- Offer Profile

-

Linde Material Handling, a KION Group company, is a leading global manufacturer of forklift and warehouse trucks, and a solutions and service provider for intralogistics. With sales and service locations in more than 100 countries, we are close to customers in all major regions around the world.

Drawing on over 100 years of experience in providing material handling solutions to customers in virtually every industry, we help our customers to optimize their entire material handling process. Our experts analyze all workflows from goods-in to goods out and together with the customer they create solutions which fully meet their individual requirements. In doing so, Linde guarantees smooth implementation, reliable commissioning and responsive service.

FORKLIFT TRUCKS AND WAREHOUSE TRUCKS

-

Always the right product for you

With 77 product lines, Linde Material Handling offers customers the broadest range of intralogistics products. With the different chassis and mast variants, battery sizes, designs and cabins, as well as a large amount of special equipment available, the products are always configured to meet the respective requirements.

AUTOMATED TRUCKS

-

Technology in flux

Driverless around-the-clockAutomated logistics trucks are the future of the efficient flow of materials. They take over tiring transport tasks from employees, increase the handling volume, and reduce the error and accident rates in the warehouse. Linde Material Handling offers a wide range of cutting-edge automation solutions with electric forklifts, pallet trucks, and tow tractors from the MATIC series. All models are equipped with intelligent navigation and safety technology, but can also be maneuvered conventionally via manual control.

P-MATIC : POWERFUL ROBOTIC TOW TRACTOR

-

Versatile load transport in all areas of operation

The autonomous Linde P-MATIC electric tow tractor with operator platform is designed for load transfers in work areas with restricted space. It can move towing loads of between 3000 and 5000 kilograms. Typical uses in warehouses and industrial businesses include the delivery of production materials, disposal of waste products, and hauling of larger loads. The tow tractors, whether as individual vehicles or part of an autonomous fleet, thereby form an integral link in the supply chain - from production to the delivery area. The versatile and robust vehicles have powerful, maintenance-free drive motors with high torque.

L-MATIC : A POWERFUL PALLET LIFTER

-

EFFECTIVE LOAD HANDLING FOR LOW LIFT HEIGHTS

The Linde Material Handling L-MATIC pallet stacker is suitable for storage or removals at low level. It tackles loads of up to 1,200 kg and lift heights up to 1.9 meters. Thanks to infrastructure free geo-navigation, the L-MATIC can be used flexibly as an individual truck or as part of an automated fleet. When operating in this manner, the robotic forklift is able to integrate safely and efficiently with people, non-automated trucks or the customer's infrastructure, such as belt conveyors or packing stations. Furthermore, manual operation is possible at any time, used to, for example, move the equipment away from a dangerous zone quickly in the event of an emergency, or to use the truck to carry out another short-term task.

L-MATIC HD/HD k

-

Ideal for heavy loads and high lifting heights.

The automated L-MATIC HD pallet stacker is ideally suited for the storage and retrieval of Euro and industrial pallets in wide-aisle warehouses and as an infeed truck for narrow-aisle applications. The truck is available in two versions, the L-MATIC HD and the L-MATIC HD k. Both models lift loads of up to 1,600 kilograms and reach lift heights of up to 3.5 meters. The combination of powerful hardware and intelligent software results in significant performance benefits. A wide array of sensors for load and environment detection ensure high process reliability. Various localization procedures ensure that the trucks can be optimally adapted to the processes on site. The comprehensive safety concept protects the load, trucks and the environment. Both trucks are available with either lead-acid batteries or lithium-ion batteries. They are designed for 24/7 operation and automatically seek out the charging station when their charge level is low.

L-MATIC AC : EFFICIENT PALLET STACKER

-

Counterbalanced stacking and transporting

The autonomous Linde L-MATIC AC pallet stacker with cantilevered forks simplifies transport of closed carriers and the receipt of goods at transfer stations which are not accessible with load wheel supports, for example on conveyor systems. The counterbalanced truck, which can also be operated manually at any time, can handle loads of up to 1200 kilograms and lifting heights of 1.9 meters. It can be used individually or integrated as part of an automated fleet. The intelligent navigational system functions without the addition of tracks in the floor or laser reflectors. The L-MATIC AC can therefore be used flexibly, in a wide variety of different environments or in environments which change frequently. Its comprehensive suite of safety features reliably perceives people and obstacles in its area of operation.

K-MATIC : FUNCTIONAL LOGISTICS ROBOT

-

Reliable logistics in narrow aisle warehouses

The Linde K-MATIC autonomously driven turret truck is suitable for loads of up to 1,500 kg and lift heights of up to 12 meters. The intelligent geo-navigation system guides the K-MATIC safely without additional guide rails in the floor or laser reflectors, and is compatible with all common narrow aisle applications. Whether as an individual truck carrying out defined process steps, or as part of a centrally controlled fleet of robotic trucks, the superior functionality of the K-MATIC provides high handling performance even for complex operating requirements. When doing so, the truck interacts seamlessly with the customer's infrastructure, such as belt conveyors or packing stations.

As an autonomous logistics truck, it mitigates damage to loads and pallets and is particularly well-suited to the handling of high-value goods. Quick and easy to maintain, the robotic truck can be relied upon to be ready for use round-the-clock and can also be operated manually by a driver.

R-MATIC : AUTOMATIC PRECISION LIFTER

-

Efficient and precise handling at high lifting heights

The autonomous R-MATIC reach truck transports and stores and retrieves goods up to 1600 kg at heights of up to more than eleven meters. The range of masts means that it is especially suited to handling at medium to high lifting heights and to supplying workstations, as well as being suitable for warehouses or material transportation. The R-MATIC uses its innovative 3D camera to detect the storage location in the rack and the pallet openings. It can store and retrieve its load precisely by adjusting the prongs. The truck's geonavigation does not require any additional infrastructure and it interacts safely and efficiently with individuals, non-automated trucks, or conveyor belts and packing stations. Dual Mode means that the R-MATIC can also be controlled manually.

Autonomous mobile robots (AMRs) from Linde Material Handling

- Autonomous mobile robots (AMRs) are becoming increasingly important in modern intralogistics. The driverless platform trucks are used for automated or partially automated goods transport and thereby noticeably increase efficiency in warehouses and logistics hotspots. With their low heights, they pass under transport racks and trolleys, or lift pallets from transfer racks, taking them to the defined destination independently. They detect and avoid any obstacles en route themselves. AMRs either use QR codes attached to the floor or laser-assisted natural feature navigation as orientation. With the autonomous C-MATIC and C-MATIC HP guided carts, Linde Material Handling offers compact AMR models for automated material flow.

C-MATIC : FLAT LOAD CARRIER

-

Driverless transport in the tightest spaces

The C-MATIC automated mobile platform from Linde Material Handling is ideal for transporting material over short and medium distances in confined spaces. The load can be picked up and set down together with trolleys that the C-MATIC can drive underneath. Transport between static reloading stations or conveyor belts is also possible. Depending on the model, the automated platform can handle maximum loads of 600, 1000, or 1500 kilograms. Routes and transport orders are controlled via software. The mobile platforms navigate within the space using the QR codes affixed to the floor, stop automatically in front of obstacles, or drive round them. The safety technology and extremely compact external dimensions mean that C-MATIC trucks can also be used in places where pedestrians and other trucks are moving around. The applications of the C-MATIC trucks can be changed flexibly or expanded by combining them with additional trucks.

C-MATIC HP

- The C-MATIC HP detects anything in its immediate vicinity using a laser scanner and reacts instantly when people, trucks, or static obstacles are blocking its path. Thanks to real-time data processing, the truck can avoid any obstacles it detects and automatically find an alternative route. The precise movements of the C-MATIC HP ensure a stable load pick-up when transporting pallets or rolling racks. It is equipped with a customized adapter plate to provide additional stability when handling pallets. Emergency stop switches are located on both sides of the truck and can be easily reached in the event of an incident. With all these features, the C-MATIC HP offers an optimum combination of flexibility, productivity, and the highest possible levels of safety.

E-TRUCKS

-

Electronic Compact Drive for Precision and Performance

Versatile, Comfortable, and Cost-EffectiveLinde Material Handling offers a wide range of electric forklift trucks for loads weighing in at between 1000 and 8000 kilograms and for virtually any application from the worlds of industry and commerce. These trucks really shine thanks to their precision and agility, which together combine to ensure high handling performance.

In order to be able to transport loads quickly, Linde has developed powerful drive technology with sensitive traction and incredibly precise steering. The entire range of Linde electric forklift trucks feature a maintenance-free compact axle with two independent wheel motors, allowing the truck to be maneuvered down to the last millimeter via the dual pedal control.

Linde electric forklift trucks offer both comfort for the driver and cost-effectiveness, and all with Linde's trademark safety concept. This includes, among other things, a robust protective zone for the driver and the optionally available Linde Safety Pilot driver assistance system that provides extra safety when handling loads.

E20 - E35 : HIGH PERFORMANCE INDOOR SPECIALIST

-

Safe and quick in tight spaces

The E20 – E35 electric forklift trucks are ideally suited to indoor use. Their compact design and agility ensure high handling capacities even in tight spaces. In particular, the twin-motor front-wheel drive together with the Linde combined steering axle facilitates exceptional maneuverability. Thanks to a common platform for both electric and combustion engine trucks, the electric forklifts further impresses with improved ergonomics and by a generous driver workspace. The synergies of this platform means the electric forklift truck gives the driver significantly more space and an especially comfortable operating experience.

E35 - E50 : THE VERSATILE LOAD CARRIER

-

Maximum Performance for a Wide Range of Applications

The E35 - E50 series offers powerful electric forklifts with a load capacity of 3.5 to 5 tons and a comprehensive range of construction and equipment variants in order to best meet a wide variety of application requirements. These include compact models for confined spaces as well as trucks with long wheelbases for bulky loads. Two powerful three-phase AC motors built into the compact front axle, together with control elements designed for precision and intuitive operation, ensure high handling performance. The driver is able to control the driving direction and acceleration with dual pedals, and the lifting functions with the Linde Load Control joysticks integrated into the armrest - without unnecessary physical strain. Top-mounted tilt cylinders and electronic traction control ensure safe load handling. The optional on-board charger offers additional flexibility and cost-effectiveness.

E60 - E80 : ELECTRIC POWER PACK

-

Electric Power for Heavy Loads

The powerful E60 - E80 electric forklift models from Linde are designed for efficient and safe handling of heavy loads of up to 8,000 kilograms. The forklifts are driven by two powerful three-phase AC motors integrated into the compact axle with maintenance-free brakes. The electronic vehicle control as well as the precisely operable control elements such as the Linde Load Control and the double pedal control ensure the perfect interaction between man and machine. Linde's energy management system also contributes to the high cost-effectiveness of the large electric forklifts.

E10 : AGILE ALL-ROUNDER

-

Versatile Load Handling in Confined Spaces

The compact E10 electric forklift truck from Linde Material Handling combines high maneuverability with a wide range of application options. With a lifting capacity of up to 1,000 kilograms, it is the smallest model in its series but is suitable for a multitude of applications thanks to its optimal weight distribution. Its short wheelbase, compact construction with a width of just 828 millimeters and optimal steering concept enable stacking, transporting, order picking, loading and unloading, even in the tightest spaces. Automatic speed reduction when cornering also gives the E10 high stability.

X20 – X35 : ELECTRICALLY POWERED HIGH PERFORMERS

-

The first truly emission-free alternative

The X20 – X35 counterbalance forklift trucks from Linde Material Handling are the first electric forklifts whose high performance and robustness means they can be used as a genuine alternative to internal combustion (IC) trucks. Customers therefore enjoy absolute freedom of choice and are able to choose a quiet, emission-free alternative for even the most challenging applications, without having to allow for any loss of performance. The basis for all of this is the common platform developed by Linde for counterbalance forklift trucks, whether powered by internal combustion engines or electricity. This means that the X20 – X35 forklifts combine the best of two worlds: the characteristic output and power development of IC trucks and the dynamics, flexibility, and freedom from emissions offered by electric trucks.

IC-TRUCKS

-

Hydrostatic Drive for Greater Handling Performance

Rapid handling processes are only possible if forklift trucks possess precision power transmission and control, which also saves time and increases handling capacity. For decades, Linde Material Handling has set the standards for productivity and efficiency in the development of internal combustion trucks.

The interplay of the hydrostatic direct drive, dual pedal control, and Linde Load Control, as well as the outstanding ergonomics of Linde trucks, ensure that the driver can quickly and precisely carry out all travel and lifting tasks at all times. Thanks to intelligent controls and the tuning of the diesel, propellant gas, and natural gas engines, the necessary output is always available.Safety is yet another essential principle for Linde's IC truck development, leading to a sophisticated design; all parts and components are exceptionally robust while still ensuring optimum visibility. What's more, a range of mechanical and electrical systems enhances both the trucks' active and passive safety levels.

Linde's wide range of internal combustion trucks covers a load bearing capacity of 1.4 to 18 tons.

H16 – H20 EVO : COMPACT AND ROBUST ENDURANCE RUNNER

-

Maximum working capacity at low service costs

The Linde H14 - H20 EVO IC trucks can go the distance even in the toughest conditions. The combination of the hydrostatic direct drive, robust engines, and the Linde Load Control facilitates both rapid and precise operation and exceptional handling performance. At the same time, service costs remain low, as the hydrostatic drive operates without a transmission, clutch, or drum brakes, meaning it is maintenance-free. Choose from a range of cost-effective, low-emission diesel, propellant gas, and natural gas engines.

H20 - H35 : ROBUST PERFORMER WITH ALL-ROUND VISIBILITY

-

Networked and Easy to Service for Maximum Efficiency

The IC truck H20 - H35 is powerful, easy to operate, robust, low-maintenance, and versatile. The forklift for loads between 2,000 and 3,500 kilograms is particularly well suited for high loads in multi-shift operation and assignments in the harshest outdoor conditions. Hydrostatic drive, dual pedal control, Linde Load Control, and optimal visibility ensure precise interaction between man and machine. Design details combined with intelligent assistance systems guarantee the highest possible levels of safety. The H20 - H35 can be integrated into software systems, e.g. for fleet management, via wireless data transmission. The truck fulfills the latest EU 5 (2016/1627) exhaust emission regulations and it even undercuts the required emissions massively.

H35 – H50 : ROBUST ALL-ROUNDER

-

Powerful and versatile in all applications

The reliable and robust H35 – H50 IC trucks for loads ranging from 3,500 to 5,000 kilograms are designed for maximum handling performance. Their hydrostatic drive together with the tough industrial engine ensure a powerful and precisely controlled drive performance in a wide range of driving and work situations. Extreme temperatures and dusty, uneven floors are no match for the robust forklift trucks. They are perfectly suited to intense continuous operation and the harshest outdoor operating conditions, such as in recycling companies or construction material yards. Long service intervals and maintenance-free components ensure outstanding availability. The dual-pedal control and Linde Load Control ensure exceptional comfort and efficient operation. The combination of perfectly tailored performance, robust construction, and efficient handling make the H35 – H50 IC trucks extremely productive and economical to operate.

H50 - H80 EVO : SUSTAINED PERFORMANCE

-

Impressive Operating Performance - Minimal Maintenance Breaks

Safe handling and high handling performance - with the H50 - H80 EVO IC trucks, the two go hand in hand. These robust trucks are ideally suited to heavy-duty applications with large loads. The protective driver's roof and frame form a single compact unit to ensure greater safety, while the slim profile of the lift mast improves the driver's vision. Powerful engines, the hydrostatic direct drive, and the Linde Load Control lift mast control system all guarantee high operational performance. Plus, the hydrostatic drive operates without a transmission, clutch, differential or drum brakes - reducing servicing time and further increasing handling capacity.

H100 - H180 D : THE AGILE HEAVYWEIGHT

-

Handle heavy loads precisely and swiftly

The H100 - H180 D IC trucks can transport even the heaviest of loads precisely, swiftly, and cost-effectively, securing a competitive advantage in terms of handling performance. All this is made possible by Linde's hydrostatic drive, which allows heavy trucks to be moved with millimeter precision. The driver can quickly and smoothly shift between backward and forward movement, while modern diesel engines guarantee high torque and low fuel consumption.

HT100 - HT180 Ds : AN EXTRA STRONG LONG-DISTANCE RUNNER

-

Cost-Effectively Transport Heavy Loads

The HT100 - HT180 Ds IC trucks are fast and efficient when handling heavy loads: a fact guaranteed by the well coordinated combination of modern diesel engines, transmission, and hydrodynamic drive. This technology ensures exceptionally strong handling performance, particularly for transport over long distances. What's more, drivers of trucks in this class benefit from excellent all-round visibility, as essential components, such as the mast and counterbalance, have been designed for optimal vision.

PALLET TRUCKS

-

Quick processes at short distances

Even for shorter distances you need the performance of the transport truck, because the pallet trucks have to master many difficult situations in a short time: Narrow aisles, tight truck loading bays or steep ramps make goods receiving and transport difficult. So that your handling capacity stays high under all circumstances, Linde Material Handling offers a large selection of particularly agile pallet trucks. They have compact and precise steering systems. This makes many maneuvers easier in tight environments.

The models with electric power steering also profit from powerful motors, which Linde combines with quick-reacting brakes. Often multiple braking systems are used, which complement each other. This makes transport from A to B not only faster, but also safe. The lifting capacity of the pallet trucks and pallet lift trucks from Linde ranges from 500 to 3.300 kg.

M25 : ROBUST TOOL

-

Rapid transport of heavy loads over short distances

The pallet lift truck M25 has a rugged construction and will not bend under heavy loads. Its steel chassis can take about 25 percent more weight than comparable models of this size. The hydraulics of the M25 are protected from dust and are well suited to long, hard working days, with a minimum of service. The drive wheels and rollers increase handling capacity with their low rolling resistance. The tiller also has a large steering angle on both sides. It's therefore easy to maneuver the M25 in a tight space, such as the truck loading bays. A broad tiller handle protects the hands from injury. The pallet lift truck M25 has a maximum load capacity of 2500 kg.

T20 – T25 RW : THE COMFORTABLE ALL-ROUNDER

-

Quick and convenient for versatile use

Thanks to its high-performance 3-kW three-phase motor, the T20 – T25 RW pallet truck from Linde Material Handling effortlessly achieves its top speed of 12 kilometers per hour. Even with a full load of 2500 kilos, it still reaches 10 kilometers per hour. While transferring pallets, the operator can enjoy a spacious 970 mm-wide chassis and a raised, comfortable seating position transverse to the direction of travel. This provides the best possible visibility of the warehouse environment at all times, both in front and behind the truck. The driver is able to control the transportation, loading and unloading of pallets with their fingertips using the intuitively arranged control elements. The pallet truck is especially suitable for quick pallet transfer, but also works for the occasional loading and unloading of containers or trucks.

M10 X/XE : FLEXIBLE WORK PLATFORM

-

Flexible transport, lifting, and order picking

The pallet lift trucks M10 X and M10 XE can lift their forks via scissor lift to a height of 800 mm and have a very compact design. This is why these trucks are used flexibly in transport tasks, as mobile working platforms, or for occasional order picking in the tightest of spaces. Linde offers two versions: The M10 XE model has an electric lift drive. The operator doesn't have to use any strength to lift or lower the load. In the model M10 X, lifting is initiated manually by the operator using the tiller. The direction of movement can be changed using a single lever located on the handle. Both models have a rugged, warp resistant chassis and a reinforced tiller. The pallet lift truck with scissor lift M10 X/XE can carry and lift a maximum load of 1000 kg.

MT15 : AGILE TRANSPORTER

-

Easy turning maneuvers in tight spaces

The MT15 electric pallet truck unfolds its potential above all on short distances and demanding terrain: narrow aisles, steep ramps and packed loading areas are no problem for the agile all-rounder. Its compact design, for example the truck's length including the back of the fork at only 400 mm, makes it easy to maneuver in narrow aisles in the warehouse or in retail stores. As a light weight of only 180 kilograms, the pallet truck can also be used in mezzanine floors. The electric traction and lifting performance relieve the operator, who hardly needs to exert any force to transport loads weighing up to 1.5 tonnes. The long tiller protects the operator, as they'll automatically keep a safe distance from the truck. The MT15 is particularly flexible with the lithium-ion battery, which allows intermediate charging.

MT15 C : COMPACT TRANSPORTER

-

Easy load transport in confined spaces

Whether in retail trade or in production areas, wherever hand pallet trucks have been used up to now, the MT15 C electric low-lift pallet truck can offer higher handling capacities with less use of force. In pedestrian mode, the pallet truck effortlessly transports loads of up to 1.5 tonnes. Thanks to its compact design, the truck is easy to maneuver even in narrow aisles and tight curves. When loading and transporting pallets at ground level over short distances, the compact truck is a cost-effective, powerful alternative to the manual hand pallet truck. The truck relieves employees of physically demanding transport tasks and contributes to higher productivity in the warehouse and quicker city deliveries.

T16 - T20 P : THE FAST CARRIER

-

Ergonomic Platform Solution for Fast Processes

The T16 P and T20 P pallet trucks from Linde Material Handling guarantee fast transport processes over shorter and medium distances. The highly responsive 1.2 kW engine very quickly reaches its maximum speed of six kilometers per hour - with and without load. In addition, the tandem load wheels ensure a good drive even on uneven ground. Service technicians can configure important operating parameters such as maximum acceleration to make the truck even more suitable for individual requirements. As a result, processes run more efficiently and safely. If necessary, the driver can fold up the stand-on platform. This turns the low-platform truck into a pedestrian model. The T16 P model has a load capacity of 1,600 kilograms, while the T20 P transports a maximum of 2000 kilograms.

T14 S, T20 - T25 S/SF : NIPPY AND AGILE

-

Productive, agile, and precise in narrow aisles

The T14 S, T20 - T25 S/SF pallet trucks have a particularly narrow chassis, barely wider than a pallet. Together with a precise electrical steering unit, this feature ensures that the pallet truck is perfectly maneuverable. You can increase handling capacity even in constricted spaces. The construction of the platform plays an important role. It is completely separate from the chassis and absorbs most vibration arising from uneven surfaces. The high standing position makes processes safer. From their position, the driver can keep an eye on the fork, and pick up pallets quickly. The T14 S, T20 - T25 S/SF pallet trucks have a maximum lifting capacity of 1400, 2000 or 2500 kg depending on the model.

T16 L : ERGONOMIC TRANSPORT AID

-

Transport and occasional order picking is more ergonomic, safer, and quicker

The pallet truck with order picking lift T16 L makes handling and occasional order picking easier. The operator lifts the pallet to a comfortable height and can then deposit or load the goods. In addition, the truck adapts this lift automatically with the optional AutoLift function. The load height for the operator thus remains the same even when goods are stacked on the pallet. A rugged steel construction protects the truck from damage during tough, continuous use. The low chassis covers the wheels and protects the operator's feet. The powerful three-phase motor provides good acceleration, even with the maximum load of 1600 kg. At the maximum lift height, the truck has a residual load capacity of 800 kg.

T25 – T30 : COMPACT LOAD TRANSPORTER

-

Precision and Safety in Narrow Warehouse Environment

The T25 - T30 pallet trucks from Linde Material Handling are designed for use in confined and highly frequented storage areas. Thanks to a narrow chassis and innovative rollers, load handling is much easier. The intuitively arranged control elements on the ergonomically designed tiller head means the operator can easily control the pallet truck with either the right or left hand. The long, low mounted tiller keeps the truck at a safe distance. In tight curves, the operator can maneuver with precision in creep speed when the tiller is in a vertical position meaning that both goods and the truck as well as other employees are well protected. If the operator releases the butterfly steering or changes the direction of travel, the truck brakes automatically.

M25 Scale+ : BALANCED TRANSPORT SYSTEM

-

Weighing and transporting in one step

The pallet lift truck M25 Scale+ has a scale system with a tolerance of only 500 g. This means users are spared a trip to an external precision scale and save time when loading a truck. Linde also offers printers and memory cards if the user wants to store the measurement. For example, deviations from actual order quantities can be documented. The warp-free construction of the M25 Scale+ ensures high handling performance. In this way, the truck not only has an extraordinarily high load capacity for the class, but can also handle tough, continuous use with no need for servicing. The operator's hands are protected by a wide tiller handle. The M25 Scale+ pallet truck can transport weights of up to 2500 kg.

T20 - T25 R : THE AGILE ALL-ROUNDER

-

Fast and Versatile Pallet Handling

The T20 - T25 R pallet trucks move loads of 2,000 to 2,500 kg effortlessly at speeds of up to 10 km/h. This is ensured by its powerful 3 kW AC motor. Without a load, the maximum speed is as high as 12 km/h. These compact forklifts are also ideal for loading and unloading trucks. Thanks to the high seating position, which is perpendicular to the direction of travel, drivers have a clear view of the load and their surroundings in both directions. If energy-saving operation is required, ECO mode can be activated for the trucks. This reduces power consumption by 12 percent.

T20 - T25 SR : THE POWERFUL SPRINTER

-

Best Productivity in the Tightest of Spaces

The T20 - T25 SR pallet trucks are suitable for a wide range of applications over medium distances and in tight spaces, such as transporting and storing pallets and loading and unloading trucks. This is made possible by the particularly compact 790 mm-wide chassis, which is narrower than a Europallet. In addition, with a top speed of 12 km/h, the trucks ensure extremely fast and productive handling. Thanks to a stabilization system for level compensation, this applies even under difficult conditions, e. g., in areas with many uneven or sloping surfaces. The driver also has excellent visibility in all directions due to the lateral standing position on the vehicle.

T20 - T25 AP : ERGONOMIC ALL-ROUNDER

-

Convenient and fast pallet handling

The T20 – T25 AP pallet truck from Linde Material Handling is equipped with a fold-out, fully suspended stand-on platform. Over longer distances, the operator can comfortably ride on the platform at speeds of up to 10 km/h, protected by the folding side guards. The platform also registers when the operator leaves the platform and automatically brings the vehicle to a halt. If necessary, the operator can steer the vehicle as a pedestrian truck. The truck is also suitable for loading and unloading applications: with its narrow chassis, innovative castor wheels and creep speed function, it allows precise maneuvering and offers optimum stability. If the operator releases the butterfly steering or changes direction, the truck brakes automatically. When cornering, it reduces its speed. The pallet truck is available with alternative fork lengths and the Linde BlueSpot™ as options.

PALLET STACKERS

-

Flexible warehouse assistants

Quick and agile in tight warehouse environmentsSuitable for any transport distance and stacking height: Linde has a wide range of electro pallet stackers for loads between 800 and 2,000 kilograms. Their strengths can be utilized anywhere requiring fast work and where safety is of the highest order, even if there isn't much space available. That's why these pallet stackers, with their narrow chassis, are not only agile, but handle the load with particular precision.

In addition, they shunt and accelerate with precision, with no jerking, and are energy saving. Their modern drive control makes that possible. And: High performance drive technology ensures rapid transport of the goods. The ergonomic tiller head enables efficient and fatigue-free work, as users can reach its elements easily and operate the truck intuitively.

ML 10 / MM 10 : FLEXIBLE ORDER PICKING PACKAGE

-

Effective Combination of Picking and Transporting

The electric pallet stackers ML 10 and MM 10 are extremely versatile. For example, they can be used as an ergonomic order picker platform or for transporting lighter goods. During order picking, the operator lifts his work surface to a comfortable height, which protects his back. During the transport of goods, an initial lift provides more ground clearance. Unevenness or ramps are not a problem. It is also important that different mast heights are available. This enables the truck to be precisely adapted to the respective area of application. Safety is ensured by the long tiller arm, hand guards and an effective parking brake. The electric pallet stackers ML 10 and MM 10 have a maximum load capacity of 1000 kilograms.

L10 - L12 : AGILE PALLET HANDLING

-

Agile and versatile thanks to the slim chassis

Whether storing or picking, distance transport or pallet transfer: The electro pallet stackers L10 - L12, with their slim chassis and good clear view masts make many maneuvers easier, especially where there is little space available. The operator profits from the tiller being mounted at a low point, which guarantees a safe distance from the stacker. There is also a creep speed function for very slow and tight maneuvers. Here the tiller is in an upright position. Overall the truck operates completely intuitively. All control elements are ergonomically arranged within the tiller head and provide for fatigue-free work.

L14 C : QUIET AND PRECISE

-

Precise Movement of Light to Medium Loads

The L14 C pallet stacker is a flexible and efficient handling solution for the transport of pallets, gitter or pallet boxes. With the help of the OptiLift mast control, the storage and retrieval of light to medium-weight goods can be carried out smoothly, precisely and quietly. All control elements of the ergonomic tiller head can be conveniently operated with both hands. A hand guard on the tiller head protects the operator from injury. At the same time, the long and low mounted tiller arm ensures that it is at a safe distance from the truck. An effective parking brake holds the truck securely on a slope. A maintenance-free AC motor reduces operating costs. The L14 C pallet stacker transports loads with a total weight of up to 1,400 kilograms.

L14 – L16 R : COMFORTABLE HIGH-REACH

-

Fatigue-Free Working in All Situations

The L14 - L16 R pallet stackers can achieve lifting heights of up to 5,316 millimeters. Thanks to the optional initial lift and overhead guard, they are also suitable for safe loading and unloading of trucks via ramps or bridge plates. With a compact width of 820 mm, the truck is both maneuverable and comfortable. Due to a lateral and raised seating position, drivers have the best view of the loads and their surroundings. The vehicles are equipped with a powerful 3 kW motor and reach speeds of up to 10 km/h. In ECO mode, energy consumption is reduced by 12 percent.

L14 - L16 AS/AS AP : MANEUVERABLE ALL-ROUNDER

-

Quickly and Nimbly through Narrow Aisles

The L14 - L16 AS/AS AP electric pallet stackers are perfectly suited for quick, efficient pallet handling in tight spaces. The compact dimensions and the small steering radius of the straddle stackers enable a high handling performance in the tightest of spaces. With two different versions available, the trucks can be adapted to suit the exact requirements in the warehouse: The version without a driver platform is more convenient for narrow aisles in high rack warehouses and block warehouses. The version with the folding driver platform offers greater comfort over long distances. Both models put the safety of the driver first, and their feet are protected by the low chassis with rounded corners. Thanks to the powerful 2.3-kW AC engine, the straddle stackers can move loads of between 1,400 and 1,600 kilos at top speeds of up to 10 km/h (for foldable platform version). The adjustable straddle legs enable the transport of closed pallets and load carriers with different widths. The electric steering also helps to achieve a high handling speed, allowing the truck to be maneuvered effortlessly and with the utmost precision.

D12 RW : COMFORTABLE DOUBLE PALLET STACKER

-

Ergonomic and fast transport for high handling performance

The D12 RW double pallet stacker is a fast and agile all-rounder for the simultaneous transport of two pallets of up to 1,000 kg each. Equipped with a powerful 3-kW three-phase motor, it reaches a speed of up to 12 km/h without load and 10 km/h with load. This makes it particularly suitable for medium and long distances in warehouses with a high handling capacity. It is also ideally adapted for loading and unloading trucks. An ergonomic seating position and intuitive controls allow comfortable, fatigue-free working. The wide chassis of 970 mm ensures a high degree of freedom of movement.

D06, D08 : MULTIFACETED DUO

-

Compact and agile for double the handling performance

The pedestrian double stackers D06 and D08 are ideal for easy logistical use, for example where there are rapid transport and order picking processes in the supermarket. Despite a lift height of 2024 mm, the trucks are very compact. This makes working in narrow warehouses easier. And using the innovative creep button, the truck can still maneuver precisely even when there is very little space available. The innovative caster system provides even more safety. It improves traction and stability even on uneven floors. The operator has a good view of the load and the path through the special mast construction. The D06 and D08 pallet stackers can simultaneously transport two palettes with a total capacity of 600 kg or 800 kg respectively.

D12 S - D12 SF : NARROW DOUBLE-LOADER

-

Transport two pallets in the tightest spaces

The D12 S/SF pallet stackers have a chassis that is narrower than a pallet. So these trucks can transport two pallets at a time, and maneuver within the tightest spaces. In addition, the operator has a high stance and thus a free view of the fork tips. This makes load handling easier. The operator platform is separated from the chassis by a layer of rubber. This protects the body from strong vibrations during travel so the operator can concentrate longer. Linde offers the D12 pallet stacker in two standard versions: In the S model, the operator is standing at a right angle to the direction of travel and has a good view to the front and back. In the SF model, he is standing frontal to the direction of travel and always has the load in view. Both models have mast variations for various load heights. The pallet trucks have a lifting capacity of up to 2000 kg.

D12 R : THE MASTER OF DOUBLE-DECK MANEUVERING

-

High Throughput Performance Even in Confined Spaces

The D12 R double pallet stacker transports two pallets of up to 1000 kg each at the same time and achieves a speed of up to 10 km/h with its 3 kW three-phase AC motor. This makes it particularly suitable for fast transport over medium and long distances where high throughput rates are required. Thanks to the initial lift, the vehicle is also suitable for loading and unloading trucks. Precise control enables particularly safe, comfortable and productive handling. Thanks to its compact chassis and excellent maneuverability, the D12 R can be maneuvered safely and quickly, even in confined spaces. The high seating position, which is perpendicular to the direction of travel, provides the driver with the best possible visibility of the loads and the surroundings.

L14 - L20 AP : ON A PADDED PLATFORM

-

Quick and comfortable storage in medium lift heights

The L14 - L20 AP pallet stackers can be used for many applications and create efficient and quick processes in the warehouse. With a 2.3 kW three-phase motor, the truck achieves a maximum speed of 10 km/h with the platform folded down. It has a load capacity of up to 2000 kg. All of the control elements are located on the tiller head and allow for intuitive operation of the pallet stacker. The truck can also be controlled with very little effort thanks to the electric power steering. And using the Linde Load Control, any load can be handled sensitively and with precision. A scale installation shows the operator the load weight.

L14 - L20 : POWERFUL LIFTING

-

Precision handling for high loads

The L14 - L20 pedestrian pallet stackers enable increasing handling performance with the powerful 2.3 kW three-phase motors and high load capacities. They are ideal for handling in narrow aisles or service lifts. There is an optional initial lift version for more ground clearance. The truck can transport loads up to 2000 kg safely over ramps and uneven ground. The delicate OptiLift lift mast control makes handling easy, because all lifting motions run very precisely.

Pallet Stackers with Folding Platform

- Pallet stackers that can be used either as a pedestrian or ride-on truck are ideal for storing and retrieving medium-weight loads over short to medium distances. The trucks with a folding stand-on platform are particularly efficient in areas such as external warehouses, delivery areas, and indoor warehouses where long distances are not covered but medium-heavy loads have to be transported. Depending on the required lifting height, load capacity, and door clearance, Linde has the ideal model in its portfolio.

D10 AP: PRECISE DOUBLE STACKER

-

Move comfortably through the warehouse with two pallets

The pallet stacker D10 AP from Linde Material Handling can be used as a pedestrian or ride-on truck, providing flexibility. When transferring goods, it accelerates to a maximum of 10 kilometers per hour while the operator stands on the fully suspended, folding stand-on platform. Thanks to its narrow chassis, the truck is particularly suitable for loading and unloading trucks and for use in confined warehouse environments. The double-deck pallet stacker can transport two pallets at the same time with a total weight of 2,000 kilograms. The Linde OptiLift system ensures easy pallet handling and enables fully proportional lifting and lowering thus protecting the load. Since the rotation speed of the lifting motor is adjusted accordingly, lifting movements are extremely precise, quiet and smooth. Two folding side guards keep the operator within the truck's chassis contour at all times. In addition, the creep speed and automatic brake function ensure optimum safety and high productivity.

D10 AP : ERGONOMIC DOUBLE-DECK PALLET STACKER

-

Move comfortably through the warehouse with two pallets

The pallet stacker D10 AP from Linde Material Handling can be used as a pedestrian or ride-on truck, providing flexibility. When transferring goods, it accelerates to a maximum of 10 kilometers per hour while the operator stands on the fully suspended, folding stand-on platform. Thanks to its narrow chassis, the truck is particularly suitable for loading and unloading trucks and for use in confined warehouse environments. The double-deck pallet stacker can transport two pallets at the same time with a total weight of 2,000 kilograms. The Linde OptiLift system ensures easy pallet handling and enables fully proportional lifting and lowering thus protecting the load. Since the rotation speed of the lifting motor is adjusted accordingly, lifting movements are extremely precise, quiet and smooth. Two folding side guards keep the operator within the truck's chassis contour at all times. In addition, the creep speed and automatic brake function ensure optimum safety and high productivity.

L14 - L20 AP : ON A PADDED PLATFORM

-

Quick and comfortable storage in medium lift heights

The L14 - L20 AP pallet stackers can be used for many applications and create efficient and quick processes in the warehouse. With a 2.3 kW three-phase motor, the truck achieves a maximum speed of 10 km/h with the platform folded down. It has a load capacity of up to 2000 kg. All of the control elements are located on the tiller head and allow for intuitive operation of the pallet stacker. The truck can also be controlled with very little effort thanks to the electric power steering. And using the Linde Load Control, any load can be handled sensitively and with precision. A scale installation shows the operator the load weight.

Platform Pallet Stackers

- Platform pallet stackers make light work of ground-level transport over longer distances, as well as the lifting and lowering of loads. Lithium-ion batteries are available as an option and can be charged easily and quickly at any socket. Thanks to their endurance and the ergonomic standing or seated workplace, platform pallet stackers are particularly suitable for transporting high loads over longer distances, for example in external warehouses and delivery areas, as well as for loading and unloading trucks, and on production lines. Depending on the required lifting height, load capacity, and local conditions, the pallet stackers can be equipped with a double or triplex mast.

D12 RW : COMFORTABLE DOUBLE PALLET STACKER

-

Ergonomic and fast transport for high handling performance

The D12 RW double pallet stacker is a fast and agile all-rounder for the simultaneous transport of two pallets of up to 1,000 kg each. Equipped with a powerful 3-kW three-phase motor, it reaches a speed of up to 12 km/h without load and 10 km/h with load. This makes it particularly suitable for medium and long distances in warehouses with a high handling capacity. It is also ideally adapted for loading and unloading trucks. An ergonomic seating position and intuitive controls allow comfortable, fatigue-free working. The wide chassis of 970 mm ensures a high degree of freedom of movement.

D10 FP : NARROW DOUBLE DECK PALLET STACKER

-

Agile with two pallets

The D10 FP pallet stacker is a compact and powerful double deck loader. With a chassis width of just 720 mm and electric power steering, it is extremely maneuverable even in the tightest of spaces. It is therefore particularly suitable for loading and unloading and for medium-to-long pallet transfer. The powerful 2.3-kW engine enables powerful acceleration up to 10 km/h. The D10 FP can pick up two pallets at the same time, which guarantees maximum handling performance. The truck is equipped with a steel chassis skirt to protect the driver from minor impacts.

D12 R : The Master of Double-Deck Maneuvering

-

High Throughput Performance Even in Confined Spaces

The D12 R double pallet stacker transports two pallets of up to 1000 kg each at the same time and achieves a speed of up to 10 km/h with its 3 kW three-phase AC motor. This makes it particularly suitable for fast transport over medium and long distances where high throughput rates are required. Thanks to the initial lift, the vehicle is also suitable for loading and unloading trucks. Precise control enables particularly safe, comfortable and productive handling. Thanks to its compact chassis and excellent maneuverability, the D12 R can be maneuvered safely and quickly, even in confined spaces. The high seating position, which is perpendicular to the direction of travel, provides the driver with the best possible visibility of the loads and the surroundings.

L14 – 16 RW : THE ERGONOMIC ALL-ROUNDER

-

Safety and Comfort for Versatile Pallet Transfer

The L14 – L16 RW pallet stackers allow for lifting heights of up to 6.2 m. Fitted with a powerful 3-kW three-phase motor, the pallet trucks are ideal for the fast transfer of loads of up to 1600 kg over medium and long distances. Thanks to the optional initial lift, they are also suitable for safe loading and unloading of trucks via ramps or bridge plates. The spacious 970 mm chassis keeps the driver protected inside the contours of the truck at all times. The side position of the seat offers excellent visibility in all directions. The easily accessible control elements, which are integrated into the console, ensure highly efficient truck handling.

D12 – D14 AP : FLEXIBLE TRUCK WITH GUARANTEED PERFORMANCE

-

Versatility combined with high performance

The fold-out driver platform means that the electric double stacker D12 – D14 AP can be used as either a pedestrian or ride-on truck, providing flexibility. It transports up to 1,400 kilograms on two levels and increases productivity during loading and unloading, as well as when transporting loads over long distances. The driver can stand safely and comfortably on the suspended platform. The creep speed function slows down the truck and makes difficult maneuvers in narrow aisles easier and safer. Operators can lift and lower the load with precision using the Linde OptiLift® mast control. The excellent visibility through the mast enables loading and unloading with millimeter accuracy even on higher shelves and guarantees safe load handling. Powered by powerful 2.3-kW engines, the double stackers reach a maximum speed of up to 10 km/h and increase the handling capacity with a fast working speed.

D12 – D14 : SAFE PRODUCTIVITY BOOSTER

-

Drive power for double handling performance

The electric double stackers D12 – D14 are flexible all-rounders that can transport two pallets at the same time. They can move up to 1,400 kilograms and can lift their loads to a height of 4.2 meters, helping to increase productivity during loading and unloading, as well as when transporting loads over long distances. The comprehensive safety package provides all-round protection for drivers. The long tiller of these pedestrian forklift trucks protects the operators, by ensuring that they keep a safe distance from the truck. The creep speed function slows down the truck and makes difficult maneuvers in narrow aisles easier and safer. Operators can lift and lower the load with precision using the Linde OptiLift® mast control. The excellent visibility through the mast enables loading and unloading with millimeter accuracy even on higher shelves and guarantees safe load handling. Powered by 1.5-kW engines, the double stackers reach a maximum speed of up to 6 km/h and increase the handling capacity with a fast working speed.

VERY NARROW AISLE TRUCKS

-

High handling performance in narrow aisles

Quickly and safely around the narrow aisle warehouseHigh throughput rates and particularly safe handling processes in the most limited space - Linde Material Handling has designed its turret trucks and vertical order pickers specifically to meet the demands of narrow aisles. This includes powerful drive and lift engines that enable the forklift to move off and lift at the same time, so that the required location in the racking is reached quickly.

At the same time, the Linde System Control regulates the lift and driving speed according to the weight of the load, optimizing performance according to the driving conditions. Optional Linde assistance systems protect against accidents and assist with rapid navigation through the warehouse. Energy recovery during braking and lowering the load saves energy costs and increases availability. Dependent upon the model and configuration, the lifting capacity can reach up to 1500 kilograms.

A : NARROW PACE SETTER

-

High throughput in narrow aisles

The turret truck A from Linde Material Handling delivers a high throughput rate in particularly narrow aisles. This is achieved by a modern drive that, even at maximum lift heights, can achieve high-speed lifting and driving. In addition, the forklift truck can accelerate and lift at the same time. Just as beneficial are the large residual load capacity and various camera and assistance systems. These assist with things such as navigation in the warehouse, accident prevention or rapid handling at great heights. The very narrow aisle turret truck A is of modular construction. The customer can choose from different engines, batteries, lift masts, chassis, and many other features to meet their individual operating requirements.

K : COMBINATION WORKER IN NARROW AISLES

-

Work effectively and with a view in the high shelving

The K man-up turret truck from Linde Material Handling enables high turnaround capacity for order picking and handling processes in high rack warehouses. The powerful drive trains make this possible, as the truck can move and lift at the same time. Also, even at high lift levels the speed remains high and a high level of residual lift capacity is available. Various assistance systems are available which help to navigate accurately through warehouse or to avoid obstacles. Not least, Linde System Control improves the process: Depending on the version, the system adjusts the lift and travel speed according to the weight being transported. There are various versions of the mast, chassis, battery and cab for the very narrow aisle trucks, which can be combined according to usage requirements. There are around 10 million possible truck configurations.

REACH TRUCKS

-

Fast handling in narrow high rack warehouses

Flexible, efficient and safe in the warehouseLoad handling in warehouses requires numerous movements and maneuvering, often in confined spaces and at height. Linde reach trucks are tailor-made for these conditions and ensure extremely efficient operation in high rack warehouses. Besides their outstanding maneuverability, special display and assistance systems support the driver to allow safe and quick handling. For example, they automatically adjust the lift and travel speed, or precisely compensate for mast oscillation in certain models.

The design of the driver's cab and the masts provides optimum all-round visibility. In addition, the driver's cab and control elements are developed based on the driver's individual ergonomic requirements. For example, the Linde Load Control integrated into the armrest and a vibration-free driver's cab make fatigue-free working possible. Additional equipment, such as a panorama armored glass roof, increases driver safety in narrow rack aisles and when handling loads at height.

All models are extremely cost-effective to service thanks to low-maintenance components and long maintenance intervals. Companies can choose the right truck for their requirements from a wide product range. Depending on the model, mast heights can reach up to about 14 meters with lifting capacity of up to 2.5 tons.

R14 - R20 G : FLEXIBLE OFF-ROADER

-

Reach trucks for halls and yards

R14 - R20 G-series reach trucks are ideal for combined hall and yard use, that is to say, for transport operations in a changing environment, such as when loading and unloading trucks. Oversize super-elastic wheels, a vibration-damped drive unit, increased ground clearance as well as a vibration-free driver's cab ensure driving comfort and safety. This means that the versatile R14 - R20 G reach trucks enable low-vibration operation on uneven outdoor surfaces as well as efficient load handling in narrow rack aisles in warehouses. They can be adapted to the personal comfort requirements of every driver and are distinguished by powerful engines and numerous safety features.

R14 - R17 X : COMPACT WITH OUTSTANDING COMFORT

-

Innovative design for short reach distances and double the available space

R14 - R17 X reach trucks have an exceptional design, which significantly increases performance, driving comfort and safety. They are ideal for the efficient handling of loads up to 1.7 tons and a working height of over 11.5 meters in narrow rack aisles. The positioning of the battery under the cabin means that the driver has double the amount of space and the field of vision through the mast has doubled, compared to conventional reach trucks, thanks to a new mast concept. The mast is permanently mounted on the chassis. The reach travel movement is now performed by a special fork carriage. This design ensures extremely stable load handling. The position of the battery means that the center of gravity is very low, which leads to high residual load capacities. The special design with extremely short reach travel movements enables narrower aisles in high rack warehouses.

R10 - R16 B : VERSATILE ENTRY-LEVEL MODEL

-

Comfortable and cost-effective to use in high rack warehouses

R10 - R16 B reach trucks are ideal for storage and removal at height and in narrow rack aisles. With negligible costs per pallet movement, they provide the necessary output for light to medium-weight tasks in the entry-level class. In addition to the extensive model range, the trucks can be extensively tailored with e.g. mast heights ranging from 4.4 to 7.7 meters. The trucks have a high residual load capacity and boast a high level of comfort for fatigue-free operation. In particular, a vibration-free operator compartment and individually adjustable control elements help achieve this.

R20 - R25 F : NIMBLE LONG GOODS TRANSPORTERS

-

Four-way reach trucks for narrow aisles

R20 - R25 F four-way reach trucks are specifically designed for transporting particularly long items in narrow aisles. They are not only able to move forwards and backwards, but can also move sideways in both directions. Their adjustable prongs, which can be set to a width of up to two meters, also allow extra-long loads to be transported and stacked. With lift heights of up to nine and a half meters, they are also suitable for use in high rack warehouses. R20 - R25 F-series trucks can even easily handle high loads of up to 2,500 kg. This makes them ideal for long and heavy loads, such as steel girders and wooden beams for the building and timber industry as well as for use on production equipment and in the logistics sector.

ORDER PICKERS

-

Enhanced handling with reduced physical strain

Optimal Paths when PickingHow quickly the picking goes ultimately depends on the truck operator. If the strain on them is low and the paths are short, this saves power and time. But warehousing processes and types of goods differ depending on sectors and operations. That's why Linde Material Handling uses trucks with a modular design for its picking devices, in order to help to minimize physical strain on the driver and increase the efficiency of the picking process in any working environment.

All-round ergonomic working conditions are a fundamental part of the truck designs, including vibration-cushioned platforms, intuitively laid out control panels, low entry height and sufficient space for terminals and mounting brackets. Linde assembles each truck individually based on the modular system. Once complete, every last detail is suited to the application - vital when it comes to high handling capacities.

TOW TRACTORS AND PLATFORM TRUCKS

-

Ergonomic transport solutions for rapid movement of goods

Goods transport at any operating siteThe efficiency of transport processes with tow tractors and platform trucks is proven in difficult areas: narrow aisles, small loading areas, steep ramps or uneven surfaces make smooth operation difficult and place strain on the driver. Tow tractors and platform trucks from Linde Material Handling are designed to meet these requirements, and so provide high throughputs. Modern steering systems allow precise driving maneuvers and small turning circles.

Comprehensively damped driver work stations ensure that the operators can work without fatigue. In addition, many trucks have several braking systems for greater safety in any driving situation. The tow tractors and platform trucks from Linde Material Handling tow trailer loads of between three and 25 tons. Large trucks with separate platforms can also take a load of up to two tons.

P60 – P80, W08 : CONVENIENT POWER PACKS

-

High throughputs, even in the smallest of spaces

The P60 – P80 rider-seated tow tractors and W08 platform trucks from Linde Material Handling tow trailers with heavy loads and provide quick, safe and flexible processes. This allows the decoupled and spring-mounted suspension of all three wheels. It ensures quiet and safe travel. At the same time, the truck has high towing force and a small turning circle. Therefore, the throughput remains high even if there is only a small amount of space available in the warehouse. The driver benefits from a work station with lots of leg room, an adjustable driver’s seat and steering wheel, as well as intuitively arranged control elements. The P60 – 80 electric tow tractors and W08 platform trucks have a towing capacity of 6 to 8 tons. The top speed without load is 20 kilometers per hour.

P20, W04 : SLIM TOWING MACHINE

-

Quick and safe transport processes in narrow aisles

The P20 electric tow tractor and the W04 platform truck feature a particularly slender design. Direct, responsive steering makes tight turns possible. As a result, these tow tractors are perfect for transport processes in narrow aisles and tight spaces. Ergonomic working conditions are ensured, for example thanks to the height-adjustable seat. The seat also folds up and down. This allows the driver to control the tow tractor from either a standing or seated position. The P20 and W04 can pull a maximum load of two tons. There is also a different version of the W04 model available with a platform that has a load capacity of up to 400 kilograms.

P40 - P60 C : DYNAMIC TOWER

-

Fast Transport Even in Confined Spaces

The electric tow tractors P40 - P60 C are compact and maneuverable towing vehicles which are particularly suitable for indoor transport and line supply in production. Thanks to a wide range of trailer couplings, the P40 - P60 C are compatible with a wide variety of trailer types. The special design of the vehicles allows the driver an optimum view of the trailer and load. The design is very ergonomic: the dashboard, backrest and driver's platform are decoupled from the chassis and absorb shocks and vibrations. The ergonomic and intuitive Linde steering wheel is height-adjustable and can be adapted to the driver's needs.

TUGGER TRAINS

-

In modern industrial production, material supply must be precisely coordinated with the work cycles of the production machines and assembly lines. To ensure a synchronized and continuous material flow, it is crucial that the required materials are delivered to the right place (just in sequence) at the right time (just in time). This often requires the use of several intralogistics trucks at the same time, which in turn means higher investment and follow-up costs as well as an increased risk of accidents.

This is where the tugger train comes into play. It consists of a towing vehicle with one or more trailers. The different trailer types allow a variety of goods to be transported simultaneously using a single tugger train. The trailers are characterized by high directional stability, which allows the train to be driven precisely and reliably.

EXPLOSION PROTECTION IN INTRALOGISTICS

-

Safely through the hazardous area

No matter whether you work in chemistry, pharmaceuticals, food, logistics or recycling, potentially explosive mixtures of gases, vapors and dust are created in numerous industries. Industrial trucks that are used in these hazardous zones must guarantee comprehensive explosion protection. At the same time, they need to be just as efficient and ergonomic as in any other area of intralogistics.

Explosion protection from Linde Material Handling is geared towards precisely these requirements. Suitable explosion-proof versions are available for numerous counterbalanced trucks, reach trucks, pallet stackers and pallet trucks. They comply with EU regulations (EN 1755) and the ATEX Directive (2014/34/EU). Linde can provide the right truck solution tailored to the relevant processes. This means that the material flow can be processed with a high handling capacity and level of ergonomics even in explosion-protected conditions.

Solutions

-

Solutions for maximum added value

Every company has its own individual needs and basic requirements, whether financial resources, business processes, general technology and safety standards, infrastructure or IT systems. Each type of use requires something different from products and solutions.

Well-designed products and solutions that meet one hundred percent of a company's own individual requirements are Linde Material Handling's strength, whether customer-specific truck solutions, fleet management and automation, leased- and used-vehicle business, financing and service packages, or advice on material flow planning, fleet optimization or safety.

Short Term Rental

-

Be prepared for unexpected peaks in demand

If you need to cover a seasonal peak, prepare for an upcoming event or just deal with the fact that your order books are full, you will need to make it as easy as possible for your workforce and machinery to manage the extra workload. Our short-term “Linde Rental Solutions” are on hand around the clock to work with your company as a reliable partner. Wherever you are in the world, you can rest assured that we will have just the right forklift truck, warehouse handling equipment or fleet you are looking for, and you know you will be getting state-of-the art technology and the usual Linde quality.

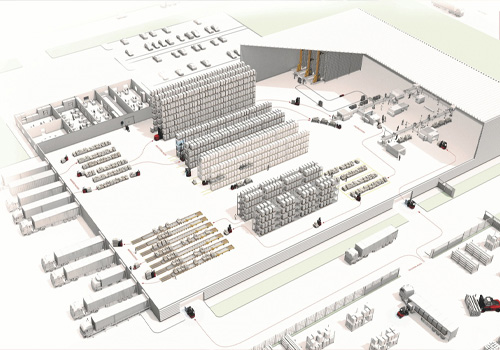

Automation for your warehouse

-

Everything perfectly in sync

Scalable and cost-efficient automation is a critical element of an optimal material flow. Automated procedures ensure consistent, efficient, and flexible processes. They improve your goods handling times and help minimize personal injury and damage to goods and infrastructure. We provide automated trucks, the latest technology, and a comprehensive material flow consulting service to help you fully exploit your economic potential. From delivery through to dispatch, we use our comprehensive understanding of intralogistics to analyze individual process steps or entire material flows. Whether an existing system or new project: the goal of automation is always to maximize your efficiency gains. Our offer is not just limited to our automated trucks. Together with our partner companies, we provide everything that you need to automate your processes.

Fleet Management

-

MAKE YOUR FLEET MANAGEMENT INTELLIGENT

Digitization is changing the world of intralogistics. Modern logistics devices continuously collect data, which is analyzed and can then be used to optimize complex warehouse and transport processes. Networking and advanced sensors even enable the forklift trucks to act autonomously. This results in the fleet and fleet management becoming intelligent, and networking and real-time data access becoming increasingly important.

The Linde connect fleet management system provides precisely the information that you need for efficient fleet management. Whether it is in production or the warehouse, connect networks your forklift trucks and continuously informs you of the current status of the entire fleet. connect thus makes fleet management more cost-effective and increases the availability of each individual forklift truck. You can choose between the local connect:desk fleet management software or the connect:cloud cloud-based version as required.

Consulting

-

Recognizing Potential

When it comes to material flow management, there are many challenges but also new opportunities. The new requirements relating to material flow are very complex: cost pressure, larger product portfolios or altered logistical structures all influence change. What's more, planners have to consider the many factors affecting optimization. As a result, material flow must be planned quickly and precisely. This is only possible with thorough evaluation.

Linde offers comprehensive consulting services for the thorough evaluation of these potential factors and can also assist you on site.

Financing

-

Save costs and conserve capital - with financing solutions from Linde

Our tailored financing plans - such as leasing, rental or rent-to-own - ensure that your company uses its capital optimally, and that your fleet remains up to date with the latest technology at the lowest possible cost. The goal is to have the solution meet the individual requirements of your company - even looking beyond purely financial considerations and regardless of whether you need a single truck, several vehicles, or an entire fleet.