ALTEC

- Offer Profile

- For every application the right loading aid. Altec is your partner from design to the production of aluminum ramps! Experience, best cost / benefit - ratio, security. All products are GS - tested and comply with the guidelines of the professional association.

Product Portfolio

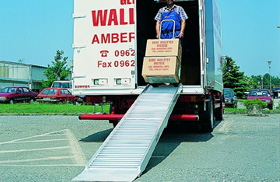

LOADING RAMPS

- For every loading situation there is a correct

solution. Only Altec have a product range wide enough to suit most

applications. If you can’t find what you need we will design and manufacture

the best solution for you.

At Altec we believe the most important factors are experience, cost and safety.

All of our products are certified and agree with the rules laid down by our chamber of commerce. The capacities shown on this Website are calculated for two axle vehicles with a weight distribution of 40% to 60%.

For single axle vehicles the capacity is reduced to 60% of that shown. All capacities are calculated with a safety factor of 2.1.

From design to production we offer top quality, made in Germany!

Typ AOS

- AOS ramps have been designed to provide the maximum load

capacity in their range, with the slimmest of profiles and with the lowest

possible unit weight in maintenance free aluminium.The standard AOS design

includes integral reinforcement.

The slim design of the bottom section of AOS ramps which comes into contact with the ground, ensures a smooth transition from the horizontal surface to the ramp running surface with a maximum 5mm step.

Typ ABS

- This aluminium ramp offers an excellent balance between a

very low weight and a high load capacity.

With an internal width of 150mm, and an overall width of 235 mm, these ramps are ideal for loading/unloading items such as motorbikes, high pressure cleaners, generator sets, wheelchairs etc...

Their profile allows them to be stacked one inside the other for ease of storage. A folding option is also available.

Typ ABS FOLDING

- A foldable option is also available.

RAMPS FOR SACK TRUCKS

- This type of ramp is mainly used for sack trucks with

pneumatic tyres.

Removal firms, furniture companies or beverage carriers are the main users of this lightweight, nonslip loading ramp.

Options include a moveable lip and foldable versions.

EVENT RAMPS

- The event ramp has been designed especially for the

loading of trolleys or cases with small wheels.

Probably used by musicians, event engineers or those loading flight cases.

KVS coating surface ensures minimal vibration.

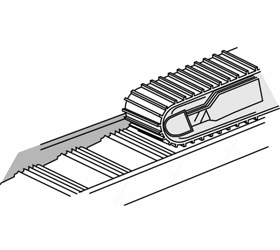

Typ AVS 80

- for rubber track and pneumatic tyre vehicles

These ramps are ideal for loading smaller rubber track and pneumatic tyre vehicles.

The surface profile is extruded from a high quality aluminium alloy which guarantees longevity even with constant use. As with all AVS ramps, these are available with or without curbs or with curbs on one side only.

Typ AVS 110

- for rubber track and pneumatic tyre vehicles

up to 4050 kgs/pair

Made for loading rubber track and pneumatic tyre plant the AVS 110 is an ideal ramp for use with most plant trailers and 3,5 tonne trucks.

The robust surface ensures minimal wear even with constant use. Curb and folding options are also available.

Typ AVS 130

- for loading rubber track and pneumatic tyre

up to 5150 kgs/pair

Made for loading rubber track and pneumatic tyre plant the AVS 130 is an ideal ramp for use with most large plant trailers and 7.5 tonne trucks.

The robust surface ensures minimal wear even with constant use.

Curb and folding options are also available.

Drop bolts supplied as standard.

Typ AVS 150

- for loading rubber track and pneumatic tyre

up to 7350 kgs/pair

Made for loading mid range to heavy equipment the AVS 150 has a larger and wider track than its smaller cousins.

Folding and curb options are available. Although still very light weight, given the capacities offered, we are able to offer spring assistance when used with the hinged option.

Typ AVS 170

- for loading rubber track and pneumatic tyre

up to 8270 kgs/pair

Made for loading mid range to heavy equipment the AVS 170 has a larger and wider track than its smaller cousins.

Although capacities are not much greater than the AVS 150 the extra width is useful for wider track or tyre vehicles.

Folding, curb and spring assistance options are available.

Typ AVS 200

- for loading rubber track and pneumatic tyre plant

up to 11250 kgs/pair

The biggest and strongest of the AVS ramps and ideal for loading large excavators and tractors.

They also make useful yard ramps for unloading containers. As with all AVS ramps, the high quality alloy used ensures that these ramps will last for years even with constant use.

Folding, curb and spring assistance options are available.

Typ AVS 150-200

- for steel tracked vehicles up to 8500 kgs/pair

These ramps are designed for use by all equipment including steel tracked vehicles.The ramps can be supplied with or without safety curbs.

The running surface has been engineered with steel tracked equipment in mind, and is of a much harder wearing and heavier construction than the standard design.

As an option these ramps can be supplied hinged, foldable, and with or without springing to balance the weight of the ramps.

SPRING SYSTEM

- With the optional spring system, the ramp types

AVS 150, 170, 200, VFR 120/134

are easily placed into position by one person.

Typ VFR 105

- These ramps are for use by heavy machines equipped with

pneumatic tyres, solid wheels, and rubber or steel tracks. They use a

special aluminium construction for strength, durability and

weather-resistance.

These ramps can be supplied with a hinged end, or with a hook, which fits into a guide rail.

As an option, the ramps can be fitted with a spring system.

A foldable option is also available

Typ VFR 120

- up to 22700 kgs/pair

These ramps are for use by machines equipped with pneumatic tyres, solid wheels, and rubber or steel tracks.They use a special aluminium construction for strength, durability and weather-resistance.

These ramps can be supplied with a hinged end, or with a hook, which fits into a guide rail.

As an option, the ramps can be fitted with a spring system.

A foldable option is also available.

Typ VFR 134

- up to 32000 kp/pair

Type VFR 134 up to 32000 kgs/pair

The heavy duty profile and high grade aluminium used in our VFR 134 ramps ensures durability even when loading steel track machinery.

These ramps are available with a hook on option or hinged to take a 60 mm bright steel bar. For heavier hinged ramps we recommend our spring counter- balance system.

Typ VFR 185

- up to 80000 kgs/pair

Our extra heavy duty profiles enable us to produce special ramps with capacities up to 80,000 kgs.

Typ VFR WEDGE

- These ramps are used mainly on trailers and low loaders.

The profile used in the construction of these ramps maximises its dimensions and load bearing capacity.

These ramps are for use by machines with pneumatic tyres, solid wheels, and rubber or steel tracks.

For ease of handling, several units can be positioned adjacent to each other.

Typ RRK

- Construction: This aluminium ramp is designed for easy

one man operation. The folding and unfolding of the ramp is made almost

effortless by the use of gas struts to balance the weight of the ramp.

The ramp surface is fabricated from extruded aluminium profiles which are perforated and embossed to give a perfect anti-slip surface.This also allows rain and snow to disperse very easily.The light weight of the ramp allows most of the pay load of the vehicle to be retained.

The RRK is held in the vertical position by two latches, mounting blocks are used to keep the assembly rigid and prevent any vibration during transport.

Typ RRD rotable

- The RRD is a logical development from the RRK.

Basically the same ramp but with the facility to swivel back against the side panels of your van.

An optional locking latch is available to keep the unit in the swivelled position.

Perfect for parcel delivery firms.

MAINTENANCE RAMPS

- Ideal for the maintenance of vehicles (inspection,

cleaning etc.).

These ramps are manufactured mostly as required, and can be supplied with or without safety curbs.

Loading ramps for hydraulic tail-lifts

- Side ramps for tail-lifts and tail-boards.

These ramps facilitate the loading/unloading operations from vehicles alongside the kerb.

They bring security and quicker unloading times for carriers who have to deliver within a town centre using vehicles equipped with hydraulic tail-lifts.

Solutions:- Tpye LBGM

- Type LBWM

- Type LBK

- Type LBG

- Typ LBW

Typ RWB / Typ RPB-30 / Typ RPB-40

- Typ RWB

Hinged tailboard with a five-bar treadplate surface .

Typ RPB-30

Hinged tailboard with 30 mm honeycombe profile.

Typ RPB-40

Hinged tailboard with 40 mm honeycombe profile.

Special-Solution

- Special solutions are available on request. Please conact us for more information. Our technicians will find a suitable solution for your loading situation. Please find examples in our galerie.

LOADING BRIDGES

- Made of steel and aluminum. For every loading situation

there is a correct solution!

Only Altec have a product rangewide enough to suit most applications.

If you can’t find what you need we will design and manufacture the best solution for you.

What´s important!

At Altec we believe the most important factors are experience, cost and safety. All of our products are certified and agree with the rules laid down by our chamber of commerce.

From design to production we offer top quality, made in Germany!

Typ AWB

- AWB bridge plates are fabricated from aluminium plate

with a five-bar tread anti-slip surface.

Designed for loading and unloading with sack trucks, pump trucks and roll cages.

Features:- easy transport

- non slip surface

- light weight

- integral handles

- weather resistant

- low cost

Typ AOS-F

- Ideal for loading small wheel containers such as Danish

trolleys and flight cases. Available as one wide ramp or a more versatile

pair.

Easy to handle and store. The non slip surface guarantees safe use.

Typ HFB 55 / 60

- Both of these types of ramp are designed for use where

there is a very small difference in levels. They are fabricated from one

Aluminium profile.

The plates are easy to handle and can be placed into position rapidly.

Typ HFB

- The mobile loading ramp type HFB is produced to bridge

over height differences up to 130 mm.

It is fabricated from 40 mm thick aluminium honeycomb plate with a ribbed anti slip surface and is fitted with spacer plates between the vehicle and the loading platform.

Typ HF

- Model HF heavy duty bridge plates are fabricated from a

40 mm thick aluminium honeycomb plate with a non-slip surface.

Heavier capacity bridge plates have reinforcement sections welded underneath.The bottom section includes a hinged lip to assist the passage of small wheeled trolleys and is fitted with rubber profile to prevent any risk of slippage.

Type MC

- The mobile bridge ramp MC is used specifically for

loading and unloading shipping containers.

The heavy duty combination of steel and aluminium ensures a strong construction for use in this tough environment. Integral fork lift handles ensure easy movement. Type MC

PIT COVER

- Aluminium pit covers are availa- ble to help make maintenance areas safe when the pits are not in use.Manufactured in small light weight sections to your pit configuration, these covers are available in capaci- ties up to 4000 kgs.

Type MBD

- With this three piece, movable bridge plate, it is

possible to balance big height differences between dock and lorry.

Forklift openings make it possible to position the bridge where ever it is needed. An optimum help, flexible in use, easy to store.

TypE SBK / Type SB

- SB-K ramps have been designed to allow easy access over

doorsteps. They have an non-slip surface and are maintenance free.

The height difference (H) is needed when ordering.

SB ramps have been designed to allow easy access over doorsteps.

They have an non-slip surface and are maintenance free.

The height difference (H) is needed when ordering.

WHEEL RAMPS

- These wheel ramps are made to safely increase the height

of low vehicles to allow easier loading from a loading bay.

They are lightweight and are easily moved around using the castor fitted to the front plate.

Type BB Bridge plate

- This bridge plate is designed to eliminate minor height

differences on a railway platform.

It is not hinged, but rotates within a steel guide rail. The guide rail is available in black or galvanized steel.

It should be welded to the the edge of a dock with installed channel section with a face height of a min.of 120 mm.

The BB bridge is simple to use. When not in use the ramp is located in the downward position. It easily lifted using the handle or handles supplied. The bridge plate is then placed into position on the wagon floor with the other end in position in the guide rail.In the downward parked position the bridge is unaffected by the passage of trains.

Typ KBS

- The KBS drawbridge leveller is perfect for minor

differences in levels.

Robust and maintenance free, they are suitable for a wide variety of uses and users.The KBS can slide from side to side and should be stored in a vertical position.

The automatic safety latch prevents the plate from falling when not in use and is easily released by foot.

Typ SKB

- SKB drawbridge dock levelers are designed for medium duty

applications and to provide easy, flexible loading of lorries up to a height

difference of 190 mm from dock height.

It is available as a static version, or as a sliding version to run in a steel guide rail. Additional rails can be fitted to allow the leveller to serve more than one loading position.

The SKB guide rail is designed with an open base which prevents the collection of dirt or debris and ensures smooth, easy sideways movement.

Type FBS STEEL

- The FBS drawbridge leveler covers most loading

applications and can be used for height differences of up to 250 mm with a

load capacity of 6000 kgs.

The five bar tread plate surface gives a high quality antislip surface. Finish is available in either galvanised or paint. Both options protect against corrosion. They are available in static or in sliding version.

The sliding model runs in a open base guide rail which prevents the collection of dirt and debris, ensuring smooth, easy sideways movement. Every leveler is fitted with underside springing to balance the weight of the platform.

Type FBA Aluminium

- The FBA drawbridge leveler offers a versatile light

weight option which cover loads up to 4000 kgs.

Available in lengths up to 2315 mm.The FBA can be used with height differences of up to 310 mm.

Typ FBT Tandem Aluminium

- The FBT is an aluminium two stage dock leveler.

Special-Solution

- Special solutions are available on request. Please conact us for more information. Our technicians will find a suitable solution for your loading situation. Please find examples in our galerie.

Aluminium Wheelchair Access Ramps

- For every situation there is a correct solution

Only Altec has a product range wide enough to suit most applications. If you can’t find what you need we will design and manufacture the best solution for you.

At Altec we believe the most important factors are experience, cost and safety.

All of our products are certified agree with the rules laid down by our chamber of commerce. border. A perfect environment to put ideas in action.

From design to production we offer top quality, made in Germany!

Type SBA

- This two part threshold ramp can be used for different

heights.

They are lightweight and easy to handle.

SBA bridge is not self supporting and must rest on the threshold.

Type SBS

- SBS bridge ramps are designed as standard to span door

steps or thresholds up to 35 mm high and 120 mm wide.

They are easy to handle, alternative dimensions are available on request.

Type SBK

- SB-K entrance ramps have been designed to allow easy

access over doorsteps. They have an anti-slip surface, and are maintenance

free.

The height difference (dimension “h”) is needed when ordering.

Type BTR

- The BTR is a two piece threshold ramp, allow easy access

to outside areas.

The external section can be left in place, while the internal can be placed when required.

Type ABS

- This aluminium ramp offers an excellent balance between a

very low weight and a high load capacity. Robust and easy to handle.

These ramps are fabricated from an extruded profile which is cut to length and angled as required. With an internal width of 150 mm, and an overall width of 235 mm, these ramps are ideal for wheel chairs.

Their profile allows them to be stacked one inside the other for ease of storage, and the 45 mm high safety curbs on each side prevent any lateral slippage.

Type ABS-F folding

- A folding version of the ABS is available for ease of storage and use.

Type ABS-Z

- In case of small luggage space, the three times foldable

ABS ramps are an ideal solution. They are fabricated from an extruded

profile and offers an excellent balance between low weight and capacity.

With an internal width of 150 mm, they are also ideal for wheelchairs with offset axles.

Type RAS

- The loading ramps, type RAS are fabricated From a high strength aluminium alloy. The running surface is covered with an anti-slip coating.

Type RAS-F folding

- The loading ramps, type RAS-F are fabricated from a high strength aluminum alloy. The running surface is covered with an anti-slip coating. A folding version of the ABS is available for ease of storage and use.

Type RAS-W

- These ramps can be permanently installed inside the

vehicle. The ramps pivoting and sliding mechanism uses ball bearings for

ease of use. During transport the ramps are maintained vertically inside the

vehicle by the safety straps supplied. If required, the ramp surface can

easily be renewed with an anti-slip adhesive.

Each pair of ramps is supplied With a mounting kit.

The complete set consists of:- 1 pair of ramps

- 1 steel axle (length 1800 mm)

- 1 installation kit to fix the axle to the floor of the vehicle

- 2 safety straps to hold the ramps in vertical position.

Type RLK

- This aluminium ramp is designed to allow for easy one man

operation. The folding and unfolding of the ramp is made effortless by the

use of gas struts to balance the weight of the ramp.

The ramp surface is fabricated from extruded aluminium profiles which are perforated and embossed to give a perfect anti-slip surface, and also allow rain and snow to disperse very easily.

The light weight of the ramp allows most of the initial loading capacity of the vehicle position by two latches, and mounting blocks are used to maintain the assembly rigid and prevent any vibration during transport.

Type RLK-Z

- Derived from the RRK ramp. The RLK-Z is designed for use

in vehicles with a low roof height. Folding twice in three sections the RLK-Z

is made for easy installation and easy use.

This aluminium ramp is designed to allow for easy one man operation.

The folding and unfolding of the ramp is made effortless by the use of gas struts to balance the weight of the ramp.

The ramp surface is fabricated from extruded aluminium profiles which are perforated and embossed to give a perfect anti-slip surface, and also allow rain and snow to disperse very easily.

The light weight of the ramp allows most of the initial loading capacity of the vehicle position by two latches, and mounting blocks are used to maintain the assembly rigid and prevent any vibration during transport.

Type RRD

- Another version of RLK-ramp is type RRD.

Basically the same ramp but with the facility to swivel back against the side panels of your van.

An optional locking latch is available to keep the unit in the swivelled position.

Type AOL-R

- The wheelchair ramp AOL-R is made to bridge over stairs

or high steps.

The surface is fabricated from extruded aluminium profiles which are perforated and embossed to give a perfect anti-slip surface and allow rain and snow to disperse very easily.

Special-Solution

- Special solutions are available on request. Please conact us for more information. Our technicians will find a suitable solution for your loading situation. Please find examples in our galerie.