EXPRESSO

Videos

Loading the player ...

- Offer Profile

- We are a highly innovative company with a tradition. For more than half a century, our experience and our quality products have been helping people all over the world to transport and handle small goods. In close cooperation with our customers, our engineers develop professional products for industrial and commercial use, which are then manufactured responsibly with close attention to detail. In addition, we provide service concepts for the lasting value preservation of EXPRESSO products. Hereby, our manual transport equipment and the powered goods handling systems not only result in higher efficiency, but also make a decisive contribution for maintaining the health of working personnel. It is our philosophy at EXPRESSO always to place human requirements in the forefront.

Product Portfolio

POWERED HANDLING AND TRANSPORT SYSTEMS

- The powered solutions in this group are intended for effortless lifting, handling, and moving goods of all types.

lift2move

-

INDIVIDUAL STANDARDS FOR INCREASED PRODUCTIVITY

EXPRESSO‘s mobile lifting aids provide individual handling solutions that are matched precisely to your goods, the location, the operator, and the specific handling task. Customized load handling attachment in the shape of forks, prong, roller platform, hook attachments, and grippers permit ergonomic loading of machines, shelves, filling & conveying systems, centrifuges, pallets, roller tables, etc. at your workplaces.

Thanks to their user-oriented application possibilities, our mobile lifts increase productivity. These intelligent goods handling solutions enable complex and physically demanding operations to be carried out simply, safely, ergonomically, and therefore efficiently. Everything is possible with lift2move: Lifting, lowering, rotating, turning, gripping, tipping, holding, order picking, positioning, pushing, pallet loading, ... and lots more. Apart from higher productivity, and thanks to its modular design, the lifter provides the technical foundation for future innovations and updates. Innovations can be integrated

quickly into the existing platform and the extensive modular system. This is the guarantee that the lifter generation will adapt easily to future customer requirements and innovations.

Our experts design and build every handling system in close cooperation with the end user. EXPRESSO‘s handling consultants first examine and discuss the task

on your premises, and then prepare an individual handling analysis. Within a few days, you will receive a detailed offer for the corresponding handling concept.

BalanceLift Systems

-

BALANCELIFT – PNEUMATIC LIFTING CYLINDER FOR ERGONOMIC LOAD HANDLING

An enormous range of vacuum, pneumatic, magnetic, and mechanical load handling attachments and gripping devices offers application-oriented solutions for handling the most varied goods weighing up to 300 kg, and with lifting heights up to 4 m. Simple, continuous and precise manoeuvrability via up/down controls or with the balancer function (without control buttons – the load is balanced automatically). In this way, the operator always has perfect control of the load – without any physical effort, and with natural working movements. This increases productivity, and contributes towards maintaining employee health.

Load handling is pneumatic, i.e. without a connection to electric power. All that is needed is a compressed air supply (6 bar). Because compressed air is only required for lifting, this type of energy supply is extremely cost effective. Moreover, the BalanceLift offers flexible mounting options: In combination with BalanceRail overhead rails, floor or wall-mounted crane booms, with the mobile BalanceStand or BalancePort, or mounted in existing customer installations, the BalanceLift system optimizes the necessary handling tasks at the workplace.

In close cooperation with the end user, our experts design and build customer-specific vacuum, pneumatic, magnetic, and mechanical load handling attachments. EXPRESSO‘s handling consultants first examine and discuss the task on your premises, and then prepare an individual handling analysis. Within a few days, you will receive a detailed offer for the corresponding handling concept.

touch2move

-

THE PATENTED DRIVE SYSTEM

Thanks to the touch2move drive technology, logistics operations are optimized, and transporting heavy goods is not only more efficient, but also significantly safer. Simply by touching the sensor handles, the vehicle “obeys” the operator‘s natural movements, and automatically adapts to his/her walking speed. Heavy loads are moved safely and ergonomically without effort – and the operator needs neither a driving license nor any special training.

The touch2move drive concept can be fitted to practically all four-wheel trolleys and other transport carts – it also complies with Safety at Work Regulations, and has the CE mark.

Every touch2move drive system is designed and built by our experts in close cooperation with the end user. EXPRESSO‘s handling consultants first examine and discuss the task on your premises, and then prepare an individual handling analysis. Within a few days, you will receive a detailed offer for the corresponding handling concept.

Compact LEO tugs

-

SENSOR-CONTROLLED SYSTEM SOLUTIONS

The LEO is designed as a compact tug that combines EXPRESSO‘s unique, patented touch2move drive concept with the principles of motorized ‚walkie‘ type transport equipment using tiller handle control.

This trend-setting unit closes a handling gap that could previously be overcome only by means of bulky transport equipment such as forklifts and electric pallet trucks, or with considerable physical effort using manual pallet trucks. With sensor handles and a high-torque drive motor, the tug permits convenient and effortless towing and manoeuvering of one or more trolleys/dollies with loads up to 2500 kg. The gains in mobility together with saved time and space lead to increased productivity and safety for companies.

Our experts design and build every handling system in close cooperation with the end user. EXPRESSO‘s handling consultants first examine and discuss the task on your premises, and then prepare an individual handling analysis. Within a few days, you will receive a detailed offer for the corresponding handling concept.

MANUAL HANDLING EQUIPMENT

- These intelligent products are designed to assist your manual work, and to make goods handling safer, easier, and more efficient.

HAND TRUCKS

-

HAND TRUCKS – FROM EXPERTS FOR EXPERTS

With us, individuality is standard

Not conventional – but individual! Instead of a standard general-purpose hand truck, it is your specific logistic application that determines the appearance and the functionality of your professional transport device. Since 1967, EXPRESSO’s modular system provides unlimited possibilities for configuring application and user-oriented transport solutions.

Aluminium – 50% lighter, and far higher loading

Since decades, EXPRESSO hand trucks have been made of a special high-strength aluminium alloy and are therefore 50% lighter and far stronger than steel versions. The elliptical aluminium tube used for the hand truck frame is reinforced in the main direction of stress, which ensures utmost strength even under extreme loads.

We set the standards that are used to evaluate others!

ORDER-PICKING CARTS

-

SYSTEMATIC APPROACH – PROFESSIONAL ORDER-PICKING CARTS

Heavy loads moved easily, safely, and quickly: The use of high-quality, professional order-picking and four-wheel carts supports and improves productivity and efficiency during goods handling and transport.Our comprehensive range of carts and trolleys offers smooth-running, application-oriented solutions that are convenient and flexible. A decisive contribution for optimized logistic procedures.

Convincing details – the modular system

The most convincing arguments for our order-picking carts are the many application- and user-specific features: Various heights, sizes, materials (steel, aluminium, powder coated or bright galvanized), load capacities, several shelf levels, diverse load platforms, end panels, wire-mesh sides, storage compartments, notepad supports, extra shelves, universal baskets, plus a range of high-quality wheels and castors are just some of the numerous product options.

Special features – the future is here!

Particular highlights are the self-propelled order-picking vehicles that obey the user’s natural, intuitive movements during manoeuvering, thanks to the smart touch2move drive technology. This enables your employees to move loads efficiently and at the same speed throughout the working day. What’s more, it greatly improves employee motivation, and helps you comply with increasingly strict accident prevention regulations. All order-picking carts with a minimum width of 500 mm can be fitted with the smart touch2move drive technology.

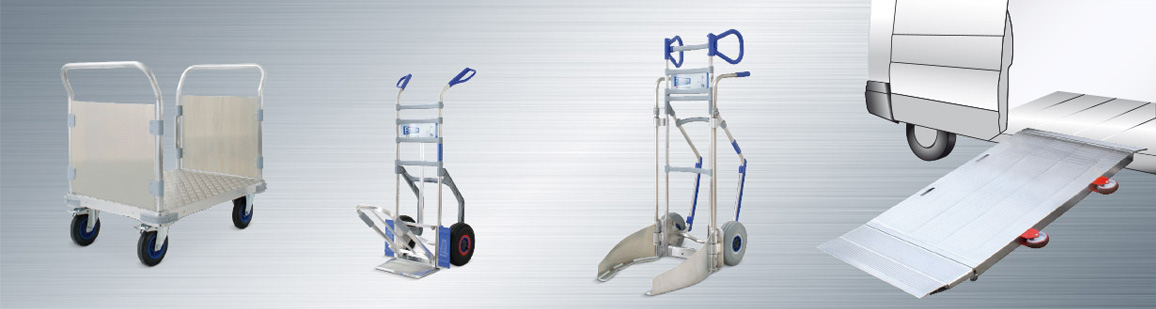

DOCK BOARDS & PLATES

-

EXPRESSO OFFERS A COMPLETE RANGE FOR SOLVING EVERY LOADING TASK

The demands for reliability and flexibility expected from delivery companies are increasing continuously. Short loading/unloading times with no waiting periods for vehicle drivers are essential to give a company that competitive edge. EXPRESSO‘s aluminium dock plates & dock boards provide individual and application-oriented solutions for optimized logistic procedures Reason: Even a narrow gap can make a loading/unloading procedure impossible.

Aluminium – our preferred material is light and strong

The special aluminum alloy is 50% lighter than, but as strong as steel. This simplifies handling and moving loading aids for your service staff. Their high product quality provides extensive corrosion protection and maximizes the conditions for a long service life.

High-grade treadplate surfaces

The surfaces of our aluminium dock plates & dock boards ensure non-slip traversing in unfavourable weather conditions. Whether five-bar, cross-grooved or cross-grooved ‘Plus’, all available treadplate surface options meet the highest quality standards, and offer increased safety and mobility.

Answering the following questions is important for selecting the perfect solution for your loading task:- What weight must the plate/board be able to support?

- How will the plate/board be loaded? – e.g. fork-lift truck, pallet truck, hand truck?

- What is the height difference, e.g. between loading ramp and truck?

- What distance must be bridged?

- Whatever the question, EXPRESSO has the answer.

LOADING TECHNOLOGY

- Our extensive range of loading technology equipment provides everything that assists, simplifies, and makes vehicle loading/unloading safer. The range includes products that can be stowed in a vehicle, as well as solutions for loading ramps. In the latter case, our engineers will develop an optimum, individually tailored solution to suit the situation on site. All products and solutions are featured by top quality, long service life, and utmost safety.

WHEEL CHOCKS

-

The simplest way to immobilize a truck is to use our wheel chocks, which are available in various sizes. They reliably prevent the truck from rolling during loading/unloading operations.

Our wheel chocks are available as hard-wearing rubber or steel versions.

TRAFFIC LIGHT SET IN COMBINATION WITH ELECTRIC WHEEL CHOCKS

-

By coupling traffic lights and electric wheel chocks, loading/unloading operations can be made safe in an economic manner.

Bay gate and/or an adaptable ramp can be networked with the wheel chock and the traffic lights.

By means of corresponding colours (red/green), the traffic lights in the building or outside on the dock provide information about when loading/unloading operations can start or when the truck driver can remove the chocks safely.

The system is independent of possible access connections between truck and dock, i.e. regardless of whether an adaptable ramp, dock board, or some other device is used, operator safety is ensured.

AUTOMATIC TRUCK IMMOBILIZER

-

For increased safety during loading/unloading operations we recommend our automatic truck immobilizer –

named Stop Trucks.

SAFETY ZONE FOR PERSONNEL PROTECTION

-

EN Standard 349 specifies that a minimum safety gap of 500 mm must be provided between dock edge and truck.

The gap serves to minimize accidents and crushing injuries.

EXPRESSO offers three suitable solutions.

WHEEL GUIDES

-

Wheel guides simplify truck manoeuvering.

They ensure that the truck reverses to the dock at the correct angle, thereby protecting the building and possible loading equipment from damage.

TRAILER SAFETY SUPPORTS

- Trailer supports provide safety for uncoupled semi-trailers during loading/unloading operations.

TRAILER TRESTLES

-

Also these trestles are intended for supporting the front end of uncoupled semi-trailers.

Thanks to the full-width support, only one trestle is required.

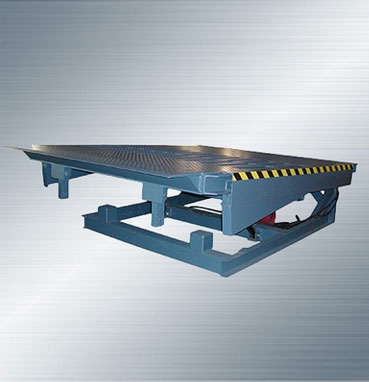

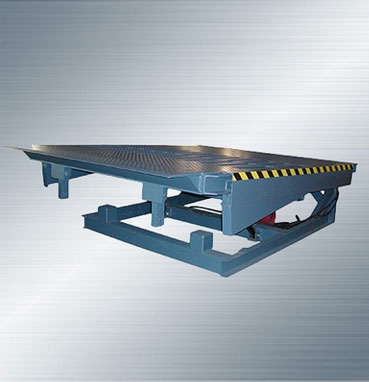

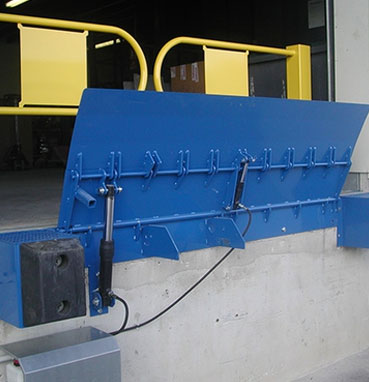

LOADING RAMPS

-

Our adaptable ramps are suitable for installation in existing pits.

With rated loads up to 12 tons, they help to optimize the goods handling operations on the dock.

The following features can be guaranteed:- Safety and simple handling for the operators

- Profitability thanks to extremely long service life

- Low maintenance costs

If the structural conditions are not suitable for the installation of an adaptable ramp, we can supply the ramp with an external frame.

MINI ADAPTABLE RAMPS

- Our mini adaptable ramps have a simple but rugged mechanism, and are absolutely maintenance-free. For optimum bridging of small dock distances (adapts easily to higher and lower truck platforms). Cost-effective solution, as no constructional measures are required.

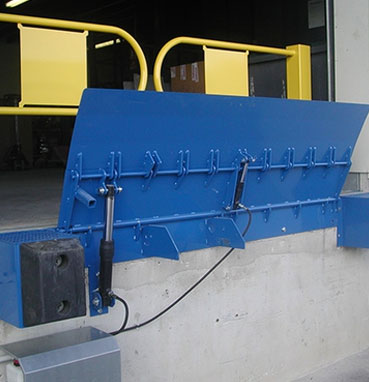

DOCK BOARDS

-

Rail-mounted dock boards provide a simple and flexible solution for serving several loading bays.

An automatic locking mechanism for the vertical position prevents accidents.

The robust aluminium design permits loads up to 5 tons.

DOCK BOARD WITH INSTALLATION FRAME

- The frame with dock board can be mounted easily to the dock wall. It is fitted with safety railings, adjustable feet, and rubber buffers.

RAMPS

-

Loading ramps are ideal in cases where buildings are rented and no large investments or constructional changes are possible.

A loading ramp can be delivered and installed in less than one working day.

GATE SEALS

-

Gate seals provide a tight joint between the end of the truck or trailer, and the warehouse wall.

They prevent large temperature variations and protect personnel from inclement weather during loading/unloading operations.

DOCK BUFFERS

- Dock buffers are used to attenuate the impact when a vehicle backs up against the ramp, thereby protecting the vehicle, the dock, and the building.

BAGGAGE CART SYSTEMS - EXPRESSO AERO

Landside baggage carts

COMPACT MARK V

-

THE "CLASSIC" CART ON THREE WHEELS

The "classic“ baggage carts Compact Mark V and Mark VI feature modern design and utmost manoeuvrability, particularly in a nested train. Thanks to EXPRESSO's lifting mechanism for the rear wheels, which has proved its reliability for decades, entire nested trains can be moved sideways easily or rotated on the spot. Extremely long service life and robustness underline the cost effectiveness of the Compact versions. Moreover, all versions are fitted with EXPRESSO's “Long Life” brake system that ensures maximum safety and minimum maintenance costs.

The Compact "classics" are available in two design versions:- Compact Mark V: short uprights, and push handle angled upwards

MAIN PRODUCT FEATURES- Compact construction

- Three smooth-running wheels for utmost manoeuvrability in tight spaces

- Safe handling of nested baggage cart trains

- High loading capacity

- Easy traversing of obstacles (e.g. kerbs and steps)

- Extra large castor yoke absorbs shock loads

- Wheel guards prevent the baggage becoming soiled

- Angled load platform ensures secure transport of baggage on inclines

COMPACT MARK VI

-

THE "CLASSIC" CART ON THREE WHEELS

The "classic“ baggage carts Compact Mark V and Mark VI feature modern design and utmost manoeuvrability, particularly in a nested train. Thanks to EXPRESSO's lifting mechanism for the rear wheels, which has proved its reliability for decades, entire nested trains can be moved sideways easily or rotated on the spot. Extremely long service life and robustness underline the cost effectiveness of the Compact versions. Moreover, all versions are fitted with EXPRESSO's “Long Life” brake system that ensures maximum safety and minimum maintenance costs.

The Compact "classics" are available in two design versions:- Compact Mark VI: long uprights, and push handle angled downwards

MAIN PRODUCT FEATURES- Compact construction

- Three smooth-running wheels for utmost manoeuvrability in tight spaces

- Safe handling of nested baggage cart trains

- High loading capacity

- Easy traversing of obstacles (e.g. kerbs and steps)

- Extra large castor yoke absorbs shock loads

- Wheel guards prevent the baggage becoming soiled

- Angled load platform ensures secure transport of baggage on inclines

COMPACT BASIC

-

COMPACT BASIC – REDUCED TO THE ESSENTIALS

Reduced to the essentials – where expedient and effective: The Compact Basic it reduced to the basic functions required for a baggage cart, but offers all the advantages of branded EXPRESSO quality that is essential for safe, smooth, and reliable baggage transport.

MAIN PRODUCT FEATURES- Compact construction

- Three smooth-running wheels for utmost manoeuvrability in tight spaces

- Safe handling of nested baggage cart trains

- Easy traversing of obstacles (e.g. kerbs and steps)

- Extra large castor yoke absorbs shock loads

- Angled load platform ensures secure transport of baggage on inclines

LIGHTLINER

-

THE "CRUISER" FOR RETRIEVAL WITH A PUSHING/TOWING VEHICLE

The LightLiner is the "cruiser" of our baggage cart range. Covering long distances, e.g. during cart retrieval, is its speciality. Thanks to EXPRESSO's ingenious “Winglet” brake release system, the last cart pushed into the rear of a nested train releases the parking brake of the cart in front – whereby all the cart wheels remain on the ground. This guarantees precise tracking and a minimum curve radius. However, its main advantages come to bear in tight spaces and narrow passages.

MAIN PRODUCT FEATURES- An extremely tight turning radius (nested) of only 2,5 m makes it particularly suitable for use in confined spaces

- Ideally suited for towing, pushing, and manoeuvering as a nested train over large distances with a tug or pusher vehicle

- Easy traversing of obstacles (e.g. kerbs and steps)

- Extra large castor yoke absorbs shock loads

- Angled load platform ensures secure transport of baggage on inclines

VARICART

-

EASY HANDLING ON FOUR WHEELS

Thanks to its slim frame geometry, the VariCart is the perfect baggage cart for use in tight locations and narrow entrances. Its four wheels provide a secure stand and excellent manoeuvrability.

MAIN PRODUCT FEATURES- Four wheels for a secure stand

- Slim width

- Wheel guards prevent the baggage becoming soiled

MULTICART

-

THE TRANSPORT WONDER ON FOUR WHEELS

Thanks the extra long load platform and rigid front retainer, the MultiCart is ideal for the safe transport of large and bulky baggage items. Its four wheels provide a secure stand and excellent manoeuvrability. Available with or without brakes, the MultiCart can be adapted precisely to individual customer needs. The small panel on the front retainer, and the panel on the rear basket can be used for advertising or safety instructions.

MAIN PRODUCT FEATURES- Four wheels for a secure stand

- Slim width

- Wheel guards prevent the baggag

- Four wheels for a secure stand

- Available with / without brakes

- Perfectly suited for the safe transport of large and bulky baggage items such as skis, snowboards, golf clubs, etc. thanks to the extra long load platform and rigid front retainer

- With rear basket panel for advertising or safety instructionse becoming soiled

SAFETY FIRST

-

SAFETY ON ESCALATORS – FUNCTIONALITY FULFILLS THE DESIGNED PROMISE

A perfect combination of safety and design, the Safety First unites the convenience and manoeuvrability of a standard baggage cart with the safety features required for use on escalators.

For more than 25 years EXPRESSO’s escalator carts have given worldwide reliable service to ensure smooth and safe operations and satisfied travellers.

MAIN PRODUCT FEATURES- Designed for use on escalators

- Ergonomic and safe handling

- Available in V2A stainless steel or aluminium

- Low luggage platform for convenient loading

- Rigid front retainer ensures secure hold of baggage

- Notched profiles lock onto the escalator steps reliably

Airside baggage carts

AIRSIDE

-

THE IDEAL COMPANION FOR AIRPORT SHOPPING

Thanks to its high maneuverability and stability, EXPRESSO's elegant Airside baggage cart is an ideal partner in airport shopping areas. Its compact design permits the Airside cart to be pushed and guided safely and easily through narrow passages.

Plastic bumpers at the front prevent damage to the building interior. Large advertising panels provide space for in-house promotion or can be rented to third parties.

MAIN PRODUCT FEATURES- Designed for indoor use, e.g. in the duty-free area

- Transport of hand luggage and shopping items

- Convenient and maneuverable

- Optically appealing design

- Without brakes

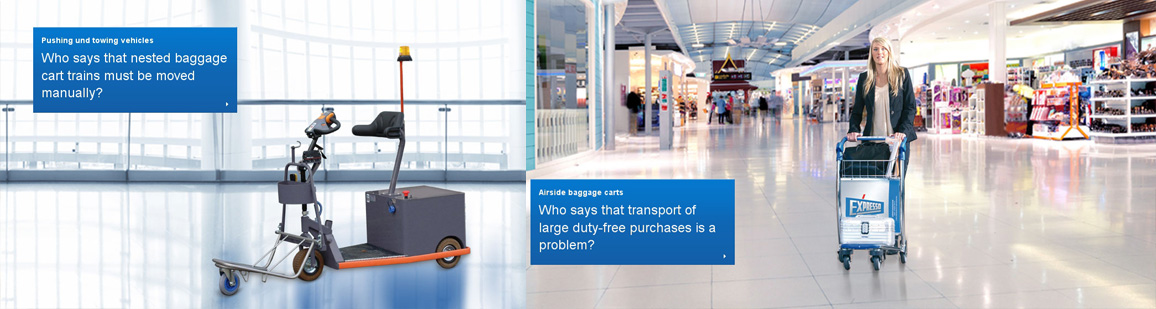

Pushing und towing vehicles

PUSHBUDDY

-

PUSHBUDDY WITH PUSHING ADAPTER

EXPRESSO baggage trolley pushing vehicle PushBuddy incl. pushing adapter for landside baggage carts

The PushBuddy is a powerful, highly maneuverable, battery powered pushing device built for perfect use on level and slightly inclined surfaces.

ADVANTAGES- Easy and safe organization and reallocation of baggage trolleys

- Effective and safe solution for your baggage cart management

- Relief of your service personnel from the strenuous task of transporting nested baggage cart trains

- Saving time and human strength, ergonomic design

- Increased trolley availability

- Reduction of injury risk of staff

- Operation in various climate conditions

- Transport of up to 40 EXPRESSO baggage trolleys on level ground and on inclines up to 2°

TOWBUDDY

-

TOWBUDDY WITH TOWING ADAPTER

EXPRESSO baggage trolley towing vehicle TowBuddy incl. towing adapter for landside baggage carts

The TowBuddy is a powerful, highly maneuverable, battery powered towing device built for perfect use on level and slightly inclined surfaces.

ADVANTAGES- Easy and safe organization and reallocation of baggage trolleys

- Effective and safe solution for your baggage cart management

- Relief of your service personnel from the strenuous task of transporting nested baggage cart trains

- Saving time and human strength, ergonomic design

- Increased trolley availability

- Reduction of injury risk of staff

- Operation in various climate conditions

- Transport of up to 40 EXPRESSO baggage trolleys on level ground and on inclines up to 2°

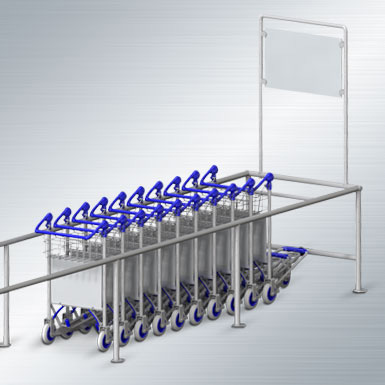

DEPOT SYSTEMS - EXPRESSO AERO

- EXPRESSO's depot systems organize and identify the baggage cart dispensing locations. The carts are collected and nested to save space, and then made available to passengers at the indicated depot locations. Various versions of the depot systems are available, whereby their size (capacity) can be matched to local needs, and also increased at a later date. Every depot system can be fitted with a starting chain that fits into the coin unit of the first cart.

COIN BOX DEPOT SYSTEMS

-

EXPRESSO's coin unit systems identify the baggage cart dispensing location as a depot for nested carts without guidance rails. They are available as steel or stainless steel constructions with a starting chain for the first cart's coin unit.

MAIN PRODUCT FEATURES- Rugged steel construction, hot galvanised

- Suitable for indoor and outdoor use

COIN BOX DEPOT SYSTEM (STAINLESS STEEL)

-

EXPRESSO's coin unit systems identify the baggage cart dispensing location as a depot for nested carts without guidance rails. They are available as steel or stainless steel constructions with a starting chain for the first cart's coin unit.

MAIN PRODUCT FEATURES- Rugged, optically high-grade stainless steel construction

- Suitable for indoor and outdoor use

COLLECTING STATION FOR BAGGAGE CARTS

-

Made of high-grade stainless steel, EXPRESSO's collecting stations ensure space-saving storage of nested baggage carts for convenient use by passengers. Thanks to the large signboards, the station locations can be seen from a distance. The number of carts and their arrangement in the station is determined by means of guide rails.

MAIN PRODUCT FEATURES- Modular system (subsequent lengthening possible)

- High flexibility of length sections

- Rugged, optically high-grade stainless steel construction

- Suitable for indoor and outdoor use

- Available with one or more lines