- Offer Profile

- Committed to the principle Vision of Packaging, we transform our visions of modern packaging and automation technology continuously and successfully into trend-setting and innovative technical solutions. This enables us to inspire our customers in the fields of pharmaceuticals, cosmetics, chemicals, food, confectionary and bakery as well as non-food again and again.

Packaging Solutions

- Individual components, machines or complete packaging lines up to turnkey lines - all our solutions are based on the proven modular UNIROB system. Intelligently combined and customized to suit your products and individual needs.

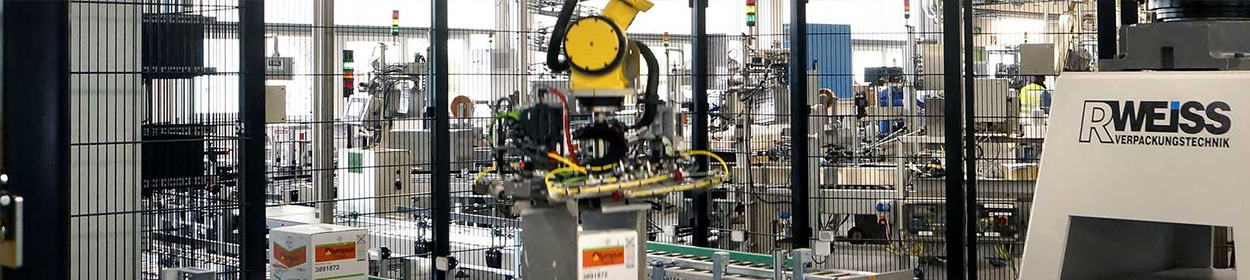

The UNIROB Modular Design - Flexibility through modularity

-

Today the packaging industry is confronted with frequent format and product changes. Similarly, there is a constant increase in the variety of packaging means and formats. This results in increasing demands on the flexibility of packaging machines.

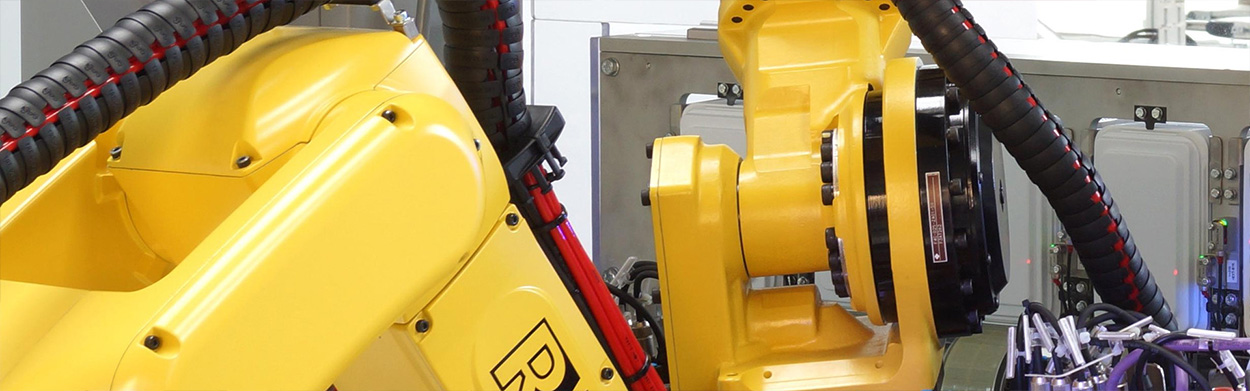

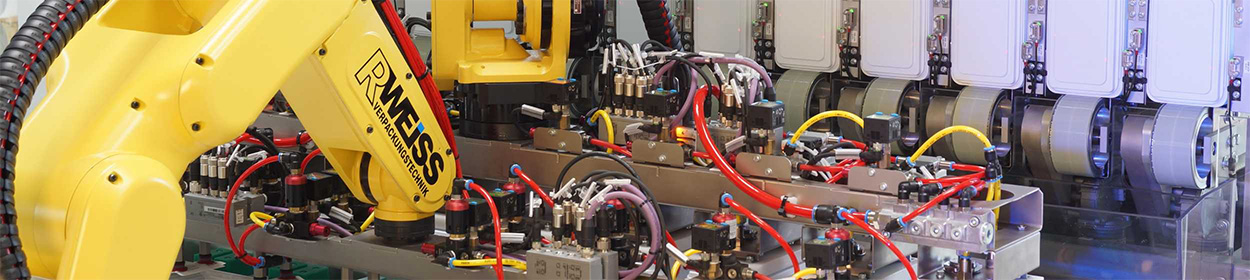

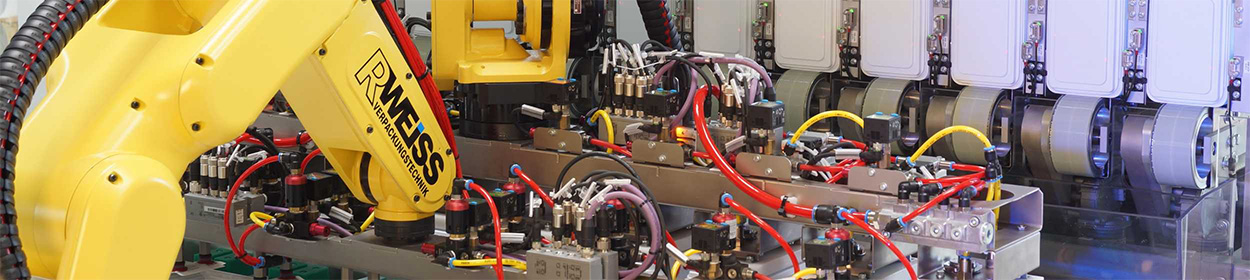

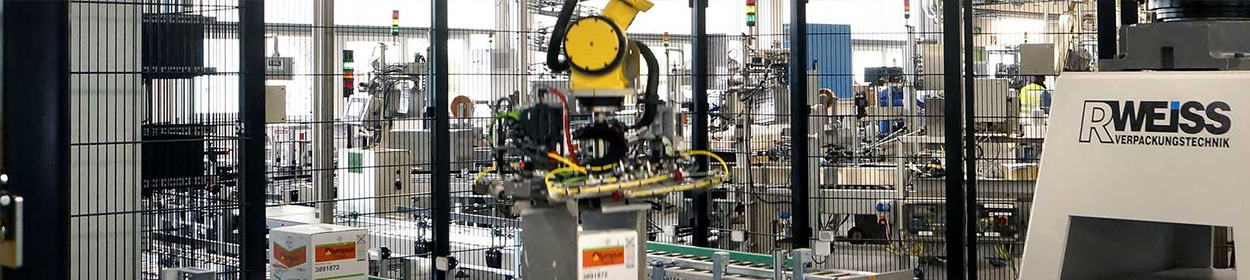

The impressive flexibility of the packaging solutions from R.WEISS is the success resulting from modular concept which extends throughout all parts and components in mechanics as well as in electrical engineering and software.

The modular UNIROB system is based on standardized components or modular building blocks which can be individually configured according to customer requirements up to a holistic packaging solution.

The basic module consists of a stable steel frame which is available in several standard sizes and conveniently accessible through large guard doors. It includes, depending on the task, one or more standard robots with four, six or seven degrees of freedom which are mounted upside down in a space-saving way.

For all packaging processes, such as erecting carton blanks, product mixing, grouping and top loading of the products as well as for closing the boxes, labeling and palletizing, proven standard modules are frequently used.

The sum of all the configured standard modules ultimately results in an application-specific overall concept tailored to the individual requirements of our customers. The UNIROB concept is rounded off by a comprehensive, user-friendly and open system control according to the most recent standards.

In addition, the use of standard modules offers you a high degree of development and as a result absolute reliability and safety for you and your packaging processes.

Your advantages:- Customized packaging solutions for your individual requirements

- High flexibility and design of the packaging system fitting to your spatial conditions

- Packaging system can be flexibly extended by additional modules

- Rapid adaptation of the packaging system to changing production plan

- Packing different products and formats on one machine

- Fast format change through the use of quick-change devices

- Flexible adaptation of the layout possible even after the planning and design phase

UNIROB Toploading Machines

-

Since the beginning of 2001, R.WEISS began the development of the UNIROB toploading machines with upside down mounted robots in the packaging cells. Due to the overhead position of the robots, which is not yet known in the packaging industry by then, optimum accessibility through large guard doors and very good view of the individual packaging processes are possible.

The UNIROB Toploading machines are suitable for the industry-independent use and packaging of all piece and prefabricated products which can be inserted into containers or erected folding boxes by means of the so-called top loading method i.e. from above. The products can also be fed to the machine uniformly sorted and finally mixed into the boxes according to a specific pattern.

By UNIROB toploading machines, the product and packaging material feeding is possible from any side arbitrarily and can thus be adapted individually to the mostly limited spatial conditions of the customer.

The unbeatable advantages of the UNIROB Toploading technology are convincing all the way:

- Modular design of the entire machine up to a complete line

- Compact, space-saving toploading position of the robots

- Automatic change of the robot tools

- Machine is freely expandable by modular design

- Fully-developed standard robotics technology

- Easy and intuitive operating concept with touch panels

- Free positioning of the peripheral devices

- Good packaging machine accessibility all around via large guard doors

- Optimal operator insight into the packaging process

- Product and packing material feeding from all sides is possible

- High flexibility for product or packaging changes

- Absolute reliability and safety in packaging processes granted by high degree of development of the standard modules

- Reliable, efficient and economical systems engineering

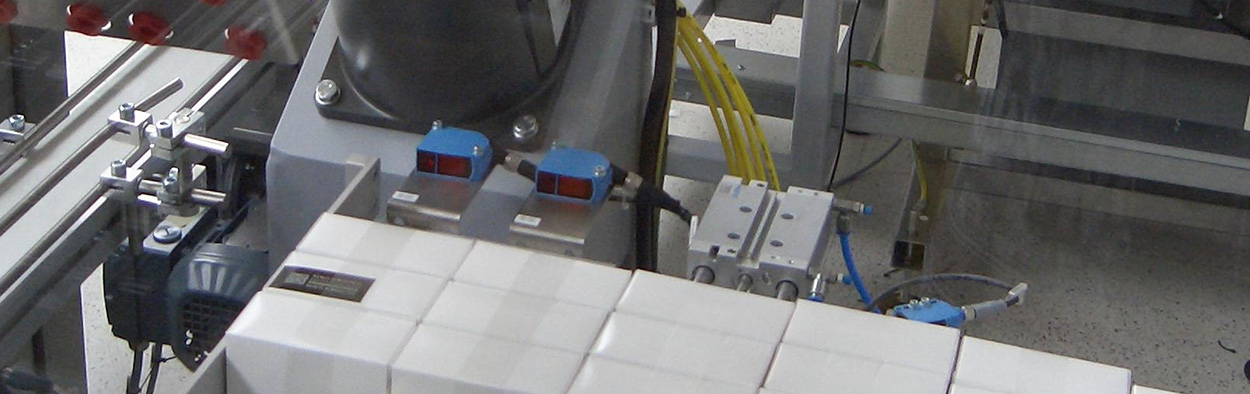

The basic modules of a UNIROB Toploading Machine include the UNIROB Erector for erecting flat carton blanks or folding cartons, the UNIROB Toploading Module for placing the products into the previously erected cartons and boxes from the top by means of gripper tools or vacuum suckers.

The final component of a Toploading Machine is the UNIROB Closer. Within this standard module, the folding cartons are sealed by either adhesive tape or hot glue.

Depending on customer requirements, a UNIROB Toploading Machine can be equipped and expanded with additional modules, such as a UNIROB Case Packer or a UNIROB Palletizing System. This also allows us to produce individual mixes of products which are fed to the machine sorted, and finally grouped into folding cartons or other containers by means of toploading process.

UNIROB Picker Lines - Flexibility all along the Line

-

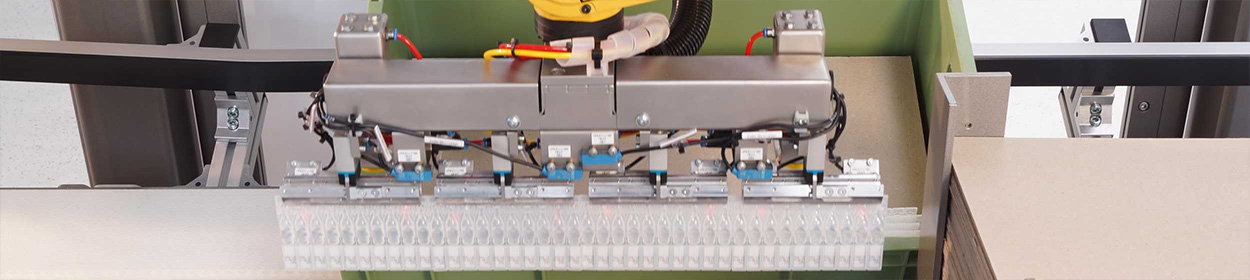

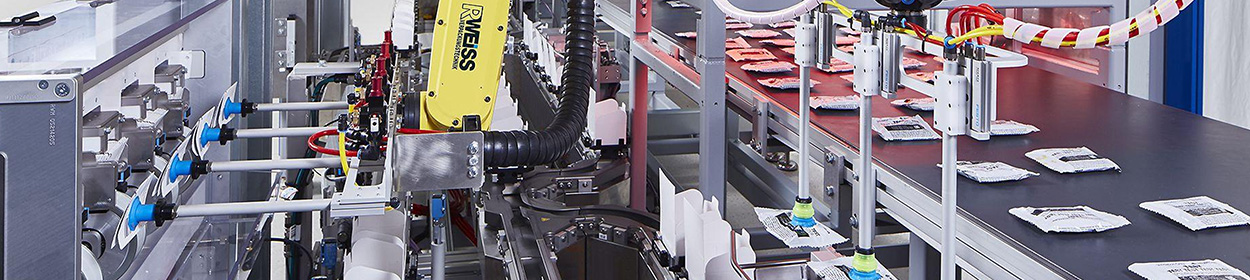

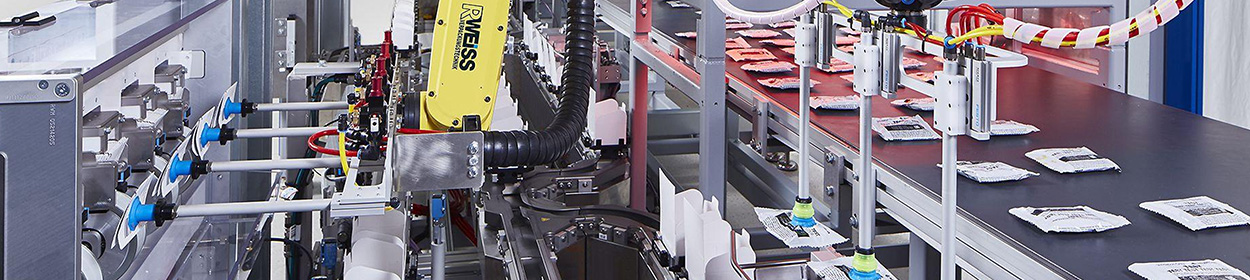

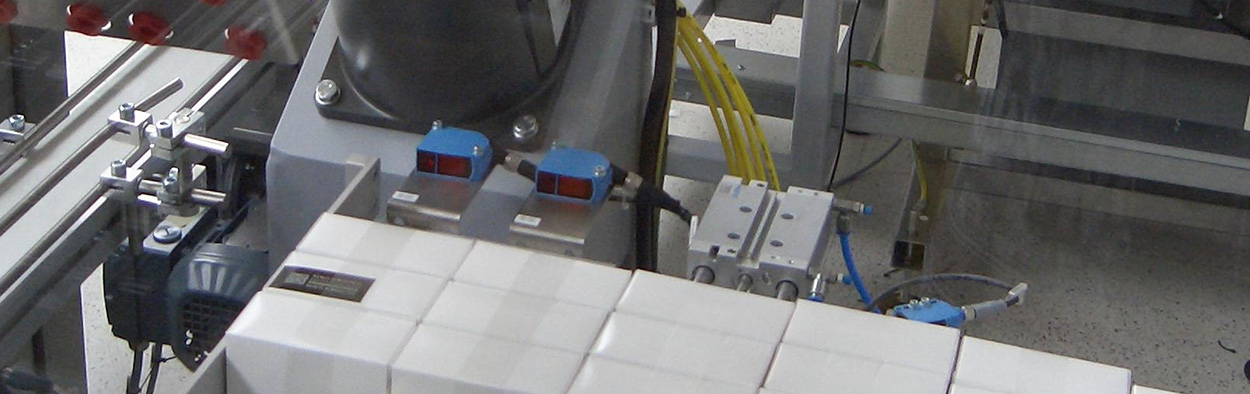

UNIROB Picker Lines pack your products with the highest performance and they are efficiently and successfully in use in a wide range of industries. High-speed packaging systems of this type are used wherever highest productivity, high cycle rates and absolute precision are required.

The core of these packaging systems is the Toploading area with several successively connected delta robots. Depending on product characteristics, these robots have a special vacuum or gripping tools. The products are therewith gently and quickly handled by pick and place application and inserted into the previously errected folding boxes via individual or multipick.

With a throughput of up to 180 Pick & Place cycles per Delta robot, the UNIROB Picker Lines are not comparable to any other system in terms of packaging speed. The supplied product stream is processed by several delta robots depending on the requirements. The last delta robot in the sequence serves as performance reserve and ensures that all products find their way into the folding cartons.

By the use of state-of-the-art sensor technology, the products can be also fed randomly to the toploading area. Cameras systems capture hereby the positions of the individual products and pass those position data to the Delta robots. This allows them to process the products with the highest accuracy and precision (with deviations up to 0.1 mm).

Depending on the requirements, metal detectors as well as Track & Trace systems can also be integrated into the UNIROB Picker Line, and the line can be individually adapted to changes in the production capacity by extending the Picker Line by additional standard modular cells.

Your advantages:- Depending on product and load, up to 180 Pick & Place cycles per minute per Delta robot

- Gripper tools or vacuum suckers designed for different products and applications

- Toploading of the products by Pick & Place process employing single or multiple pickers

- Fast and gentle product handling with absolute precision

- Possibility of picking and packing even more difficult and pre-packaged products

- Flexible adaptation of the system to changes in capacity and performance due to modular design

- Absolute reliability and safety in packaging processes granted by high degree of development of the standard modules

- Reliable, efficient and economical systems engineering

- Easy and intuitive operating concept with touch panels

- Free positioning of the peripheral devices

- Good packaging machine accessibility all around via large guard doors

- Optimal operator insight into the packaging process Product and packing material feeding from all sides is possible

UNIROB Turnkey Lines - Packaging solutions from one source

-

Our key to the success of any Turnkey project is a common understanding and partnering with our customers in the planning phase.

"Planning in Dialogue" is our motto which is why our design and development engineers are already involved in project planning. This includes a visit to the production of our customers and discussions with their experts from product development and production. General requirements, product properties and details which are not contained in any specification can be taken into account during the design and planning phase.

On this basis, the detailed planning of a tailor-made packaging concept follows. From carefully selected standard modules, we generate a reliable packaging system which is adapted to your individual needs and meeting all your requirements. As a result, we are an attractive general contractor for customers in the fields of pharmaceuticals, cosmetics, chemicals, food, confectionery as well as non-food.

As a competent partner, we take over the overall responsibility for realizing your individual and automated UNIROBTurnkey Line throughout the all phases of the project. The individual components of your new packaging solution are compiled and provided by us independent of the supplier. When selecting suitable suppliers, we always pay attention to the highest quality at the best possible price-performance ratio.

Your advantages:- We take over the overall project responsibility and selection of suitable suppliers

- Project manager is at your disposal as a single point of contact for the entire project implementation

- Competent team for the installation and commissioning of the packaging machine

- We take over the entire order processing for your packaging machine - from ordering, delivery and assembly phases up to handover to you

- Clarification of interfaces, preparation of required detailed plans, attention to deadlines, cost, quality and preparation of the project documentation

- Our project managers and assemblers are also available for you as on-site support in the start-up phase.

- Organization of additional training and technical support for your machine operators

- Comprehensive After-Sales Service by qualified service personnel

With our UNIROB technology, you are best prepared for the future. You will benefit from its advantages also in the future. (This section was previously listed above "Your Advantages ") As a leading German manufacturer of top-loading packaging machines, R.WEISS Verpackungstechnik offers not only turnkey solutions, but also a comprehensive after-sales service. The modular design of the UNIROB Turnkey Lines allows you to upgrade, convert, or expand your packaging line at any time to adapt it to your production plan.

The UNIROB Erector

-

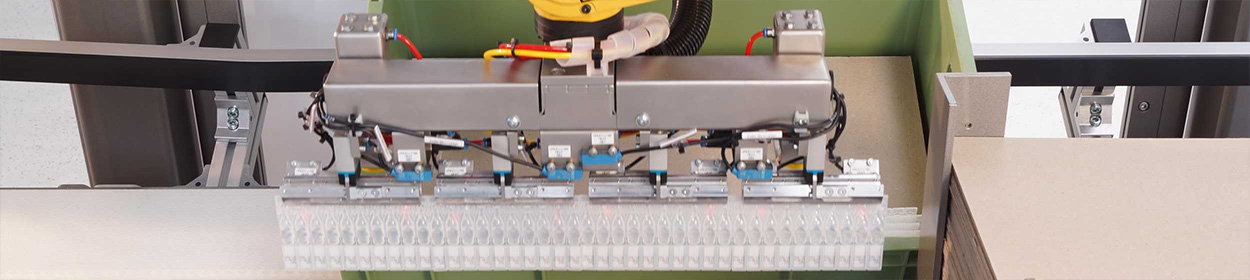

The UNIROB erector is usually the first module in the series of modules in the R.WEISS packaging machines. The handling of the carton blanks is carried out with our UNIROB erector by the use of robots. The blanks are picked up from the magazines using vacuum and guided through the hot melt nozzles. Then, the robot presses the carton blank with its forming tool through a folding chute, thereby connecting the side flaps to the carton. Afterwards the robot pushes the blank with its forming tool through a folding frame, whereby the side flaps are combined with the carton. Depending on the application, the erected boxes are then fed to the toploading area via a transport unit where they are finally filled with the products.

Each UNIROB Erector is customized to the different requirements, formats and the desired performance of our customers. The modular design offers you the highest degree of flexibility. For even greater versatility, the UNIROBErectors can also be modernized without any problems at any time in the case of changes in format or production, or can be easily extended by additional modules.

The folding carton blanks are stacked in an ergonomic and easily accessible blank magazine. This also enables the operators to easily fill the magazine during operation without interfering with the ongoing packaging process. Machine downtimes are therewith history. In addition, quick-change devices on the blank magazines enable quick and easy switching between different formats.

Your advantages:- Maximum performance with low space requirements

- Ideal for packaging line integration

- Ergonomic position of the blank magazines

- Optimal access and insight into the erection process through large guard doors

- Easy filling of the blank magazines without machine downtime

- Quick-change device for easy changeover between different formats and packaging sizes

- Erection of extremely flat lying folding carton blanks is possible

- Low repair and maintenance costs through high-quality kinematics and smooth-running drives

- Carton sealing possible by means of hot glue or self-adhesive tape

- Good packaging machine accessibility all around via large guard doors

- Easy and intuitive operating concept with touch panels

- Hygienic and easy-to-clean design

In summary, the UNIROB Erector offers a high degree of flexibility and reliability in the packaging of products of various types.

The UNIRob Closer

-

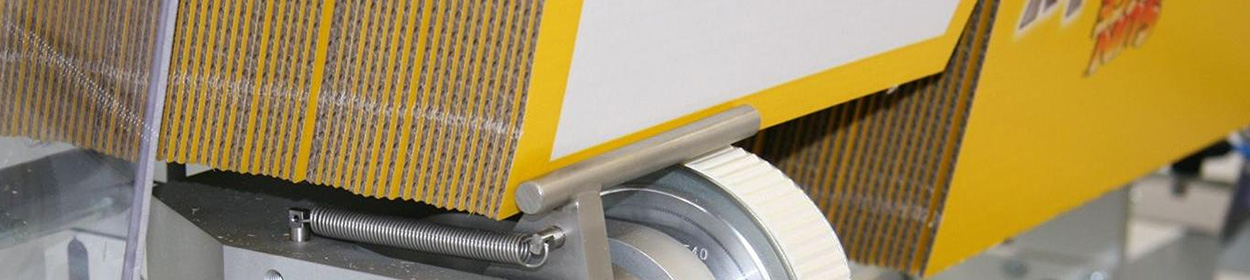

The UNIROB Closer can be used to process different closures and lid shapes as required. Hereby two different closure possibilities can be applied.

On the one hand, the folding cartons can be closed by the application of hot glue and by the means of a multi-head tool. The multi-head tool is at the same time capable of gripping the closed folding boxes in order to transport them directly to different conveyor belts which feed the boxes to various labeling stations or palletising systems. On the other hand, the folding boxes can also be closed by a self-adhesive tape applied from above.

The most common types of fasteners that are processed with the UNIROB Closer are, for example, lids with closure flaps, lids with plug-in-flaps glued from inside, glue flaps to be glued from outside, U-shaped slip lids, fitted snap-on lids, wrap-around lids, and folding boxes put over the tray and many more.

The UNIROB Closer can, of course, be supplemented by further units. For example, the insertion of product information can also take place before closing.

Your advantages:- Fully automatic closing of single-side, double-side and three-side closures as well as various other lid forms by multi-head tool

- Closing of the folding boxes is done by means of hot glue or self-adhesive tape

- Convinient access into the packaging machine all around through large guard doors

- Optimal insight for the operators into the packaging process

- Easy and intuitive operation concept with touch panels

- Reliable, efficient and economical systems engineering

- Flexible adaptation of the system to changes in capacity and performance due to modular design

- Absolute reliability and safety in packaging processes granted by high degree of development of the standard modules

The UNIROB Case Packer

-

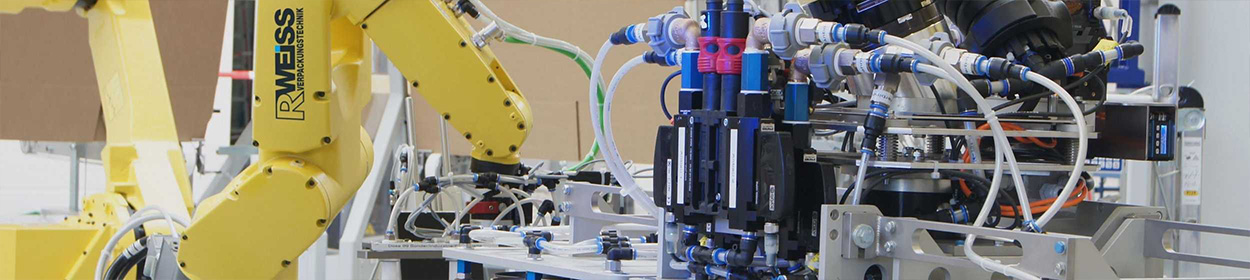

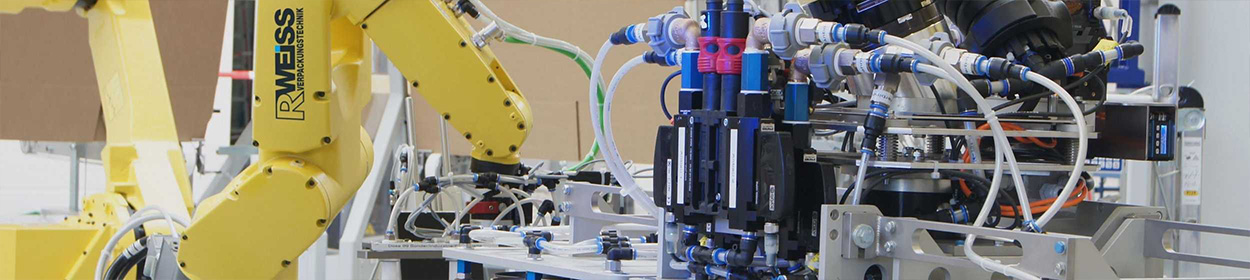

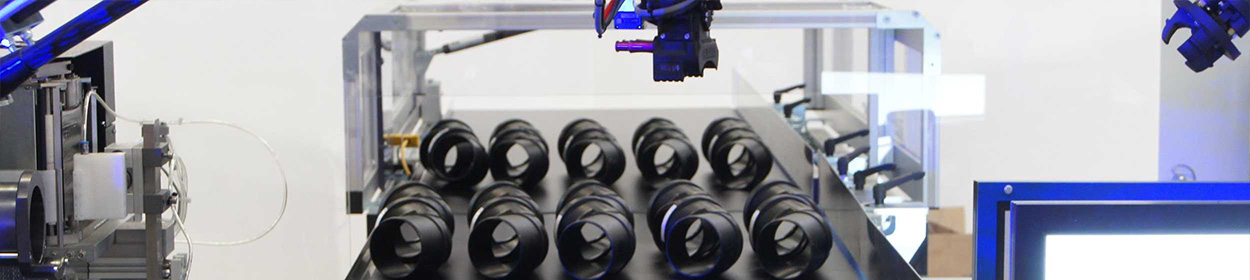

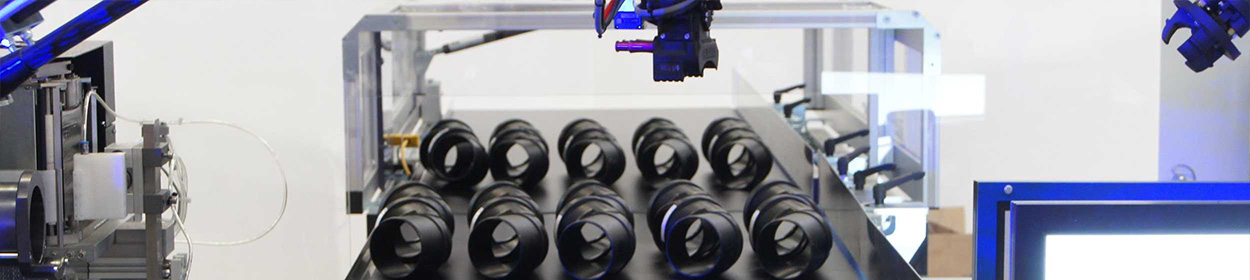

Group products – Erect the carton - Fill the carton – Close the carton. All these work steps are combined in a single module, the UNIROB case packer. Due to its complex design, we are able to realize complex packaging processes in limited space.

The UNIROB Case Packers are designed for the packaging of stackable products. Within the machine, trays and boxes are efficiently and safely erected, filled and sealed. In addition, the processing of pre-glued sleeves is also possible. Through the individual configuration of the case packer modules, we offer a wide range of different packing solutions, such as case packers, box packers, tray packers, tray & hood packers for displays, bag packers and stick packers.

This results in numerous possibilities for the design of your individual final packaging. Laying or standing product arrangements, line or layer formations, boxes with front flaps, top flaps or 3 side closure – diversity of the packaging applications is enormous. We design our individual packers according to your specific requirements.

Your advantages:- Small footprint due to compact design

- Group products in the limited spaces

- Bundling different formations

- Preparation of customized groupings for shipping to different countries

- Fast format change through the use of quick-change devices

- Integration of Serialization and Track & Trace systems possible

- Good accessibility all around the packaging machine via large guard doors

- Optimal insight for the operators in the packaging process

- Reliable, efficient and economical systems engineering

- Fully-developed standard robotics technology

- Easy and intuitive operating concept with touch panels

- Processing of pre-glued sleeves possible

As a result of our long-standing experience and numerous realized projects, our engineers and technicians work out fully-developed case packers that meet the highest quality requirements and are absolutely efficient and durable due to their robust construction.

The carton design can be modified so that it will have the function of a display tray after opening. Additional staple edges for better fixing of the product can be incorporated.

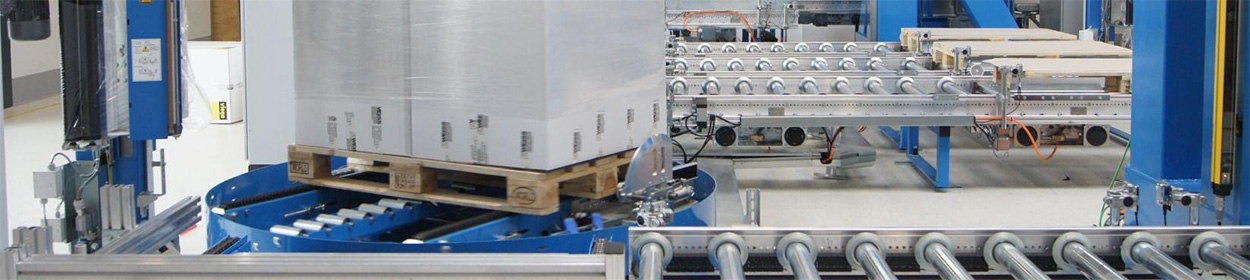

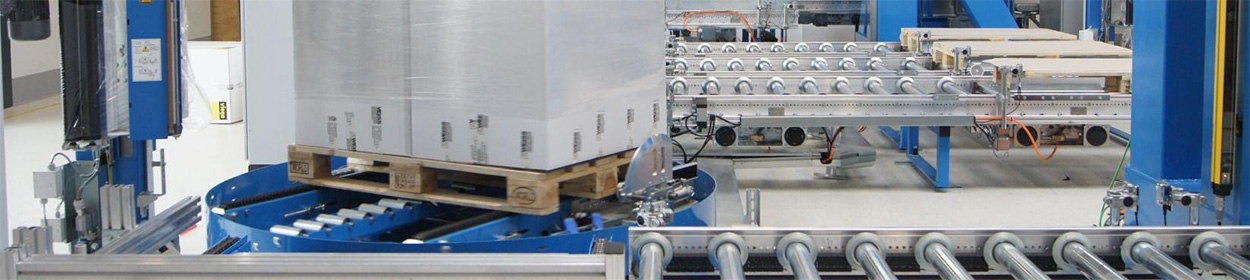

UNIROB Palletizing Systems

-

The use of robots is today standard in numerous automation tasks. The final stage of a UNIROB packaging line can be a robot-based UNIROB palletizing system depending on the customer's requirements. This packaging process can be carried out in various automation stages, ranging from the semi-automatic compact to the multi-pallet and central palletizing.

In palletizing applications, absolute accuracy is required to ensure safe transport of your goods. Therefore, a detailed layout of your system is prepared in advance. Using simulations during the design phase, our engineers are able to recognize possible hazards or risks prior to the realization of the project and to develop specific solutions to avoid them. This results in a high process safety and reliability.

We offer you individual palletizing solutions for different carton sizes and packing patterns. With intelligent process control, the carton dimensions and weights are automatically transmitted to your enterprise resource planning system. This allows you to inspect and control all the data on your palletising system at any time.

Depending on the customer's needs, further components such as depalletizers, pallet stretchers, interlayer magazines, transport lines, camera monitoring, labelers, laser or inkjet coders and other modules can be integrated into the UNIROB palletizing system.

Your advantages:- Flexible application possibilities

- Customized palletizing solutions through standard modules

- Application-specific modification to different pallet variants

- Space-saving palletizing via compact design

- Optimal accessibility all around the palletizing system

- Systems can be expanded arbitrarily as required by modular design

- High flexibility in product or packaging changes

- Program modules for connection to existing PIM and SAP systems for centrally controlled order management

- Planning and delivery of complete conveyor systems for automation, logistics and storage systems

- Flexible extension with additional components, such as depalletizers, pallet stretchers, interlayer magazines as well as labellers, laser or inkjet coders

Industries

Packaging machines for products of pharmacy and medicine

-

Manufacturers of medical products currently have to upgrade enormously in the field of packaging through new guidelines. Marking systems, printers and control systems are necessary to meet the new requirements of the EU. In the packaging process, integrated serialization systems have become indispensable for a complete traceability of the product suppy chain via the use of Track & Trace applications.

On the other hand, pharmaceutical products have special requirements for their packaging. In addition to the optimal protection and safety of the products, a significant labeling of the packaging as well as their complete traceability are the main focus.

Packaging machines which meets the highest standards

-

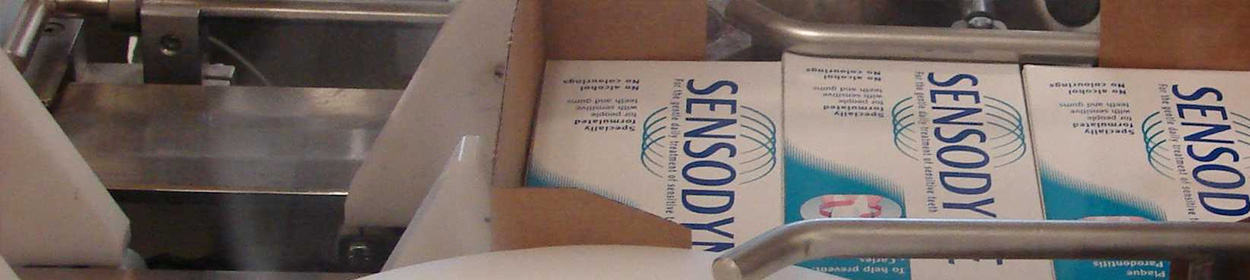

In the packaging of cosmetic products, in addition to an attractively high-quality design, the optimal protection against light and spoilage as well as perfect hygiene also play a important role.

Shower gel, shampoo, conditioner, creams, cosmetics as well as toothpaste belong to the daily body care. Our UNIROBmachines and systems are used for all piece products which can be placed into containers by means of toploading.

Your requirements are our challenges - our packaging solutions meet even the most stringent requirements of the food industry:

-

- Highest flexibility with regard to changing products and formats

- Hygienic-design and machine construction compliant with food legislation

- Adaptation of the packaging process to seasonal products by modular design

- Gentle product handling by means of a special vacuum or gripper tools

- Highest product safety through the integration of camera systems, metal detectors, etc.

- Optimal machine accessibility for operators, maintenance and cleaning

- Processing of high quantities using high-performance delta robots Fully automatic changing of robot tools with storage inside the robot cell

Bakery and confectionery products

-

When it comes to the packaging of confectionery and pastry products, high-quality packaging, the gentle handling of the product and a high quality are in the foreground of the packaging process.

The efficient UNIROB packaging machines and systems are ideally suited for the packaging of sensitive sweets and pastries, such as chocolate bars, pralines, cakes, biscuits, pastry products, fruit gums and candies.

Packaging machines for beverages

-

Tastes are different - especially for the beverage industry. In the market there are a variety of different thirst quenchers. Just as numerous are the different packaging and dosage forms.

In addition to a large selection of glass and PET bottles, beverages in stand-up pouchs, beverage cartons and beverage cans, the handling of packaging also plays an important role for the consumer. Whether mixed cartons, special packaging, trays, cluster packaging or other sales packaging - we offer you the right packaging machine for your thirst quencher.

Non-Food - Different areas of application for various products

- In the non-food sector, the application areas of UNIROB Toploading machines are as diverse as your products. Packing machines for the industry require, above all, little space for installation, the highest quality standards and a high performance - No problem for our flexible UNIROB toploading machines. Whether screws, saw blades, hoses, paint canisters, adhesive tapes or other industrial products, we offer the most suitable packaging solution for every non-food product

Packaging machines for chemical products

-

The packaging of chemical products such as fertilizers, adhesives, lubricants, cleaning agents and detergents imposes special requirements on packaging processes. For the packaging of various types of chemical products, a large number of packaging solutions are already being used by our customers worldwide.

The production plants make particular demands on the packaging processes by the further processing of chemical products.