- Offer Profile

- Complete Solutions from

Sigmatek

If you would like to equip machines and installations with a fully intergrated consistent automation system, SIGMATEK is your partner: Our area of specialization is fast automation processes, by which the combination of performant control with dynamic drive axes and strong visualization is in demand.

Control Systems

-

Full speed ahead

The core expertise of SIGMATEK is the fast and precise control and regulation of industrial machines and equipment. We provide the right control system for any application: compact CPU modules for the DIN rail – control panels, which combine control, visualization and operation and high-performance industrial PCs.

Your Benefits- Single and Multiple CPU Solutions

- Scalable and Cost Efficient

- Integrated Engineering Platform

CPU Modules

-

Intelligence and efficiency in pocket format

Equipped with high-performance, low-loss processors, the robust DIN rail CPUs in S-DIAS format are the right choice for single and multi-CPU concepts. They can be used with simple, as well as complex and very fast control, regulation and motion tasks as a flexible system solution (bus speed – 100 Mbit/s).

CP 102 - CPU Module

-

- Process control for up to 12 local I/O modules

- EDGE2 Technology processor

- 1x Ethernet, 1x CAN

- 1x USB-OTG

CP 111 - CPU Module

-

- Process control for up to 64 local I/O modules

- EDGE2 Technology processor

- 1x Ethernet, 2x VARAN Out

- 1x CAN, 2x USB

CP 112 - CPU Module

-

- Process control for up to 64 local I/O modules

- EDGE2 Technology processor

- 2x Ethernet, 1x VARAN Out

- 1x CAN, 2x USB

Control Panels

-

All-in-one: control, visualize, operate

The control panels with integrated CPUs combine control, visualization and operating in one compact device. In addition to installable control panels, mobile control panels for use on-site are also available.

Built-in Panels

-

Space-saving and cost efficient automation

With our selection of intelligent built-in panels, you can choose from various sizes, processors, front designs and configurations.

The slim control panels are equipped with a standard resistive color touch screen, which provides comfortable operation and clear visualization.

Mobile Control Panels

-

For use directly on-site

Our HGT handheld operating panels with CPU are the right choice when mobility during control, operation and monitoring is demanded. The EDGE2 Technology processors combine high power and low loss.

Industrial PCs

-

Well equipped for diverse control tasks

The IPCs from SIGMATEK combine new PC technology with industrial usability. They were designed for very high-performance machines. Robustness, reliability in 24/7 continuous operation and long-term availability speak for the use of SIGMATEK IPCs.

IPC 221 - Industrie-PC

-

- DIN rail IPC

- Intel® Celeron 1020E

- 2 GB DDR3 RAM

- 256 kB SRAM

C-IPC - Compact IPC

-

- AMD Geode LX800 processor

- 32-512 MB SDRAM

- 256 kB SRAM

PC 400 - Control Cabinet PC

-

- Intel® Celeron G1820 processor

- 4 GB DDR3 SDRAM

- 32 GB Solid State Disk

- HMI-Link

S-IPC - Smart IPC

-

- Intel® Atom D510 processor

- 1 GB DDR2 SDRAM

- 256 kB SRAM

ETV 1591 - Control panel 15"

-

- Intel® Celeron B827E processor

- 15" resistive touch screen

- 2 GB DDR2 SDRAM

- 4 dig. in and outputs

I/O Systems

-

For various requirements

The SIGMATEK I/O Systems open all possibilities – whether in the control cabinet or directly in the field. Both series, S-DIAS (IP20) and P-DIAS (IP67) have a very high package density, are simple to use and can be flexibly combined.

Your Benefits- Functional Versatility – Safety Included

- Safe High-speed Data Transmission

- Openness

S-DIAS

-

Control and I/O system in pocket format

S-DIAS combines the highest package density with high performance, mechanical stability and comfortable handling. Up to 20 channels are packed into one I/O module. The right DIN rail module is available for any automation task. CPU and Safety modules (TÜV certified) are also obtainable in S-DIAS format.

Products for S-DIAS

-

We offer:

- CPU & Bus Connection

- Interfaces & Splitters

- Digital Input

- Digital Output

- Digital Mix

- Analog Input

- Analog Output

- Analog Mix

- Counter & Position Recording

- Motion

- Special Functions

- Safety

Highlights

-

- Saves Control Cabinet Space

- 100 Mbit/s Bus Speed

- Mechanically Stable I/Os

- CPU in Mini-Format

- Seamlessly Integrate Safety

- Comfortable: Status LEDs & Push-in Wiring

- Simple and Safe Mounting

P-DIAS

-

For use directly on the machine

The P-DIAS modules expand the family of systems in the IP67-protected area and are optimized for use in harsh environmental conditions. Analog and digital data can be collected or distributed directly in the field.

PVDM 086 - Digital IP67 Mixed Module

-

- 8 digital outputs (back-readable)

- 1x VARAN In

- 1x VARAN Out

PVDM 087 - Digital IP67 Mixed Module

-

- 4 digital inputs (+24 V DC/6 mA/6 ms)

- 4 digital short-circuit proof outputs (back-readable/+24 V DC/2 A)

- Can also be used as digital inputs (+24 V DC/6 mA/6 ms)

- 1x VARAN In (M12), 1x VARAN Out (M12)

- Protection type: IP67

PVAI 011 - DMS IP65 Module

-

- For evaluating measuring bridges (e.g. strain gauge load cells)

- 1 DMS input (M12, 4-wire connection, 12 bits)

- 1x VARAN In (M12)

- Protection type: IP65

Human-Machine Interfaces

-

Intuitive, scalable and with "Zeitgeist"

Whether operating or control panels with an integrated CPU – in the broad selection of HMIs from SIGMATEK, you will definitely find the right panel for your automation. In addition to the installed units, mobile panels for use directly on-site are available to choose from.

Regardless of whether single, dual, multi or haptic touch screens – We put the main focus on all our human-machine interfaces to ensure that you can work intuitively, quickly and safely.

Your Benefits- Wide Variety

- Strong Visualization

- Remote Solutions up to 100 m

- Long-term Availability

Operating Panels

-

Comfortably operate and monitor

The human-machine interfaces from SIGMATEK without an integrated CPU are remote, economic solutions for operating and monitoring automation systems.

Built-in Panels

-

High operating comfort compactly packaged

With their compact design and low mounating depth, SIGMATEK operating panels are ideal for installation in the control cabinet, as well as for direct installation in the machine casing.

Mountable Panels

-

HMIs for decentral installation

With compact dimensions and low installation depth, the mountable panels from SIGMATEK always cut a good figure. They can be placed exactly where they are needed – on the machine or in the surrounding area of the machine or system. Interfaces such as CAN, S-DVI and USB ensure simple integration for the operating panels.

Mobile Panels

-

Operate flexibly on-site

The handheld operating panels of the HBG series are ergonomic lightweights. With the elimination of an internal computer in the panel, no heat is generated – even after several hours of operation. You can flexibly design the CPU performance in the control cabinet.

Keypads

-

Various function buttons

The keyboards of the TE series expand our HMIs. Equipped with lots of buttons (40-89), they are designed for industrial use (IP20 to IP54) and increase your flexibility with complex applications. The buttons can be allocated as desired and according the application via the software. Via the CAN bus interface, keyboard units can be simply connected to a control panel. The foil is tailored specifically for your HMI.

Control Panels

-

All-in-one: control, visualize, operate

The control panels with integrated CPUs combine control, visualization and operating in one compact device. In addition to installable control panels, mobile control panels for use on-site are also available.

Build-in Panels

-

Space-saving and cost efficient automation

With our selection of intelligent built-in panels, you can choose from various sizes, processors, front designs and configurations.

The slim control panels are equipped with a standard resistive color touch screen, which provides comfortable operation and clear visualization.

Mobile Control Panels

-

For use directly on-site

Our HGT handheld operating panels with CPU are the right choice when mobility during control, operation and monitoring is demanded. The EDGE2 Technology processors combine high power and low loss.

Mobile Panels

-

Mobile HMI tasks made easy

- Our handheld operating panels are the right choice when mobility for visualization, operation and control is in demand: compact, light and equipped with Safety-relevant elements. The mobile HMIs are available with an 8.4 or 10.4-inch color touch display and in two versions:

- The HBG panels for classic operation and monitoring with integrated HMI-Link (loss-free data transmission up to 100 meters distance)

The panels of the HGT series with EDGE2 Technology processors perform additional control tasks

with CPU

-

- 8.4"/10.4" resistive touch screen

- EDGE2 Technology processor

- Safe operation

- Front: IP54

without CPU

-

- 8.4"/10.4" resistive touch screen

- HMI-Link Technology (100m) processor

- Safe operation

- Front: IP54

Motion

-

Flexible drive system with high dynamics

For any application: With an optimized and fully integrated drive concept, the efficiency of the machine – and the energy efficiency in particular – can be increased.

SIGMATEK provides you with a coordinated motion control system, in which drives, motors, gears and software interact perfectly. They achieve highly dynamic, precise motion sequences – in real time and from one source. At the same time, our modular motion system provides you with complete freedom in designing your drive solution.

Your Benefits- Flexible System Solution for Motion Control

- High Precision Dynamics

- Fast, Integrated Software Design

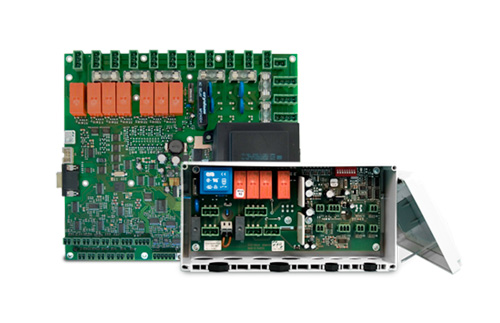

Drives

-

Dynamic, flexible and safe drive systems

With the DIAS Drives from SIGMATEK, the right servo system is available for any motion application:

- the modularly constructed DIAS Drive 100 series for 1-8 drives

- the compact multi-axis drive system DIAS Drive 300 for up to 3 drives

- the brand new compact drive amplifier DIAS Drive 1000 for 4-6 servo drives

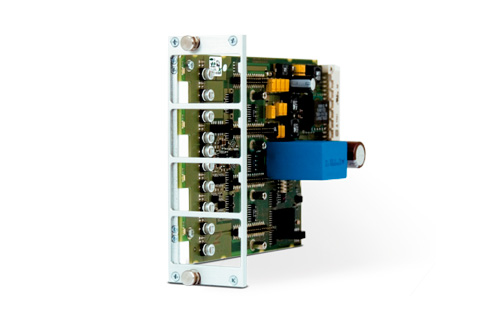

DIAS Drive 100

-

Modular multi-axis servo drive system

The DIAS Drive 100 series is a modular servo drive system. Conceived for highly dynamic machines in the mid and lower power range, it convinces with a very compact design and optimized loss. Per component, up to 8 servo axes are possible - supplied by a power module (MDP)

DIAS Drive 300

-

Compact multi-axis servo system

The DIAS Drives of the 300 series are compact drive systems for 1 to 3 axes – ideal for multi-axis applications in the lower and mid power range (8-14 kVA).

DIAS Drive 1000

-

Compact drive for 4 and 6 servo axes

The SIGMATEK servo drives of the DIAS Drive 1000 series can control up to 6 motors. In addition to the housing, the drive regulators also share the controller, heat sink and DC-link. This carries efficient benefits: reduced construction volume, higher stability and lower device costs.

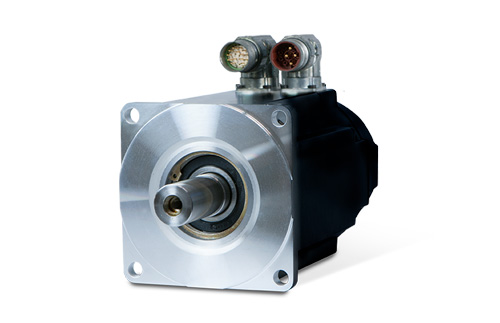

Servo Motors

-

For highly dynamic applications

The use of synchronous servo motors increases the energy efficiency of your application. Through the low inertial torque, our brushless AC motors of the AKM series are highly dynamic and have very low cogging. That makes them the right choice for demanding motion applications.

AKM 1 - Servo Motor

-

- Pn: 0.14 - 0.30 kW

- nn: 8000 min-1

- M0: 0.18 - 0.41 Nm

- M0max: 0.61 – 1.46 Nm

AKM 2 - Servo Motor

-

- PN 0.28 - 0.94 kW

- nn: 2000 - 8000 min-1

- M0: 0.48 - 1.42 Nm

- M0max: 1.47 – 4.82 Nm

AKM 3 - Servo Motor

-

- Pn: 0.28 - 1.31 kW

- nn: 1000 - 7000 min-1

- M0: 1.15 - 2.88 Nm

- M0max: 3.88 – 10.22 Nm

AKM 4 - Servo Motor

-

- Pn: 0.24 - 1.73 kW

- nn: 1200 - 6000 min-1

- M0: 1.95 - 6 Nm

- M0max: 6.12 – 20.4 Nm

AKM 5 - Servo Motor

-

- Pn: 0.55 - 3.83 kW

- nn: 1000 - 6000 min-1

- M0: 4.70 - 14.4 Nm

- M0max: 11.6 – 38.4 Nm

AKM 6 - Servo Motor

-

- Pn: 1.87 - 6.45 kW

- nn: 1200 - 6000 min-1

- M0: 11.9 - 25 Nm

- M0max: 29.7 – 65.2 Nm

AKM 7 - Servo Motor

-

- Pn: 3.94 - 7.46 kW

- nn: 1200 - 3000 min-1

- M0: 29.4 - 53 Nm

- M0max: 78.5 - 143 Nm

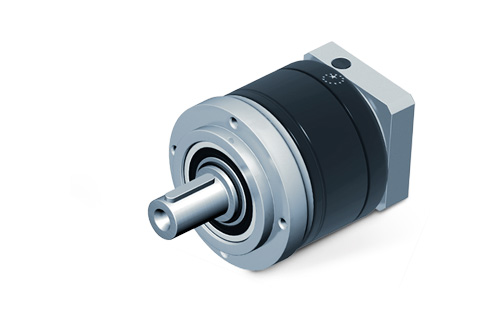

Planetary Gears

-

Efficiently accelerate inertial mass

With the compact, low-backlash planetary gears from the PEII series, you have a cost-efficient solution for applications in which no particularly low backlash in required.

PEII 050 - Planetary Gear

-

- Gear ratio i: 3-100

- Nominal output torque T2N: 10-16 Nm

- Nominal input speed n1N: 4500 rpm

- Backlash Λφ2: ≤ 8-≤ 10 arcmin

- Max. allowed acceleration torque T2B: 18-28.8 Nm

PEII 070 Planetary Gear

-

- Gear ratio i: 3-100

- Nominal output torque T2N: 27-43 Nm

- Nominal input speed n1N: 4000 rpm

- Backlash Λφ2: ≤ 7-≤ 9 arcmin

- Max. allowed acceleration torque T2B: 48.6-77.4 Nm

PEII 090 Planetary Gear

-

- Gear ratio i: 3-100

- Nominal output torque T2N: 68-123 Nm

- Nominal input speed n1N: 3600 rpm

- Backlash Λφ2: ≤ 6-≤ 8 arcmin

- Max. allowed acceleration torque T2B: 126-221.4 Nm

PEII 120 Planetary Gear

-

- Gear ratio i: 3-100

- Nominal output torque T2N: 155-232 Nm

- Nominal input speed n1N: 3600 rpm

- Backlash Λφ2: ≤ 6-≤ 8 arcmin

- Max. allowed acceleration torque T2B: 279-417.6 Nm

PEII 155 Planetary Gear

-

- Gear ratio i: 3-100

- Nominal output torque T2N: 295-459

- Nominal input speed n1N: 2500 rpm

- Backlash Λφ2: ≤ 6-≤ 8 arcmin

- Max. allowed acceleration torque T2B: 531-826,2 Nm

Motor Output Stages

-

Compactly control motors

Compact solutions are available for controlling stepper and synchronous server motors. The VST modules (VST 011 and VST 012) are compact power components for controlling 2-phase stepper motors (micro-stepping). The DC 061 and DC 062 – axis modules in S-DIAS format – are used for controlling synchronous servo motors.

VST 011 Stepper Motor Output Stage

-

- Control of stepper motors

- Max. 5 A and 50 kHz

- 1x VARAN In, 1x VARAN Out

- Full, Half, Micro-step

DC 061 Servo Motor Output Stage

-

- +48 V DC, 6 A

- 1 Resolver input

- 1 STO (2-channel enable input)

- Controls synchronous servo motor

VST 012 Stepper Motor Output Stage

-

- Control of stepper motors

- Max. 10 A and 50 kHz

- 1x VARAN In, 1x VARAN Out

- Full, Half, Micro-step

DC 062 Servo Motor Output Stage

-

- +48 V DC, 6 A

- 1 incremental encoder input

- 1 STO (2-channel enable input)

- Controls synchronous servo motor

Bus Connection

-

Drive technology in hard real-time

A low update time, as well as high data security are essential aspects of motion control. Using the real-time Ethernet system VARAN, it is possible to update drives with 16 bytes of actual and preset values each in 5 µs using a single write/read command. With the DIAS Drives, VARAN is already on board. For communication between a SIGMATEK control and drives from other manufacturers, VARAN interface cards are available.

VBI 021 VARAN-Baumüller Interface

-

For communication between servo amplifiers (b maXX-4000 series) and VARAN control

- 1x VARAN In (RJ45)

- 1x "BACI" bus

- +5 V DC supply voltage "BACI"

VKI 022 VARAN-KEB-F5 Interface

-

For communication between the KEB-F5 converter and VARAN control

- 1x VARAN In (RJ45), 1x VARAN Out (RJ45), distributor function

- 1x HSP5 (RS232 to converter, 9-pin DSUB plug)

- 1x HSP5 (diagnosis, RJ45)

- Communication via DPRAM

Cable

-

Accessories

The right cable for the respective task. As a systems provider, we also offer preassembled VARAN, motor and encoder cables that ensure secure data transmission.

Encoder Cables

-

- Preassembled and shielded

- Flexible and drag chain suitable

- Resolver, EnDat or Hiperface

- Lengths: 1-5 m, 10 m, 15 m, 20 m

Motor Cable

-

- DIAS Drives 100 and 300 - Motor Cable

- Preassembled and shielded

- Flexible and drag chain suitable

- Lengths: 1-5 m - 20 m

VARAN Cables

- put only pictures

Safety

-

Seamlessly integrated safety technology ensures efficiency

The Safety technology is a component of all SIGMATEK's complete automation systems. All Safety modules, such as S-DIAS Safety controllers and I/Os, as well as drives with Safety functions are seamlessly integrated into the entire system.

With the LASAL SAFETY Designer, you have a comfortable and efficient tool for programming and configuring the Safety system. This consistency provides you with an important competitive edge: the engineering of the machines and equipment is simplified considerably.

Your Benefits- High Flexibility

- Simple Engineering

- One Bus System for Standard and Safety

S-DIAS Safety System

-

Fully integrated or stand-alone

Thin, flexible and cost-optimized – that is the S-DIAS Safety system. The modular Safety solution for the DIN rail consists of a Safety controller (SCP), which monitors or controls the application and the corresponding Safe I/O modules.

SCP 111 - Safety CPU Module

-

- Safety Controller

- 1x USB Device

- MicroSD Slot

- SIL 3/PL e, Cat. 4

SDI 101 - Safety Digital Input

-

- 10 safe digital inputs

- Cross-circuit detection

- SIL 3/PL e, Cat. 4

STO 081 - Safety Digital Output

-

- 8 safe digital outputs

- SIL 3/PL e, Cat. 4

SDM 081 - Safety Digital Mix

-

- 6 safe digital inputs

- 2 safe digital outputs

- Cross-circuit detection

- SIL 3/PL e, Cat. 4

SRO 021 - Safety Relay Output

-

- 2 safe relay outputs

- SIL 3/PL e, Cat. 4

SSI 021 - Safety SSI Absolute Value Encoder

-

- Availability of 2 SSI values

- Monitoring of the parameter limits

- SIL 3/PL e, Kat. 4

SIB 061 - Safety Input Box

-

- 6 safe digital inputs

- SIL 3/PL e, Cat. 4

- For decentralized mounting

Drives

-

Dynamic, flexible and safe drive systems

With the DIAS Drives from SIGMATEK, the right servo system is available for any motion application:

- the modularly constructed DIAS Drive 100 series for 1-8 drives

- the compact multi-axis drive system DIAS Drive 300 for up to 3 drives

- the brand new compact drive amplifier DIAS Drive 1000 for 4-6 servo drives

DIAS Drive 100

-

Modular multi-axis servo drive system

The DIAS Drive 100 series is a modular servo drive system. Conceived for highly dynamic machines in the mid and lower power range, it convinces with a very compact design and optimized loss. Per component, up to 8 servo axes are possible - supplied by a power module (MDP)

DIAS Drive 300

-

Compact multi-axis servo system

The DIAS Drives of the 300 series are compact drive systems for 1 to 3 axes – ideal for multi-axis applications in the lower and mid power range (8-14 kVA).

DIAS Drive 1000

-

Compact drive for 4 and 6 servo axes

The SIGMATEK servo drives of the DIAS Drive 1000 series can control up to 6 motors. In addition to the housing, the drive regulators also share the controller, heat sink and DC-link. This carries efficient benefits: reduced construction volume, higher stability and lower device costs.

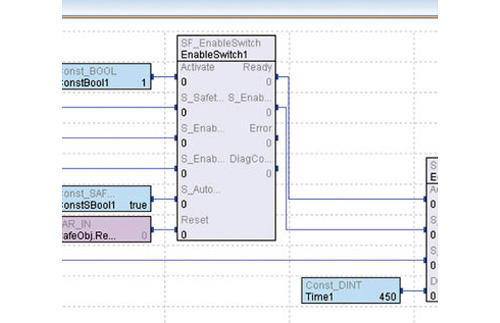

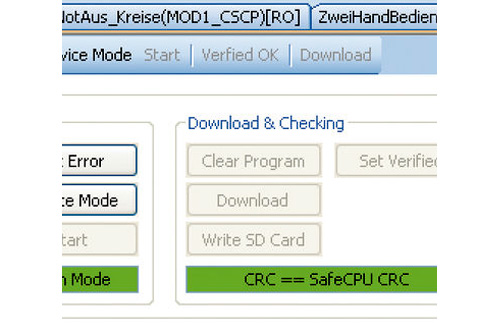

LASAL SAFETY

-

Safety technology

Using the LASAL Safety Designer, you can quickly and comfortably program or configure your Safety applications. The graphic, clear representation and predefined function blocks reduce your overhead considerably. With this tool seamlessly integrated into engineering platform, you can easily create logic connections and configure the Safety I/Os. Troubleshooting and validation can also be comfortably performed.

- Library with standard, as well as Safety function blocks (based on the PLCopen standard)

- Emergency Stop, Two Hand Control, Guard Locking, etc.

- Place function blocks and in/outputs via Drag & Drop

- The debugger enables the graphic display of all values and signal flows

Integrated graphical editor

- In the integrated graphical editor, you can easily place function blocks and I/Os via Drag & Drop and connect them to non-safe variables of the PLC.

Online actions

- The online actions (logging in, cancelling errors, downloading etc.) are run centrally in the Online State dialog.

LASAL SAFETY Designer library

- The LASAL SAFETY Designer library contains, in addition to function blocks based on the PLCopen standard, standard and numeric function blocks as well.

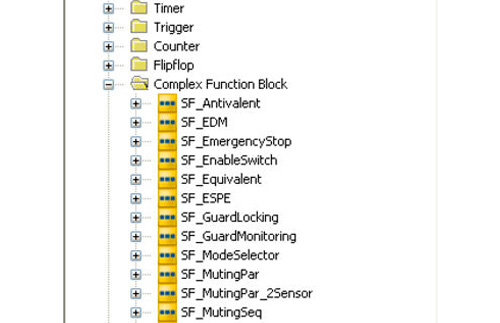

Real-time Ethernet VARAN

-

For hard real-time tasks and secure data transfer

When selecting the right bus system for machine automation, reliability plays a central role in addition to the speed.

SIGMATEK relies on the hard real-time capable Ethernet bus system VARAN, which meets all the demands of a modern industrial network. VARAN is based on standard Ethernet physics and the protocol is implemented in the hardware. Using the manager-client principle, collisions on the bus are avoided.

Our extensive product portfolio includes, in addition to VARAN managers (HMIs, IPCs, CPU modules, expansion cards) and VARAN clients (motion, I/O, interface and splitter modules), design kits for implementation and analysis.

Your Benefits- Optimized Real-time Performance

- High Data Reliability

- Flexible Topologies

- Openness

- Fast and Streamlined Implementation

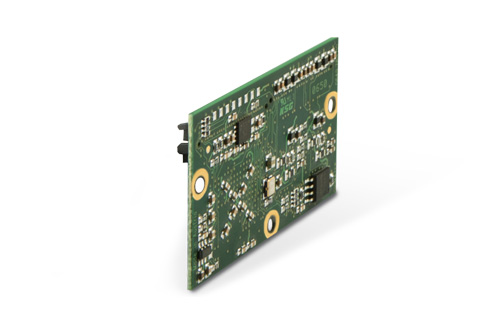

Implementation

-

Integrate industrial Ethernet quickly and easily

The compactly specified VARAN protocol requires only a few commands. Data exchange with clients is limited to read and write access, which keeps the software slim and implementation simple. The integration of VARAN into a control or peripheral device – as well as in small sensors/actuators – can be implemented in the form of VHDL code or in individual hardware components.

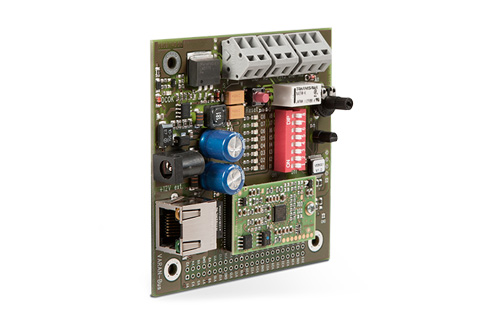

VEB 031 - Manager Board

-

- 2x VARAN Out (Manager)

- 1x PCI bus interface

- 16 Mbit Flash internal memory

- 0 ... +70 °C operating temperature

VEB 011 - Client Board

-

- 1x VARAN In (Client)

- bus, I/O, DPRAM interface

- 4 Mbit Flash internal memory

- 0 … +70 °C operating temperature

VEB 011C - Client Board

-

- 1x VARAN In (Client),

- CANopen, DPRAM interface

- 4 Mbit Flash internal memory

- 0 … +85 °C operating temperature

VEB 011-SPI - Client Board

-

- 1x VARAN In (Client),

- SPI, DPRAM interface

- 4 Mbit Flash internal memory

- 0 … +70 °C operating temperature

VEB 012 - Client Board

-

- 1x VARAN In (Client)

- Bus, I/O, DPRAM interface

- 4 Mbit Flash internal memory

- 0 … +85 °C operating temperature

VEB 013 - Client Board

-

- 1x VARAN In (Client), 1x VARAN Out

- Bus, I/O, DPRAM interface

- 4 Mbit Flash internal memory

- 0 … +70 °C operating temperature

VEB 013-SPI - Client Board

-

- 1x VARAN In (Client), 1x VARAN Out,

- SPI, DPRAM interface

- 4 Mbit Flash internal memory

- 0 … +70 °C operating temperature

VEB 021 - Evaluation Board

-

- Simple intro to VARAN

- Digital and analog I/Os on board

- 1x RJ45, ext. supply +12 V

- VARAN connection over VEB 01x

VEB 022 - Evaluation Board

-

- Simple intro to VARAN

- 1x RJ45, ext. supply +12 V

- 1x DPRAM interface

- VARAN connection over VEB 01x

VSK 001 - Starter Kit

-

- Simple intro to VARAN

- Evaluation Board VEB 021,

- Client Board VEB 011

- Software, Cable, Supply

VSK 002 - Starter Kit

-

- Simple intro to VARAN

- Evaluation Board VEB 021,

- Client Board VEB 011

- PC network card PCV 521

Interfaces & Splitters

-

Flexible topologies and strong real-time performance

The VARAN bus excites not only with excellent real-time performance and data security, but also with flexible topologies. With the VARAN splitter, bus participants are connected via tree, star or linear structures, or a combination thereof. In the most varying configurations, features such as Power over VARAN (PoV), IP tunneling (VtE) or interfaces to third-party systems are integrated. The right solution for any application.

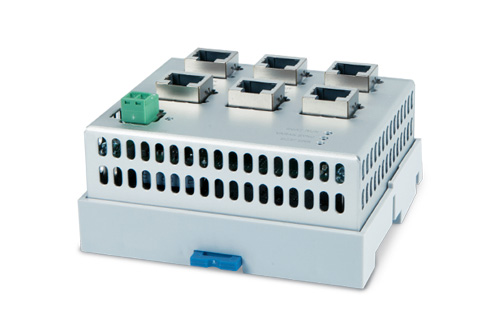

SV 141 - VARAN Splitter

-

- 1x VARAN In

- 4x VARAN Out

VBC 021 - VARAN Coupler Module

-

- Connection of 2 VARAN systems

- 2x VARAN In

- 3x VARAN Out

- 1x IP (VtE)

VI 021 - VARAN Connection

-

- 1x VARAN In

- 1x VARAN Out

- +24 V DC supply

VBC 121 - Coupler Module VARAN - EtherCAT

-

- Connection of VARAN & EtherCAT bus systems

- 4x VARAN

- Optional 1x Ethernet (VtE)

- 2x EtherCAT

VSP 042 - Splitter VARAN - Profinet

-

- 1x Profinet, 1x IP (VtE)

- 1x VARAN In

- 3x VARAN Out

- Star, tree, linear topology

VSP 044 - Splitter VARAN - Profinet

-

- 1x Profinet, 1x IP (VtE)

- 1x VARAN In

- 3x VARAN Out +24 V DC (PoV)

- Star, tree, linear topology

VSP 045 - Splitter VARAN - Profinet

-

- 1x Profinet, 1x IP (VtE)

- 1x VARAN In

- 3x VARAN Out +24 V DC (PoV)

- Fuse in compliance with UL248

VSV 041 - VARAN Splitter

-

- 1x VARAN In

- 4x VARAN Out

- 1x IP (VtE)

- Star, tree, linear topology

VSV 043 - VARAN Splitter

-

- 1x VARAN In

- 4x VARAN Out +24 V DC (PoV)

- 1x IP (VtE)

- Star, tree, linear topology

VSV 046 - VARAN Splitter

-

- 1x VARAN In

- 5x VARAN Out +24 V DC (PoV)

- Of which optionally 1x IP

- Star, tree, linear topology

Products for VARAN Cables

Mini I/O to Mini I/O - Drag Chain - VARAN Cable

-

- 2x Mini I/O

- 4-pin

- Assembled

Mini I/O to Mini I/O - Flexible - VARAN Cable

-

- 2x Mini I/O

- 4-pin

- Assembled

RJ45 to Mini I/O - Drag Chain - VARAN Cable

-

- 1x RJ45 to 1x Mini I/O

- 4-pin

- Assembled

RJ45 to 1x Mini I/O – Flexible - VARAN Cable

-

- 1x RJ45 to 1x Mini I/O

- 4-pin

- Assembled

RJ45 to RJ45 - Drag Chain - VARAN Cable

-

- 2x RJ45 Industrial

- 4-pin

- Over molded

- Assembled

RJ45 to RJ45 - Flexible - VARAN Cable

-

- 2x RJ45 Industrial

- 4-pin

- Over molded

- Preassembled

CAT-5 Cables – Drag Chain - VARAN Cable

-

- For specific system cable

- 4-pin, 2x2xAWG22/7

- 100 meter ring

- Double shielded

CAT-5 Cables – Flexible - VARAN Cable

-

- For specific system cable

- 4-pin, 2x2xAWG22/7

- 100 meter ring

- Double shielded

Mini I/O Piercing - Connector Set

-

- TE Mini I/O connector

- Space-saving

- Toolless cable assembly

RJ45 CAT5 - Connector set

-

- RJ45 industrial connectors

- Toolless cable assembly

- 4-pin, CAT5

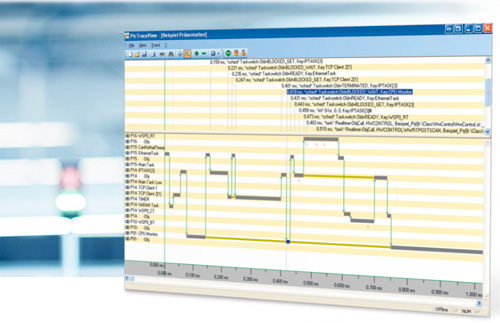

VARAN Analyzer

-

Analyze real-time communication directly on the machine

With the VARAN Analyzer, an efficient tool is provided for monitoring and analysis of the real-time Ethernet bus system. Depending on customer requirements, the VARAN bus data transfer properties can be analyzed using an insertable card for the C-IPC or a stand-alone device.

ETVA 0501 - VARAN Analyzer

-

- VARAN communication analysis

- 5.7" resistive touch screen

- 1x VARAN Out or Ethernet

VA 062 - VARAN Analyzer Expansion Card

-

- VARAN communication analysis

- Display in VARAN Service Tool

- 1x VARAN In

- 2x VARAN Out (opt. 1x transparent)

Valve Terminal Interface

VVO 323

-

- Valve Terminal Interface

- For controlling valves or magnetic coils

- 32 digital, short-circuit proof outputs (+24 V DC/50 mA)

- Valve terminal series: SY3000/5000/7000, SV1000/2000/3000, VQC1000/2000/4000, S0700

- 1x VARAN In, 1x VARAN Out

- Protection type: IP67

- Valve Terminal Interface

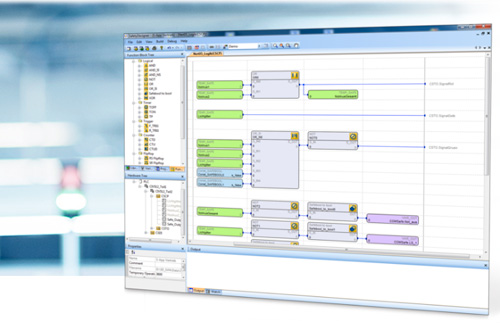

Engineering Tool LASAL

-

All automation tasks with one software

With the engineering platform LASAL, you are provided with an integrated and user-friendly tool set for all phases of machine design: project development, control programming (CLASS) visualization (SCREEN), motion control (MOTION), Safety (SAFETY), simulation, initial start-up, service, diagnostics and remote maintenance (SERVICE) of the machine and system in the field.

LASAL combines object-oriented programming (IEC 61131-3 standard) with graphic representation and makes mechatronic engineering possible: Real machine components can be represented by software objects.

Your Benefits- Integrated Engineering Reduces Development Costs

- Object-oriented: Flexible Software Design System

- Comfortable and Efficient: Numerous Integrated Tools

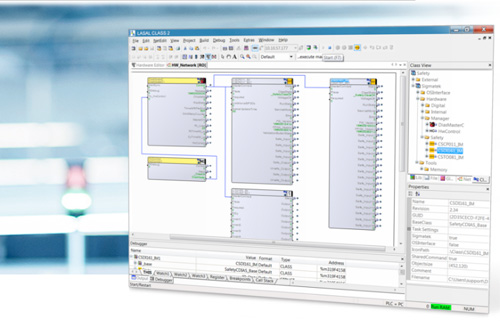

LASAL CLASS

-

Control programming

From the most simple machine to complex control tasks – with the project development software LASAL CLASS, an efficient solution is available for your automation jobs.

- Object-oriented programming and design in compliance with 61131-3

- Graphic representation ensures a clear overview

- Modular and reusable: reduce Engineering times and costs

- Predefined software components

- Graphical Hardware Editor: place hardware as mounted in the control cabinet

LASAL SCREEN

-

Visualization

Operating and monitoring are essential components of every automation task. With LASAL Screen, a comfortable tool for visualization design is provided.

- Simple: knowledge of a programming language not required.

- Efficient: hardware-independent development of visualization

- Several standard graphic functions, integrated designs and large graphic library

- Export and import of project sections and graphics possible

- Visualize machine data in Windows

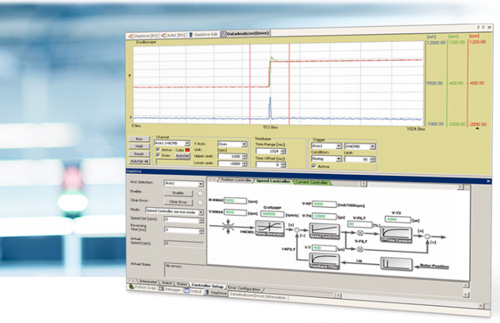

LASAL MOTION

-

Drive technology

The LASAL MOTION software package is responsible for motion control and is seamlessly integrated into the programming and project development tool LASAL CLASS. Robotics, PLC and motion control are unified on one platform and as in the machine, also overlap in the software. Complex tasks for axis control and regulation can also be solved modularly and comfortably.

- Axis motion without programming: simple input of data and commands

- Motion control is independent of the hardware used

- Extensive motion library

- Central management of drive parameters: exchange of hardware without software tool

LASAL SAFETY

-

Safety technology

Using the LASAL Safety Designer, you can quickly and comfortably program or configure your Safety applications. The graphic, clear representation and predefined function blocks reduce your overhead considerably. With this tool seamlessly integrated into engineering platform, you can easily create logic connections and configure the Safety I/Os. Troubleshooting and validation can also be comfortably performed.

- Library with standard, as well as Safety function blocks (based on the PLCopen standard)

- Emergency Stop, Two Hand Control, Guard Locking, etc.

- Place function blocks and in/outputs via Drag & Drop

- The debugger enables the graphic display of all values and signal flows

LASAL SERVICE

-

Practical tools

An extensive package of service tools round out the automation software LASAL.

Modern server technologies ensure efficient remote control access for diagnostics, service and remote maintenance.

- Web Server with LRMView

- VNC client and server

- OPC UA server

- OPC server

- LASAL remote manager and server API

- USB boot stick

- LARS simulation and visualization tool

Special Applications and Industries

-

Need for customized solutions

Our customers come from the most varying industries. In addition to classic machine and equipment manufacturing, manufacturers of energy technology systems have also been counted among our customer base for over 20 years. Several customers are also active in measuring, control and regulation technology. For these industry sectors, we have developed branch-specific products and solutions.

A product that makes data maintenance easier for every machine and equipment manufacturer, is our Diskette Emulator CFF 011, which can store data from up to 99 floppy diskettes on one Compact Flash card. Energy Automation

-

Tailor-made components from a toolkit

For more than 27 years, SIGMATEK has been active in the energy automaton sector: Pellets and wood chip furnaces, heat pumps, solar and biogas systems. The highly modern components for controlling and operating your application come from a system toolkit. A modular construction of the hardware enables simple expansion of the system.

Regardless of whether with the intelligent control panels, space-saving room operating devices, table PC or smart phone - you have your energy management system well in hand.

Furnace and decentral modules- such as for photovoltaic system or effective boiler and buffer management - can be quickly and easily integrated. Measuring Technology

-

Measuring, controlling, regulating in a new dimension

With its modularity, the SIGMATEK MSR system is ideal for the most varying tasks in data recording, measuring and testing. The measuring modules can be flexibly populated, so that you can compile the measurement values specifically for the application. A tailor-made solution is thereby provided for measuring and regulation technology:

- Modular construction: user-specific placement – up to 192 digital or 64 analog I/Os

- Flexible configuration: recoding of various measurement values (4..20 mA, ±10 V DC, etc.)

- High precision: 25-µs conversion time per channel (40 kHz), 18-bit resolution

- High Performance: the highest data security and bus cycle times from 100 µs (jitter < 100 ns)

- Programming in LASAL: simple integration and simulation in real-time

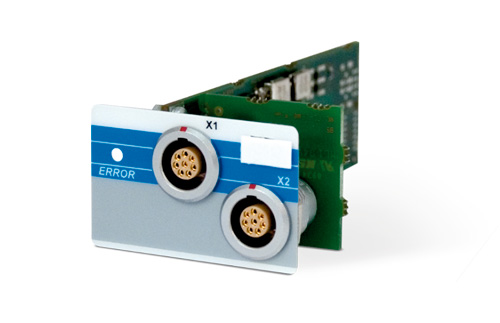

MSR 111 - Module Carrier

-

- 8 I/O slots

- 1 interface slot

- 1 fan slot

MSR 121 - Interface Module

-

- VARAN bus control module

- 1x VARAN In

- 1x VARAN Out

MSR 131 - Fan Module

-

- Exchangeable fan unit

- DC radial fan

MSR 211 - Base Module

-

- Analog base module

- 4 signal conditioning modules

MSR 221 - AI Insertable Module

-

- 2 analog voltage inputs

MSR 222 - AI Insertable Module

-

- 2 analog current inputs

MSR 223 - AI Insertable Module

-

- 2 analog temperature inputs

MSR 231 - 8B Insertable Module

-

- Signal conditioning

- Carrier module for 8B modules

- 2 analog inputs

MSR 241 - AO Insertable Module

-

- 2 analog outputs

MSR 251 - FC Insertable Module

-

- 2 counter inputs or SSI absolute value encoder

MSR 261 - NC Insertable Module

-

- 2 ABR counters (RS422 signal)

MSR 281 - Strain Gauge Insertable Module

-

- 2 strain gauge inputs

- Measurement range 3 mV/V

MSR 282 - Strain Gauge Insertable Module

-

- 2 strain gauge inputs

- Measurement range 10 mV/V

MSR 311 - I/O Module

-

- 24 digital short-circuit proof outputs (back-readable/+24 V DC/2 A)

- Can be used in groups of 4 as digital inputs (+24 V DC/5 ms/5 mA)

Diskette Emulator

-

Compact flash floppy drive

You have a machine system control with a floppy drive? The machine still functions perfectly but you are no longer happy with floppy technology? With the CFF 011, we offer an operating-system independent replacement device. Psically, the compact flash floppy drive is no different from a conventional floppy drive.

- High capacity: copy the data from up to 99 floppy diskettes onto a single CF

- Plug & Play: simple exchange without installation

- Platform-independent: supports all commercial operating systems

- Robust: designed especially for industrial applications

- Flexible configuration: horizontal and vertical installation possible

CFF 011 - CompactFlash Floppy Drive

-

- 1x CF connector

- 1x Floppy connector

- 2x jumper

Industries

-

We Automate Many Industries

Globally successful with solution expertise and quality

Integrated automation system solutions; that has been SIGMATEK's core expertise for over 25 years. Our engineers love complex, fast processes that depend on the combination of performant control, dynamic drives and strong visualization. An extensive applications team is there to support you during implementation with advice and assistance, or you can put us in charge of creating the application software.

You profit from synergies generated from our deep and broad machine know-how, as well our industry expertise. Because: SIGMATEK solutions are used worldwide in the most varying industries. We therefore have precise knowledge of industry-specific requirements.

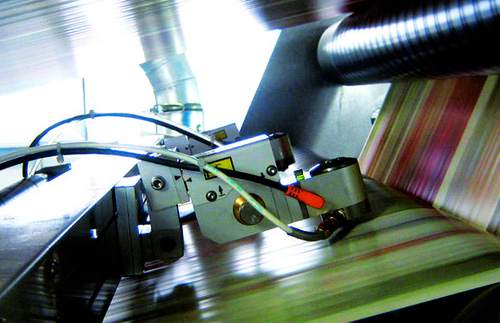

Printing and paper

-

Flexible automation, quick changeover

Always hot off the press, individual in design and format as well as tailored to the target group. And often with a smaller circulation, including personalized publication - the requirements of the printing and paper industry are continuously increasing.

Renewable Energy

-

Automate flexibly and efficiently

"Green Energy" is in trend - whether alternative heating technology with pellets, wood chips and logs, heat pumps, biogas systems, wind power, solar or photovoltaic systems. SIGMATEK has more than 25 years of experience in energy automation and provides highly modern control technology for the generation, distribution and conversion of alternative energy.

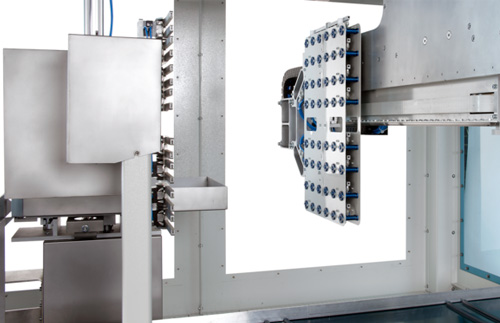

Plastics Technology

-

Meets industry experts

SIGMATEK has more than 25 years of experience in the automation of plastic processes. We offer the right system solution for all areas of plastics processing. From extrusion and blow molding technology to injection molding, you will find the right hard and software with us. Our industry know-how also includes downstream machines, handling tasks, finishing processes, as well as peripheral devices. Such processes can be performed by the machine directly or connected to one another via real-time Ethernet standards such as VARAN.

Logistics and Transport Technology

-

Automation: efficiency and safety count

SIGMATEK has many years of experience in the logistics and material flow sector. Our modularly constructed, integrated and scalable automation system makes it easier for you to cover the versatility of your customers' applications. Even complex applications with demanding axis control requirements can be efficiently run with our system solutions. A complete solution also contributes to reducing the total costs and getting your equipment and systems on the market faster.

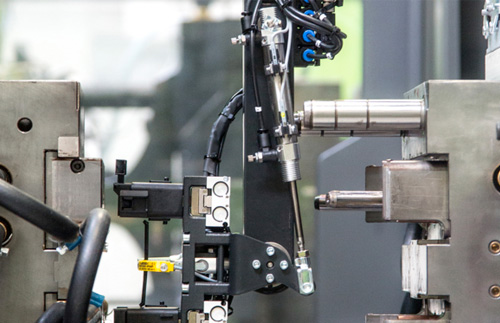

Metal Processing

-

Precision and modularity are trumps

Metal presses, bending machines, coil processing, cutting and grinding machines, folding machines or punching and welding machines – including robotics, band-straightening machines and transfer systems: the automation tasks in the metal machine manufacturing are diverse.

Analysis and Testing

-

Absolute precision and reliability when measuring and testing

For analysis and testing systems, absolute precision, speed and flexibility are the Alpha and Omega. And SIGMATEK provides you with efficient complete solutions for exactly such control and regulating functions, high-speed measurements, motor controls, as well as condition and temperature monitoring of machines, which meet any challenge.

Robotics and Handling

-

Control, robotics and motion control combined

Handling systems, assembly machines and robots must quickly and cost-efficiently adapt to the different products and increasingly more complex conditions of production. Modularly constructed machine and system concepts – equipped with an automation system that is also modular in design – provide the required flexibility. And that is where SIGMATEK comes into play.

Textiles

-

Precision and quality for guaranteed success

With the automation of textile machines, high precision and availability must be combined with high efficiency and flexibility. SIGMATEK knows the demands of the textile industry and has established itself as complete solutions provider.

Packaging and Food Industry

-

High performance, flexible automation is in demand

The demands on your machines and equipment are permanently increasing: smaller lot sizes, more flexible product and format changes, as well as higher production speed. Modular machines and equipment with an integrated automation system that is just as modular provide more cost efficiency and flexibility.