- Offer Profile

- DistriSort specializes in sorting concepts. In these concepts sorting is the core process completed with additional actions such as in- and outbound conveying, identification, labeling, packing. For the sorting concept we always use sorting machines. The reliability, continuous innovations on the machines, low and simple (DIY) maintenance on these machines give the concept a lean character.

Logistic flows

-

All logistic flows start with careful sorting. Automated sorting will contribute to the profitability of your business and your customer satisfaction. DistriSort sorting solutions will cover:

- Inbound

- Outbound

- Returns

- Cross-docking

- Omnichannel

- E-commerce

In most cases, all the mentioned flows can be processed with the same sorter.

Inbound

- What does inbound sorting mean? In short, this is your flow of -incoming goods-, from both suppliers and the returns (retail and e-commerce). An automated process, in which items are scanned and then sorted according to predetermined criteria. Inbound sorting means sorting goods that come in from manufacturers, suppliers and/or returns. The purchase orders can be linked to the sorter. Everything that comes in, is counted and registered. This means the correct quantities and in the case of clothing, for example, also the correct sizes, colours, models, designs, etc. This makes it easy to determine whether everything that was ordered has actually been delivered. Return goods can be sorted according to the same criteria.

Outbound

- Huge cost savings can be achieved here. The order lists are read into the sorting system and the sorting can begin. The cost savings come from a more efficient picking process. Instead of picking each order separately, we now switch to batch picking. This means a number of orders for a product are picked in one go and loaded into the sorter. This allows more picking to be done with far fewer people. Each order is assigned to an exit (chute) and is assembled. Each order can vary from 1 item to many hundreds.

E-commerce

- E-commerce means a lot of customers and a lot of small orders. This requires high processing speed and great accuracy. And that is exactly what we offer. Reliable and versatile sorting concepts that can handle a wide packaging spectrum in size, weight and shape. Error-free and fast sorting of both single items and orders via sales platforms.

Cross-docking

- Cross-docking is a combination of inbound and outbound. Goods are returned and go directly back into the outbound (sales) flow. This can be done via a VAS location (Value Added Logistics, where returns are checked and if necessary, repackaged). This makes it possible to take returned goods straight back into the Outbound flow as a new order.

Omnichannel

- These days everything revolves around customer satisfaction, everything for a smile. DistriSort helps you to get the right product to the right customer, at the right time and in the right place. With an omnichannel approach, the focus is on a carefully tailored total experience and brand experience for the customer.

Returns

- The headache for e-com; returns. On average, 60% of online purchases are returned. The costs for handling these items are 400% - 500%* higher than for shipping an order. It is labor-intensive (looking, smelling, possibly repackaging). So there is every reason to make the returns process as efficient as possible and so reduce costs. DistriSort helps you to smoothen the path.

Discover our turn-key solutions by branche

- At DistriSort, we understand that each industry has unique challenges and needs. That's why we offer customized solutions for various sectors, from logistics and e-commerce to the food industry and retail. Our advanced sorting systems and technologies are designed to increase efficiency, reduce costs, and optimize your business processes, no matter the industry you operate in. Discover how our expertise can elevate your business to the next level.

Parcel & Post

- Our sorting solutions run 24/7 at major postal and parcel processing organizations in Europe. Thanks to our many years of international experience, we know your business. Faster, better and error-free sorting of packages in all shapes (round, egg, cylinder, square) and sizes (up to 600 mm x 800 mm and 21 kg). With a capacity of 4,500 – 13,500 items per hour. Furthermore, robot infeed, automatic emptying of postal containers, weighing and postage checking are all possible (and more).

Consumer goods

-

Many individual orders, plenty of addresses, and today's orders are delivered tomorrow. This is what we make possible 24/7. The picking process becomes more effective, and the error margin decreases. From entering orders to barcode scanning, sorting, weighing, labeling, and sealing boxes, everything is completed in a single operation. This results in faster, better, and more cost-effective e-commerce.

Our experts develop tailor-made sorting solutions with a proven track record. This ensures that you will receive the best results for a diverse or specialized product range.

Fashion

-

Almost all major clothing brands and fashion retailers use our sorting solutions. And actually, that says it all.

We know the issues and pitfalls in your business. All this knowledge and (international) experience makes DistriSort the expert when it comes to sorting clothing, shoes and apparel. Both inbound, outbound and returns.

And our commitment goes further. A standard configuration has been developed especially for scale-ups that makes automatic sorting (also financially) even more accessible.

3PLs

- The responsibility of delivering the right product, at the right price, at the right time, to the right address is significant. And that’s exactly where we help companies in 3PL (Third-Party Logistics) and 4PL. With smart cost-saving measures and innovative sorting solutions designed to work quickly, efficiently, and flawlessly. Our solutions operate 24/7 and provide an optimal workflow for logistical processes.

Pharmaceutical

- Pharmaceuticals are small, delicate, and sensitive to damage. This calls for a special approach. DistriSort leverages the knowledge and extensive experience gained by our trusted US sorter manufacturer (EuroSort). Our sorting solutions are up and running at major pharmaceutical companies and specialized distribution centers in the US.

Media Distribution & Books

- Books involve various flows: inbound, B2B, B2C, store replenishment, inter-branch, cross-docking, and returns. This places high demands on the versatility of a sorter. In practice, the Split Tray proves to be a top candidate that meets all requirements and offers many exits on a small footprint. Thanks to our patented tray opener, this sorter can automatically stack books in a box. Sorting speeds up to 8,500 items per hour.

Sorting systems

-

Every situation and industry requires a specific approach and implementation. Therefore, there is no 'one size fits all' sorter.

- What is the available space?

- How large are your products?

- Do you want to apply cross-docking?

- What do you want to do with packaging materials?

These are just a few of the questions we consider in our advice. Below is an overview of the available sorters and their specifications.

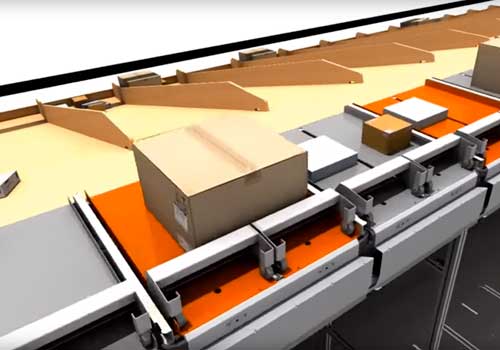

Split Tray Sorter

-

The ideal, high-capacity sorter, is suitable for a wide range of products. Available as Single Split Tray and Dual Split Tray. The international favorite for clothing, mail, parcel processing, e-commerce, and books.

The Split Tray sorter is an internationally proven success. The patented opening system opens the tray sections at the same moment, allowing products to drop straight down, making stacking in a box or crate possible (think: books, clothing, etc.). Sorting and stacking can be done in a single run. Products are enclosed on all four sides of the carrier, ensuring that even round shapes (round, oval, cone-shaped, etc.) stay in place, even around curves. Safety nets and time-consuming post-sorting are not necessary.

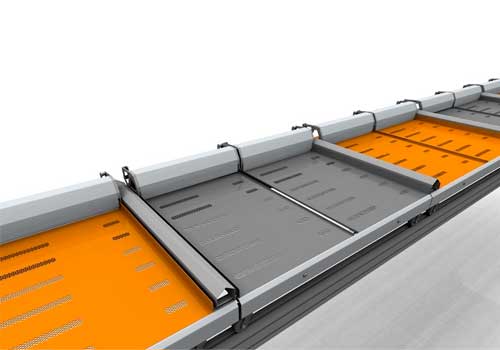

Push Tray Sorter

-

The Push Tray Sorter features an open carrier, each with a conveyor belt with an open edge at the rear. This slider moves forward at the desired moment, picks up the item, and ejects it into the designated chute. The Twin Push Tray Sorter, in addition to the Push Tray Sorter, features two slides in the tray, which can also be used as a Single. Depending on the configuration, the capacity ranges from 8,800 to 25,000 items per hour.

- Both manual and fully automatic induction

- Higher volume, greater efficiency, fewer errors

- Fast ROI, low TCO

- Low noise level

- Minimal maintenance

Cross Tray sorter

-

Sorts a wide variety of items, from small, lightweight articles to packages, including e-commerce products, fashion, and pharmaceuticals.

The Cross Tray has an extensive track record in various industries. This experience is reflected in various exit options, such as sorting directly into boxes, mailbags, crates, bins, and more. The Cross Tray sorter meets all the needs of modern logistics.

The Cross Tray sorter features enclosed trays and a conveyor belt inside the tray for ejecting items. With four raised edges, the Cross Tray is highly suitable for items with irregular shapes (round, cylindrical, conical, etc.) or limited weight. Additionally, due to its lower maximum speed, the Cross Tray sorter occupies a smaller footprint.

Standard Fashion Sorter

-

The Sweeper Belt sorter is an easy-to-integrate sorting machine with a modular structure. It is easy to extend the number of exits and the main supply track. The sorting machine brushes the product from the main supply track into the allocated exit. Exits can be found on one side or both sides of the main supply track. At the exits it is possible to collect the items in boxes, bags or trays. This machine is very suitable for sorting small items, parcels, polybags, accessories, multimedia, books and pharmaceutical items with a maximum height of 150 mm and weight up to 2 kilos. Depending on the average dimensions of the items to be sorted, the machine can sort up to 7,200 items per hour.

What are the possibilities of the Sweeper Belt sorting machine?

This machine is very suitable for sorting small items, parcels, polybags, accessories, multimedia, books and pharmaceutical items with a maximum height of 150 mm and weight up to 2 kilos. Depending on the average dimensions of the items to be sorted, the machine can sort up to 7,200 items per hour.

Peripheral equipment

- The additional options that can make the process even faster and more efficient fall under peripheral equipment. Depending on the preferences and capabilities of our customers, there are various possibilities. These include fully automated input/induction with a robotic arm or parallel input. We can automate weighing and labeling for postal purposes, as well as automatically seal boxes and use conveyors to remove empty boxes or crates.

Case study

- Our case studies are popular. The reader gets a good impression about the competences of DistriSort and the implementation of a successful project. DistriSort would very much like to share the available case studies with interested parties. This is why we ask your details so that you can log in. As a result we know who is interested in our concepts.

Norah

- A fashion brand with affordable fashion for modern women with 90 stores and online sales. To keep up with growth and a weekly changing collection, Norah invested in automated sorting with a Dual Split Tray Sorter. Efficient and flexible, this system supports both B2C and B2B flows.

Logistar

- A leading 3PL (3rd Party Logistics) provider in Serbia, processing 125 million items annually. To address the challenges of inbound, outbound, returns, and B2C orders, Logistar has invested in a EuroSort Cross Tray sorter with slide chutes.

LPP

- The largest fashion company in Central and Eastern Europe, with over 2,000 stores and 5 retail brands, operating in nearly 40 global markets. To tackle the challenges of maximizing chute capacity and processing at least 25,000 items per hour, LPP opted for a Push Tray sorter with slide chutes and chute pitch reducers.