- Offer Profile

-

As the Group's original activity, our Public Works division has the benefit of a hundred years of expertise, which our different companies apply to the management of all their projects, whether large-scale or more local, complex or innovative, in Nouvelle-Aqutaine, France and abroad: earthworks, civil engineering, underground work, sewerage, road construction, etc.

- Underground works

- Major Engineering Structures

- Dams

- Industrial and nuclear civil engineering

- Linear infrastructure and earthworks

- Environment and urban engineering

- Sanitation

- Roads & other networks

- Decontamination

MOVING BRIDGE

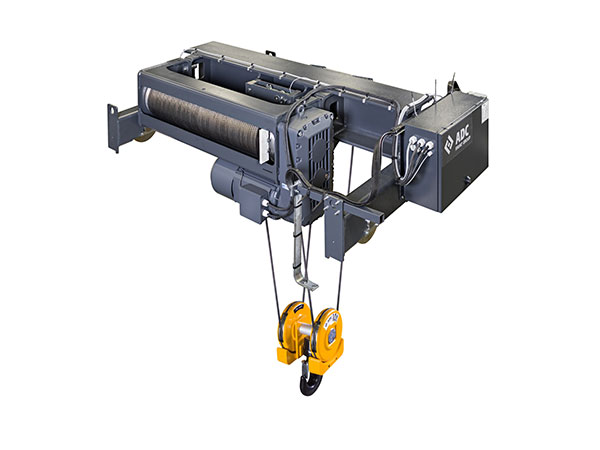

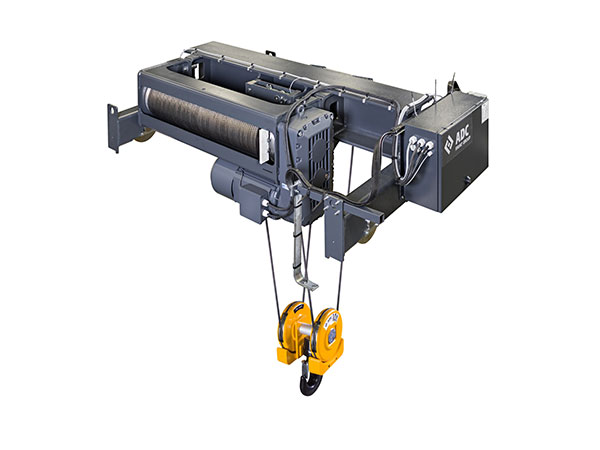

Double girder overhead cranes

- Made from tested and then standardized components, ADC Double-girder Overhead Cranes are configured to meet business requirements as much as possible.

ADC standard double-girder overhead cranes are designed for heavy loads and/or to gain lifting height.

Depending on the configuration of your building, we can offer you a suitable solution. Our overhead cranes are manufactured in profiles or boxes.

Single girder overhead cranes

-

ADC single-girder overhead cranes are perfectly suited to everyday uses and present few constraints. These overhead handling cranes are designed for your needs with lifting capacity of up to 12.5t and a span of up to 30 meters, and can be installed in new or existing buildings. Our single-girder overhead cranes are manufactured either with commercial profiles with wide wings for good horizontal inertia, or in box sections, for large spans. The box beams are produced on an automatic welding bench in our factory in Parthenay (79). The beam-box spring connection benefits from particular attention in our design, thus making it possible to create a rigorous geometric whole. This entire assembly is implemented on an assembly bench in the workshop.

OVERALL CRANES WITH REDUCED HEADROOM

Our handling cranes are equipped with cable hoists with reduced headroom and allow maximum lifting height to be obtained. These cable hoists, also designed and manufactured in Parthenay (79), make ADC the only French manufacturer of complete overhead cranes. In addition, thanks to its Metal Frame department, ADC is able to calculate and provide the supporting structure (rollover paths, self-supporting structure), and even the complete building. This dual skill considerably strengthens the advisory and advocacy role of our company.

Converted overhead cranes

-

Made from tested and then standardized components, the ADC Overhead Cranes are configured to meet business requirements as much as possible. They are designed and produced in accordance with our instructions and quality procedures, in compliance with the ISO 9001 standard and the Rules of the European Handling Federation.

Our bridge frames are QUALIBAT certified. Single-girder or double-girder, standing or suspended, ADC Overhead Cranes can adapt to all scenarios. Our technical teams take charge of the complete realization of your project: studies, advice, manufacturing, assembly, after-sales service (9 agencies in France).

Suspended overhead cranes

-

For architecturally complex buildings, we offer ADC Standard Rolling Beams, which are configured to adapt to buildings with suspended runways.

For complex constructions, we offer ADC Standard Rolling Beams, which are configured to adapt to buildings with suspended runways.

ADC rolling girders make it possible to make maximum use of the available space in buildings by reducing the approach heights. Our range of standard rolling girders also allows you to obtain maximum hook height (with our range of reduced headroom hoists). The standard range extends up to 12.5t lifting capacity and up to 30 meters of reach to which can be added, on both sides, 3 meters of fore-noses.

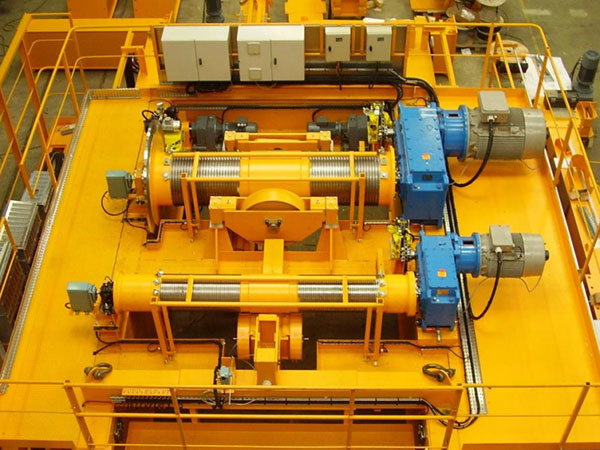

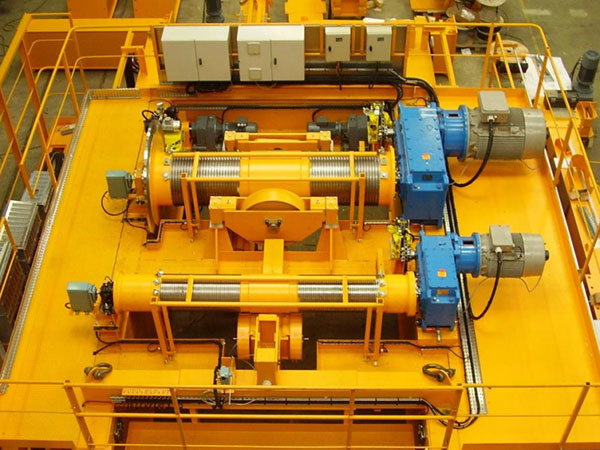

Process overhead cranes

-

ADC has developed recognized expertise in process and large capacity overhead cranes, as well as special equipment.

PROCESS AND LARGE CAPACITY OVERALL CRANES

Whatever your specifications, we study the most suitable solution.Made from tested and then standardized components, ADC Overhead Cranes are configured to meet business requirements as much as possible.

They are designed and produced in accordance with our instructions and quality procedures, in compliance with the ISO 9001 standard and the Rules of the European Handling Federation.

Our bridge frames are QUALIBAT certified.

Portals & semi-portals

-

They are designed to be installed in contexts where existing structures cannot support the lowering of loads generated by overhead cranes. They can be built from standardized elements or in a specific way to meet production requirements.

LIFTING GANTRY AND SEMI-GANTRY

Designed to be installed in contexts where existing structures cannot (partially or totally) support the lowering of loads generated by overhead cranes, lifting gantry and semi-gantry gantry can be built from standardized elements or in a manner specific to meet production requirements. ADC lifting gantry cranes also allow easier use outdoors. They can be supplemented with a large number of options.

MEETS YOUR SPECIFICATIONSThey are designed and produced in accordance with your instructions and our quality procedures, in compliance with the ISO 9001 standard and the Rules of the European Handling Federation (FEM). Our bridge frames are QUALIBAT certified.

Our technical teams take care of the complete realization of your project: studies, advice, manufacturing, assembly, after-sales service (9 agencies in France).

Rails & tubular profiles

-

Rolling rails and beams allow you:

- Flexibility of use, flexibility.

- Great wealth of components.

- Universal design.

Effortless movement of loads with precise positioning.

The design of the system makes it possible to minimize stress on building structures.

- Ease of use up to 2t.

- Expandable, changeable as needed.

In addition, the lightweight aluminum beams offer you great comfort of movement up to 500kg. Delivery of turnkey installations, including suitable structures.

HOISTS

- With more than 35 years of experience and research, ADC offers you robust, reliable and efficient hoists.

With chain, cable, standard, modular or special winches, they adapt to all your needs.

Cable hoists

-

For several decades, ADC has been developing and producing ranges of electric wire rope hoists covering a very wide range of needs.

CABLE HOISTS UP TO 80 TONSWith more than 35 years of experience and research, ADC offers you powerful and reliable hoists.

Design, tests, series production in compliance with construction standards and rules make ADC a privileged contact.

We offer you compact (reduced headroom) single-rail and double-rail design wire rope hoists. They offer you high performance, robustness, safety and great comfort of use.

Chain hoists

-

Designed for handling small loads, electric chain hoists are lightweight, compact and robust in design, low maintenance and easy to use.

Designed for handling small loads, electric chain hoists are lightweight, compact and robust in design, low maintenance and easy to use. From 80 kg to 6.3 tonnes, the range of electric chain hoists can extend from post office equipment to occasional "heavy" handling. Possibility of : speed variation, hour meter, thermal probe, etc.

High performance electric lifting winches

-

Process and large capacity winches, high performance equipment (capacities up to 200t and lifting speed up to 90 m/min) are developed to adapt perfectly to very specific specifications.

Lifting winches respond to a combination of linking factors:

- Charge

- Speed

- Lifting height

- Ranking

These high-performance electric lifting winches (capacities up to 200t and lifting speed up to 90 m/min) are developed according to the specific specifications of our customers. Adopting exploded kinematics, process and large capacity winches can be composed of branded equipment selected by the customer such as reduction gears, motors and brakes.

STEMS

-

The lifting jibs for handling are designed and produced with the greatest rigor and in accordance with the standards and coefficients in force. The components are determined to ensure the greatest safety for the user.

Wall-mounted or column-mounted partial rotation jib cranes : with tubular profile, Triangulated jib cranes with IPE profile, Inverted jib cranes with IPE profile, including the following technical characteristics:

- Adjustable rotation stop system

- Coverage angle up to 270°

- Adjustable end of stroke system if the rotation is motorized

- Wear check of plain bearings without dismantling the boom

- Optimized system for adjusting the verticality of the barrel

- Chemical anchoring solution on thin concrete slab (up to 120mm minimum)

- Expanded electrification solutions, radio control integration with or without button box

- Addition of standard options: 3-position lock, rotation brake, “bad weather” cover for the hoist and garland, protective cover for the disconnector.

LIFTING JIBRANCES

-

The lifting jibs for handling are designed and produced with the greatest rigor and in accordance with the standards and coefficients in force. The components are determined to ensure the greatest safety for the user.

ADC manufactures jibs covering spans of up to 10 meters and supporting loads of up to 5 tonnes.

360° JIB

- ADC also manufactures 360° column-mounted jib cranes with full rotation. The numerous options associated with an already very complete basic supply allow you to optimally adapt the configuration of this equipment to your real needs. Possible options: independent control box – tropicalization – galvanization – protective cover – special paint – chemical anchors – rotation motorization, etc.

LIFTING TABLES

-

ADC offers a wide range of lifting tables that can reach lifting heights of 10 meters and capacities of 80 tonnes.

Lifting tables

- Whatever your need, one of our tables meets it

ADC offers you a wide range of lifting tables that can reach lifting heights of 10 meters and capacities of 80 tonnes. Our teams of experts design and manufacture lifting solutions for you adapted to your needs, your constraints and your installations.

- Column tables

- Scissor lift tables

- Special purpose elevators

- Personnel elevators

- Heavy duty tables

- Mobile lifting tables

- Dock tables

- Rockers

METALLIC CONSTRUCTION

- ADC is also raceways

Raceways

- THE TRAVEL TRACKS: In order to offer you turnkey services, we also manufacture supports for overhead cranes and light handling equipment: Raceways included on the structure of your building Self-supporting structures if your building cannot withstand the forces linked to the installed device