- Offer Profile

-

Productivity, competitiveness, reliability and flexibility.

Itoh Denki provides high quality, intelligent solutions for intralogistics conveyor applications.

What's new ?

Spring 2025 - It's show time !

-

It soon comes around again. No sooner is the Christmas and New Year break over than we are preparing for what is arguably our most important period of the year in terms of marketing. We’re referring of course to trade show season, with three of the most important international events at which we exhibit coming up over the next couple of months. Even with so much business transacted online, we find there’s still nothing better than to get out there and meet face to face the people who specify, buy and use our technologies.

Our view is that the only way to get a real feel for what our acclaimed MDR-based conveying, sorting and diverting systems can offer is to see them in the flesh, get a real understanding of how they work – and how they can optimise performance in a large variety of applications, whether in transitics or in production processes. That’s why we’ll once again be showcasing our latest technologies at three major forthcoming events: LogiMAT and SiTL in Europe, and ProMat in the US.

Taking place this year in Stuttgart from March 11-13, LogiMAT is established as the global ‘Mecca’ for systems designers and specifiers from Europe and around the world seeking innovative solutions for intralogistics applications.

Times may be tough - but capital investment is still the way forward

-

Amid continued uncertain political and economic times, it is easy to see why some companies globally may consider shelving major planned investments in capital equipment.

However, irrespective of these challenges, for businesses seeking to enhance the capacity and quality of their logistic processes, implementing a certain level of automation into their processes is key. Even in better times, it can be tempting to ‘sweat the asset’ – to continue using an older manufacturing, assembly or conveying system, as long as it is functional. But to do this can often fail to address the real needs of the business – and its customers.

Older systems are of course more prone to breaking down – often without notice – and the more aged the system, the harder it can be to find spares, and someone to fit them, at short notice.

Marrying speed and sensitivity : keeping fragile products safe

-

It’s often said that speed is of the essence. And while that’s certainly true in modern processing, warehousing and e-logistics facilities, facing requirements for ever quicker throughput, just as important is product safety.

Handling fragile or sensitive products – safely and effectively – is a challenge that has faced system designers and manufacturers for many years. Items ranging from cartons of fresh eggs and glass bottles, to sensitive electronical parts and chemicals, need to progress through the facility without the risk of damage that will mar their value and potentially damage equipment, resulting in costly downtime.

In these applications, products simply cannot be subjected to sharp lateral movements, sudden drops or stops, or impacts from other products or equipment.

Transitic and Itoh Denki : working together to drive innovation and intralogistics performance

-

In the intralogistics market, some partnerships stand out for their impact and durability. This is certainly the case for Itoh Denki when it comes to our collaboration with and Transitic, a leading French designer and integrator of automated solutions.

For 15 years, the two companies have shared a common vision: intralogistics focused on technological innovation and operational performance. Through the life of each project, the two companies combine their expertise to offer customers automated conveyor solutions which marry precision, modularity and efficiency.

By 2023, Transitic had equipped eight of its customers with Itoh Denki systems. In the space of a year, Transitic’s teams installed 1,000 motorised rollers and transfer modules for a wide variety of appplications.

A diverting experience : how our new M-RAT compact diverter ensures safe handling of larger loads

-

The need to safely, rapidly and effectively transfer product between processing areas is a well-established one across material handling functions in both manufacturing and logistics.

The challenge of efficienlty transfering heavier itemsFor smaller and lighter product, specifiers can select from a range of modular and easily commissioned options.

However, when it comes to larger and heavier items, the choices have traditionally been more limited.

But this requirement is growing, especially in sectors such as automotive where items such as electric vehicle batteries, as well as other larger components, must be transferred or routed between different processes.

System designers must also consider evolving operational requirements and how systems may need to be reconfigured to meet them.

Here, the ability to quickly rearrange process layout can be a significant advantage.

Choosing the right braking option for your motorised rollers

-

In automated conveyor lines, it is sometimes necessary to precisely stop or position the article being transferred.

To ensure safety of both the operators and the products, for example on declining lines, the optional POWER MOLLER built-in electromagnetic brake should be used.When not powered, the built-in electro-magnet uses spring force to lock the motor and prevent the tube rotation.

The motor is released when the brake is powered (energised). Ordinarily, the power to the brake and motor is controlled simultaneously. In most cases, an external mechanical stop can be eliminated by using the POWER MOLLER motorised roller with the built-in brake.

However, the stopping distance may vary slightly depending on different parameters, like the load material load, weight, transfer speed, etc.

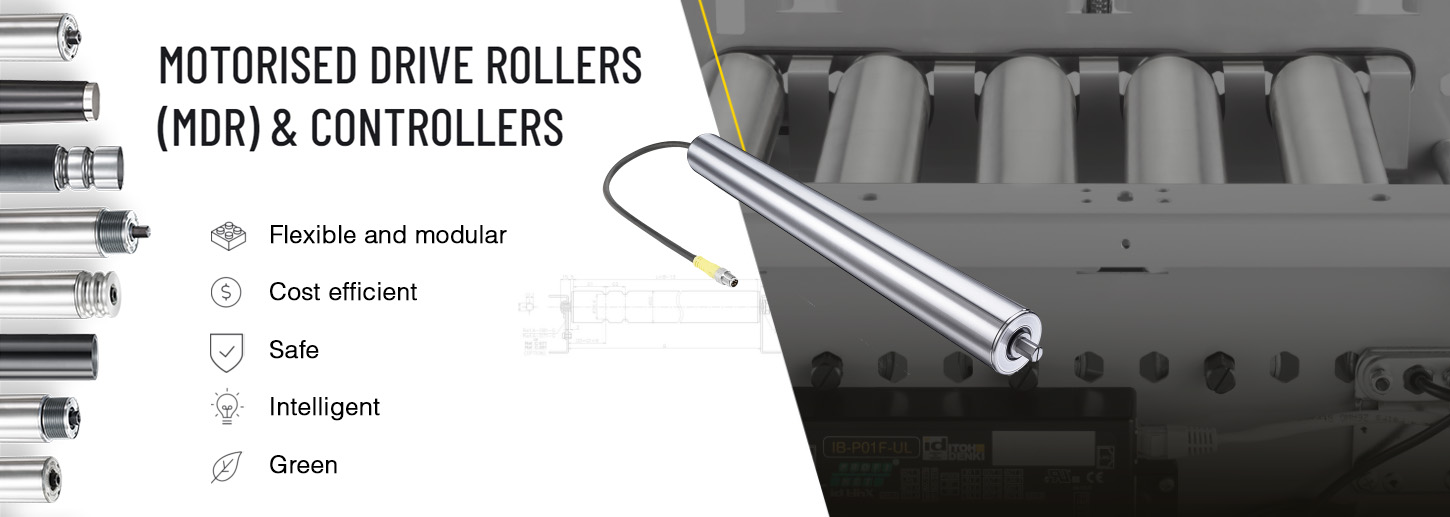

MOTORISED DRIVE ROLLERS (MDR) & CONTROLLERS

-

Developed and improved for over 40 years, Itoh Denki’s motorised drive rollers or MDR are the core component of advanced automated conveyor systems, it is now widely used and praised by a variety of industries and innovative logistic centers around the world.

MDR are used in the design of high capacity, cost efficient, flexible, reliable and safe installations.

Our extensive range of MDR and customisation options, can efficiently drive most types of conveyor applications, for light, medium or heavy loads transportation. It allows flawless automated material flows, all along the intralogistic processes (reception, storage, order preparation, shipping, assembly…)Itoh Denki’s MDR are controlled either by internal circuit boards, or with external controllers, which range from standard control features (speed, direction..), to ZPA integrated logic, up to intelligent programmable IoT networked controllers.

PM500XE With internal controller

-

- Diameter: 50mm

- Recommended for: Light to medium loads

- Available versions: IP54 . IP65

The PM605XP is designed for conveying light and medium loads (up to 500kg) , for order preparation, distribution, on assembly lines …

It provides a very high starting power, as required in automatic shops with shuttles, trolleys, etc …The circuit board is integrated within the roller body, allowing a simple installation, easy wiring thanks to the M8 connector and better protection of both the roller and the controller.

The PM605XP is an ideal solution for difficult work environment (dust, liquid…)It can be easily controlled with a PLC, Asi-Bus via Bihl & Wiedemann module, or logic sensors with integrated ZPA from Wenglor.

PM605XE With internal controller

-

- Diameter: 60.5mm

- Recommended for: Light to medium loads

- Available versions: IP54 . IP65

The PM605XE is designed for conveying light and medium loads (up to 500kg) , for order preparation, distribution, on assembly lines …

The circuit board is integrated within the roller body, allowing a simple installation, easy wiring thanks to the M8 connector and better protection of both the roller and the controller.

The PM605XE is an ideal solution for difficult work environment (dust, liquid…).

It can be easily controlled with a PLC, Asi-Bus via Bihl & Wiedemann module, or logic sensors with integrated ZPA from Wenglor.

PM500XP With internal controller

-

- Diameter: 50mm

- Recommended for: Light to medium loads

- Available versions: IP54 . IP65 . Cold store

The brushless motorized roller PM500XP has the circuit board and gear-motor integrated within the roller allowing a good tightness, easy wiring with M8-5pins connector and space saving.

It can be easily controlled by PLC, Asi-Bus via Bihl & Wiedemann module or logic sensors with integrated ZPA from Wenglor, etc.It is designed for conveyor lines of light and medium loads (up to 300Kg max), in order preparation, in distribution, for assembly lines and especially for the automatic shops with shuttles, trolleys, etc … which require a high power at the start.

The motorized roller PM500XP is the ideal solution for difficult working environments (liquid, dust, …).

The control circuit board is integrated inside the roller and it can be used in combination with a Bihl & Wiedemann AS-Interface module to control 2 PM500XP, managing convey with ZPA.

PM605XP With internal controller

-

- Diameter: 60.5mm

- Recommended for: Light to medium loads

- Available versions: IP54 . IP65 . Cold store

The PM605XP is designed for conveying light and medium loads (up to 500kg) , for order preparation, distribution, on assembly lines …

It provides a very high starting power, as required in automatic shops with shuttles, trolleys, etc …The circuit board is integrated within the roller body, allowing a simple installation, easy wiring thanks to the M8 connector and better protection of both the roller and the controller.

The PM605XP is an ideal solution for difficult work environment (dust, liquid…)It can be easily controlled with a PLC, Asi-Bus via Bihl & Wiedemann module, or logic sensors with integrated ZPA from Wenglor.

Motorized rollers with integrated circuit board

PM500VE 24VDC Motor Driven Roller with external controller

-

- Diameter: 50mm

- Recommended for: Light to medium loads

- Available versions: IP54 . IP65

The PM500VE is designed for conveying light and medium loads, for order preparation, distribution, on assembly lines …

The controller is separated from the gear-motor in order to optimize the performance and durability of the roller. The M8 connector ensures an easy and secured wiring.

PM605VE

-

- Diameter: 60.5mm

- Recommended for: Light to medium loads

- Available versions: IP54 . IP65

The PM605VE is designed for conveying light and medium loads (up to 500kg) , for order preparation, distribution, on assembly lines …

The controller is separated from the gear-motor in order to optimize the performance and durability of the roller. The M8 connector ensures an easy and secured wiring.

PM500FE With external controller

-

- Diameter: 50mm

- Recommended for: Light to medium loads

- Available versions: IP54 . IP65 . Cold store . Mechanical brake

The PM500FE is designed for conveying light and medium loads (up to 300kg) , for order preparation, distribution, on assembly lines …

The controller is separated from the gear-motor in order to optimize the performance and durability of the roller.

PM605FE With external controller

-

- Diameter: 60.5mm

- Recommended for: Light to medium loads

- Available versions: IP54 . IP65 . Cold store.

The motorized roller PM605FE with brushless technology 24VDC, used with circuit board CBM-105 or HB510 is designed for conveying light and medium loads (up to 500kg) or order preparation, distribution, and for assembly lines. This circuit board is separated from the gear-motor in order to optimize the performance, durability of the roller and to offer diverse functions such as pulse signals, acceleration/deceleration, optional position holder… The assembly can be controlled by PLC.

PM605KT With external controller

-

- Diameter: 60.5mm

- Recommended for: Light to medium loads

- Available versions: IP54 . IP65 . Cold store . Mechanical brake

The PM605KT is designed for conveying medium and heavy loads (up to 1000kg). It is the most powerfull 24Vdc MDR on the market and can be used for carrying heavy unit loads (manufacturing, automotive…) or pallets. It is also a solution of choice for high tension or heavy loaded belt conveyors.

The controller is separated from the gear-motor in order to optimize the performance and durability of the roller.

PM320HS With external controller

-

- Diameter: 32mm

- Recommended for: Very light to light loads

- Available versions: IP54 . IP65

The PM320HS is designed for applications in distribution and assembly lines, used in belt conveyors conveying very light loads, for weighing, feeding, evacuation of parts …

Available from a length of 170mm, the PM320HS is the shortest motor driven roller on the market, allowing the design of very compact conveyor.

The controller is separated from the gear-motor in order to optimize the performance and durability of the roller. The assembly can be used independantly or controlled by PLC.

CONFIGURATION OPTIONS

- All our MDR (Motor Driven Rollers) can be configured to your requirements : diameter, lenght, tapperings, endcaps and shafts... Find the most common configurations on this page or consult us for other special options.

Circuit boards

Standard circuit board: CB018

- Setting of speed, direction

Error signal

Standard circuit board: CBV-108

-

- Setting of speed, direction

- Error signal

- AS-I power connection

Standard circuit board: CBM-105

-

- Setting of speed, direction

- Error signal

Standard circuit board: CBK-109

-

- Setting of speed, direction

- Error signal

- Compatible with mechanical brake MDR

Integrated ZPA logic: HBK-608

-

- Setting of speed, direction

- Error signal

- ZPA logic (zero pressure accumulation)

- Can control 2 MDRs, 2 sensors

Integrated ZPA logic: HBV-609

-

- Setting of speed, direction

- Error signal

- ZPA logic (zero pressure accumulation)

- Can control 2 MDRs, 2 sensors

Integrated ZPA logic: HB510

-

- Setting of speed, direction

- Error signal

- ZPA logic (zero pressure accumulation)

IoT Profinet Networked: IB-P01

-

- Setting of speed, direction

- Error signal

- ZPA logic (zero pressure accumulation)

- Controls 2 MDRs, 2 sensors

- Programmable control logic

- Networked communication

- Separate power supplies motor/control

- Remote control and diagnosis

IoT Profinet Networked: IB-P02

-

- Setting of speed, direction

- Error signal

- ZPA logic (zero pressure accumulation)

- Controls 2 MDRs, 2 sensors

- Programmable control logic

- Networked communication

- Separate power supplies motor/control

- Remote control and diagnosis

IoT Profinet Networked: IB-E01/03

-

- Setting of speed, direction

- Error signal

- ZPA logic (zero pressure accumulation)

- Networked communication

- Separate power supplies motor/control

- Remote control and diagnosis

- Programmable

IoT Profinet Networked: IB-E04

-

- Setting of speed, direction

- Error signal

- ZPA logic (zero pressure accumulation)

- Networked communication

- Separate power supplies motor/control

- Remote control and diagnosis

- Programmable

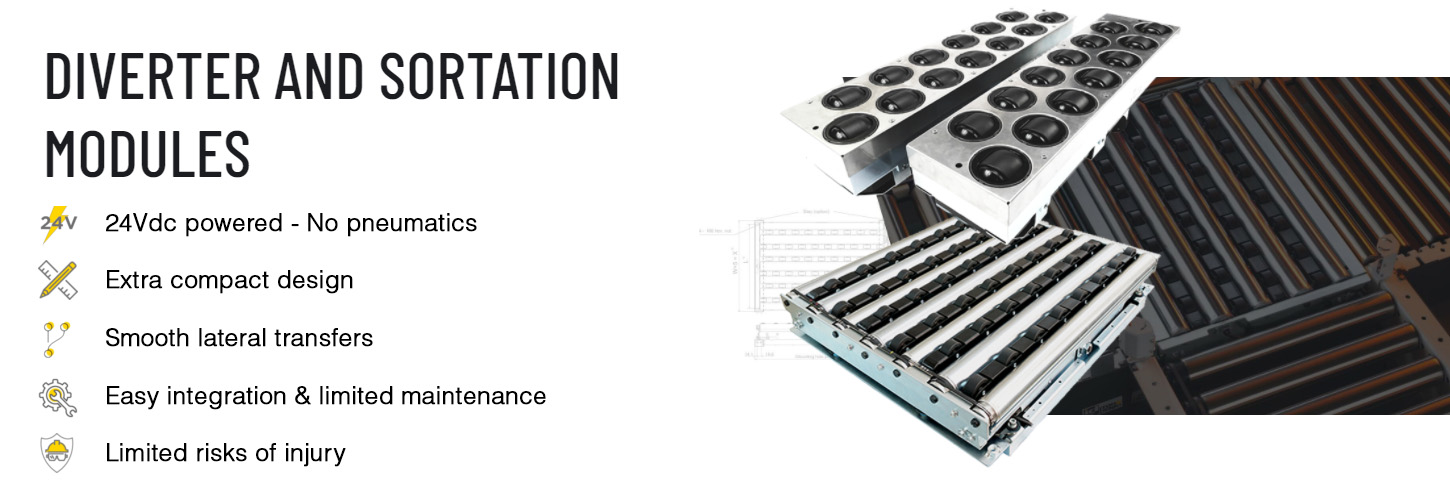

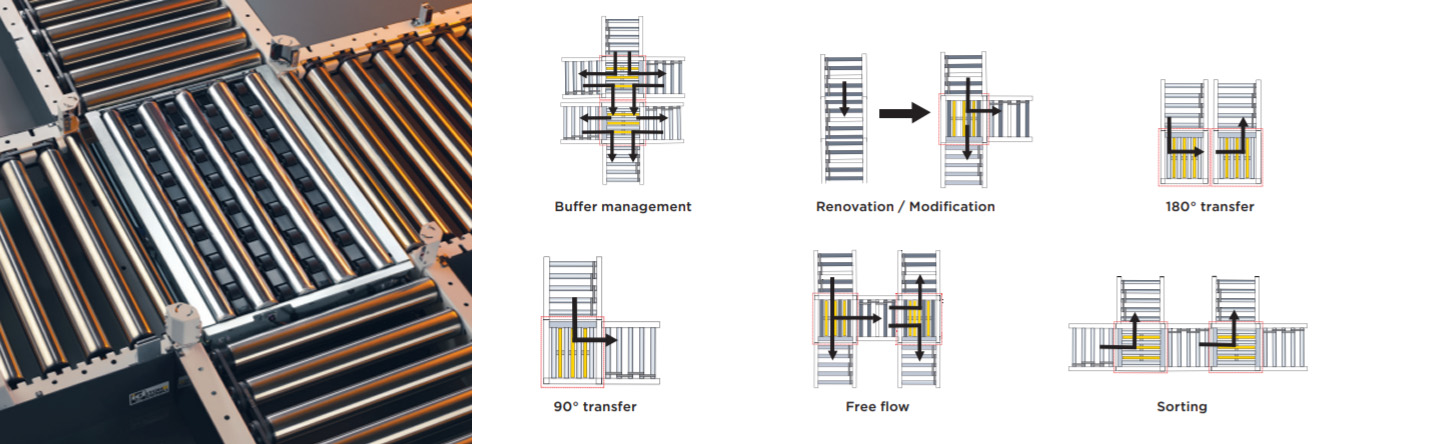

Diverter and sortation modules

- Itoh Denki’s range of diverter modules offers flexible and cost efficient solutions for sortation and diversion on your conveyor lines. Exclusively powered by 24Vdc Motorised drive rollers (MDR) and intelligent controlers, our diverters deliver top performance with minimal energy consumption. The compact cassette design allows easy integration into new and reconditioned conveyors. With the capacity to smoothly and swiftly divert a large range of packages, it can be used in many applications and industries (distribution centers, parcel and postal, manufacturing…).

F-RAT S 90° Multidirectional diverter module

- The F-RAT S is a compact module used for 90° lateral diversion on conveyor lines. Powered by 24Vdc motorised drive rollers without any pneumatic system, it transfer loads with no change in level between entry and exit, offering a smooth transfer for even the most fragile packages. Transfer of a great variety of loads is made possible thanks to the high friction driving belts on the surface of the module.

F-RAT NX 90° Multidirectional diverter module

- The F-RAT NX is a multidirectional 90° diverter module, used for routing, merging and sorting applications. Its unique flat transfer sequence ensures the smooth and quick diverting of even the most fragile products. With its compact cassette format, the F-RAT NX has a reduced footprint and can be easily fitted into both new or repurposed conveyor lines. Entirely powered by 24VDC brushless motors, it provides high safety standard, easy installation and low maintenance.

POP-UP 30°/45° diverter module

- The POP-UP diverter module range offer high capacity lateral transfers at either 30° or 45°. With its compact cassette design, it can be easily fitted into most conveyor frames and used in a variety of applications for routing, sorting or merging a wide variety of loads . It is available in different sizes, for either 30° or 45° transfers, left or right.

MABS Multi Angle Ball Sorter

- Available in the coming months, the MABS (Multi Angle Ball Sorter) is the most advanced diverter module in our range. With up to 4 entries and exits, it can smoothly and quickly transfer products at 30°, 45° or 90°. With a throughput of up to 5300 cases/hour, it complements the F-RAT NX module at the highest traffic hubs of a sortation line. The 20cm thin MABS modules are available in a variety of widths and can be combined together, to suit the size of the products to transfer.

F-RAT-NX Series

-

With the new F-RAT NX, ITOH DENKI introduces a high performance Right Angle Transfer Unit, allowing high throughput flawless 90° transfers. Entirely powered by 24VDC brushless motors, providing high safety standard and low maintenance. A groundbreaking patented flat transfer technology for advanced automation and IoT within your conveyor systems.

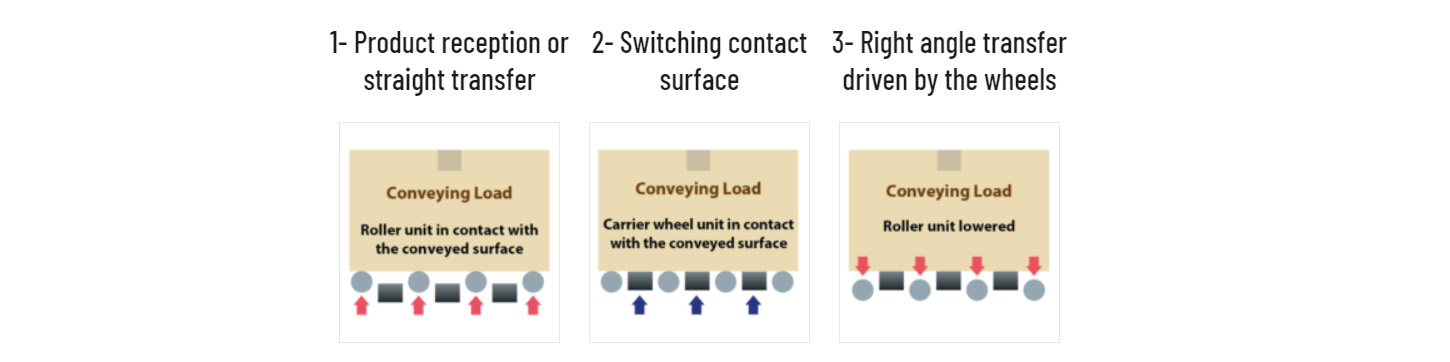

Smooth flat transfer operation

-

The diverted product always stays at the same level and is not lifted during the transfer operation, this allows a faster and smoother transfer, eliminating any shock and limiting vribrations. Furthermore, all entries and exits are set at the same level, simplifying the conveyor design.

Multidirectional Flat Transfer

-

The diverted product always stays at the same level and is not lifted during the transfer operation, this allows a faster and smoother transfer, eliminating any shock and limiting vribrations. Furthermore, all entries and exits are set at the same level, simplifying the conveyor design.

Transferring without changing levels optimizes time and therefore increases productivity. Our technology allows:

- Smooth & secure transfer: no lifting and no vibrations. Fragile loads are safely transfered.

- High throughput: Boost your sorting efficiency with a transfer rate of up to 2,250 totes handled per hour (at a 50% transfer rate).

- Up to 4 reversible entries and exits, with the possibility of quick reassignments. It is possible to combine several F-RATs for advanced sorting or sequencing systems.

Markets and references

SHINGAKUSHA SHIPPING LINES

-

Just 3 days to install idPAC to improve sorting operation

Shingakusha Co. Ltd. is a publisher specialising in educational materials for children. The company has more than 3,000 references and 1,300 national distributors to serve schools, homes and private education.

Kusatsu Logistics is one of its logistics centres which is a real bottom line for the operation in Shingakusha.SOLUTION WITH IDPAC : ‘LIGHT, THIN, SHORT AND SMALL’

The improvement plan had reached a standstill, but it suddenly gained momentum when the manager in Kusatsu logistics dep. Mr. Matsui visited “Logis-Tech Tokyo 2016” to collect information and he was impressed by the compactness of idPAC, which was also a unique and completely opposite solution “Light, Thin, Short and Small”.

With idPAC, an optimal assembly line layout can be built freely and easily, he found that this solution would satisfy their condition of having a limited footprint.

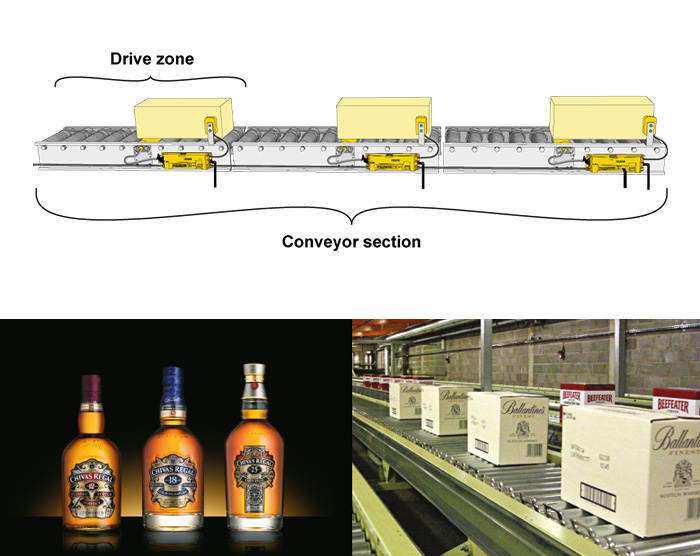

CHIVAS – ORDER PREPARATION

-

Chivas Brothers’ success in its drive to become the global leader in Scotch’s fast-growing premium sector required a significant increase in production from the company’s Palletisation and Automatic Despatch facility in

Dumbarton on the outskirts of Glasgow. The facility plays a key role in the distribution of brands such as Ballantine’s, Beefeater Gin and Chivas Regal 25 Year Old. A recently completed project to upgrade the palletising and conveyor systems included a significant quantity of motorised rollers and Zero Pressure Accumulation controls from Itoh Denki. The system is designed to ensure maximum production from the site and provide Chivas Brothers with an estimated 50% increase in output.OUR SOLUTION

The new conveyors transport different sized cartons containing a variety of bottle sizes, from eight existing production lines in the Clyde bottling hall to a completely new palletising system. Cases leave the bottling hall on eight separate conveyor lines at speeds of up to 60 cases per minute. All eight lines then travel underground for approximately 100m and around several bends before returning above ground to the feed eight new palletisers.

URO-NEGOCE – DISTRIBUTION

-

Euro-Negoce, is a leading independent wholesaler of electrical engineering products who distribute products to customers throughout Europe. Thanks to its large network of suppliers, huge stock capacity and purchasing power, Euro-negoce is able to provide its customers with the best price and immediate availability of thousands of products. Central to this service provision is their powerful in-house product inventory management system. These data processing systems manage multi-tarif purchases, daily imports, inventory control, order picking, shipment tracking and invoicing.

So when Euro-negoce constructed a dedicated new distribution warehouse in Epagny near Annecy in France, they required a modular and flexible automated material handling solution which could be integrated with their ERP and WMS systems in order to showcas

OUR SOLUTION

The conveyor solution is driven by runon-demand Power Moller® 24v DC Motorised Drive Rollers (MDR) from Itoh Denki. These drive rollers are incorporated within drive zones which are controlled by Itoh Denki’s HB510 circuit board with unique Zero Pressure Accumulation logic. This technology allows the conveyor to transport cartons and totes, zone-by-zone between the storage areas, order picking and despatch locations. The HB510 is configurable to allow adjustment of roller speed, transfer configuration and error monitoring. The zones automatically start and stop according to the demand for product and allows fast picking and sorting of orders as they are retrieved from stock.

e their logistics expertise.

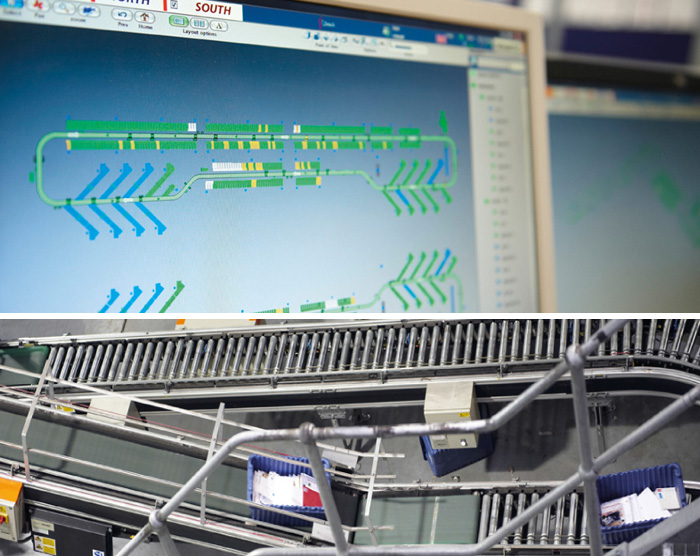

ROYAL MAIL – MAIL SORTATION

-

Royal Mail’s state-of-the-art international mail centre near Heathrow, London is one of the most technically advanced mail handling centres in the world. Costing £367million and occupying an area the size of six football pitches, the Heathrow Worldwide Distribution Centre sorts and distributes every letter or parcel that leaves and enters Britain.

The centre replaces eight foreign mail sorting offices that previously served Britain and is designed to handle up to 10 million mail items per day and operates 24hrs a day. This single distribution centre is designed around a highly automated operation that includes 12 kilometres of conveyor which incorporate Itoh Denki’s energy efficient Power Moller® motorised drive rollers.

Itoh Denki’s modular and compact drive solution not only reduces space requirements, they also reduce noise levels and energy consumption compared to traditional external drive solutions. The roller conveyor is made up of lots of drive zones that comprise of a single motorised roller and several slave rollers. In this way a drive zone is able to readily transfer the trays from one zone to the next. Because each zone is independently controlled the motors can be operated on a run-on-demand basis enabling substantial energy savings to be made compared with continuously running external drives with complex belt drives and pneumatic actuators or slipping clutches.

Calculations show that when comparing a similar section of conveyor driven by a continuously run external motor, Power Moller® drives can reduce energy consumption by up to 60%. The whole-life-costs of the installation are also affected by belt drives and clutches that often require replacement as little as two years after installation. With a typical life expectancy of around 20,000 hrs Itoh Denki motorised rollers are being selected by system integrators and end users as the preferred solution to unit conveying applications.

VOW DISTRIBUTION CENTER

-

VOW Europe Ltd is one of the UK and Ireland’s leading wholesalers of business and office supplies. Following the centralisation of their Sales and Service Centre, VOW opened a high-tech distribution centre in Normanton, England.

Leading 4th party integrator Logistex was selected by VOW to supply the integrated storage and materials handling systems. These included an extensive range of conveyor equipment manufactured by leading OEM Conveyor Units.

The system is built around a sophisticated one-kilometer carton conveyor. Where product separation is critical the conveyors are powered by low-energy 24v motorised rollers from Itoh Denki. Totes and cartons are routed around a zoned system for picking, before being checked and scanned and finally routed through a sorter at up to 2,850 items per hour.From an early stage Itoh Denki’s Technical Sales Engineers worked closely with Conveyor Units and Logistex to provide the best conveyor solutions and specifications to meet the system challenges. The installation has been designed to handle the diverse range of order size, volume and changes in demand. Totes can carry up to 25kg and cartons as slim as 50mm can be conveyed directly to dispatch to keep space and shipping costs to a minimum.

The HB510 incorporates control logic and zone-to-zone communications that facilitate valuable product buffering and separation throughout the conveyor system. The HB510 is also configurable to allow adjustment of roller speed, transfer configuration, and zone release modes. This made it ideally suited to the various control requirements of the project and was used extensively throughout.

The combination of HB510 and Power Moller® 24v motorised drives provided the ideal solution to the high speed sortation conveyor installed in the despatch area.

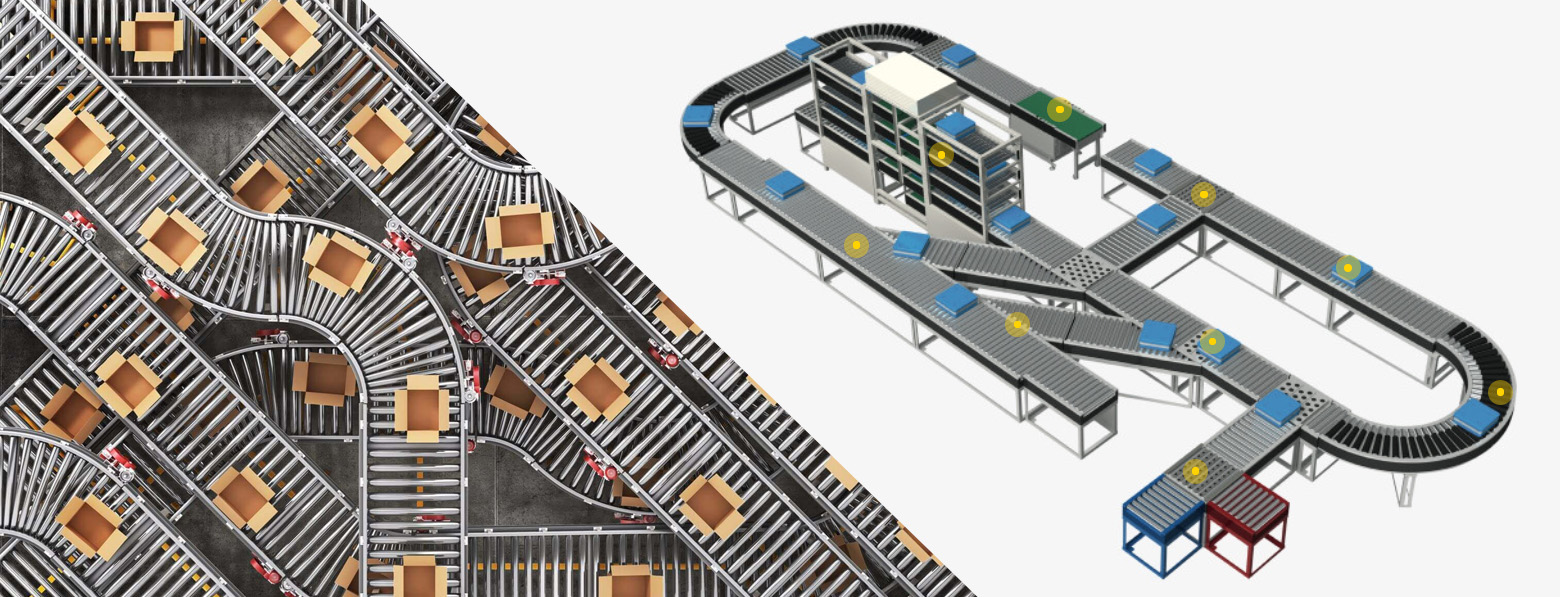

IDPAC Turnkey, flexible conveyor platform

-

idPAC is Itoh Denki’s turnkey modular conveyor plateform, allowing quick and easy installation, configuration and modification of your conveyor lines.

Total flexibility is made possible thanks to the combination of Itoh Denki’s 24V MDR + diverter modules conveyor sections pre-embedded with control logic and the advanced transport control software.

Without using a PLC and complex programming, you can simply set up or change your conveyor layouts, according to the evolution of your activity and easily manage the flow, using the intuitive idPAC software.

Turnkey modular conveyor platform, ready to go and ready to change!

-

Time and cost optimisation through increased operational efficiency and flexibility

ITOH DENKI - the pioneer of motorized drive rollers - has drawn from the 70 years of experience as industry leader to create an innovative modular conveyor platform, idPAC.

The powerful idPAC solution takes care of everything so that you can focus on what is important to you!idPAC benefits ready to use

Powered by Itoh Denki's renown 24VDC Power Moller motorized rollers, together with an advanced,

autonomous decentralized control system.A revolutionary modular platform based on the combination of conveyor sections with specific

functions (straight line, curve, diverter...).Standardised software and conveyor dimensions that allows unlimited reconfigurations:

building your conveyor is now as easy as assembling Lego blocks.idPAC allows for a quick, easy and efficient installation and commissioning of your conveyor line.

idPAC systems ensure an early start of operations and a fast return on investment.