MasterMover

Videos

Loading the player ...

- Offer Profile

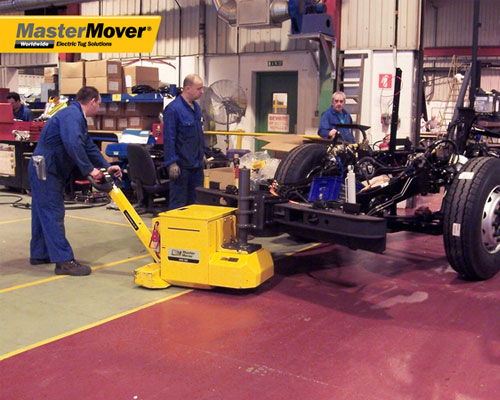

- MasterMover Ltd is based in the UK and is the world's leading manufacturer of electric tugs. We are a British business success story with innovative handling solutions capable of moving wheeled and semi-wheeled loads from 50 kg up to 360,000 kg.

Our machines are trusted by market leading organisations and worldwide brands across a broad cross-section of industries including aerospace, automotive, pharmaceutical, retail and healthcare.

Today, we have subsidiaries in America, France, Brazil and Germany alongside a sales partner and service network that extends right across the globe.

Product Portfolio

Electric tugs

- MasterMover® manufacture premium quality electric tugs and tows that safely and efficiently move a variety of wheeled loads weighing up to 360,000kg.

Small - up to 2,000 kg

SM100 TOW | Up to 500 kg

- The SmartMover® SM100 TOW utilises its two drive motors to generate the traction required to move loads up to 500 kg.

As the SM100 TOW is a self-weighted unit, it is the ideal electric tow for applications where weight transfer is not possible and with the addition of anti-slip, puncture-proof tyres and supporting castors, operator safety is maintained at all times.

The interchangeable battery provides 24/7 operation and is perfectly suited for loads fitted with a draw bar or towing eye.

The SmartMover® SM100 TOW is a versatile and compact electric tug, which can be fully customised and built to perform at its best in your workplace environment. Various couplings, additional safety features and machine options are available.

To see how the SM100 TOW can help improve your safety and efficiency, why not get in touch for more information or for a free quotation.

Key Features- Pull any load safely up to 500 kg

- Interchangeable battery for 24/7 operation

- Safely connect loads with draw bar or tow eye

- Throttle release automatic braking system

- Internal weight packs for added stability

- Support castors for operator safety

- Fully customisable and bespoke couplings

- Available in ATEX

SM100 | Up to 1,000 kg

- The SmartMover® SM100 is a battery powered tug that generates traction through a leveraged weight transfer system. This allows a single operator to easily and safely move loads weighing up to 1,000 kg.

A simple lever system ensures a secure coupling to the load making the SM100 a safer alternative to manual handling of heavy wheeled loads. The addition of anti-slip, puncture-proof tyres and supporting castors, operator safety is maintained at all times, even on slopes or in congested areas.

The SmartMover® SM100 compact electric tug can be fully customised and built to perform at its best in your workplace environment, with various couplings, additional safety features and machine options available.

To see how the SM100 can help improve your safety and efficiency, why not get in touch for more information or for a free quotation

Key Features- Push and Pull any load safely up to 1,000 kg

- Interchangeable battery for 24/7 operation

- Throttle release automatic braking system

- Leveraged weight transfer system

- Simple lever coupling system

- Fully customisable and bespoke couplings

- Available in ATEX

SM100+ | Up to 1,200 kg

- The SmartMover® SM100+ is simple and easy to use, with single trigger operation allowing for full control whilst maintaining operator safety.

The variable speed button allows for the efficient movement of parts, stock or containers through various environments.

The safe and secure hydraulic coupling creates an unbreakable connection between the electric tug and attached load, giving total peace-of-mind and complete control. The SM100+ can even operate on slopes and uneven ground with the added benefit of reducing the need for manual handling.

The SmartMover® SM100+ compact electric tug can be fully customised and built to perform at its best in your workplace environment, with various couplings, additional safety features and machine options available.

To see how the SM100+ can help improve your safety and efficiency, why not get in touch for more information or for a free quotation.

Key Features- Push and Pull any load safely up to 1,200 kg Interchangeable battery for 24/7 operation

- Safe & secure hydraulic coupling

- Throttle release automatic braking system

- Anti-slip and puncture-proof tyres

- Simple operation with no licence requirement

- Fully customisable and bespoke couplings

- Available in Stainless Steel and ATEX

MT200 | Up to 2,000 kg

- The MasterTug® MT200 is the smallest electric tug in the MasterTug® range and is designed to move loads weighing up to 2,000 kg.

The internal weight packs provide maximum traction, allowing the high powered AC motor to work at maximum efficiency. Coupled with the variable speed button, the MT200 is the perfect electric tug for moving parts, stock or containers through various environments.

The automatic tiller cut off, self-adjusting castor guard and anti-crush button all maximise operator safety and the interchangeable battery ensures the machine is available for use 24/7.

To see how the MT200 can help improve your safety and efficiency, why not get in touch for more information or for a free quotation

Key Features- Push and Pull any load safely up to 2,000 kg

- Interchangeable battery for 24/7 operation

- Tiller arm release automatic braking system

- Anti-crush button for operator safety

- Internal weight packs for added stability

- Fully customisable and bespoke couplings

- Available in ATEX

New AT200 TOW

- The New AT200 TOW is simple and easy to use offering towing capabilities of up to 2,000 kg. A single operator can safely manoeuvre and connect securely to any load in seconds without the need for an operator license.

Ergonomically designed, the AT200 TOW improves both safety and efficiency across a number of working environments and terrains.

With the addition of anti-slip, puncture-proof tyres and automatic tiller cut off, the AT200 TOW maximises operator safety at all times and the interchangeable battery ensures the machine is available for use 24/7.

The AT200's optional switchable steering mode allows a single operator to change from a fixed steering position; which can be used for manoeuvring larger, heavier loads, to direct steering, giving full control and manoeuvrability via the tiller arm to move connected loads through space restricted areas.

Attaching to any load up to 2,000 kg with a draw bar, towing eye or ball hitch fitting is easy thanks to the AT200 TOW’s coupling crawl function. This allows the operator to move the machine slowly and connect simultaneously.

To see how the new and improved AT200 TOW can help improve your safety and efficiency, why not get in touch for more information or for a quotation.

Key Features- Pull any load safely up to 2,000 kg

- Interchangeable battery for 24/7 operation

- Attach loads with a draw bar, towing eye or ball hitch

- Anti-crush button for operator safety

- Optional switchable steering mode

- Fully customisable and bespoke couplings

- Available in Stainless Steel and ATEX

Medium - up to 6,000 kg

AT300 TOW | Up to 3,000 kg

- The New AT300 TOW is simple and easy to use offering towing capabilities of up to 3,000 kg. A single operator can safely manoeuvre and connect securely to any load in seconds without the need for an operator license.

Ergonomically designed, the AT300 TOW improves both safety and efficiency across a number of working environments and terrains.

With the addition of anti-slip, puncture-proof tyres and automatic tiller cut off, the AT300 TOW maximises operator safety at all times and the interchangeable battery ensures the machine is available for use 24/7.

The AT300's optional switchable steering mode allows a single operator to change from a fixed steering position; which can be used for manoeuvring larger, heavier loads, to direct steering, giving full control and manoeuvrability via the tiller arm to move connected loads through space restricted areas.

Attaching to any load up to 3,000 kg with a draw bar, towing eye or ball hitch fitting is easy thanks to the AT300 TOW’s coupling crawl function. This allows the operator to move the machine slowly and connect simultaneously.

To see how the new and improved AT300 TOW can help improve your safety and efficiency, why not get in touch for more information or for a quotation.

Key Features- Pull any load safely up to 3,000 kg

- Interchangeable battery for 24/7 operation

- Attach loads with a draw bar, towing eye or ball hitch

- Tiller arm release automatic braking system

- Optional switchable steering mode

- Fully customisable and bespoke couplings

- Available in Stainless Steel and ATEX

MT300+ | Up to 3,000 kg

- The MasterTug® MT300 is a compact electric tug and is designed to move loads weighing up to 3,000 kg.

The MT300+ utilises an innovative hydraulic weight transfer system, which allows the machine to use the weight of the attached load to generate the traction needed move safely and efficiently. Coupled with the variable speed button, the MT300 is the perfect electric tug for moving parts, stock or containers through various environments.

The automatic tiller cut off, self-adjusting castor guard and anti-crush button all maximise operator safety and the interchangeable battery ensures the machine is available for use 24/7.

To see how the MT300 can help improve your safety and efficiency, why not get in touch for more information or for a free quotation

Key Features- Push and Pull any load safely up to 3,000 kg

- Interchangeable battery for 24/7 operation

- Tiller arm release automatic braking system

- Variable speed controls

- Hydraulic Weight Transfer for improved traction

- Fully customisable and bespoke couplings

- Available in ATEX

MT400+ | Up to 4,000 kg

- The MasterTug® MT400+ is a single person operated, simple, but versatile electric tug which can be used across various applications.

The MT400+ utilises an innovative hydraulic weight transfer system, which allows the machine to use the weight of the attached load to generate the traction needed move safely and efficiently.

The automatic tiller cut off, self-adjusting castor guard and anti-crush button all maximise operator safety and the interchangeable battery ensures the machine is available for use 24/7.

To see how the MT400+ can help improve your safety and efficiency, why not get in touch for more information or for a free quotation.

Key Features- Push and Pull any load safely up to 4,000 kg

- Interchangeable battery for 24/7 operation

- Hydraulic Weight Transfer for improved traction

- Variable speed controls

- Tiller arm release automatic braking system

- Fully customisable and bespoke couplings

- Available in Stainless Steel and ATEX

MH400+ | Up to 4,000 kg

- The MasterHandler® MH400+ is the only tug in the MasterMover® range which is capable of moving swivel mounted loads without the need for locking wheels, giving full control and manoeuvrability in space restricted areas.

The low profile of the MH400+ allows it to keep the travelling loads of up to 4,000 kg straight and stop uncontrolled sideways movement. The hydraulic coupling creates an unbreakable connection between the electric tug and attached load.

The variable speed button allows for the efficient movement of parts, stock or containers through various environments, whilst the tiller arm automatic cut-off and anti-crush buttons keep the operator safe at all times.

To see how the MH400+ can help improve your safety and efficiency, why not get in touch for more information or for a free quotation

Key Features- Push and Pull any load safely up to 4,000 kg

- Safe & secure hydraulic coupling

- Variable speed controls

- Handles swivel castor loads

- Tiller arm release automatic braking system

- Fully customisable and bespoke couplings

- Available in Stainless Steel and ATEX

MT600+ | Up to 6,000 kg

- The MasterTug® MT600+ is a single person operated, simple, but versatile electric tug which can be used across various applications.

The MT600+ utilises an innovative hydraulic weight transfer system, which allows the machine to use the weight of the attached load to generate the traction needed move safely and efficiently.

The automatic tiller cut off, self-adjusting castor guard and anti-crush button all maximise operator safety and the interchangeable battery ensures the machine is available for use 24/7.

To see how the MT600+ can help improve your safety and efficiency, why not get in touch for more information or for a free quotation.

Key Features- Push and Pull any load safely up to 6,000 kg

- Interchangeable battery for 24/7 operation

- Hydraulic Weight Transfer for improved traction

- Variable speed controls

- Tiller arm release automatic braking system

- Fully customisable and bespoke couplings

- Available in ATEX

AT600 TOW | Up to 6,000 kg

- The AT600 TOW is simple and easy to use offering towing capabilities of up to 6,000 kg. A single operator can safely manoeuvre and connect securely to any load in seconds without the need for an operator license.

Ergonomically designed, the AT600 TOW improves both safety and efficiency across a number of working environments and terrains.

With the addition of anti-slip, puncture-proof tyres and automatic tiller cut off, the AT600 TOW maximises operator safety at all times and the interchangeable battery ensures the machine is available for use 24/7.

Attaching to any load up to 6,000 kg with a draw bar, towing eye or ball hitch fitting is easy thanks to the AT600 TOW’s coupling crawl function. This allows the operator to move the machine slowly and connect simultaneously.

Controlled start acceleration gets the load moving safely and power steering provides effortless manoeuvrability, even on slopes and uneven surfaces.

To see how the AT600 TOW can help improve your safety and efficiency, why not get in touch for more information or for a free quotation.

Key Features- Pull any load safely up to 6,000 kg

- Interchangeable battery for 24/7 operation

- Attach loads with a draw bar, towing eye or ball hitch

- Tiller arm release automatic braking system

- Internal weight packs for added stability

- Fully customisable and bespoke couplings

- Available in ATEX

Large - up to 15,000 kg

MT800+ | Up to 8,000 kg

- The MasterTug MT800+ is designed to allow a single pedestrian operator to easily push, pull and steer wheeled loads weighing up to a maximum of 8,000 kg. As part of the MasterTug range, the MT800+ features a Finite Element Analysis (FEA) tested steel chassis and a durable planetary gear box. All couplings are made from robust steel for strength and the industrial drive wheel is long-lasting and provides the perfect amount of traction.

- Battery monitoring system

- FEA tested steel chassis

- Dual secured mast

- AC drive motor

- Self-adjusting castor guard

- Hydraulic weight transfer

AT800 TOW | Up to 8,000 kg

- The All-Terrain AT800 TOW electric tug is perfect for safely towing loads where weight transfer is not possible, up to 8,000 kg. The tug is self-weighted and compact, providing excellent traction for effortless load towing whilst attaching to any load with a draw bar, towing eye or ball hitch fitting. It can be used inside or outside, including on slopes and less than perfect surfaces.

- FEA tested steel chassis

- Internal weight packs

- Optimised size, puncture-proof wheels

MT1000+ | Up to 10,000 kg

- The MasterTug MT1000+ is designed to allow a single pedestrian operator to easily push, pull and steer wheeled loads weighing up to a maximum of 10,000 kg. As part of the MasterTug range, the MT1000+ features a mast secured at either end for strength and an automatic braking system that brings the tug and load to a stop if the controls are released. The tug uses hydraulic weight transfer for traction and the AC drive motor provides all the power it needs.

- Battery monitoring system

- FEA tested steel chassis

- Dual secured mast AC drive motor

- Self-adjusting castor guard

- Hydraulic weight transfer

AT1000 TOW | Up to 10,000 kg

- The All-Terrain AT1000 TOW electric tug is perfect for safely towing loads where weight transfer is not possible, up to 10,000 kg. The tug is self-weighted and compact, providing excellent traction for effortless load towing whilst attaching to any load with a draw bar, towing eye or ball hitch fitting. It can be used inside or outside, including on slopes and less than perfect surfaces.

- FEA tested steel chassis

- Internal weight packs

- Optimised size, puncture-proof wheels

MT1200+ | Up to 12,000 kg

- The MasterTug MT1200+ is designed to allow a single pedestrian operator to easily push, pull and steer wheeled loads weighing up to a maximum of 12,000 kg. As part of the MasterTug range, the MT1200+ features the ability to steer through a full 180° and hydraulics that help create an incredible amount of traction. The tugs's dual secured mast remains solid even under maximum load and a planetary gear box adds further durability.

- Battery monitoring system

- FEA tested steel chassis

- Dual secured mast

- AC drive motor

- Self-adjusting castor guard

- Hydraulic weight transfer

AT1200 TOW | Up to 12,000 kg

- The All-Terrain AT1200 TOW electric tug is perfect for safely towing loads where weight transfer is not possible, up to 12,000 kg. The tug is self-weighted and compact, providing excellent traction for effortless load towing whilst attaching to any load with a draw bar, towing eye or ball hitch fitting. It can be used inside or outside, including on slopes and less than perfect surfaces.

- FEA tested steel chassis

- Internal weight packs

- Optimised size, puncture -proof wheels

MT1500+ | Up to 15,000 kg

- The MasterTug MT1500+ is designed to allow a single pedestrian operator to easily push, pull and steer wheeled loads weighing up to a maximum of 15,000 kg. As part of the MasterTug range, the tug features a safe maintenance-free battery that can be upgraded to become interchangeable and a display screen that shows remaining charge. The tug's steel chassis is FEA tested to ensure there are no weaknesses and loads are manoeuvrable through 180°.

- Battery monitoring system

- FEA tested steel chassis

- Dual secured mast

- AC drive motor

- Self-adjusting castor guard

- Hydraulic weight transfer

Heavy Duty - Over 15,000 kg

MT2000+ | Up to 20,000 kg

- The MasterTug MT2000+ is designed to allow a single pedestrian operator to easily push, pull and steer wheeled loads weighing up to a maximum of 20,000 kg. As part of the MasterTug range, the tug features a castor guard that self-levels to prevent foot trap risks as the back of the tug raises under load. An automatic braking system is a safety feature that stops machine and load if the operator releases the controls or as the tiller arm returns to vertical.

- Battery monitoring system

- FEA tested steel chassis

- Dual secured mast

- AC drive motor

- Self-adjusting castor guard

- Hydraulic weight transfer

PS3000+ | Up to 30,000 kg

- The most powerful pedestrian electric tug offered by MasterMover is the PS3000+ which is capable of moving loads on castors up to 30,000 kg. A single operator can drive using a wireless transmitter to push, pull and manoeuvre loads aided by power steering, the only tug to boast this feature. A robust hydraulic mast and a coupling system provide maximum traction to the industrial drive wheel whilst the drive motor and side loading industrial capacity battery supply the power to move.

- Complete wireless control

- Hydraulic weight transfer

- Interchangeable batteries

- Up to 30,000kg load capacity

- Self adjusting hydraulics

- FEA tested steel chassis

Multi-link | Up to 360,000 kg

- Multi-Link Systems by MasterMover allows a single remote operator to simultaneously control up to 12 tugs through a synchronised movement.

This modular, scalable and future-proof application enables a Multi-Link System of PS3000+ units to manoeuvre loads ranging from 30-360T.

Multi-link systems ensure safe, precise and effective product manipulation leading to improved production efficiency and reduced risk of product damage.- Complete wireless control

- Hydraulic weight transfer

- Interchangeable batteries

- Up to 360,000kg load capacity

- Self adjusting hydraulics

- FEA tested steel chassis

- Link up to 12 machines

All Terrain

MP400 | Up to 80,000 kg*

- The MasterPusher MP400 is designed to push loads on rails. Using leverage to gain traction, the single operator simply pushes the machine towards the load in order to start it moving. The impressive power originates from its AC drive motor and high torque gearbox whilst the automatic braking system and emergency stop button ensure high safety levels are maintained.

- Battery monitoring system

- FEA tested steel chassis

- AC drive motor

- High-torque gearbox

- Emergency stop button

- Leveraged weight transfer

ATP400 | Up to 80,000 kg*

- The All Terrain Pusher ATP400 is designed to push wheeled loads, even if the floor surface is less than perfect. Whether it be a long train of roll cages or a huge load on rails, the ATP400 possesses more than enough power. A combination of its AC drive motor and high-torque gearbox provide that power whilst traction is achieved via a leverage system and chunky pneumatic wheels. A steel chassis gives the tug strength and a self-levelling castor is one of many safety features.

- Battery monitoring system

- FEA tested steel chassis

- AC drive motor

- High-torque gearbox

- Emergency stop button

- Leveraged weight transfer

ATT400+ | Up to 5,000 kg

- The ATT400+ is the most effective electric load mover to pull and push wheeled loads. With an application on castors and using the high performance hydraulic coupling over 5000 kg can be moved. The direct gearbox and motor supplies endless power, supported by the tug's tough steel chassis. The automatic height adjustable support wheel adds performance and operator safety as standard making it very easy to use.

- Powerful yet easy to use electric load mover

- Reduces compensation claims Improves safety

- Reduces manual handling Low maintenance, high power electric tug

- Increases productivity

- Electric tug which operates on rough terrain

- Compact size

- Supplied with full 1-year guarantee

Trailer Moving System

TMS1100+ | Up to 11,000 kg

- The Trailer Moving System TMS1100+ allows a single pedestrian operator to move unladen articulated lorry trailers weighing up to 11,000 kg. Using a clever hydraulic weight transfer system, the TMS1100+ connects to the fifth wheel pin and lifts the front of the trailer off its stands. Controlled start acceleration and an AC drive motor then mobilise the load and automatic braking brings tug and trailer to a stop if the controls are released.

- Battery monitoring system

- FEA tested steel chassis

- 11,000 kg trailer capacity

- Hydraulic king pin lift

- Automatic braking system

- Hydraulic weight transfer

TMS2000+ | Up to 20,000 kg

- The Trailer Moving System TMS2000+ allows a single pedestrian operator to move unladen articulated lorry trailers weighing up to 20,000 kg. Using a clever hydraulic weight transfer system, the TMS2000+ connects to the fifth wheel pin and lifts the front of the trailer off its stands. Controlled start acceleration and an AC drive motor then mobilise the load and automatic braking brings tug and trailer to a stop if the controls are released.

- Battery monitoring system

- FEA tested steel chassis

- 20,000 kg trailer capacity

- Hydraulic king pin lift

- Automatic braking system

- Hydraulic weight transfer

Stainless steel

SM100+ SS | Up to 1,200 kg

- The SmartMover pedestrian operated tug is a versatile machine for moving loads in many different manufacturing processes. This frequently includes environments that require a specific level of cleanliness or where the machine needs to be corrosion resistant. For this reason the SmartMover is also available in 316 grade stainless steel as the SM100+ SS. This is often used by food processing and pharmaceutical companies to remove the risk of injury caused by manual handling of heavy loads. The SmartMover is a compact machine that can pull loads up to 1,200 kg making it ideal for moving trolleys and mixing vessels in confined spaces that would otherwise be moved by hand.

- Avoid manual handling injury risk

- Can move multiple trolleys

- Ideal for mixing vessels or vats

- Corrosion resistance for hygiene

- Push button connection to load

- Easy to use

- No operator licence required

MT5/400+ SS | Up to 4,000 kg

- The MasterTug MT5/400+ SS is an electric tug completed in a 316 grade stainless steel chassis with a minimum IP44 protection. The compact size and easy to use functions makes this electric tug perfect for moving heavy loads up to 4000 kg in areas with restricted space. The excellent performance in all working environments is due to the MasterTugs detailed designed and ability to gain traction from the coupling system. It's very effective, safe and easy to use making it perfect for any pharmaceutical or food business wanting to improve safety and efficiency using electric tugs.

- Increases productivity

- Superior corrosion resistance

- Reduces manual handling

- Improves safety

- Reduces compensation claims

- Powerful yet easy to use electric tug

- Perfect for use in Food, Pharmaceutical and Chemical industries

- Supplied with full 1-year guarantee

MH400+ SS | Up to 4,000 kg

- The MasterHandler MH400+ stainless steel electric power tug moves loads where all application wheels are multi directional. It is designed to keep the travelling load straight and stop uncontrolled sideways movement. It benefits from a hydraulic coupling system that creates excellent traction. The compact machine works well in space restricted areas which allows turning within its own space. Variable speed and auto stop controls are also standard.

- Ensures health and safety compliance

- Offers complete control and manoeuvrability

- Reinforces lean manufacturing principles

- Reduces manual handling

- Makes your operation mobile and flexible

- Increases safety and efficiency

- Optional upgrade to IP55

MT20/800+ SS | Up to 8,000 kg

- The MasterTug MT20/800+ SS is an electric tug completed in a 316 grade stainless steel chassis with a minimum IP44 protection. The compact size and easy to use functions makes this electric tug perfect for moving heavy loads up to 8000 kg in areas with restricted space. The excellent performance in all working environments is due to the MasterTugs detailed designed and ability to gain traction from the coupling system. It's very effective, safe and easy to use making it perfect for any pharmaceutical or food business wanting to improve safety and efficiency using electric tugs.

- Supplied with full 1-year guarantee

- Powerful yet easy to use electric tug

- Compact size

- Improves safety

- Reduces compensation claims

- Electric pedestrian operated tug

- Reduces manual handling

- Increases productivity

MT20/1200+ SS | Up to 12,000 kg

- The MasterTug MT20/1200+ SS is an electric tug completed in a 316 grade stainless steel chassis with a minimum IP44 protection. The compact size and easy to use functions makes this electric tug perfect for moving heavy loads up to 12000 kg in areas with restricted space. The excellent performance in all working environments is due to the MasterTugs detailed designed and ability to gain traction from the coupling system. It's very effective, safe and easy to use making it perfect for any pharmaceutical or food business wanting to improve safety and efficiency using electric tugs.

- Increases productivity

- Electric pedestrian operated tug

- Reduces manual handling

- Improves safety

- Reduces compensation claims

- Powerful yet easy to use electric tug

- Compact size Supplied with full 1-year guarantee

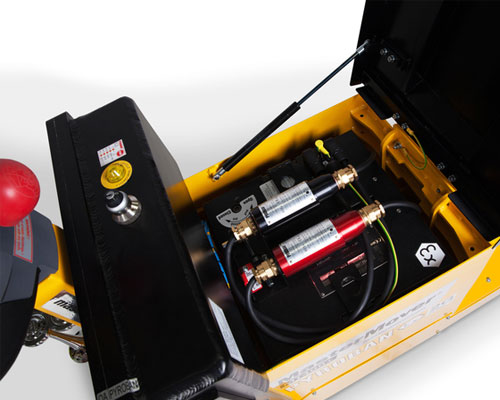

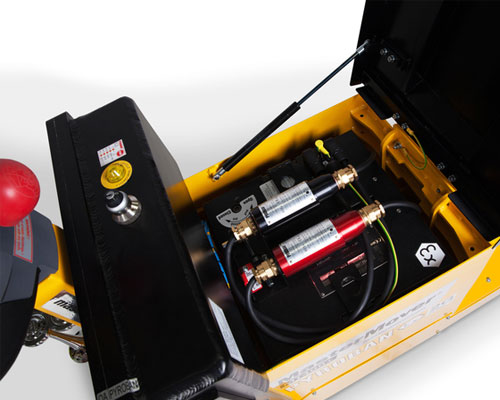

ATEX machines

ATEX MasterTug Range | Up to 20,000 kg

- MasterMover is able to modify all existing MasterMover electric tugs or design new tugs, to operate in zones 1 & 2 (gaseous explosive environments) and zones 21 & 22 (powder or dust explosive environments) to meet ATEX and IECEx standards.

The EX conversion process removes the risk of arcing and sparking from the motors, brakes, electrics and other components of the electric tug and removes the risk of temperature induced auto-ignition of flammable solvents and dust particles within the operating environment.- ATEX Zone 1 or Zone 2

- Battery monitoring system

- FEA tested steel chassis

- Dual secured mast

- AC drive motor

- Self-adjusting castor guard

- Hydraulic weight transfer

ATEX MasterTug Stainless Steel | Up to 15,000 kg

- MasterMover is able to modify all existing MasterTug stainless steel electric tugs or design new tugs, to operate in zones 1 & 2 (gaseous explosive environments) and zones 21 & 22 (powder or dust explosive environments) to meet ATEX and IECEx standards.

The EX conversion process removes the risk of arcing and sparking from the motors, brakes, electrics and other components of the electric tug and removes the risk of temperature induced auto-ignition of flammable solvents and dust particles within the operating environment.- Increases productivity

- Reduces manual handling

- Improves safety

- Powerful yet easy to use electric tug

- No operator license required

ATEX AllTerrain Range | Up to 5,000 kg

- MasterMover is able to modify all existing AllTerrain electric tugs or design new tugs, to operate in zones 1 & 2 (gaseous explosive environments) and zones 21 & 22 (powder or dust explosive environments) to meet ATEX and IECEx standards.

The EX conversion process removes the risk of arcing and sparking from the motors, brakes, electrics and other components of the electric tug and removes the risk of temperature induced auto-ignition of flammable solvents and dust particles within the operating environment.- ATEX and IECEx Compliant

- Operates on uneven surfaces, rough terrain and wet floors Improves safety and reduces risk

- Increases productivity and reduces manual handling

- Heavy duty, powerful and simple to use

- No operator license required

Bin Mover Range

Bin Mover AT300 TOW | Up to 3,000 kg

- The Bin Mover AT300 from MasterMover moves 1100 litre wheelie bins (Eurobins) with ease. It's suitable for moving any type of bin, from individual bins with a bin towing frame to a chain of bins up to 3 tonnes. A wheelie bin adaptor for moving 140-340 litre wheelie bins is also available.

The Bin Mover AT300 is perfect for moving waste bins in hospitals, car parks, hotels, residential blocks and assisting in the facilities management sector.

For more information or to request an on-site survey click the button below.- Move up to 3 tonnes of waste bins safely

- Single operator and no licence required Simple and easy to use

- No risk of escaping loads with auto brake

- Works on inclines and slopes

Industries

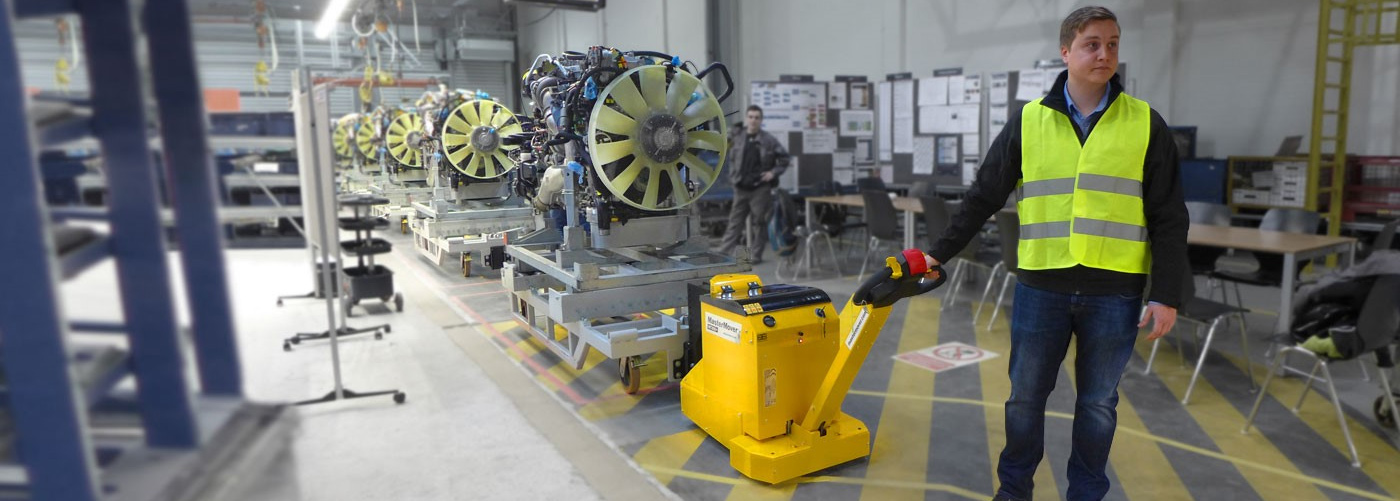

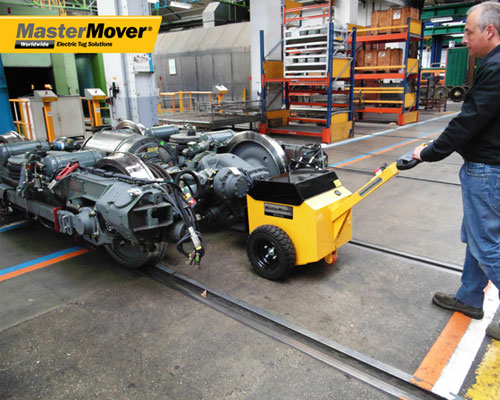

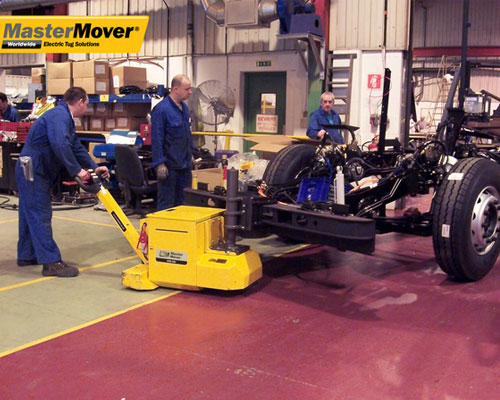

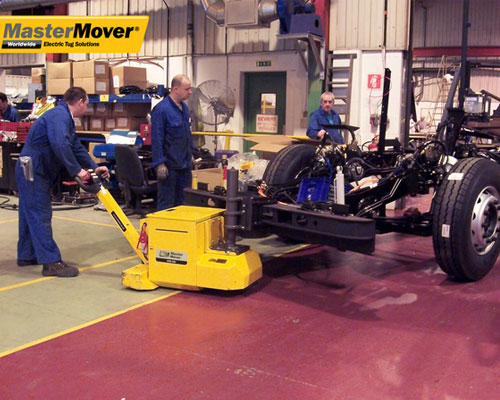

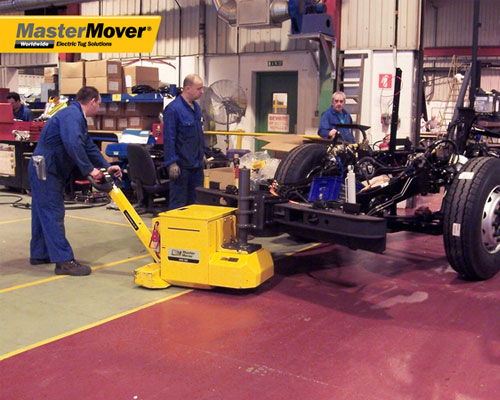

Manufacturing and Assembly

-

We provide leaner, quicker and cost-saving material handling solutions for manufacturing and assembly

Create fit-for-the-future production lines, cut downtime, improve safety

Manufacturers across the globe trust MasterMover’s material handling solutions to reduce downtime, keep production lines moving and improve safety. Our machines are used by clients in a diverse range of sectors including the aerospace, energy, pharmaceutical and automotive industries, with a range of powerful electric tugs and electric tow tugs for faster, less wasteful and smoother operations.

Whether it’s moving smaller loads up to 1,200 kg with our compact but powerful SmartMover range or the safe movement of large loads of 360,000 kg thanks to our innovative PS3000+ electric tug, lean efficiency and employee safety is at the heart of what we do.

All of our machines are designed and manufactured at MasterMover’s Derbyshire headquarters in the UK, with a sales and servicing network that extends throughout the world.

We love a challenge – so if our customers require a more bespoke design, our engineers are on hand to modify or build a completely new electric tow or electric tow tug if needed.

Meanwhile, our Special Projects Team have the capabilities to manage and handle complex material handling projects from start to finish. From machines to withstand the most difficult of production environments and the development of Autonomous Guided Vehicles, we’re helping to build the production and assembly lines of the future.

Pharmaceutical Manufacturing

-

Faster, safer and more cost-effective handling solutions for high-value pharmaceutical equipment

Meet demand, reduce time wasted and exercise complete control with minimal effort

It’s an exciting time to be involved in the pharmaceutical manufacturing industry. Still, with fast-paced innovation comes cost pressures and increasing regulation. We’ve spent the past two decades helping clients to move high-value and sensitive loads in sterile production environments – so that they can meet demand and still benefit from improved efficiency, speed and safety.

We understand that when moving pharmaceutical manufacturing equipment, expensive products need to be protected from contamination and damage. Our stainless steel electric tugs offer adjustable low acceleration speeds, precision movement and can move weights from 500 kg up to 30,000 kg.

MasterMover provides small machines for compact environments where space is at a premium. Meanwhile, even heavy equipment can be moved easily and smoothly by a single operator, with minimal effort – reducing manual handling and wasted time.

We're helping customers in pharmaceutical production move:- Chromatography columns

- Bioprocess containers

- Agitators & reactors Tanks & vessels Refrigerated cabinets

- Single-Use equipment

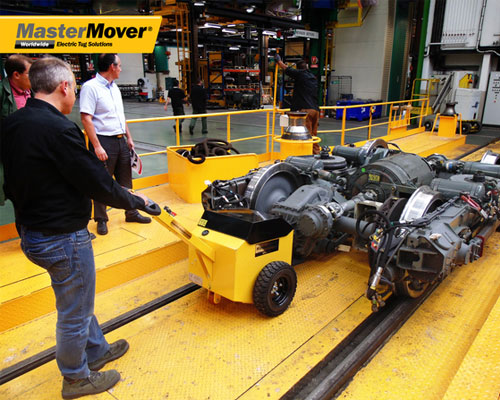

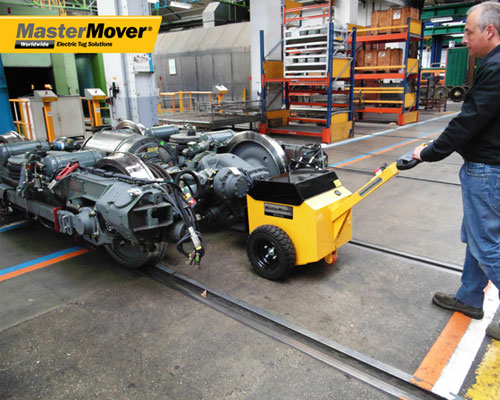

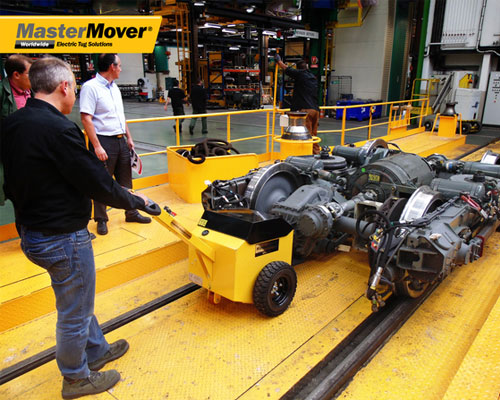

Aerospace - MRO

-

MRO aerospace operations across the globe trust us to deliver greater efficiency

Quicker turnaround times, control and precision over high-value loads – even in the most time-pressured and challenging of aircraft workshop environments

With aircraft fleets getting larger and the need to make sure older models are in optimum condition, we know that the maintenance, repair and overhaul industry working in aerospace faces pressure to get the job done well, every time – and to the most rigorous of safety standards. We keep aircraft maintenance moving with our range of material handling solutions designed for precision handling and easy manoeuvrability in a sector where compliance is key.

Our powerful electric tugs specified for the aircraft maintenance are capable of moving weights of between 500kg up to 20,000kg. For more than two decades, aircraft maintenance repair operations from across the globe have trusted us to help them move heavy goods and valuable loads such as staging, stands and aero engines.

When there is lack of visibility, there is a greater risk of damage to high-value parts during transportation. Meanwhile, waiting for a trained and licensed forklift operator can create inefficiency and unnecessary downtime. Instead, MasterMover allow a single user to handle even large components, quickly but safely and with an all-round view of surrounding obstacles.

We're helping customers in MRO aerospace move:- Aircraft engine stands & landing systems

- Aero structures & components

- Staging, stairs & work

- Access platforms

- Tooling & support equipment

Waste and Facilities Management

-

We're helping the waste and facilities management sector to move heavy loads safely

Reduce risk to staff, move different types of bins, transport heavy and awkward loads easily

Preventing delays to the workflow and keeping services moving while protecting employees from risk can be a challenge for the waste and facilities management sector.

From bins to laundry cages, transporting heavy and awkward loads necessitates a reliable and robust solution that offers improved productivity and safety. That’s why MasterMover’s manual handling solutions can be found in hospitals, hotels, shopping centres and residential developments across the world.

A single pedestrian operator can safely move loads from 50 kg up to 1,200 kg thanks to our innovative SmartMover range. Meanwhile, our machines are also capable of moving multiple cages over large distances, as well as over less-than-perfect surfaces, slopes and rough terrain.

We're helping customers in the waste and facilities management sector to move:- Bins

- Waste containers

- 1,100 litre bins

- Laundry cages

Retail and Logistics

-

We’re reducing manual handling pressures in retail and logistics operations

Greater control, safer working practices and less risk to employees.

In a busy retail and logistics environment, manual handling pressures can put a strain on staff, leading to lower productivity and an increased risk of accidents. Loaded roll cages can be difficult to manoeuvre - especially over longer distances, on uneven surfaces and around obstacles. Loading and unloading goods using a tail lift can also pose a danger to staff.

From distribution centres and warehouses to shops and retail units, our manual handling solutions reduce risk and provide complete control when moving goods in and out.

Our powerful yet compact SmartMover range is ideal for safely and securely transporting loads of up to 1,200 kg.

We also offer machines capable of moving multiple cages over large distances with ease and all-terrain electric tugs for tricky to negotiate surfaces. Additional options including remote-controlled operation for complete visibility.

We're helping retail and logistics customers to move:- Roll cages Picking trolleys

- Nested clothing rails

- Plastic product dollies

Healthcare

-

Wheeled load moving solutions for the healthcare sector

Move cages and equipment safely and easily, reduce manual handling

In busy healthcare settings, moving wheeled loads as safely and efficiently as possible while minimising risk to staff and patients can be difficult. That’s why healthcare managers trust MasterMover’s electric tugs and pushers to move roll cages, linen cages, medical equipment and more.

Our solutions are trusted by healthcare professionals to make a real difference in the running of time-pressured hospitals and care homes looking to save time and cost. In addition to our standard machines, our stainless-steel range of electric tugs is ideal for moving wheeled loads in sterile environments.

We’re helping clients in the healthcare sector to move:- Roll cages

- Linen trolleys

- Waste bins

- Medical equipment

- Sterilisation units

- HSDU trolleys

- Baxter fluids

- Clinical waste

- Gas bottles

- Regeneration trolleys

- Mortuary trolleys

Food and Beverage

-

We’re helping the food and beverage industry to keep up with demand in a sector where cost, quality and safety is everything

Reduce manual handling, move loads easily, exercise complete control

For food and drink companies operating under tight regulatory standards, meeting fast-paced deadlines while preventing contamination can be a real challenge. Our range of electric tugs and pushers save time and money when it comes to moving equipment, vats and ingredients in clean room environments.

From small pedestrian electric tugs to bespoke machines which can be coupled to a wide range of trolleys, our solutions can move wheeled loads from 50 kg up to 30,000 kg. Tugs can also be fully washed down after use, while stainless steel options ensure clean room compliance is maintained throughout the production process.

Even in tight spaces with slippery and sloping floors, a single person has complete stop/start control and total manoeuvrability. No more waiting for a trained and licensed forklift operator. Downtime is reduced to create fast and lean manufacturing environments that still deliver improved safety for employees.

We’re helping clients in food and beverage to move:- Ovens and cooling racks

- Vats and bins Hoppers & tanks

- Roll cages

Warehouse and Storage

-

Compact and powerful pedestrian electric tugs for warehouse and storage

Safely reduce manual handling, improve picking rates, boost productivity

Warehouse and storage companies looking to improve efficiency while never compromising on safety trust MasterMover’s innovative range of pedestrian operated electric tugs and pushers to deliver great results. Narrow aisles, awkward shaped items that won’t fit on racking and heavily laden cages are no longer a problem.

Whether you need to move several nested roll cages at once, order picking trolleys or kitted parts trolleys ready to head off to production, MasterMover has the answer. Our electric tugs are a cost-effective and safe alternative to traditional forklift trucks when moving loads in a storage facility or warehouse.

We’re helping warehouse and storage companies to move:- Order picking trolleys

- Kitted parts trolleys

- Nested roll cages

- Boxes, cardboard and plastic

Airports

-

Electric-powered tugs for airports across the world

Environmentally friendly, ideal for busy and congested environments

Busy airports across the world need reliable, safe and flexible load moving solutions to keep operations running smoothly and efficiently. What’s more, crowded terminal buildings can be challenging when it comes to transporting heavy and awkward wheeled loads. Logistics support from MasterMover's range of electric tugs is the answer.

Our compact yet powerful SmartMover range can safely move loads of up to 1,200 kg. Ideal for roll cages, each of our electric tugs features a secure connection, speed selector and automatic braking for complete control in the most congested of environments. Meanwhile, our All Terrain Pushers are a great choice for moving heavier loads such as baggage trolleys on different surfaces, inside and outside.

Electric power and performance guaranteed means that we’re helping airports to reduce emissions and create more sustainable logistics operations.

We’re helping airports to move:- Baggage trolleys

- Catering trolleys

- Generators

- Passenger steps

- Ground handling equipment

- Roll cages