Videos

Loading the player ...

- Offer Profile

- psb - your innovative and reliable partner

As a medium-sized, family-run company that is independent of any group, we have been mastering intralogistics challenges with our competent engineering team and high-performance project management for over 70 years. With their know-how and experience, more than 500 employees are responsible for the success of every single project.

Product Portfolio

Systems

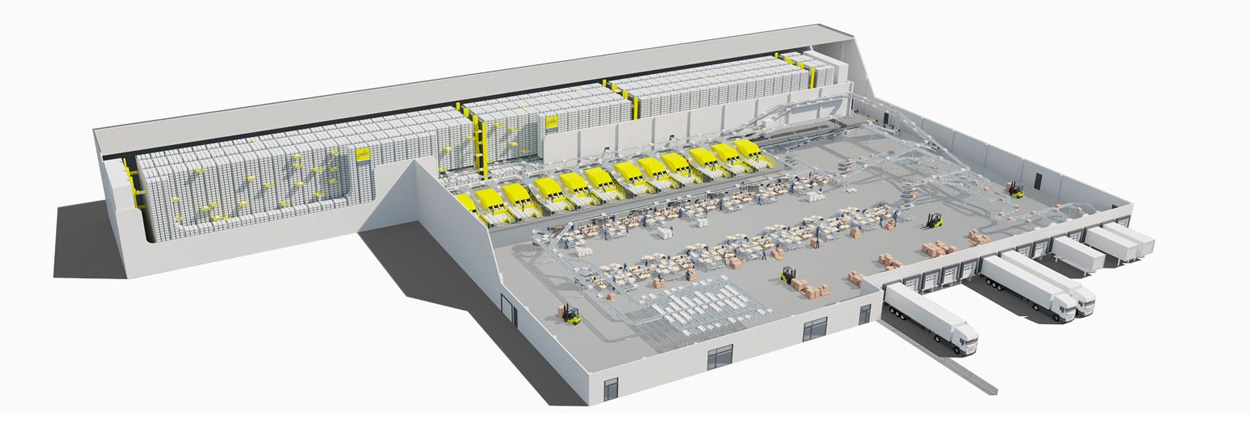

Intralogistics systems from psb

As a provider of complete intralogistics systems, psb has an extraordinarily wide range of systems in order to be able to respond optimally to all customer requirements. All components come from a single supplier:

Mechanisms, controls, software.

Whether floor-free or floor-bound system modules, our range of services extends from floor-bound conveyor technology to storage systems, picking solutions and sorters, to driverless transport systems or overhead conveyor technology. Our software suite offers the ideal platform to map your requirements and processes on the most economical level.Function

The psb system portfolio covers the entire range of the different functions of an overall intralogistics system.

Storing

-

The right automated warehousing system for every project

psb intralogistics offers a wide range of systems for automated warehousing solutions. This means that the right storage technology is available for every project. All automated warehousing systems are characterised by their modular design, up to 4-deep storage and innovative energy recovery systems.

In order to reliably transport and store the most varied load carrying devices, several versions and a number of different load handling devices are available. Depending on the requirements (storage height, capacity, performance, etc.), the automatic storage system suitable for our customers is put together from the »modular system« of tried-and-tested components.

Shuttle system - Multi Access Warehouse

- The patented Multi Access Warehouse is number 1 in terms of performance and flexibility. The innovative concept of the vario.sprinter shuttle is based on tote lifts that have been integrated into the warehouse aisles. This enables exceptional performance values ??of up to 3,000 double cycles/hour per aisle, with simple scalability and increased redundancy at the same time.

Shuttle system - vario.sprinter

- The psb shuttle system impresses with its high performance and scalability. It is ideal for small parts storage with high throughputs or for projects where the initial investment needs to be limited. The warehouse performance can easily be increased during operation by adding more shuttles. All proven pulling systems such as tray, tote and carton grippers or cassette pushers can be used as load-handling devices (LHDs). With its width-adjustable gripper arms, the vario.sprinter flex handles LHDs of different lengths and widths. This particular type of shuttle is combined with a racking concept with flexible storage location configuration.

Shuttle systems - compact warehouse microstore

- The new compact warehouse from psb intralogistics is an automated warehousing system for limited budgets: »Lean« and yet powerful. Limited neither in height nor in length, the microstore compact warehousing system is precisely tailored to the requirements of each customer project. An efficient automated solution can also be implemented in low-rise buildings. The storage system is suitable for a variety of uses, for example, as a tool storage or as a micro-fulfilment solution.

Hanging garments shuttle system - Dynamic Fashion Warehouse

- With a performance increase of up to 700% and a storage density increased by 25%, the Dynamic Fashion Warehouse of psb hanging goods storage has been rethought. The automatic storage system optimally combines the shuttle system and hanging garment technology. With its outstanding system properties in terms of performance, storage density, scalability and flexibility, the patented concept sets new standards in automatic hanging goods storage.

psb pallet shuttle

- The psb pallet shuttle is particularly suitable for being operated in multi-deep channel storage systems with high storage density. A pallet stacker crane transports the shuttle to the assigned channel. The shuttle then moves to the designated location and puts down the pallet.

The energy supply of the new pallet shuttle is provided by so-called supercapacitors. In addition to an economical system layout, this enables very flexible use, for example through the use of several shuttles per AS/RS stacker crane.

AS/RS stacker crane - sprinter

- sprinter stacker cranes are available in single-mast and double-mast versions and are suitable for storing light-weight cartons, totes and trays. They are particularly suitable for a high number of storage and retrieval tasks in automated high-bay warehouses. Like the entire system range, sprinter stacker cranes are also available with an additional mast drive.

AS/RS stacker crane - runloader

- The AS/RS stacker crane runloader from psb is optimised for heavy totes or cassettes with loads of up to 300 kg. In a special design, it can also be adapted for the hanging storage of clothing, bicycles, etc. The single-mast and double-mast units in aluminium design have very compact approach dimensions.

AS/RS stacker crane - maxloader

- These types of AS/RS stacker cranes have dynamics characteristics that set standards in their class. maxloaders are perfect for crates and pallets with loads of up to 1,250 kg, and they enable double-deep storage of the load-carrying devices.

Picking

Order picking systems for every task

psb's order picking systems impress with their economic efficiency and ergonomics. Different systems are available to suit the respective task: from manual order picking carts to fully automated high-performance workstations. We adapt the respective order picking facilities and systems individually to the requirements of your project.

Automatic order picking system autopick

- The fully automated solution for single-item picking can pick up a wide variety of bulk goods with vacuum cups and place them gently in the target tote. Previous teach-in of the individual products is not necessary.

psb pouch sorter

- With its exceptional system properties, the pouch sorter is the perfect picking solution, because it does not place any requirements on the upstream storage systems with regard to the retrieval sequences. This is an advantage for both manual and automated warehouses. By simply integrating this picking system into the overall system, costs can be significantly reduced and the performance increased.

High-performance order picking system rotapick

- Multi-source picking - Multi-order picking - Multi-target picking

Depending on the expansion stage, the modular psb high-performance system is able to buffer over 50 source or order totes at the picking station and, if necessary, make them available for picking within seconds. This eliminates uneconomical multiple transport from the warehouse to the picking station, which in turn significantly reduces order processing times. Another advantage is the order-based sequencing of goods.

With the rotapick, picking rates of more than 1,000 picks/hour can be achieved per workstation.

Flow rack - static or dynamic

- At order picking workstations on the flow rack, product totes are permanently available for order picking in flow channels. By means of »pick by light« displays, the quantity to be taken from an article tote and added to the order tote is indicated to the employee.

In static flow channels, always the same article is provided, whereas in dynamic channels, product totes are exchanged by an AS/RS stacker crane. Order picking with flow channels can be applied for all load-handling devices, from cartons to pallets.

Multi-order picking station

- The use of multi-order picking stations is useful if the majority of the orders contain identical parts or to relieve sequence-specific outsourcing.

Several order totes are available to the employee at the same time. The »put to light« display indicates to the employee in which order tote the respective picked quantity of goods is to be placed.

»One-to-one« picking

- At the picking workstation »goods to person with one-to-one picking« just one order tote is available to the employee. Product totes are made available from the warehouse in the correct sequence via conveyor technology. When the order is completed, the order tote is sent for dispatch and the next order begins.

Manually operated order picking carts

- Picking with manually operated picking carts in warehouse aisles is recommended, for example, for a large number of »A« items or for bulky goods. Depending on the solution, different aids such as »pick by voice« or »put to light« are used.

Sorting

psb sorting systems for a wide variety of goods distribution tasks

In overall intralogistics systems that are used for goods distribution, sorters are often used both in order picking and in the dispatch area. For the sorting of hanging goods and flat-packed goods, psb has various sorting systems on offer.

The innovative pouch sorter, which can also take on a buffer function and particularly shows its strengths in the efficient handling of returns, plays a special role.

Pouch sorter with automated bag unloading

- The major advantages of overhead conveyors in sorting goods is that they enable flat items such as shirts, shoes or other flat-packed goods to be handled. The goods are put into a hanging pouch and are transported, buffered, sorted or sequenced in this pouch. In the dispatch area, the goods are removed from the pouch either manually or automatically and are then directed to the dispatch process.

psb's mtr micro-trolley sorter

- This automatic buffering and sorting system is suitable for small items and for garments on coat hangers.

With the psb micro-trolley, sophisticated sorting tasks can be seamlessly integrated into integrated processes without the need to change the goods carrier. This also applies to more detailed sequence sorting. The micro-trolley is also used as a carrier in automated buffer areas.

psb's flat-packed item sorter

- The cross-belt sorter is used for the sortation and transport of flat-packed items. It is particularly efficient for handling totes, cartons, parcels and postal bags weighing between 50 g and 35 kg.

Outstanding features of the sorter are the flexible, three-dimensional routing with curved, incline and decline sections as well as the variable arrangement of infeed sections, outlets and sorting areas.

Conveying

psb's conveyor and transport technology

With an extensive modular system of floor-bound transport technology and driverless transport systems for different areas of activity, psb intralogistics has the right tools to solve your transport tasks. The overhead conveyor system family completes the portfolio with overhead components in transport technology. For detailed information, please see under the heading of ‘Hanging garments handling'.Floor conveyor technology

The psb product line for unit load conveyors is an essential part of intralogistics material flow solutions. Roller, belt or chain conveyors, including efficient transfer elements, can be combined with each other to suit individual requirements. In addition, three-dimensional configuration can be implemented using vertical and diagonal conveyors.

The conveyor technology product line from psb is suitable for transporting individual parts, totes, cartons and pallets and is adapted to the weight and dimensions of the goods to be transported, as well as the desired system performance. Even demanding sorting tasks can be handled without any problems using sorting systems.

Conveyor technology for lightweight cartons, totes and trays

- psb's conveyor technology transports, lifts, accumulates or transfers lightweight load-carrying units such as cartons, totes or trays in different performance classes. Our system modules impress with their careful transport of goods. Depending on the individual project requirements, between a few hundred and several thousand load-carrying units are moved per hour.

Conveyor technology for heavy trays and cassettes

- In the medium weight class, multi-track conveyors are used for transporting trays and cassettes. Frequency-controlled drives provide for both gentle transport and workplace safety.

Heavy-load conveyor technology

- Heavy-load conveyor technology allows both horizontal and vertical transport of, for example, pallets and crates. Additional elements such as scales, shape controls or monitoring devices for pallet runners are used depending on the individual requirements.

Automated guided vehicles - AGV psb carobot

- AGVs - Automated Guided Vehicles are flexible links between production and storage. The self-driving, battery-powered vehicles fulfil a wide range of transport tasks. The maximum configuration of the modular system is the integration into an overall concept with selektron host computers for flexible production interlinking and dynamic solutions for distribution tasks. The vehicles are controlled by laser navigation, so that no works have to be carried out on the floor.

psb has developed various carobot vehicle types for different load classes. Depending on the task at hand, these can be combined with a wide range of load-handling devices.

Overhead conveying

- psb overhead conveyor systems deliver the optimum solution for every requirement. Whether it is a long, short or micro-trolley, whether driven or with gravity tracks, whether trolleyless or with trolleys, psb offers a broad system range with the most suitable solution for any task.

This extensive system kit is complemented by the manual or automated psb warehouse for hanging items.

Pouch sorter with fully automatic bag unloading

- The major advantages of overhead conveyors in sorting goods is that it enables flat items such as shirts, shoes or other flat-packed goods to be transferred.

The goods are put into a hanging pouch and are transported, buffered, sorted or sequenced in this pouch. In the dispatch area the goods are removed from the pouch either manually or automatically and are then directed to the dispatch process.

Trolleyless transport systems

- Our trolleyless system range with individually adaptable modules enables hanging goods to be transported, stored and sorted without using any load-carrying units at all. The benefits of this concept are the continuous transport and low-pressure accumulation of goods.

Trolley transport systems

- psb Power & Free systems are based on a common platform strategy. Which trolley transport system is the one most suitable - a micro, short or long trolley - depends on, for example, the system capacity or the weight and dimensions of the goods to be transported. In addition to solutions for single parts, psb also supplies trolley systems that handle several parts. The psb micro-trolley is recommended when the emphasis is on sequencing. Different system tasks can be integrated seamlessly into the overall sequences without the need to change the goods carrier.

Electrical transport system - ets

- The psb mono rail system for the medium weight range. The speed of the individual, electrically driven transport vehicles can be adjusted individually; therefore, the system is suitable both as a pure transport system and as an assembly system in flow production.

Transport medium

- We have a comprehensive system portfolio for the handling and storage of the various load-handling devices.

Small-load carriers

psb's individually optimised intralogistics solutions for small-load carriers

Regardless of whether the small-load carrier is a carton, tote or tray, we have the right concepts and systems, which we combine to create an optimal solution for each customer. Whether for production or distribution, our wide range of systems for the storage and handling of small-load carriers meet every requirement.

Our range of solutions is also very extensive in line with the diverse tasks and applications in the field of small-load carriers: Moderate to highest performance requirements, scalability, flexible usage concepts, horizontal or vertical conveyor technology, flexible interlinking, scales … there is no requirement that our modular system cannot cope with.

Storage of small-load carriers

- For the storage of small load carriers, we offer AS/RS stacker cranes designed for the different load classes. For more performance or increased flexibility, our vario.sprinter shuttle solution is available in various configurations. The worldwide No. 1 in performance and flexibility in the field of shuttle systems, our Multi Access Warehouse operates at up to 3,000 double cycles/hour. This particular shuttle warehouse is also characterised by very good scalability, i.e. exactly the performance and capacity that is currently required is always available. Extensions are possible at any time, even during operation. Areas that are not required can simply be deactivated during off-peak times. The psb microstore compact warehouse is ideal for entry into the automated storage of small-load carriers or as an additional decentralised warehouse e.g. for tools.

Transporting small-load carriers

- Our large modular system fulfils all your transport tasks for small-load carriers as well as the linking of the various system areas in different performance classes, at a speed of up to 3,000 LCUs/hour. Adapted to your warehouse concept, we transport horizontally or vertically, with conveyor technology or flexibly with driverless transport systems, hanging or lying flat, with belt or rollers, left or right - adapted to your specific project requirements.

Picking small-load carriers

- The picking of small-load carriers is, in addition to the warehouse, the key area of ??an intralogistics system. Performance, accuracy and being able to carry out additional tasks are the parameters that influence our choice of the right solution. This leads to individual optimisation in every project.

We therefore offer a very wide range of systems for picking small-load carriers: from manual picking trolleys to one-to-one picking in the “goods to person” principle, to high-performance systems for the simultaneous processing of up to 60 orders and up to 1,000 picks/hour or the fully automatic robot picking.

Additional functions

- The requirements for an intralogistics system are not limited to these three main tasks. Only the seamless interlocking of the many complementary work and functional areas results in a successful and sustainable intralogistics solution.

These include, for example, workplaces for storage, packaging or, value-added service (VAS). Special functions such as scales and automatic or manual loading systems for tugger trains can also be integrated. A flexible crossbelt sorter takes on demanding sorting tasks in both order picking and dispatch.

In many projects, solutions for special requirements such as returns management with the use of a pouch sorter is of particular importance.

Heavy-load carriers

Individual intralogistics solutions from psb for heavy-load carriers

For heavy-load carriers - pallets, crates, totes, trays - we offer a wide, coordinated system portfolio: from transport to storage to order picking. This also makes it possible to handle heavy or large parts automatically in production and distribution processes.

In addition to systems for large storage units, we also have combined solutions with which both pallets and half-pallets can be moved and stored.

Storage of heavy-load carriers

- The maxloader AS/RS stacker crane from psb is suitable for storing heavy-load carriers such as crates and pallets with loads of up to 1,250 kg. These automatic stacker cranes have a dynamic performance that sets standards in their class and enables double-deep storage of the load-carrying units.

Multi-deep channel warehouses with a very high storage density are what the psb pallet shuttle is used for. A pallet AS/RS stacker crane transports the shuttle to the assigned channel, from where the pallet is deposited by the shuttle at the specified location. The energy supply of the new pallet shuttle is provided by supercapacitors. In addition to an economical system layout, this enables a high degree of flexibility when using the system, for example, through the use of several shuttles per AS/RS stacker crane.

Transporting heavy-load carriers

- Heavy-load conveyor technology enables the horizontal and vertical transport of heavy-load carriers such as pallets and crates. Additional elements such as scales, shape controls or monitoring devices for pallet runners are used depending on the individual requirements.

Driverless transport systems (AGVs - Automated Guided Vehicles) are flexible links between the various company areas, such as between production and storage, or between incoming goods and the supply warehouse. The self-driving, battery-operated vehicles are suitable for a wide range of transport tasks. The maximum configuration of the modular system is the integration into an overall concept with selektron host computers for flexible production interlinking and dynamic solutions for distribution tasks. The vehicles are controlled by laser navigation. Preparatory work on the floors is no longer necessary.

Picking of heavy-load carriers

- At the picking workstation “goods to person with one-to-one picking”, just one order tote is available to the employee. The heavy-load carriers are made available from the warehouse in the correct sequence using conveyor technology.

At order picking workstations on the flow rack, the pallets are permanently available for order picking in flow channels. By means of »pick by light« displays, the quantity to be taken from a pallet and added to the order tote is indicated to the employee.

Hanging goods

Overhead conveyor technology from psb: perfectly coordinated complete systems for hanging goods

We have the right solutions ready to transport and store hanging garments or other goods such as seat covers. For many years, psb has been offering its customers the complete system range of overhead conveyors for handling and storing hanging goods - regardless of whether it's for garments or bicycles.

With our know-how, we also plan and implement perfectly coordinated intralogistics systems from a single source in this particular area of ??application. In addition to a comprehensive modular system for automated overhead conveyors, a complete portfolio of manual or partially automated solutions is available for all functions.

A highlight of our in-house overhead conveyor systems is the psb pouch sorter. It uses the basic technology of an overhead conveyor for buffering and picking flat-packed items in pouches. The handling advantages of hanging garments, such as space and easy access to individual parts, can also be used for flat-packed garments.

Storage and buffering of hanging goods

- We have two automatic overhead conveyors available for efficient storage of hanging goods. Our hanging goods AS/RS stacker crane type runloader has been successfully in use for many years.

The vario.sprinter hanging garment shuttles in the Dynamic Fashion Warehouse range from psb are in a completely new performance class. The performance increase compared to the classic AS/RS stacker cranes is up to 700%. Due to their easy scalability, the required initial investment is significantly lower. Another advantage is the improved system redundancy of this hanging goods storage system.

Static or dynamic hanging goods buffers are integrated for quick access to the goods on stock. For dynamic buffers with access to individual parts, very short reaction times and correspondingly quick provision of the goods for packing and dispatch are possible.

Transporting hanging goods

- A whole family of overhead conveyor systems is available for transporting goods. Trolleyless conveyor technology ideally complements the various trolley systems. We use the ets electrical transport system for heavy goods. With our manual GTT conveyor technology, transport tasks can be solved very economically and without a high initial investment.

Sorting hanging goods

- The micro-trolley sorting system mtr with its matrix sorting of up to three stages is suitable for a precise sequence with high performance. Ideally linked with our buffer systems, it eliminates complicated system changes.

Additional functions for hanging goods

- As a full-range supplier, we have different solutions for all necessary intralogistics functions in the system portfolio for overhead conveyors. In this way, we can offer our customers a complete solution that is perfectly tailored to your project.

The various systems for overhead conveyors are supplemented by the associated workstations and connected functional areas, such as automatic truck unloading with automated inbound goods, quality assurance, value-added services, “flat to hang”, packaging and dispatch.

Polybags

Polybags

- Use of polybags in intralogistics: Solutions from psb

The handling of polybags is becoming increasingly important, especially in e-commerce. Due to their specific properties, polybags place special demands on automated logistics systems. The current generation of psb system components were developed with taking these requirements into account: Depending on the size of the polybags, they can be transported using psb's load unit conveyor technology or, for example, be sorted according to distribution relations.

Even for very small dimensions and weights, our flexible sorter systems meet the different requirements of the polybags and thus achieve high distribution rates. Of course polybags can also be transported, buffered and sorted by the pouch sorter. The bag guarantees equally safe handling - with high performance and with an adapted buffer function.

Application

- With our many years of experience in many sectors, we offer intralogistics solutions for almost all areas of application.

E-commerce

- High demands for e-commerce - psb's tailor-made intralogistics

Ordered today - delivered tomorrow! Or even better: same-day delivery. Are you familiar with this expectation that customers naturally have of online retail, regardless of whether it is e- or m-commerce?

For companies, this means many orders with a few items in each, from an often very large selection of items in the warehouse, very fast processing and delivery as well as returns management. In addition, there is sometimes the combination of different sales channels in multi-channel distribution.

These characteristics require intralogistics that is very different from that in other areas - and that is tailor-made for the e-commerce model of the respective company.

Retail

- psb solutions for the retail sector

Distribution logistics in the retail sector must cover a wide variety of tasks, such as the synchronous initial delivery of new goods to many distribution bases or the rapid subsequent delivery of batches or individual parts. Sorting by styles, sets or individual parts within the stock keeping unit (SKU) must also be taken into account when planning the system.

Whether for sales via point of sale or in a multi-channel model, the quality of delivery in terms of goods and time is key for customer satisfaction - and thus, business success.

Returns

- Efficient returns processing is essential for business success

The challenge of processing returns mainly concerns companies in online trading. But even in stationary retail, especially with changing collections, returns can occur that require a well thought-out concept for efficient processing.

E-commerce, or rather m-commerce, has been growing rapidly for several years. Online ordering however leads very often to many returns because the ordered goods don't please or fit well. This trend will not change in the near future either.

Fashion

- Complex tasks require intralogistics planning with expertise

Several season or collection changes per year and goods that have different handling characteristics for each change, for example due to different weights and dimensions, means there are special requirements for intralogistics in the fashion industry. The handling of styles or the exact order of delivery at the packing station - so that heavy shoes do not lie on light blouses - are just two other challenges.

In the fashion sector, we also experience particularly strong market fluctuations: weather-related and seasonal fluctuations within a year, as well as strongly varying business trends from year to year.

Fashion suppliers very often work in omnichannel sales, so the completely different requirements of the various distribution channels have to be taken into account when planning intralogistics. In addition, the share of returns in e-commerce is particularly high in this industry.

Production

- psb offers flexible intralogistics solutions for production supply

The terms JIT and JIS production (just-in-time and just-in-sequence) and LIVE production originate from the automotive industry. These concepts have long since established themselves as a production philosophy in other sectors.

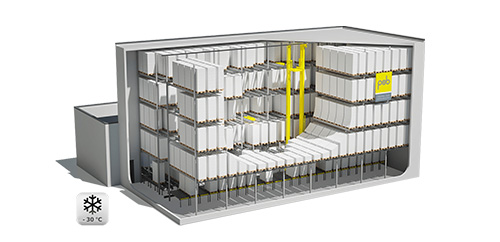

Cold storage

- psb's solutions for cold storages: economical and energy-efficient intralogistics

A high level of energy efficiency is essential for the economic operation of cold storages. A particularly high storage density, for example, is one approach to achieve this goal. In addition, special attention is paid to the continuous cold chain. For this purpose, all upstream and downstream areas such as production and dispatch must be seamlessly integrated into the overall concept.

The careful handling of goods is guaranteed with our solutions for cold storage, as well as short access times. Several different temperature ranges can also be combined with one another in an integrated concept.

Services

Consulting and planning

- The implementation of intralogistics systems that are successful in the long term requires integrated, well-thought-out intralogistics planning strategies. The intralogistics systems from psb, which are tailored to customer requirements, clearly go far beyond “off-the-peg” logistics systems in terms of efficiency and cost-effectiveness.

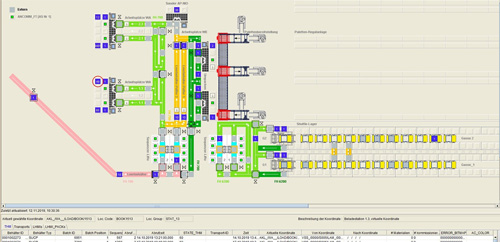

Simulation & Emulation

- In intralogistics systems, it is not just the individual systems such as the warehouse or individual conveyor lines that have to meet high standards, e.g. in terms of performance or flexibility. The particular challenge in the implementation of intralogistics systems lies in the safe interaction of all individual trades in order to meet the required overall performance. In order to ensure that the intralogistics system, designed specifically for a customer, fulfils the desired properties, psb uses an efficient simulation tool when planning the system. With the help of this, various scenarios as well as the dynamic behaviour of the planned intralogistics systems can be checked before implementation. This ensures that all intralogistics systems are optimally dimensioned and already fulfil some of the future requirements at the start of use that can only be expected in the future due to company growth or changes in the business model.

Lifecycle-Service

- Lifecycle service from psb:

Our service - your security

With our psb lifecycle service, we guarantee you maximum system availability with high performance and a long service life. We know how essential a highly available and effective intralogistics is for our customers, especially when, for example, production takes place in multi-shift operation and JIT production, or when in e-commerce goods are dispatched according to the »same-day-delivery« principle.

Service whenever it matters - 24/7

An important component in ensuring maximum system availability is our 24/7 service. You can reach our psb service team around the clock, even at three in the morning, on Sundays and public holidays; in short, whenever it matters.

There is no intermediate call center, but designated psb specialists are always directly available for you. We know your system and know what will help you quickly and reliably. From the factory in Pirmasens, our team works together with decentralised service centers in Germany and abroad.

Retrofit

- Retrofit - efficient modernisation of proven intralogistics systems

Intralogistics systems, whether large or small, represent a significant investment for every company. After many years, often several decades, in use, the question arises whether to purchase a cost-intensive replacement in order to optimally meet changing requirements.

Projects for the optimisation of existing intralogistics by psb show time and time again that this retrofit can represent a more economical alternative to the complete renewal of your system.

Service-Portal

- With the psb service portal you have direct access to the psb service system

While using our service portal, you can inform us in the event of a malfunction using our ticket system.