- Offer Profile

-

MIAS employs more than 400 staff members at four locations and, as an OEM, supplies stacker cranes and telescopic forks to customers all over the world. MIAS has a clear vision: providing general contractors and system integrators with the best possible support when it comes to load handling attachments and stacker cranes in intralogistics. From finding and developing a solution to production and implementation right through to service and maintenance.

Stacker Cranes

-

Reliable in operation, available and efficient.

From light to extremely heavy - and everything in between.

Stacker cranes from MIAS are at the hearth of automatic high rise storage facilities and automatic small components warehouses. MIAS has satisfied its customers’ requirements for operational reliability, availability and efficiency a hundred times over. And it has done this all over the world, for the most varied requirements and tasks. Miniload

-

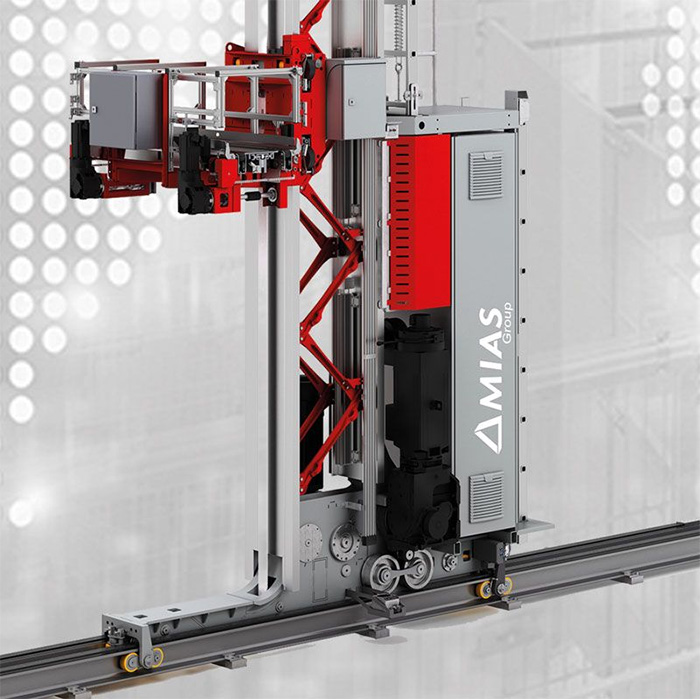

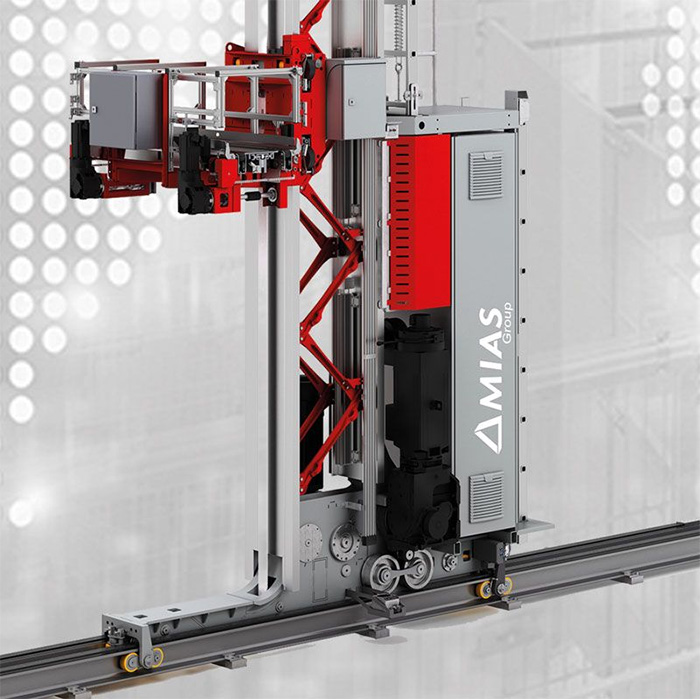

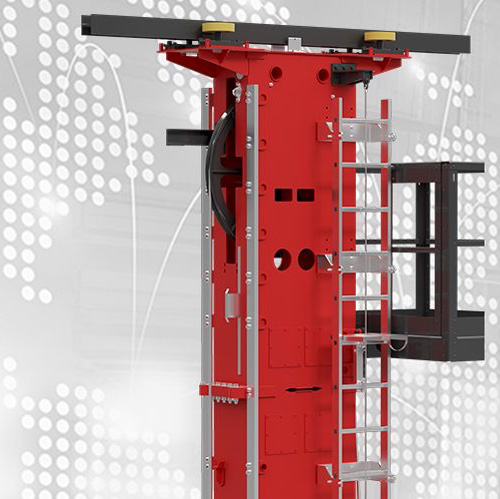

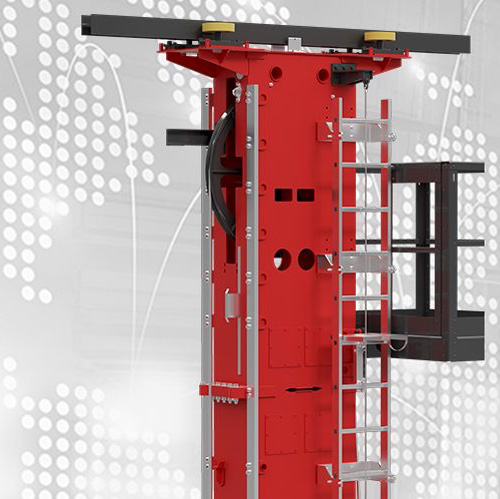

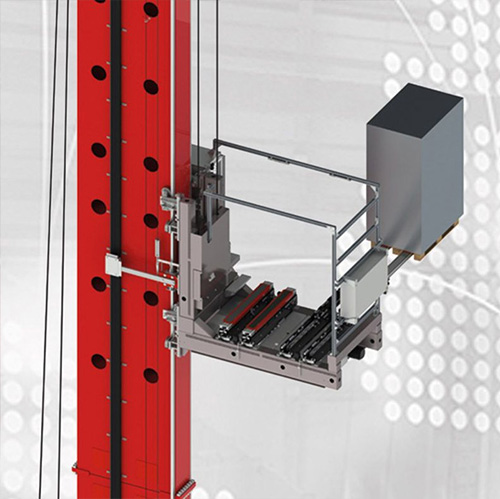

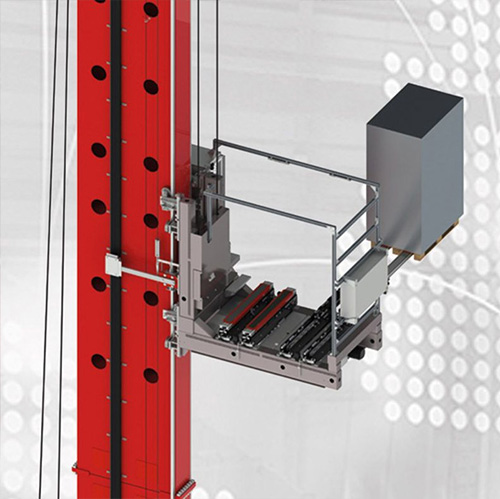

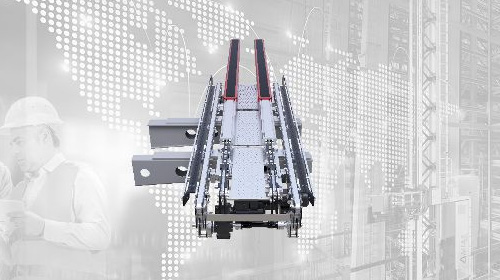

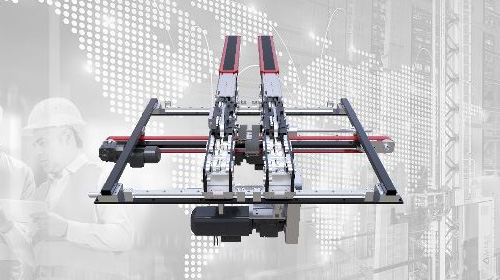

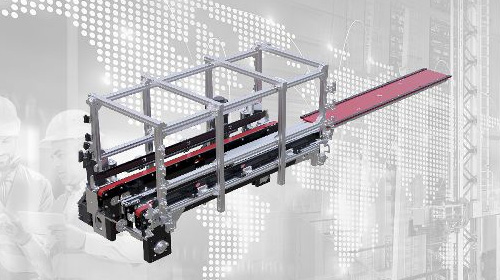

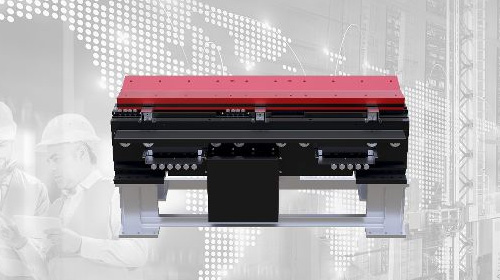

Stacker Cranes from the AKL Series

The MIAS pioneer

New standards in dynamics and efficiency.

The newly developed AKL stacker crane for automatic small components warehouses has been designed and built in conformity with state-of-the-art criteria. It boasts maximum performance data and low operating costs. The AKL series is characterized by low weight, high efficiency, minimal approach dimensions and a special design that ensures optimum use of the storage space. By combining the AKL with tried-and-tested MIAS load handling attachments, it makes a major contribution to achieving the economic and functional targets of the automatic small components warehouse system.

MIAS AKL

-

Highlights:

- Achieves maximum dynamic requirements thanks to speeds of up to 360m/min when driv-ing and 180 m/min when lifting

- Height: up to 18 m

- Working load: 2 x 50 kg

- Optimum use of space: thanks to low approach dimensions, both above/below as well as front/back

- The use of common parts in the product family reduces operating costs

- Low energy consumption thanks to optional PowerCaps, which cut energy consumption by at least 25 %.

Pallett

-

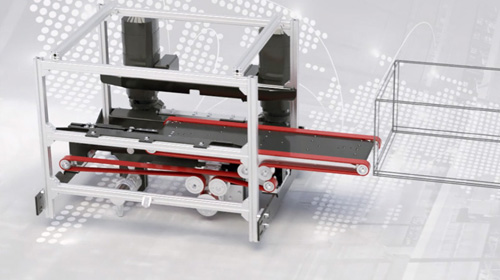

Pallet stacker cranes

The requirements define the technology

Pallets have been an integral part of logistics for over 50 years, and they are the most commonly used load carrier in high rise storage facilities. MIAS has worked to ensure the reliable storage and retrieval of pallets in automated systems for decades now. Your required throughput determines the dynamics of the stacker crane, and therefore which specific load handling attachment from our diverse range needs to be used. Whatever your requirements – one or two load handling attachments, single or double-deep, with additional conveyor and inclination unit – the design is determined by you!

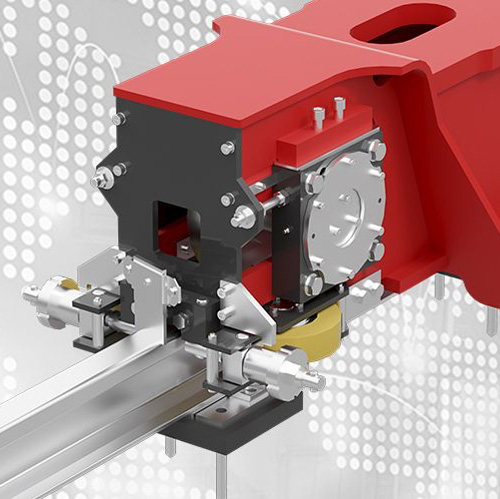

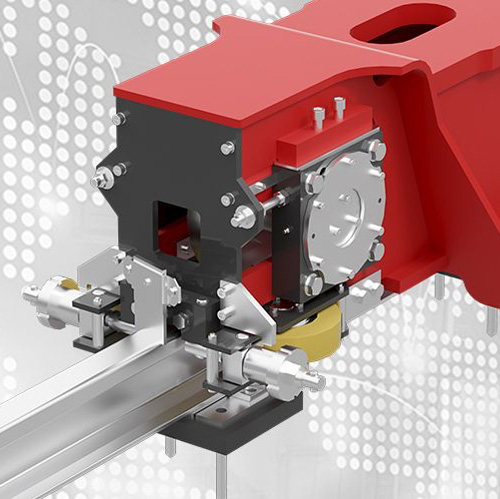

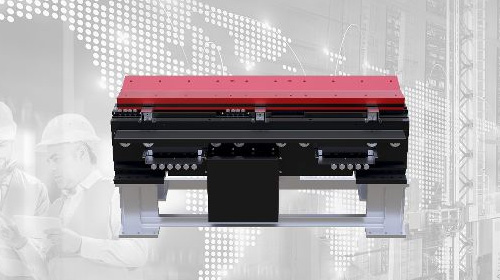

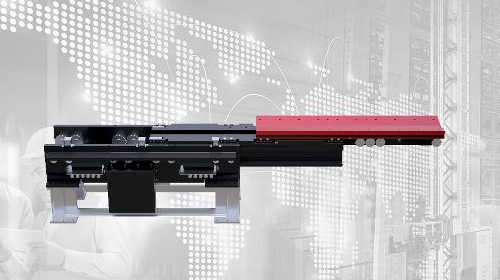

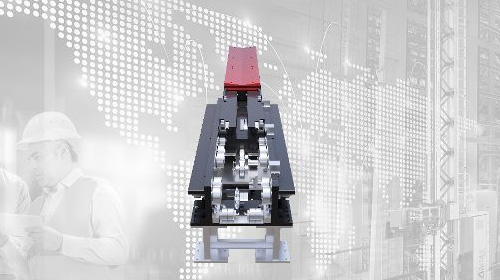

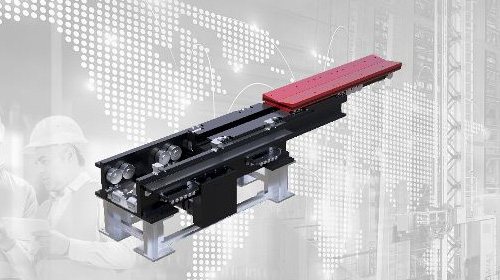

PAL 23 - STANDARD FOR Stacker Cranes NEWLY DEFINED

-

The new PAL 23 is designed for heights between 23 m and 30 m and reaches speeds of up to 240 m/min when traveling and 120 m/min when lifting.

Due to a weight reduction of up to 20 percent compared to the current series and a tapered mast design, PAL 23 scores especially in resource efficiency and reduced energy consumption.

A new type of rope drive with a large deflection pulley extends the service life of the components so that maintenance requirements are reduced. The bolted guide rail facilitates replacement and the pretensioned guide pulley enables easy and precise adjustment, which has a positive effect on running. The new development is designed for payloads of up to 1,500 kg for single-depth applications and 1,250 kg for double-depth applications. The acceleration values are between 0.5 m/s² and 1 m/s².

After the introduction of the PAL 23 units, the series will be successively extended to all configurations from 10 m to 45 m.

Pallet Stacker Cranes from MIAS

- MIAS has led the field for decades and is a constant in the industry. There are scarcely any pallet applications that have not been moved by MIAS stacker cranes. Our load handling attachments from our own production lines achieve perfect harmony in combination with our fully in-house produced stacker cranes. Having access to this one-stop shop gives you a massive advantage in expertise. Whether you need single-mast devices with two load handling attachments for double-deep loading or with gear drive, triple-deep storage using telescopic forks or multiple-depth storage with a shuttle - MIAS is the right partner for your project.

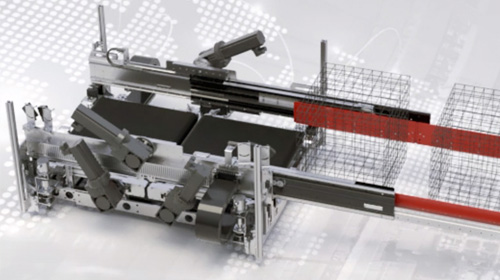

Turbo Stacker Crane

-

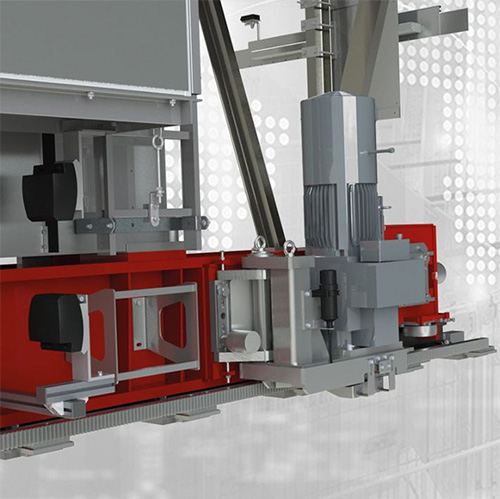

The gear drive is used for pallet stacker cranes that need to be high-powered over short distances. Extreme acceleration and braking combined with precise positioning are the strengths of the Turbo stacker crane.

Higher throughput thanks to acceleration of up to 3m/s2 and enhanced operational reliability with positive-locking power transmission. This technology also causes wheels and rails to wear less quickly, increasing their service life.

Single-Mast Devide with 2 Load Handling Attachments

- MIAS has been helping its customers out with its single-mast device with two load handling attachments since 1987. The single-mast unit has an almost unbeatable price/performance ratio, especially at heights of over 20 m. Each load handling attachment of the device can store and retrieve up to 1,200 kg, and its parallel method of operation puts it far ahead of conventional units.

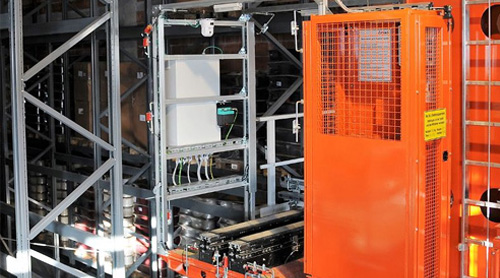

Deep-Freeze Stacker Crane

-

MIAS is your expert for stacker cranes for frozen and refrigerated products. In recent years, MIAS has installed over 100 devices in environments with temperatures from -30°C to +5°C – including in Europe’s largest cold storage facility (40 m high).

The parts under the highest stress are manufactured from special steel that boasts a long service life even in the most extreme conditions. The compact design enables optimum approach dimensions and maximizes use of the available space. Specially insulated and heated control cabinets are used in the device, to prevent condensation inside the housing and ensure optimum availability.

Shuttle Stacker Crane

- MIAS shuttle stacker cranes are the ideal solution for channel storage systems. At MIAS, the shuttle has undergone a complete revamp: the power is now supplied by PowerCaps, making them cordless.

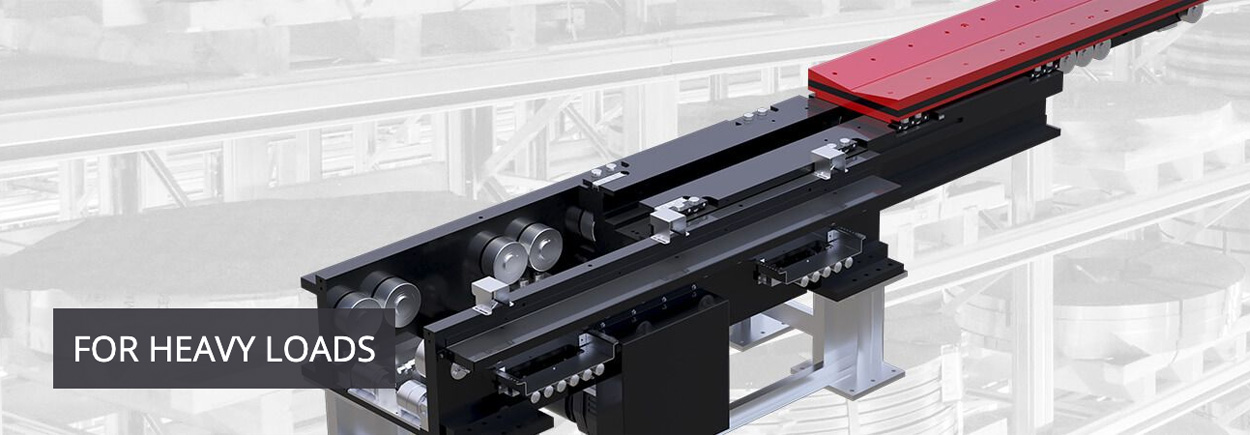

Heavy-Duty

-

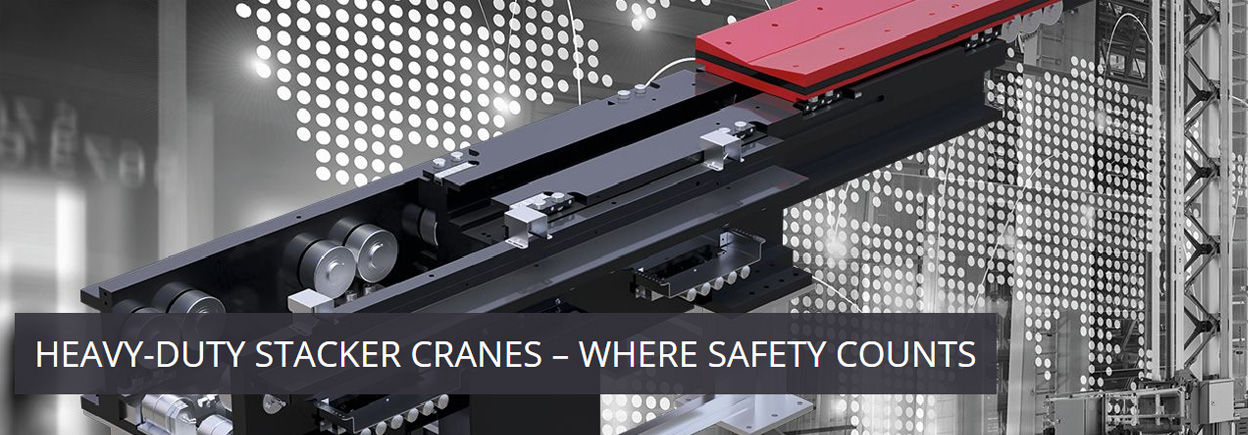

Stacker cranes for heavy-duty work

Designed for special challenges

Heavy and super-heavy loads represent a particular challenge for stacker cranes in terms of materials and design. MIAS heavy-duty stacker cranes have been designed specifically for this purpose. As well as offering the essential static and dynamic stability, our stacker cranes are designed to meet the industry’s special requirements, such as in the steel industry or the timber trade, for example. Heavy-duty stacker cranes are designed to be robust and operationally reliable for use in the toughest conditions.

Bulky and heavy goods

-

Efficient and gentle transport

Operational reliability becomes even more important when you are moving extreme weights and volumes.

With MIAS, a single tine can handle standard working loads of up to 40 tons, as already proven many times. But dynamics haven’t been forgotten. MIAS designs machines that have shifted 11 tones at 210 m/min, for example. In this high-performance environment, in particular, perfectly harmonized stacker cranes and load handling attachments are critical for success. And MIAS is your one-stop shop for both these items.

Vehicle bodies

-

Stacker cranes for vehicle bodies

For over 25 years

Automotive manufacturers and MIAS stacker cranes – a combination that has almost become a tradition. MIAS has been designing and building vehicle body equipment for all well-known manufacturers for more than 25 years. Our many years of experience can benefit you, too: from completely new concepts to integration in existing production equipment, MIAS finds the optimum solution to meet your particular requirements. For us, technical challenges such as transverse and longitudinal storage go without saying, and our equipment is extremely reliable. Stacker Cranes for Vehicle Bodies

-

Your partner for efficient storage technology in the automotive industry

The automotive industry is characterized by tight schedules and production processes that are part of a global network. As storage space is limited, precise control of deliveries is absolutely essential. Whether it’s the conveyor leading to final assembly or transfer via a decoupling module that you are looking for, MIAS is your reliable partner for efficient storage technology.Vehicle body, engine and transmission warehouses

The vehicle body warehouse makes sure vehicle bodies arrive on the conveyor belt at precisely the right moment – so maximum availability is critical. At nearly 99.9 %, MIAS vehicle body stacker cranes achieve top values. MIAS vehicle body stacker cranes are now used all around the globe, and more recently in Europe’s largest vehicle body warehouse, which has six aisles and is 40 meters high! The 20% performance enhancement of a 24/7 engine and transmission warehouse requires the use of new drive technology with positive-locking transmission. This is where the Turbo stacker crane with gear drive really comes into its own.

Load Handling Devices

-

Precision and quality from MIAS

Bearing heavy loads and mechanical stresses thousands of times over.

Whether you’re shifting pallets, vehicle bodies or heavy loads – dynamics and efficiency are indispensable. Don’t take chances – put your trust in the market leader. Load Handling Devices for Pallets

-

Reliable storage and retrieval

Basic load carriers for logistics

For decades, pallets have been an integral part of logistics and the most popular basic load carrier in high rise storage facilities. With its systems and load handling attachments, MIAS ensures the reliable storage and retrieval of pallets in automated systems. Whatever your requirements – one or two load handling attachments, single or double-deep, with additional conveyor and inclination unit – the design is determined by you!

Single-Deep Telescopic Fork

-

Tried and tested: MIAS invented this telescopic fork in the 1960s, and it has undergone continuous further development ever since. Robust, flexible, low maintenance. For pallets and skeleton containers with a maximum weight of up to 1,500 kg.

Highlights:

- Tried and tested a thousand times over

- Small overall size

- Optimal static and dynamic load-bearing capacity

- Low level of bowing under load

- Low maintenance due to positive-locking, double-row stationary gear

- Can be used at temperatures as low as -30°C

Double-Deep Telescopic Fork

-

Further developed: At the end of the 70s, the single-deep telescopic fork was followed up with the double-deep version, bringing enormous cost savings:

suddenly, twice as many goods could be stored in virtually the same storage space. The range has been extended to include the single-tine, double-deep pallet telescopic fork. The version with a wide plate upper part is specially designed for closed pallets such as Chep models.

Highlights:

- Tried and tested a thousand times over

- Small overall size

- Optimal static and dynamic load-bearing capacity

- Low level of bowing under load

Double-Deep Pickup Telescopic Fork

-

The double-deep version produces considerable cost savings: twice as many goods can be stored in virtually the same storage space.

Highlights:

- Tried and tested a thousand times over

- Small overall size

- Optimal static and dynamic load-bearing capacity

- Low level of bowing under load

- Can be used at temperatures as low as -30°C

Eccentric-Stroke Combined Telescopic Fork

-

This telescopic fork is used when goods have to be moved, hoisted or lifted onto a distribution vehicle for transport, while remaining in a stationary position.

Highlights:

- Simple assembly

- Extremely low maintenance

- Modular design

- Dynamic load-bearing capacity

- Can be used at temperatures as low as -30°C

Chain Conveyor Combined Telescopic Fork

-

Used in distribution centers with an order-picking zone for transferring pallets onto chain conveyors.

Continually optimized and further developed by MIAS for over 25 years.

Highlights:

- Dynamic load handling

- An integrated stroke can lift the chain conveyor for transferring the pallets.

- Adjustable to suit your mounting interface

- Very low maintenance

- Versions available for use at temperatures as low as -30°C

Combined Telescopic Fork With Inclination Device

-

In distribution centers with order-picking zones, pallets often need to be transferred on tilted gravity conveyors.

Combined telescopic forks with inclination device from MIAS have been specially developed for these applications and adapted to satisfy ever more demanding requirements.

Highlights:

- Dynamic load handling

- Adjustable to suit your mounting interface

- Very low maintenance

- Versions available for use at temperatures as low as -30°C

Combined Telescopic Fork With Tine Adjustment

-

Telescopic forks with optional tine adjustment are the perfect solution whenever

- the load is so large that it can no longer be handled by normal load carriers

- you are using several different load carriers, and

- the load carrier also needs to be moved sideways.

Highlights:

- Compact design

- Adjustable to suit your mounting interface

- Optimum mechanical design

- Can be combined with any type of drive

- Can be used for frozen products down to -30°C

Telescopic Forks For Industrial Trucks

-

Alongside rail-mounted stacker cranes, industrial trucks play a key role in intralogistical goods transport. Thanks to MIAS attachments with or without additional stroke, MIAS telescopic forks can be fitted to all common types of vehicle.

Highlights:

- Completely preassembled and tested load handling attachment

- Tried-and-tested technology

- Mechanical design adapted to the vehicle in question

- Optional attachments for load detection and sensors

- Optional versions with tine adjustment

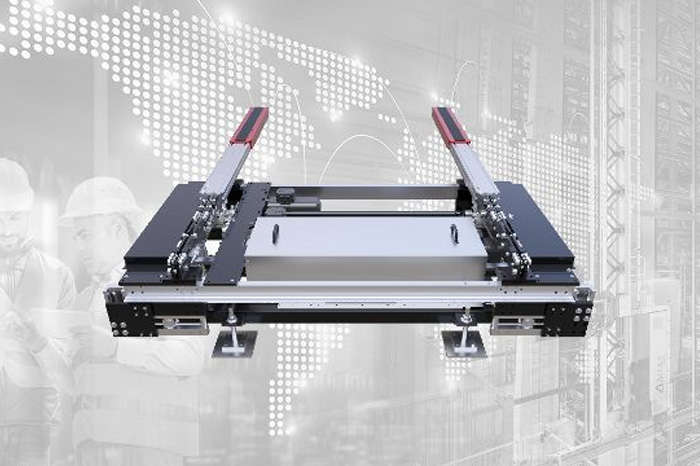

Shuttle

-

The shuttle efficiently stores palletized goods and products in consolidated channel storage systems. The shuttle is specially configured for your application.

Modular system for the individual selection of components such as sensors, electronics and controllers.

Highlights:

- Individual configuration

- Maximum speed and acceleration

- Communication via Bluetooth

- Low overall height

- Ideal in combination with MIAS pallet stacker cranes

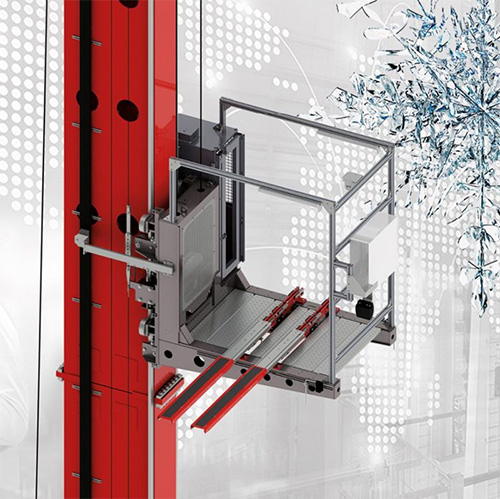

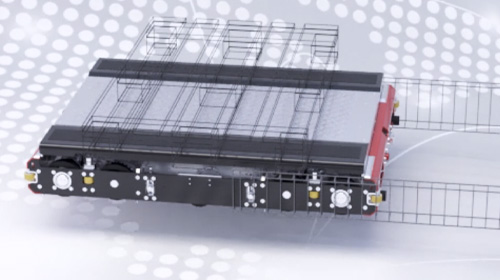

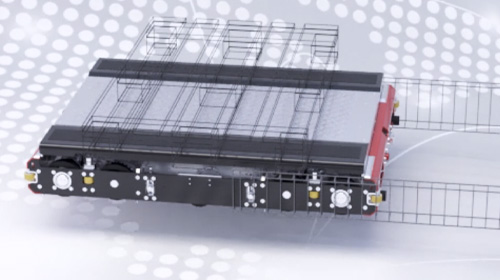

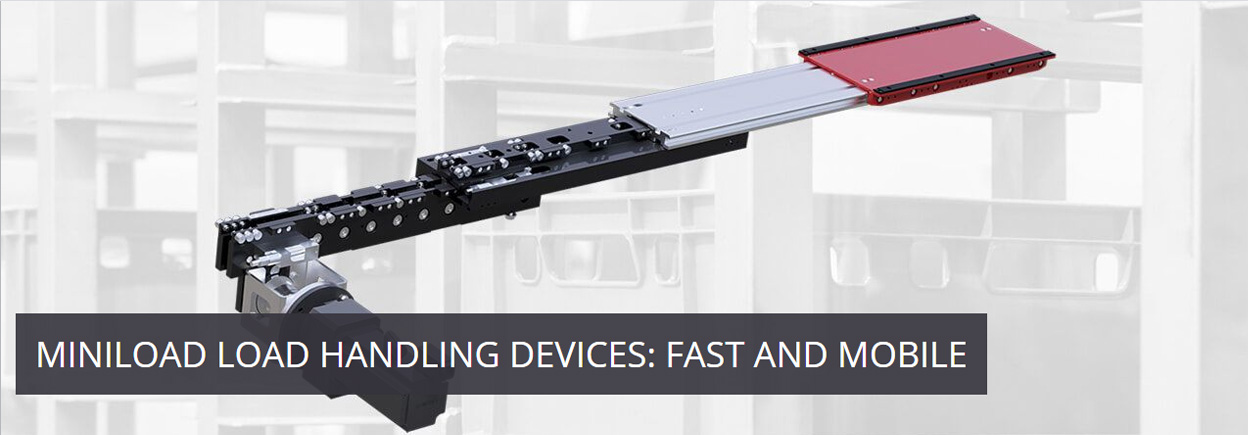

Miniload Load Handling Devices

-

For containers and cartons

Load handling devices for containers and cartons

As units that need separating and handling become smaller and smaller, automatic small components warehouses are increasingly gaining ground in intralogistics. No fast and efficient logistics system can do without them. With its systems and load handling devices, MIAS has been ensuring the fast and reliable storage and retrieval of cartons and containers for decades. Many containers are now divided into compartments to further increase their capacity. This means they have to be accessed more frequently. Here, performance and reliability are essential.

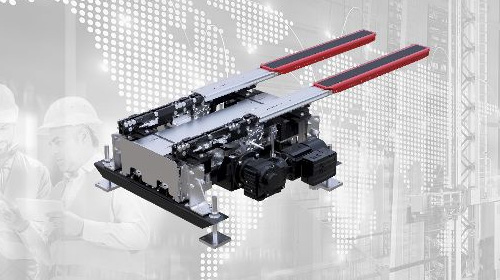

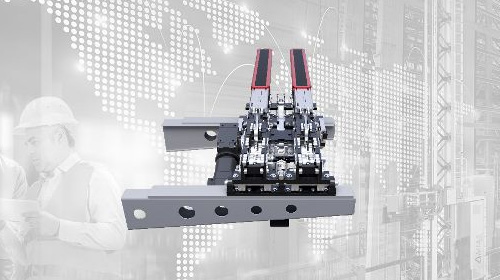

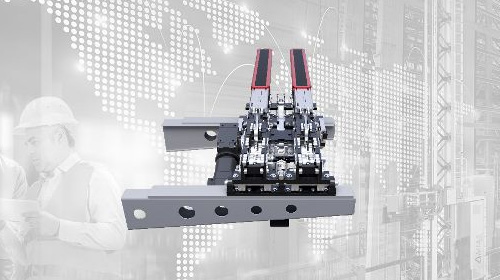

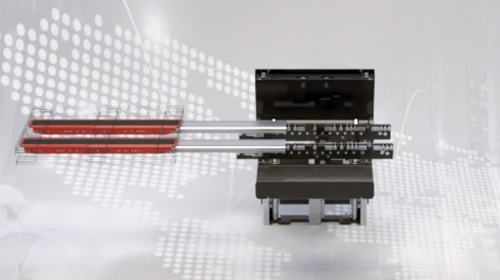

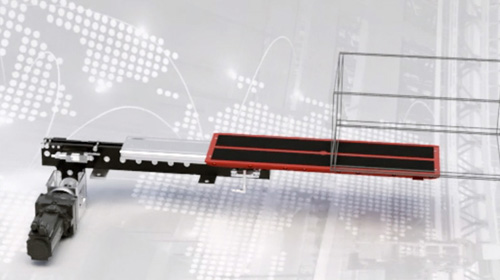

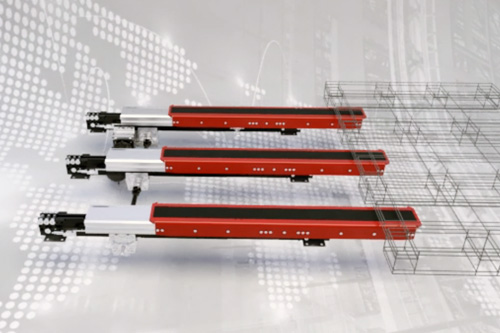

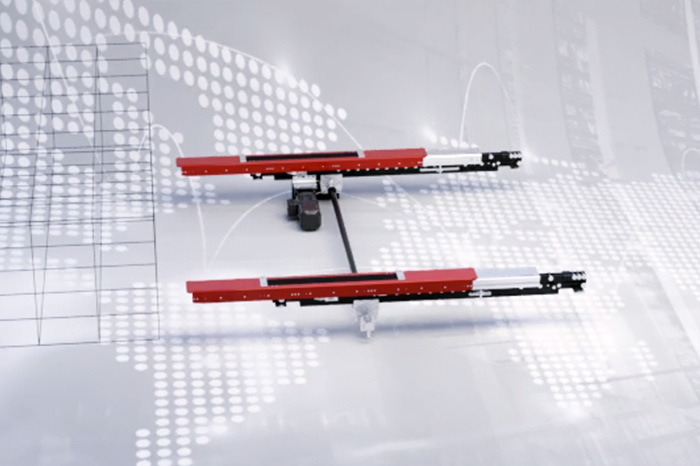

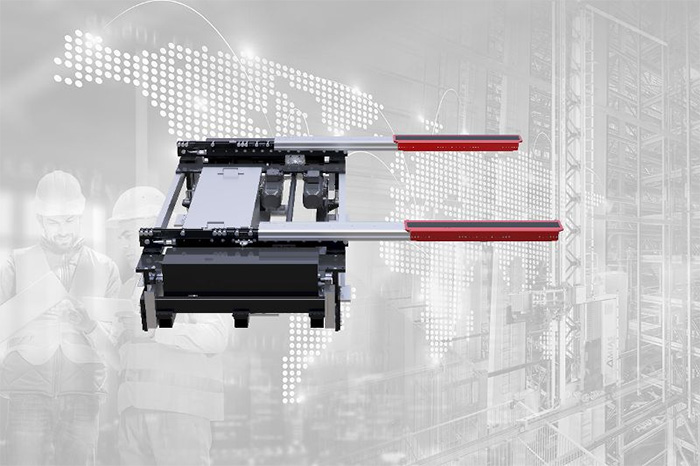

Single-Deep Miniload Telescopic Fork

-

The MIAS Miniload telescopic fork is the ideal load handling attachment for the single-deep storage of containers of the same size in single-space or multi-space shelves.

The optimized overall size enables a low shelf width and a very small distance between the shelves.

Highlights:

- High availability

- Can be used at temperatures as low as -30°C

- Compact, weight-optimized design

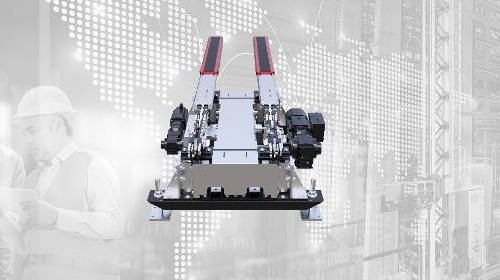

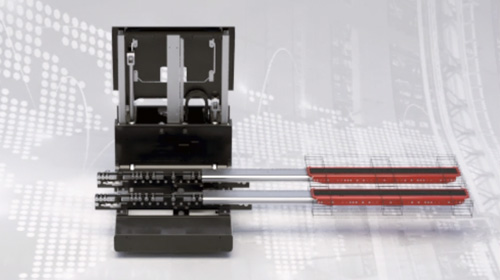

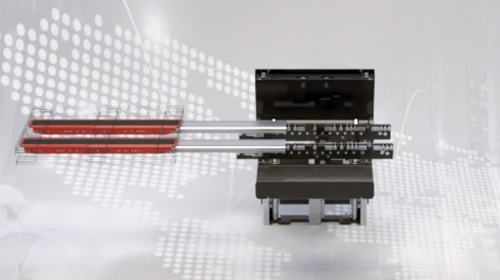

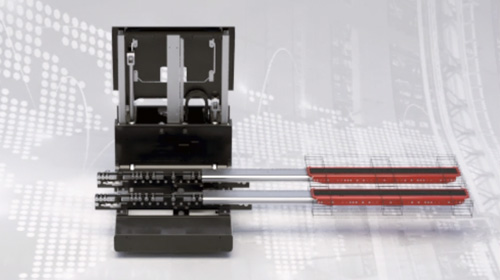

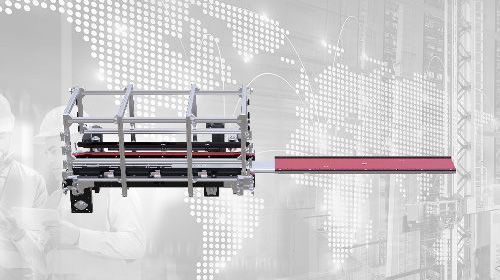

Double-Deep Miniload Telescopic Fork

-

The double-deep MIAS Miniload telescopic fork is particularly well suited to double-deep storage of containers in small components warehouses with narrow aisle clearance.

Operation: Three extending components enable a container to be placed either single-deep or double-deep in the storage compartment.

Due to the low cross-section height, a minimum distance between the containers in the shelves, and therefore a maximum number of containers in the warehouse, is achieved.

Highlights:

- High availability

- Optimum storage capacity due to narrow aisles and double-deep storage

- Can be used at temperatures as low as -30°C

- Compact, weight-optimized design

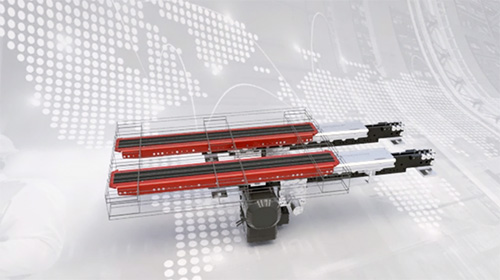

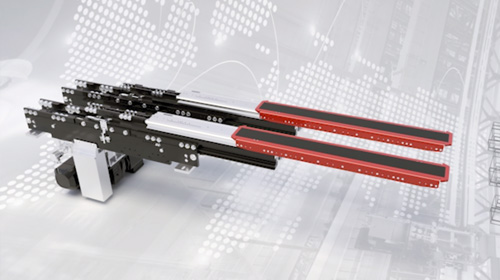

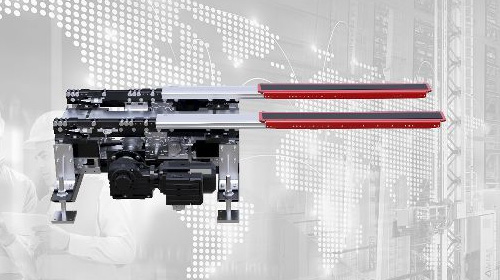

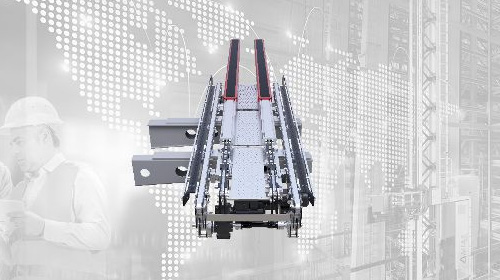

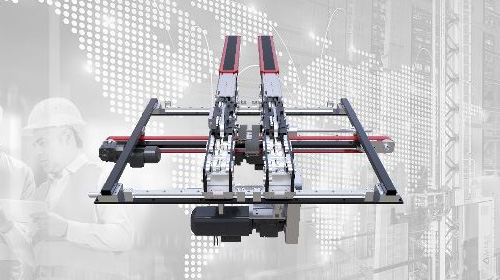

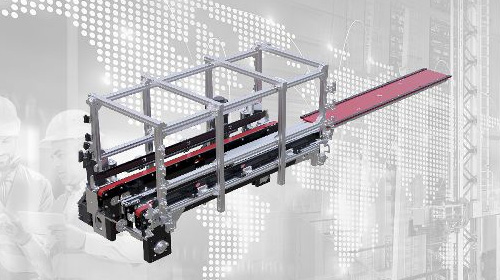

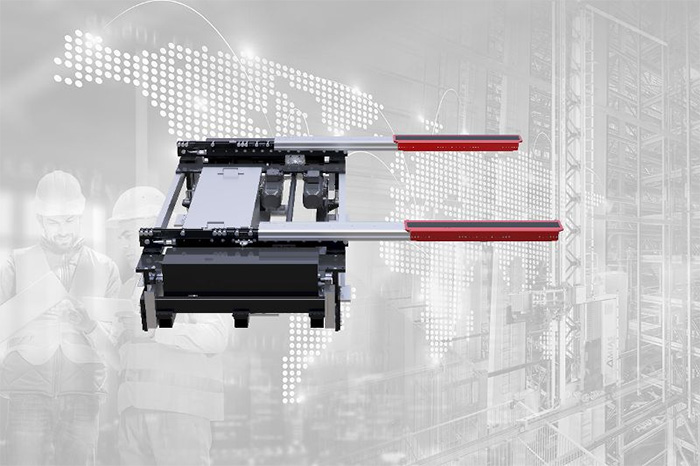

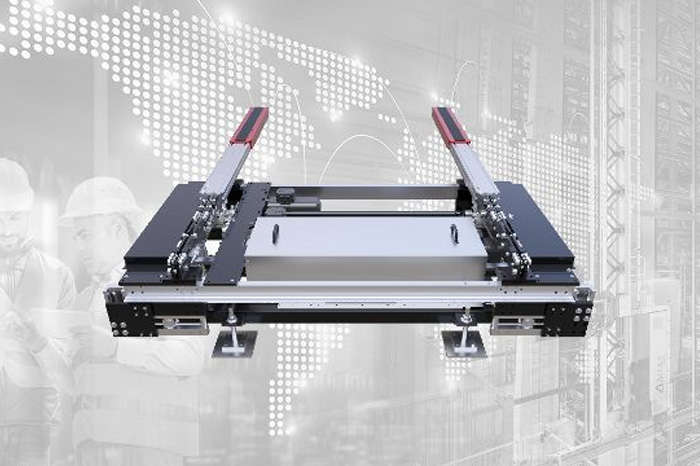

Telescopic Fork With Belt Conveyor

-

Telescopic forks with lateral belt conveyor can be used to store and retrieve containers and cartons up to a maximum weight of 100 kg, up to five levels deep, in shelf compartments.

Our positive-locking drive concept enables high dynamic values to be achieved.

The telescopic fork can also be used in combination with a laterally mounted belt conveyor to create driven conveyor systems at the storage and retrieval location.

Exact positioning of the load is ensured by the alignment and centering of the load via flaps on the load handling device.

Highlights:

- Low overall heights and therefore optimum use of the storage volume

- Optimum mechanical design

- Lightweight design

- Can be combined with any type of drive

- Can be used at temperatures as low as -24°C

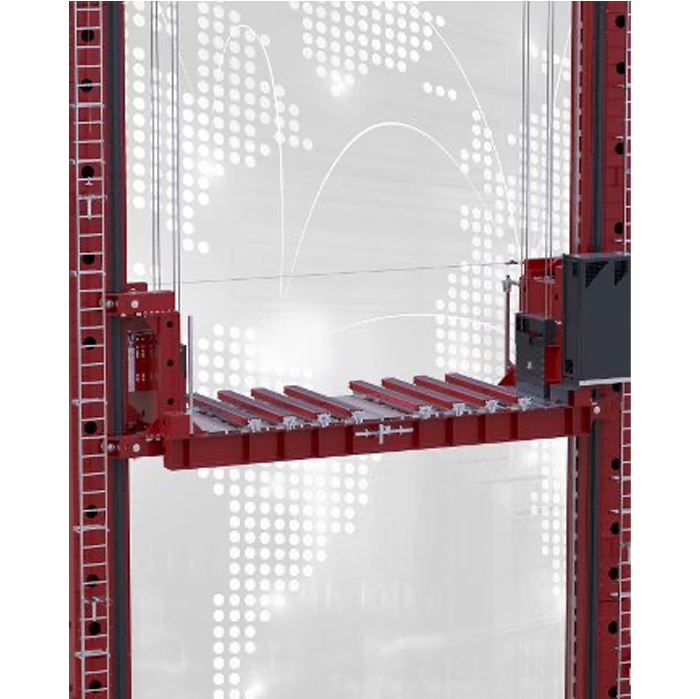

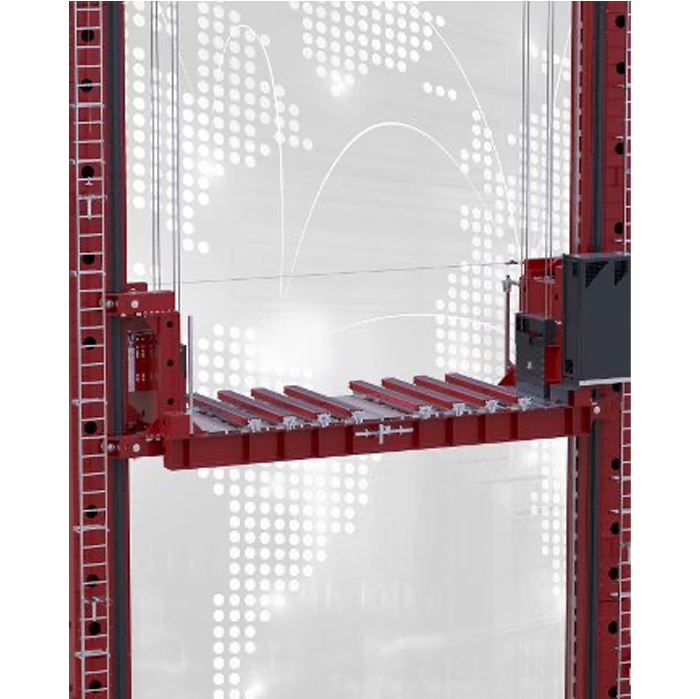

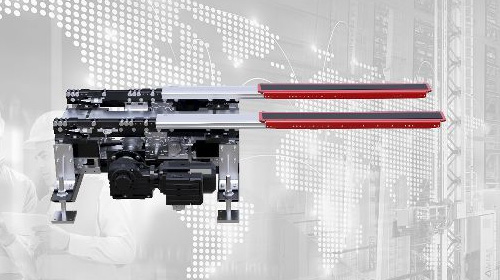

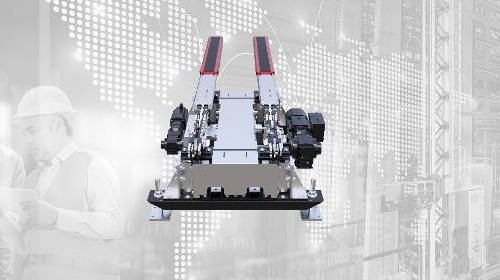

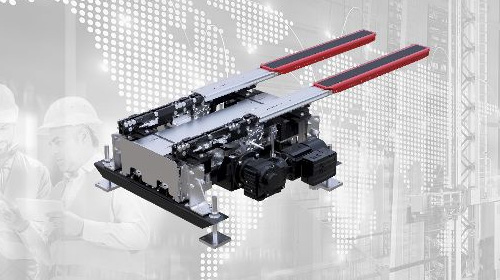

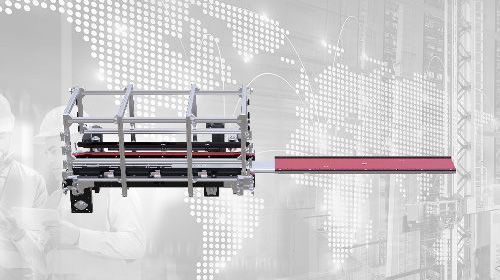

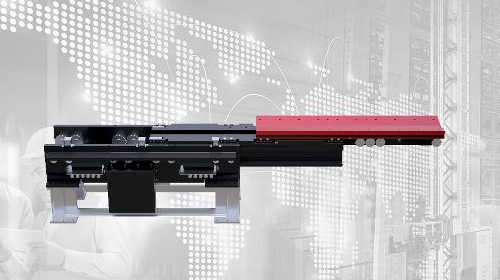

Telescope Belt Conveyor

-

These combined telescopic forks can be used to store and retrieve containers weighing up to 140 kg, single-deep or double-deep, in shelf compartments. Our positive-locking drive concept enables high dynamic values to be achieved.

The telescopic fork can also be used in combination with a belt conveyor to create driven conveyance systems at the storage and retrieval location. Finally, the additional load capacity on the double-deep version ensures the exact positioning and alignment of the load.

Highlights:

- Tried-and-tested technology

- Low overall height and therefore optimum use of the storage volume

- Optimum mechanical design

- Lightweight design

- Can be combined with any type of drive

- Can be used at temperatures as low as -24°C

Viper X Carton Gripper

-

Cartons pose particular challenges when it comes to automatic load handling: from highly diverse conditions and sizes to practically undefinable tolerances. But here too, MIAS has a solution!

With the Viper X series you have a firm grip on every type of carton. Thanks to the individually configurable number of gripper fingers, up to four loads can be stored one behind the other in a single storage compartment.

Highlights:

- Variable load sizes

- Dynamic load handling

- Optimized mechanical design

- Can be used at temperatures as low as -24°C

Heavy-Duty Load Handling Devices

-

Designed for extreme conditions

Load handling devices for heavy loads in mechanical and plant engineering.

High rise storage facilities have asserted themselves in both the steel industry and in mechanical and plant engineering. MIAS is the specialist for load handling attachments in this field. For decades, MIAS has been building and setting up these exceptionally stable and sturdy devices, which are often used in extreme environmental conditions.

Single-Deep, Heavy-Duty Telescopic Fork

-

A MIAS solution for moving extremely heavy loads weighing 1,500 to 7,000 kg. Designed for use in a challenging environment, often with a high level of pollution.

Whether you want to shift a simple steel plate or a gear for wind turbines – this is exactly what MIAS telescopic forks from the heavy-duty range are designed for.

Highlights:

- Extremely robust and durable

- Unrivaled resistance to bending

- High availability

Double-Deep Telescopic Fork

-

The double-deep storage of loads is a special challenge for design, load-bearing capacity and operational reliability. Double-deep, heavy-duty telescopic forks from MIAS tackle this challenge head on and have been demonstrating their stability all over the world for many years now.

Highlights:

- Optimal static and dynamic load-bearing capacity

- Low maintenance due to positive-locking, double-row stationary gear

- Large extension distances

- Optimum positioning reliability thanks to the combined drive concept

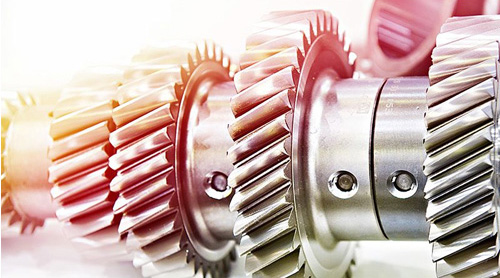

Super Heavy-Duty Telescopic Fork

-

The MIAS Super heavy-duty telescopic fork is the king among high rise storage facilities. It transports loads weighing 30 tons or more with ease, on just ONE tine. Thanks to its robust design, it is extremely low maintenance and reliable.

Operation: Perfect for high rise storage facilities in the steel industry.

Highlights:

- Up to 32 tons of working load per tine

- Optimal static and dynamic load-bearing capacity

- Low maintenance due to positive-locking, double-row stationary gear

- Can be used in high ambient temperatures

Load Handling Devices For Vehicle Bodies

-

Maximum Precision

Load handling devices for the automotive industry

MIAS has been at home in the highly sensitive processes of the automotive industry for many years now. Many of this sector’s leading manufacturers place their trust in MIAS’s special expertise in this industry.

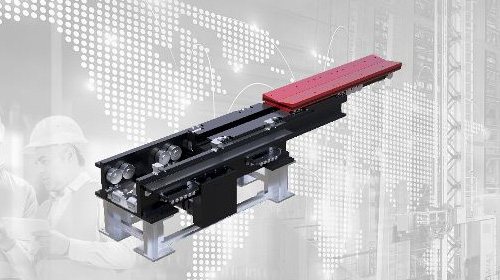

Telescopic Forks For Vehicle Bodies

-

Hardly any other branch of industry uses the telescopic fork for as many things as the automotive industry. In the production process, in particular, our telescopic forks are used wherever vehicle chassis and bodies are stored, transferred to the next production step or assembled.

Highlights:

- Reliable: more than 99% availability

- Optimum positioning reliability thanks to the combined gear – chain drive concept

- Very high stability

- Low maintenance due to positive-locking, double-row stationary gear

- With dynamic approach buffer if required

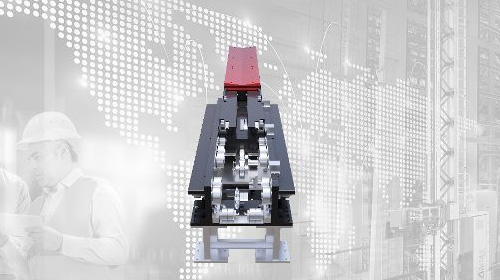

Eccentric-Stroke Telescopic Fork

-

In automotive production, chassis and vehicle bodies always have to be transferred from one production line to the next as they move through the various production steps.

Here, reliable and precise handling of the components is absolutely essential – and this is a particular strength of the MIAS eccentric-stroke telescopic fork.

It is not without good reason that automotive manufacturers around the world put their trust in our telescopic forks.

Highlights:

- Simple assembly

- Low overall heights

- Low level of fork bowing under load

- Exact component positioning thanks to the telescopic fork’s positive-locking drive concept

- With dynamic approach buffer if required

- Optional standby drives

Retrofits and Modernizations

-

Maximum quality standards

Targeted measures to ensure efficiency and future-proof your business.

Like all machines and systems, the mechanical and moving components of intralogistical parts also suffer wear.

MIAS comes up with innovative solutions in retrofit projects, to make your system high-performing, efficient, future-proof and highly available once more.

Retrofit Load Handling Attachments

-

Is your MIAS load handling attachment showing its age? Replacement isn’t the only way. With expert repair and reconditioning, many load handling attachments can be made fit for many years to come. This is how we do it:

- Actual wear analysis of the unit

- Report compilation

- Cost estimate for repair work

- Replacement of all wearing parts and faulty components such as guide rollers, guide rails, leaf chains, drive chains, gear components, chain adjusters, path measuring systems, bear-ings

- Test to ensure the reconditioned system is state of the art

- 12-month warranty for factory repairs

- For several load handling attachments, old parts can be swapped for good ones (an addi-tional load handling attachment is required)

The advantages for you

- Fixed price for peace of mind

- Allows you to plan ahead

- Higher availability and longer service life

- Saves resources

Retrofit Stacker Crane

-

Is your storage system showing its age? As an expert in stacker cranes, with targeted modernization we can optimize existing systems at low cost regardless of the manufacturer, and make them fit for the future. Refitting is carried out in the shortest possible time, ensuring you a smooth transition without significant downtime. What’s more, you will once again be able to obtain spare parts for your system.

MIAS analyzes the actual condition of the equipment, draws up a retrofit quotation for replacing or reconditioning the components that require it, and flags up possible potential for optimization.

With most systems, use of the ARATEC system makes it possible to increase throughput and minimize wear.

Grinding

- MIAS also provides services such as grinding the guide rail and track rails.

To do this, MIAS performs a situation analysis on-site, including an assessment of the rail condition, conducts a feasibility test to assist with decision-making, and suggests recommendations for improving hoisting unit guidance and running characteristics.

Naturally, when the work is complete we perform checks and test drives.

Optimization

- The first step towards optimizing actual system behavior in real-life operation is the motion analysis. This graphically analyzes current speed and motion profiles, because real-life behavior often differs from the machine model set in the PLC or converter. The analysis also enables us to verify potential optimizations beforehand. The documented results of this analysis demonstrate how use of the ARATEC positioning system optimizes travel profiles and motion sequences, eliminates traveling at creep speed, compensates for oscillations and shortens cycle times. Successful implementation of the ARATEC positioning system increases your throughput, minimizes wear and optimizes energy use. The system can be installed and brought into service in just a few hours.

ARATEC highlights

- Fully automatic identification of ideal travel profiles and controller parameters

- Oscillation compensation

- Travel profiles are optimized for time and distance

- Mechanical stress is reduced by up to 40%, resulting in lower energy consumption

- Throughput is increased by up to 33%

- Real-time, closed-loop positioning control

Service

-

MIAS after sales service

All-round support goes without saying.

The complete MIAS portfolio also includes a professional after sales service.

Every day, we work to impress our customers and partners with our service. Our performance is what makes customers recommend MIAS to others, strengthening our market position for the long term.

Inspection

-

MIAS inspects and assesses the system’s mechanical components. Based on these test results, you will be given information on any damages or risks. This enables you to nip problems in the bud proactively and in good time.

- Qualified information about current system status

- Risks and problems are flagged up

- You can plan maintenance work better and reduce repair costs

- Easier to budget

- Avoid downtimes

Maintenance

-

… extends the life of your system.

Qualified, experienced and committed MIAS engineers are specialists in the maintenance of both in-house and third-party systems, and ensure long-term and efficient operation. We strive to ensure lasting high availability and value retention.

- Recommendations for the punctual replacement of wearing parts

- Less downtime

- Increased system service life

- Can be combined with the UVV inspection, ladder,arrester and fall protection PPE inspection and oil analysis

Spare Parts

-

Even small parts can have a big impact if they are no longer working. Reliable system operation is ensured by a rapid reaction and a high level of specialist expertise. That’s why speed and quality matter when it comes to service.

- When we configure your spare parts package, MIAS also provides advice on your individual risk profile

- MIAS uses only high-quality genuine parts

- Spare parts are available for both MIAS and third-party systems

- If you wish, we can provide individually manufactured spare parts

UVV (Accident Prevention Regulations) Inspection

-

According to the BGV (German institution for statutory accident insurance and prevention), stacker crane systems must undergo an annual inspection in accordance with the UVV (German accident prevention regulations). This aims to ensure the safety of both people and machinery. We will be happy to monitor the timely performance of this inspection.

Our portfolio also includes optional inspections of ladders, arresters and fall prevention PPE.

Analyses

-

Oil analysis

- The gear oil analysis of hoist drives and drive units provides important information on the wear condition of the transmission

- The results from the analysis enable the risk of failure to be calculated and therefore re-duced

- Damage that is invisible from the outside can be discovered before a sudden failure

- The history of the analytical data for each device flags up any urgent need for action

- System availability is improved

- High costs, e.g. caused by emergency deployments, are prevented

Motion analysis

We recommend motion analysis as the first step for assessing the potential of a retrofit project to optimize your system. This establishes the potential of the ARATEC positioning system to increase throughput and minimize wear, and therefore determines its cost effi-ciency