- Offer Profile

- Dynamic is innovation plus

experience.

Long-term thinking applies to more than just the procurement of capital goods. In the case of warehouse systems in particular, development, production, sales and service need up-to-date concepts that will continue to be successful. That’s why Dambach Lagersysteme concentrates intensively on its own strengths. On dynamic in all disciplines. And the focused application of the expertise gained over many years. Focusing on new ideas, on unconventional concepts, on systems that consolidate the innovative market-leadership of Dambach Lagersysteme.

Automated Storage and Retrieval Systems (ASRS)

-

Storage and Retrieval Machines and Shuttle-Systems

The Tasks of a Automated Storage and Retrieval System (ASRS)

The aims of an automated storage and retrieval system are to optimize the actual material flows and reduce the stocks held by improving the organizational structures. Irrespective of the type of warehouse, DAMBACH ASRS help to ensure that stocks are always ready for dispatch and fluctuations in demand are absorbed. Depending on the solution adopted, operations can be carried out with storage and retrieval machines or shuttle systems. Choosing the right warehousing technology not only shortens access times and transport distances (which improves warehouse efficiency), but also increases throughput and flexibility. Automation in a warehouse can ensure a consistently high standard of deliveries.

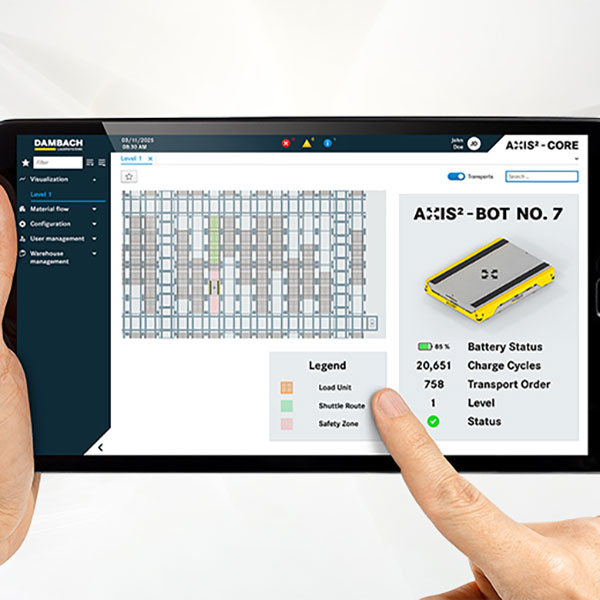

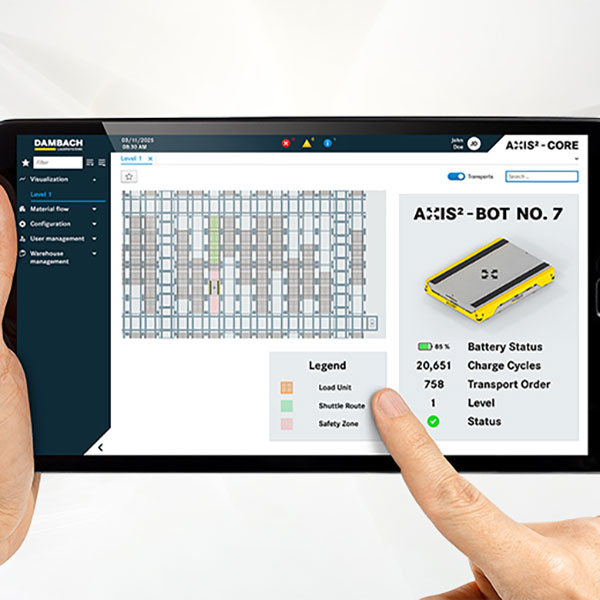

AXIS² System

-

AXIS² - SYSTEM is an automated multi-deep storage system for demanding state of the art warehousing. The system opens up new possibilities in terms of flexibility and scalability. Suitable for a wide range of pallet types and harsh environments. Perfectly matched components – shuttle, conveying elements, rack system and material flow control system – enable easy integration to general contractors.

Specific to the North American Market:

Developed in close partnership with FRAZIER, AXIS² integrates cutting-edge technology with user-centric innovation to set supply chain storage standards for the flexibility, high speed utilization and the efficient handling of diverse pallet types. This fully automated, multi-deep storage system combines the expertise of both companies to meet the unique needs of the US market.

MULTIFLEX System Mother Child Shuttle System

-

The MULTIFLEX from DAMBACH sets new standards for throughput, flexibility and efficiency. It comprises three perfectly coordinated modules with seamless interfaces: the proven COMPACT SHUTTLE, the high-performance vertical conveyor LIFT and the newly developed CARRIER. In analogy to the small-part-shuttle technology, the MULTIFLEX enables multi-deep storage and highly dynamic commissioning of various types of pallets. In addition, the compact design of the DAMBACH-shuttles and vertical conveyors ensure a very high storage density.

With this modular structure, the MULTIFLEX is flexibly adaptable to different challenges. The fields of application for this pallet-shuttle-system are as variable as its three configurations. It is suitable, for instance for cold storage, buffer storage, dispatch warehouses, sequence storage, commissioning warehouses or supply warehouses – But also for compact warehouses with low throughput.

Stacker Cranes for Heavy Loads

-

Heavy-duty SRM MAGNO - Specialized for large loads

Handling heavy loads is a demanding task, especially for storage and retrieval machines that have to meet special material and design requirements. The MAGNO series has been specifically designed to meet these challenges in various industries. In heavy-duty environments, where heavy materials are used as load carriers, a robust design is essential to ensure safe handling.

MAGNO at a glance:

- Torsion resistant twin mast design for maximum stability and safety

- Two running wheels and one S54 guide rail for a smooth and precise movement along the storage racks

- Maximum height of up to 25 meters for efficient use of vertical storage space

- Two suspension cables for easier maintenance, reduced operating costs and increased availability

- Maximum payload of up to 12 tons to handle a variety of heavy loads

MINI Automatic MINI-LOAD SRMs

-

MINI Rail-Guided Storage and Retrieval Machines: Small Loads and Great Heights

DAMBACH offers various mini-load stacker cranes for the storage and transport of small load carriers. The storage of small loads up to 100 kg and an overall height of 12 m as well as loads up to 300 kg and an overall height of 27 m is possible.

Depending on the application, an efficient aluminum design or a robust steel construction is used. Depending on the requirements, this optimizes energy consumption and minimizes the forces occurring in the rack and rail system. The compact design results in particularly low approach dimensions, both horizontally and vertically. This makes DAMBACH small parts storage and retrieval machines suitable for perfect space utilization. Thanks to the development and production of our own load handling devices, a wide range of load carriers such as cardboard boxes, containers and trays can also be reliably stored and retrieved. Depending on the load, a combination telescopic table, box grabber or clamping gripper are available. Thanks to our own production, interfaces between the stacker crane, load handling device and load carrier can be customized. To make a technically sophisticated device perfect, it also needs the control system tailored to it. Installation space is reduced by up to approx. 60 % through decentralized controls and integrated terminal boxes. This means that more space is available for parking. With DAMBACH energy recovery, operating costs can additionally be reduced.

MONO Aisle-bound storage retrieval machines

-

Aisle-Bound Storage Retrieval Machines: the MONO Series

The aisle-bound MONO series has proved a favourite with customers because of its optimum use of space. Minimum approach dimensions at the end of the aisle and at the top and bottom of the travel plus no-buffers end-of-aisle protection permit full exploitation of the storage space. And then there’s the speed factor as well: good travelling speed and acceleration figures ensure efficient storage and retrieval, also during peak times.

Depending on requirements, our MONO storage retrieval machines (SRMs) can be fitted with one, two or three drives. Where very high maneuverability is required, DAMBACH also makes use of an interlocking drive concept with a toothed rack. That results in throughput rates that are otherwise only seen in automated small parts warehouses. Another benefit of the toothed rack drive is the low load on the running wheels and the rails.

MULTI- Curve-going rail-guided SRMs

-

From Aisle to Aisle: MULTI Rail-Guided Storage and Retrieval Machines

The rail-guided storage and retrieval machines of our MULTI series are curve-going models and can reach every storage aisle effortlessly via special rails and points—directly, quickly, and safely, and without the need for a costly mechanical traverser. So operations are not interrupted. This clever solution for changing aisles improves access times considerably in any warehouse system.

When equipped with suitable load handling elements, MULTI storage and retrieval machines (SRMs) are extremely versatile. They can be supplied as single or twin mast versions for handling practically any type of load, from drinks to car bodies. DAMBACH designs and produces its own load handling attachments tailored perfectly to the respective lifting unit. For example, double-deep telescopic forks for utilizing the available space more effectively, or rotating/traverse forks with adjustable tines for handling closed pallets. Therefore, MULTI rail-guided SRMs are suitable for a whole range of applications in automated high bay warehouses.

COMPACT SRM for floor-level loading

-

Storage and retrieval machine for existing rack systems: COMPACT

The ultra-light COMPACT storage and retrieval machine opens up flexible options for use in existing warehouses. The consistently lightweight design reduces kinematic loads on the floor panels and conserves energy. Transverse forces in the rack are also minimal. A lower approach dimension of 0 millimeters allows the use of conventional stacker racks. No storage space is lost in the lowest rack level.

Depending on the application, the COMPACT machines can be equipped with a variety of load handling attachments. High handling capacities and individual location access are achieved with single- or double-deep telescopic forks from DAMBACH. With the patented rotating and swiveling traverse fork, pallets can be picked up or set down at floor level to meet the needs of manual warehouse operation. The tilting device even makes it possible to transport pallets with closed bottoms.

Materials Handling: Conveyors for High Demands in Distribution and Production

-

With its diverse range of conveyor components, DAMBACH pallet-handling technology ensures perfectly coordinated interfaces between rail-guided storage and retrieval machines and materials handling systems.

Our variable all-inclusive pallet-handling packages guarantee fast and effective materials flows from the warehouse to the apron. With a diverse range of components available, we can ensure that all pallets and mesh box pallets are handled safely and reliably. Clearance, pallet runner and contour monitoring systems are available to check the load and the many different load carriers. DAMBACH materials-handling technology is a reliable partner on the apron ‒ as is shown by the features listed below.

Features:

- High throughput rates with speeds of up to 0.5 m/s

- Transporting up to 300 pallets per hour depending on application

- High storage bay loads of up to 1.500 kg

- Operating temperatures between -30 and +40°C

- Smooth, careful pallet transport

- Low transfer heights

- Factory pre-wired

- Long-lasting, highly energy-efficient, environmentally friendly designs

Conveyor Systems: Materials Handling and Rail Guided Vehicle (RGV) System

-

With its diverse range of conveyor components, DAMBACH pallet-handling technology ensures perfectly coordinated interfaces between rail-guided storage and retrieval machines and materials handling systems.

Our variable all-inclusive pallet-handling packages guarantee fast and effective materials flows from the warehouse to the apron. With a diverse range of components available, we can ensure that all pallets and mesh box pallets are handled safely and reliably. Clearance, pallet runner and contour monitoring systems are available to check the load and the many different load carriers. DAMBACH materials-handling technology is a reliable partner on the apron ‒ as is shown by the features listed below.

Conveyors

-

DAMBACH chain conveyors consist of self-supporting chain strands mounted on a rigid frame. The number of strands can be varied to suit the application. Duplex chains with straight side plates guarantee careful transport of your goods on an optimised support surface. Chains are supported on low-friction slide rails and can be individually tensioned. All chain strands are driven via a common driveshaft fully enclosed for safety. The mounting frames bolted to the main frames are height-adjustable.

- High throughput rates

- Travelling speed up to 0.5 m/s and acceleration up to 0.8 m/s²

- Max. 1,500 kg per storage position

- Long-lasting, many parts with high-quality galvanised finish

- Simple maintenance with many identical parts

- Decentralised control concept via data and power bus

- Frequency-controlled drives for soft starting

- Logic elements and frequency controllers integrated into drives

Nodes

-

DAMBACH lift tables are efficient transfer units for mergers, crossings or branches in flows of materials. Roller or chain conveyors can be integrated as required. The interlocking lift mechanism combined with a rigid frame protects the unit loads and ensures optimum availability. As an option, variable intermediate lift positions can be included to ensure greater flexibility. The compact dimensions and safety guards expand the range of applications.

Turntables can divide or merge flows of materials without changing the orientation of the unit loads. The highly dynamic turntable drives from DAMBACH are interlocking units and ensure precise rotational angles of up to 270° with any number of intermediate stops. For optimum occupational safety, our turntables can be fully enclosed. In addition, the innovative modular design guarantees numerous and diverse applications and ease of servicing at the same time.

- Designed for high throughputs

- Max. 1,500 kg per storage position

- Long-lasting, many parts with high-quality galvanised finish

- Simple maintenance with many identical parts

- Decentralised control concept via data and power bus

- Frequency-controlled drives for soft starting

- Logic elements and frequency controllers integrated into drives

Vertical Conveyors

-

The DAMBACH Vertical Conveyor lifts efficiency to the next level. The free-standing steel construction utilizes warehouse space optimally. The consistent use of poka-yoke techniques and modularcube design allows both fast installation as well as subsequent positioning in confined conditions. Almost any flow of materials can be taken care of with diverse load-handling devices and conveyor elements – two pallets lengthwise or crosswise, a corner transfer module with or without a change of orientation of the conveyed item, and much more. The DAMBACH Vertical Conveyor is one of the highest performing on the market. Each jack can be delivered with preinstallation and decentralized controls. Deepfreeze compatibility up to -28°C comes included at DAMBACH.

- Compact construction, small lower approach dimensions

- Inherently stable multiple-column design for heavy loads: up to 3,000 kg

- Lift speeds up to 240 m/min, lift heights up to 35 m

- Hoist drive with chains or cables – depending on the required performance

Transfer Wagon

-

The transfer car is based on the innovative DAMBACH Shuttle technology, using power caps for energy storage – making bus bars unnecessary. However, if required a traditional energy supply via bus bar or cable chain is possible. The transfer car can be equipped with up to two load handling devices or with roller or chain conveyors.

- Good throughput rates

- Low height

- Low installation requirements

- With one or two load-handling units

- With optional transfer unit for safe transfer of mesh box pallets

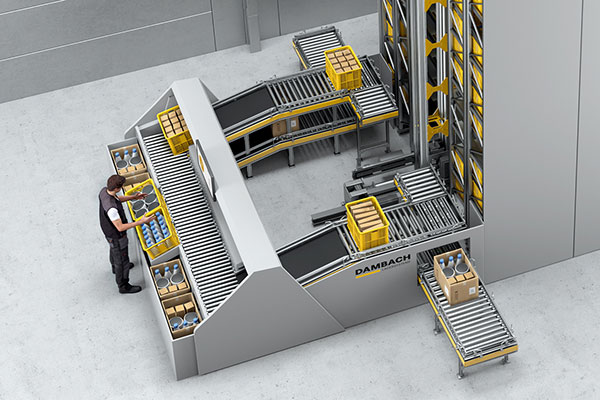

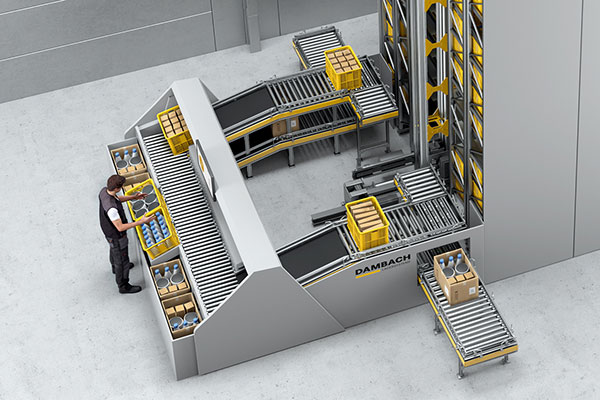

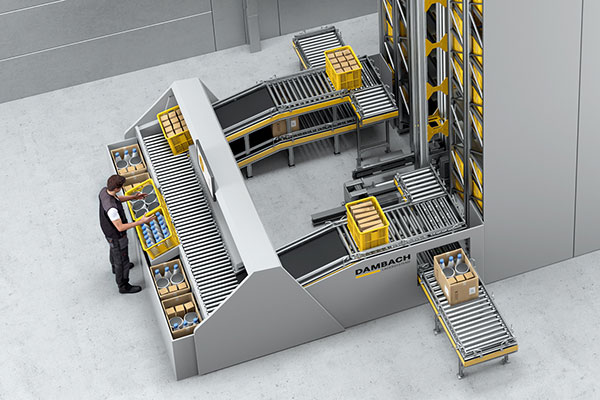

Small Parts Materials Handling

-

High performance with the new DAMBACH conveyor modules for totes, cartons and trays. With decentralized conveying functions and standardized modules, a wide range of material flows can be mapped easily and quickly.

All modules are perfectly matched and can be freely combined. Also thanks to the high level of standardization of individual assemblies. This not only increases flexibility, but also reduces spare parts inventories. The comprehensive container conveyor technology modular system consisting of roller cams, lift converters, infeed and discharge conveyors, accumulating roller conveyors, belt conveyors, lifters and leaves nothing to be desired. Our sales department supports you from the planning phase through layout design to implementation.

The robust design with integrated cable ducts and sensors ensures maximum functional reliability. Motor rollers and side guides are easily accessible without time-consuming disassembly of the cover. A well thought-out hole pattern allows quick attachment of add-on parts and stepless adjustment of the supports.

Small Parts Materials Handling

-

Thanks to the uniform power supply of the control and drive systems, installation expenses are reduced to a minimum. With the consistent 24 V technology, maintenance costs can also be kept low. Sensors and actuators such as motor rollers are suitable for plug & play - time-consuming wiring work is eliminated. All conveyor modules can be commissioned at the factory for quality control.

- Variable roller pitch

- Decentralized control concept

- Drive with motor rollers

- Uniform power supply

- Extensive construction kit

Rail Guided Vehicle (RGV): MONOFLEX System

-

High Throughput Rates and Maximum Scalability

This rail guided vehicle system MONOFLEX is powered by inductive energy. The smart track guided vehicles run on floor mounted twin rails. The MONOFLEX system sets new standards in terms of throughput, flexibility, and scalability. True to the motto “dynamic warehousing”, this rail guided vehicle system from DAMBACH Lagersysteme provides a high-performance conveying system for the apron in warehouse systems, or functions as an alternative to conveyor systems with continuous conveyors. For example, the MONOFLEX can form the ideal complement to the MULTIFLEX pallet shuttle system.

This rail guided vehicle system from DAMBACH consists of high-performance transport carts and a twin rail track. The track is made from anodized aluminum, which is not only robust, but easy to install. Simple switches ensure good availability, even in the case of complex plant layouts. With a 1:1 distribution of the material flow, the fast switching times of the switches enable throughput rates of up to 450 carts per hour. Fast cart changeovers and the inclusion of additional carts are therefore no problem, e.g. to reach peak performance in material flows.

Load-Handling Devices

-

From Telescopic Fork to Shuttle

DAMBACH Lagersysteme has been developing and producing its own load handling equipment for stacker cranes and conveyor technology for over 45 years. Possible storage goods include containers, crates, cartons, trays, lattice boxes and pallets. Depending on the load carrier, various load-handling devices are used, such as telescopic forks, telescopic tables, belt conveyors, box grabbers, roller conveyors, chain conveyors and shuttle vehicles. For problematic cargo, additional lifting, pushing or tilting devices are used. The need for functional reliability and durability has always been the company's top priority. Load handling devices form the heart of its storage and retrieval machines in particular, and help to ensure the safe and precise handling of loading aids. In conveyor systems, load-handling devices are used in particular with distribution trolleys. They can also be used in combination with other conveyor technology elements (e.g. vertical conveyors or transfer units). High reliability and short transfer times are the key characteristics of all DAMBACH load-handling devices.

Multi-Deep Storage

The Extension Arm of the Storage and Retrieval Machine

The DAMBACH COMPACT SHUTTLE for high bay warehouses, makes pallet storage and retrieval even more efficient. Used in conjunction with rail-guided storage and retrieval machines, the COMPACT SHUTTLE enables warehouse operators to achieve really compact, multi-deep pallet storage. To do this, the storage lanes are fitted with rails on which the shuttles can run. Shuttle and storage and retrieval machine (SRM) therefore form one logistical unit: the shuttle runs on the rails to the allotted storage position where it sets down or picks up a pallet, and the SRM transports the shuttle to the correct storage or retrieval point in the warehouse.

Communication between the parent vehicle and the COMPACT SHUTTLE is by way of a point-to-point radio link. This link monitors itself permanently to guarantee maximum communication reliability.

Especially a combination of transfer cars and COMPACT SHUTTLE can reduce the energy usage, while maintaining a high throughput capacity. This way the DAMBACH COMPACT SHUTTLE can demonstrate it´s strengths in the pallet-handling sector.

Compact shuttle for standardized Pallets

- The DAMBACH COMPACT SHUTTLE for high bay warehouses, makes pallet storage and retrieval even more efficient. Used in conjunction with rail-guided storage and retrieval machines, the COMPACT SHUTTLE enables warehouse operators to achieve really compact, multi-deep pallet storage. To do this, the storage lanes are fitted with rails on which the shuttles can run. Shuttle and storage and retrieval machine (SRM) therefore form one logistical unit: the shuttle runs on the rails to the allotted storage position where it sets down or picks up a pallet, and the SRM transports the shuttle to the correct storage or retrieval point in the warehouse. Communication with the COMPACT SHUTTLE is by way of a point-to-point radio link. This link monitors itself permanently to guarantee maximum communication reliability. Especially a combination of transfer cars and COMPACT SHUTTLE can reduce the energy usage, while maintaining a high throughput capacity. This way the DAMBACH COMPACT SHUTTLE can demonstrate it´s strengths in the pallet-handling sector.

Semi shuttle for variable load carriers

-

Efficient, flexible and sustainable warehouse management is a decisive factor in intralogistics. Storing different types of pallets in one rack is a particular challenge. The DAMBACH SEMI SHUTTLE offers a solution for optimum use of space and room as well as for the safe transportation of loads. The half-pallet shuttle enables the efficient management of Euro pallets and plastic Düsseldorf pallets (KDP) in a single automated storage environment. The special feature is the synchronous operation of two half-pallet shuttles and the independent operation of one shuttle at a time for transporting a pallet. Additional support points increase stability in the rack channel.

SEMI Shuttle at a glance:

- Half-pallet shuttle with power caps

- Payload of up to 800 kg per shuttle

- Wireless communication

- On-board control

- Combined function sequence with two half-pallet shuttles possible

- Optimized sensors for black plastic pallets

- All-wheel drive

Controls for stacker cranes

-

Simple operation and maximum operational reliability

Control systems decide how economically and reliably warehouse systems work. DAMBACH therefore combines expertise and experience with knowledge of this branch of industry and the latest technology.

The result is a wide range of solutions covering all the requirements of high bay and small-parts warehouses and the apron. From simple, low-cost controls for stacker cranes or materials handling systems to standard applications for fully automatic stacker crane operations – and with energy recovery if required.

The high modularity of our concepts also allows us to provide bespoke solutions that still include a high number of standard modules. So users obtain a uniform, consistent operating concept.

Multi-stage control solutions: from pre-installed wiring to control hardware to integrated software.

Minimum capital outlay

Maximum security for your warehouse investments

Our control modules for rail-guided stacker cranes and materials handling elements are based on SIMATIC-S7 or Allen-Bradley control systems. The universal use of fieldbus solutions on the sensor/actuator level reduces installation costs to a minimum, avoids sources of errors and permits cost-effective expansion at a later date. Decentralised technology makes the systems scalable and permits reliable, continuous use even under the toughest operating conditions. The coupling to a master computer is achieved either via a standardised communications interface or via flexible, programmable interfaces in the materials-flow computer which, for example, also permits a direct link between warehouse system and SAP.

The visualisation systems include comprehensive logging and statistics functions. All packages offer the option of remote diagnosis and permit remote access for rectifying problems – to relieve operating personnel yet further.- Efficient rail-guided stacker crane controls with energy recovery

- Program components for materials handling

- Upgrade options for strategy, backup and redundancy concepts

- Minimum installation costs

- Short commissioning times

- Standard interfaces

- Windows-based materials-flow and graphic display concepts

- Links to a huge range of warehouse management systems, including SAP-LES

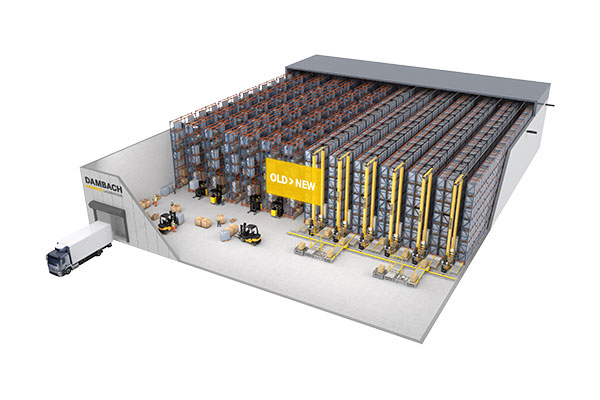

Modernisation

-

Modernisation: optimising existing warehouses and plants

Flexible responses to suit different life cycles

Even a warehouse system can become out of date. Or changing boundary conditions could make it necessary to modify or optimise a warehouse or add new functions. And the individual components of a warehouse system have different “lifetime expectancies”. Whereas the mechanical components might remain in use for 20 years or more, the efficiency of a control system could need upgrading after just 10 years or even earlier. In other words, some components in a warehouse age faster, thus constituting a risk and curbing progress.

DAMBACH has been established in the warehouse systems market for 40 years. The fact that the market is constantly changing and suppliers come and go is therefore irrelevant. Because our efficient modernisation concepts can also optimise installations when their manufacturers have gone out of business or no longer provide support for warehousing technology. This is where DAMBACH can exploit design and production synergies and offer convincing concepts for all modernisation projects.Making materials flows fit for the future

Innovative ideas for modernisation

Existing facilities can also benefit from the expertise and experience of the experts at DAMBACH. A well-conceived modernisation concept can bring mechanical elements and controls up to the latest standard. Our range of services covers the complete materials-flow strategies of small and midsize high bay warehouses with apron and order-picking. So even with older facilities it is possible to benefit from state-of-the-art technology and innovative ideas – and hence increase the productivity of your warehouse.

- Workshop for problem assessment

- Analysis of the facility

- Preparation of an updating concept

- General inspection with replacement and overhaul of critical components

- System modifications and conversions

- Re-commissioning and test runs

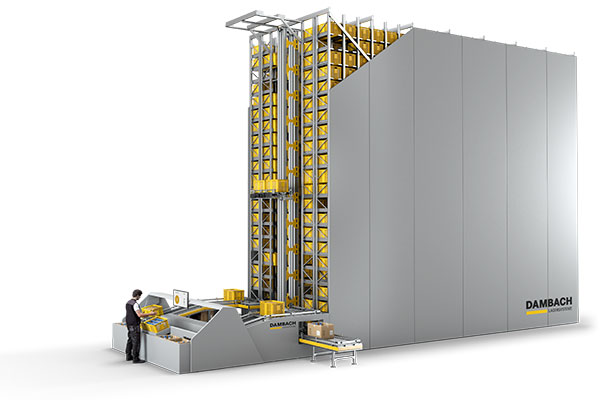

Automation Existing Warehouse

-

LOGI-KIT is the automation alternative for existing warehouses with and without forklift operation. Whether wide-aisle or narrow-aisle warehouses, retrofit automation for pallets and small parts makes logistics fit for the future. Production, trade and logistics service providers benefit equally from LOGI-KIT:

- More efficient use of space

- Higher storage and retrieval performance

- Economic picking

- Designed for pallets and small parts

LOGI-KIT offers everything from a single source: consulting, profitability calculation, provision of warehouse technology and coordination of implementation, service and support with financing.

Whether large load carriers such as Euro pallets, industrial pallets, half pallets or small load carriers such as Euro containers and cartons. DAMBACH Lagersysteme offers decisive advantages through modern technology:

- Best possible performance and cost efficiency ("goods to person")

- Consistent lightweight construction

- Can be installed in existing buildings

- Minimized energy consumption for more sustainability

- Implementable during operation

- Reduced risk of accidents or damage

- Use of existing infrastructure up to the shelf

- Access protection for stored goods

ZERO

-

Maximum automation, minimum investment

The LOGI-KIT ZERO automation solution is a cost-effective alternative to forklift operated warehouses. Whether wide-aisle, narrow-aisle or high-bay warehouses, it’s the ideal solution for efficient storage and retrieval of pallets or goods-to-person picking of individual items. Thanks to simple and quick implementation of the LOGI-KIT automation solution, you can easily update your manually run warehouse. Together, we analyze the potential of your warehouse and transform your warehouse logistics into an Industry 4.0 powerhouse.

Besides the production of sophisticated storage and retrieval machines as well as suitable materials handling technology, our competences also include material flow analysis: Analysis of the current situation on site, estimation of the potential, cost-benefit analysis and rough planning. In each project, our aim is to reduce your operating costs and increase the profitability of your warehouse. For example, power consumption can be reduced by up to 2/3 per pallet movement and current operating costs cut by up to 80%. Requirements for future storage capacity and handling frequency can also be considered in planning. Automation and optimized material flows make your warehouse future-proof.

- Analysis: Based on an assessment of the warehouse infrastructure, material flow, and storage data, the current situation is identified and compared with the customer’s target specifications

- Rough planning: A suitable automation solution is developed in collaboration with the customer based on the analysis and target specifications

- Potential estimate: The analysis and rough planning form the foundation for estimating the automation potential of your warehouse and the required investment

- Cost-benefit analysis: The automation benefits and cost savings are compared in relation with the required investment to determine the return on investment (ROI)

INFINITY

-

Maximum storage density thanks to intelligent position management

LOGI-KIT INFINITY features state-of-the-art, reliable shuttle technology. Using a channel storage rack system increases the storage capacity of your warehouse significantly. Different building geometries all the way to sloped roofs can be optimally utilized. At the same time, this solution offers flexible scaling options in terms of performance. Thanks to the powerful material flow system, channels can be filled with various articles (SKUs) – unparalleled in automated channel storage.

Besides many years of experience with warehouse technology such as the pallet shuttle system, DAMBACH also offers consultation in stock analysis, potential estimates, profitability calculations, and concept design. Together with the customer, DAMBACH develops needs-based, individual guidance. LOGI-KIT INFINITY aims to meet customer requirements for a greater storage density while lowering operating costs. Energy and personnel savings help reduce position costs by up to 50%. With its short implementation time and manageable investment, LOGI-KIT INFINITY is the cost-effective alternative to a new building in many cases.

- Analysis: Based on an assessment of the warehouse infrastructure, material flow, and storage data, the current situation is identified and compared with the customer’s target specifications

- Rough planning: A suitable automation solution is developed in collaboration with the customer based on the analysis and target specifications

- Estimation of potential: The analysis and rough planning form the foundation for estimating the automation potential of your warehouse and the required investment

- Cost-benefit analysis: The automation benefits and cost savings are compared in relation with the required investment to determine the return on investment (ROI)

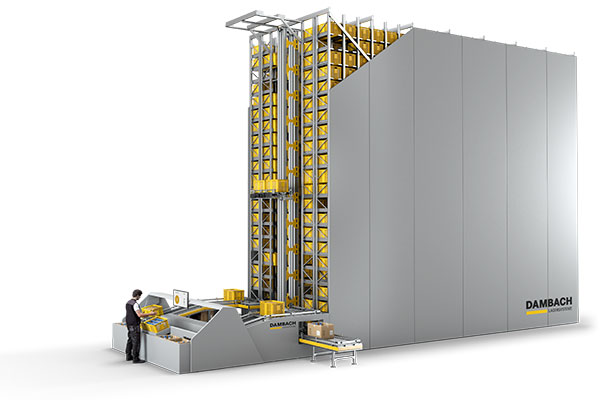

MINI

-

Efficient small parts storage in the tightest space

Automated small parts storage for a wide range of applications – whether as picking-, buffer- or distribution storage. A variety of small parts carriers and small containers can be stored efficiently with the LOGI-KIT MINI. The system is thereby as flexible as your requirements. Load weights can vary between a few grams up to 300 kg. With storage heights from 3 to 27 m, it can be integrated easily into many buildings.

High goods throughput means that the system is perfectly suitable as a "micro-fulfillment" system in the tightest space. Cartons, Euro containers and trays are automatically transported to the picking station. The "goods-to-person" principle leads to the elimination of unproductive order picking way times and time needed for order fulfillment is reduced. Ergonomically designed workspaces with a tilting and lifting mechanism thereby help further increase picking performance. Various picking systems can be fully integrated, including Pick-by-Scan, Pick-by-Light and Pick-by-Vision. Errors are thus avoided and the storage- and picking process becomes more efficient and economical.

Depending on the application, LOGI-KIT MINI can adapt to your special requirements. In addition to allowing for a variety of containers, the LOGI-KIT MINI adapts to your needs for storage capacity and performance. The shelf storage and retrieval machine is therefore available in various configurations for storage at single-, double- or multi-depth. In addition, a number of products can be stored in one space for increased product variety. Random access to each product in the assortment is always maintained.