance

When your material flow depends on a tow tractor, there is no better choice than the reliable and durable TC Series from Crown – designed from the ground up to deliver consistent performance.

In Total Control

Crown's Access 1 2 3 Comprehensive System Control provides smooth, safe operational control by continuously monitoring and adjusting the tow tractor to the working environment.

The TC Series uses electronic steering to improve control and reduce operator effort.

The award-winning X10 control handle places all tow truck functions right at the operator’s fingertips.

Smart Tools

Crown analysed a complete range of transport and picking tasks and then designed a range of accessories to enhance convenience, comfort, safety and productivity of the tow tractor.

Crown’s range of Work Assist accessories includes magnetic storage trays, soft writing mats, load trays, WMS monitors, clipboards, trash bag holder and beverage holder. Alongside the tried-and-tested Work Assist accessory tubes, an optional front version with integrated cable management is available, allowing even more power-supplied accessories to be mounted on the tube for better accessibility and visibility.

The award-winning X10 control handle places all tow truck functions right at the operator’s fingertips.

V-Force Forklift Batteries and Chargers

Power Solutions for Every Application

Versatile lithium-ion motive power products offer flexibility, reliability and efficiency for every application.

Full integration and compatibility among Crown products and services set the V-Force Lithium-Ion Systems apart from other solutions.

Next-Level Power V-Force Lithium-Ion Energy Storage Systems

- A New Generation of Power

Compared to lead-acid batteries, lithium-ion technology can save substantial time and money through increased efficiency, enhanced productivity, and a lower total cost of ownership.

The complete range of Crown forklift trucks can be equipped with lithium-ion batteries. A selection of lithium-ion Energy Storage Systems (ESS) is available to fit your Crown trucks.

Faster Charging, Extended Runtime and Longer Life

V-Force Lithium-Ion Energy Storage Systems (ESS) are ideal for multi-shift operations utilising opportunity charging. Compared to lead-acid batteries, lithium-ion systems provide:- Up to 40 percent greater energy efficiency

- Higher sustained voltage properties

- Higher rate of return during any charging event

- Up to 22 hours of runtime per 24-hour period

V-Force Lithium-Ion Technology Takes Crown Forklifts to the Next Level

The fully integrated V-Force Lithium-Ion ESS optimises battery life, performance and value with:- battery levels and warnings shown on the in-truck display

- a battery management system that monitors, tracks and prevents abuse and operation outside of warranted conditions

- an early warning system that provides alerts and limits truck functionalities during a low state of charge

- a charger integrated in the battery tray (available on select series

High Frequency. High Efficiency. V-Force V-HFB Forklift Battery Chargers

- Increase Your Efficiency and Return on Investment

V-Force chargers offer state-of-the-art charging efficiency, an exceptionally fast charge rate, optimised energy consumption and increased service life.

A range of 19 models is available for battery voltages from 24 to 80 volts. Whatever your individual requirements are, we have the right battery charger to keep your forklift fleet moving at an economical price.

Extraordinary Efficiency

V-HFB chargers feature fully resonant, high-frequency switching (from 50 kHz to 170 kHz) over the entire charging cycle.

The technology reduces power losses during the switching process.

With efficiency levels of up to 97 percent, the V-HFB Series is more efficient than other high-frequency chargers on the market.

Save Time and Energy

The V-HFB Series intelligently optimises the charge rate based on various factors to help reduce charging time and expense. With a 1 C charging factor, batteries of up to 400 Ah can be fully charged within 60 minutes.

Fully automatic charging with dynamic adjustments based on the battery's age, temperature and state of charge eliminates the need for manual programming of the charger. In case of a power outage, charging automatically continues afterwards.

An encapsulated cooling system minimises heat losses. Combined with a reduced stand-by power consumption, it saves energy and reduces the carbon footprint.

Solutions

- Lifting the Value of Your Business

A forklift is an incredible machine. And when connected with fully integrated Crown technology, it’s a rolling, lifting, streaming hub of operational insight. So you can confidently make instant, informed decisions that move your entire organisation forwards—not just what’s on the facility floor.

Engage

- Engage Operators and Managers

Training, managing, motivating and retaining employees are big challenges. Connected technology can energise your team and add new value by:

- Supporting self-directed operator improvements

- Streamlining compliance

- Increasing productivity

Inspire

- Inspire Actions that

Improve OperationsConnected equipment gives you greater control over your entire operation. Analysing and acting on connected data lets you maximise your investment in four key ways:

- Enhance operator safety and compliance

- Reduce risk of damage to facility and products

- Repurpose underused equipment

- Lower maintenance expenses

Achieve

- Achieve Productivity

and Uptime Goals

A connected warehouse and service process enables you to leverage integrated resources and meaningful data to plan for and prevent disruptions. Increase productivity while reducing costs when you:

- connect assets in the service chain,

- manage, monitor and analyse data,

- automate data collection and integration,

- use data to predict and prevent potential issues.

Grow

- Grow with Confidence

The next generation of integrated technology promises to add new value by turning reactive operations into proactive ones. Driven by data, our fully integrated technology makes you, your colleagues and your business nimbler so you can make smarter decisions that allow you to anticipate and adapt to challenges — today, tomorrow and beyond.

Automation Solutions

Expect the Unexpected

Effective warehouse automation can help ensure you're ready to react more quickly to business disruptions. Instead of a bolt-on approach, Crown is focused on integrated solutions that will help you stay ahead of the competition. Crown’s automation solutions can solve challenges today while reframing the future of material handling.

Revolutionising Order Picking

Increase productivity by up to 25 percent

Consumer demand is disrupting order fulfillment as we know it. Stay ahead of the disruption with Crown’s QuickPick Remote order picking technology. It automates picking tasks to simplify workflow, saving time, reducing risk and increasing productivity. Leverage this technology to:

- Increase operator productivity

- Lessen operator fatigue

- Promote safety

- Help reduce damage

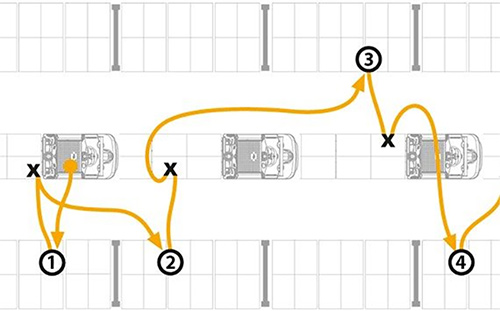

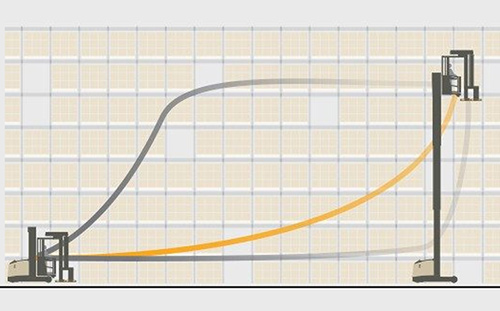

VNA Automation That Produces Sizeable Savings

-

Increase productivity by up to 25 percent

The shortest distance to big productivity gains isn't necessarily a straight line. Crown’s Auto Positioning System enables operators to get more done in less time by guiding the VNA truck along the most effective route to the next rack location. Deploy this technology to elevate your facility to the next level with:

- Increased productivity

- Increased pick accuracy

- Reduced operator fatigue

- Flexibility

- Increased productivity

Meet Our Automation Team

- There is a better way

Let Crown help you solve tough automation project challenges and help you reach your goals. - ROI doesn’t have to be a long game

Crown’s integrated approach to automation drastically reduces the ROI timeline. - Integrated solutions

Crown's automated warehouse solutions are designed for seamless integration and flawless operation. - Future-proof leading edge solutions that can grow with you

Even if you’re not ready for automation, you can maximise your investment with forklift trucks and automation technology that can evolve along with your requirements. - Multiple operating modes offer flexibility

Switch from autonomous to manual forklift operation and back, as your application demands. - Support to help ensure your long-term success

Count on solutions that are backed by an extensive dealer network and factory support from a company that has delivered reliable material handling solutions for more than 50 years.

- There is a better way

Energy Solutions

- Powering Your Performance

Realise enhanced performance, uptime, and value with Crown as your single-source supplier of solutions that power your forklift fleet.

Power Up With a Single Source

-

From our expertise in power management to our complete line of V-Force energy solutions, Crown provides the solutions you need to power your forklift fleet. That adds up to more value for your business.

- Onsite Evaluations

- Integrated Solutions

- Batteries, Chargers and Accessories

- Fleet and Battery Management

Integration That Pays In Performance

-

Whether you choose lead acid or lithium-ion as your power source, our goal is to provide a highly integrated solution in which forklifts, batteries, chargers, and service work together to optimise uptime.

This compatibility of components can deliver further advantages: reduced maintenance and parts replacement, improved safety during charging and operation, and savings in time, money and energy consumption.

Analysing Your Power Needs

-

Crown Motive Power experts can analyse and interpret energy consumption data to help you make informed decisions regarding power sources, charging methods, and equipment selection to increase your energy efficiency.

Crown technology solutions, like the InfoLink Operator and Fleet Management System, can provide insight for day-to-day power management.