- Offer Profile

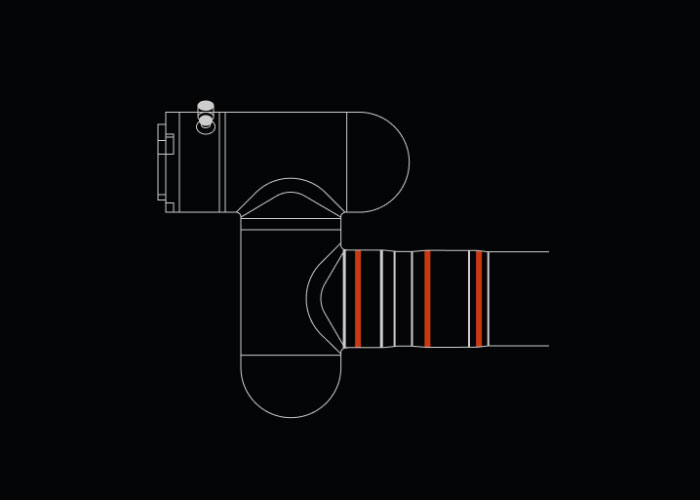

- Kassow Robots was founded in Copenhagen (Denmark) is developing and producing unique and efficient

7-axis lightweight collaborative robots for industrial applications. The five cobots offer a payload of up to

18 kilograms and a reach of up to 1800 millimeter. All these cobots also have three ports with various I/Os

and power supply signals as well as an Ethernet interface installed as standard on the toolhead – and the

free drive button allows completely new freedom when programming waypoints.

The company’s motto is “strong, fast, simple”. Its products offer speed and power, yet also have a long reach. The user-friendliness of the cobots provides businesses with greater flexibility, allowing SMEs without their own robotics specialists to achieve complex automation and programming cost-effectively and independently. What is more, the cobots are compact enough for use in confined spaces.

Two highly experienced robotics experts – Kristian Kassow as CEO and Dieter Pletscher as Head of Sales – are driving the company’s development.

THE POWER OF ROBOT ENGINEERING

-

True to our claim “strong, fast, simple”, we develop and produce uniquely efficient industrial collaborative lightweight robots with 7 axes. Despite their large reach, Kassow Robots are extremely powerful, fast and suitable for use in small spaces. What is more, they enable small and medium-sized enterprises (SMEs) to achieve complex automation and programming flexibly, independently and cost-effectively. Our technology is based on a novel design of both robot controller, user interface and arm mechanics. It has been developed by a team lead by Kristian Kassow, who, in his previous start-up years ago, was also responsible for other ground-breaking designs in the field of robotics.

Our vision is to offer a wide range of models to help all manufacturing companies, SMEs in particular produce even more competitively using cobots in a multitude of ways.LONGER REACH AND HIGHER PAYLOAD - NO MATTER THE USE

7 AXES FOR MORE FLEXIBILITY AND LOWER COSTS

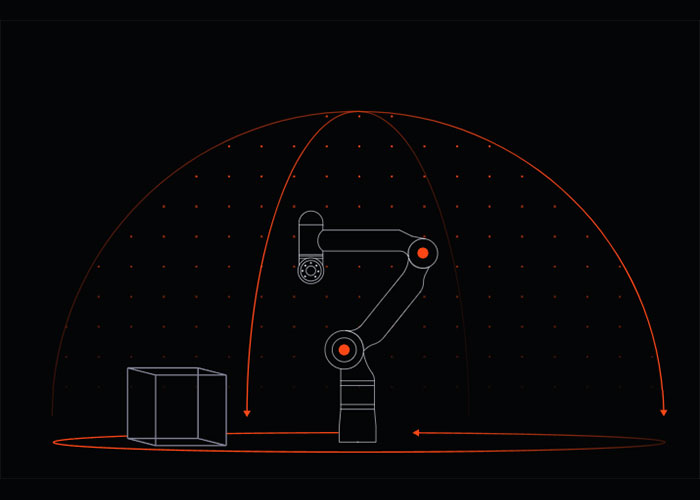

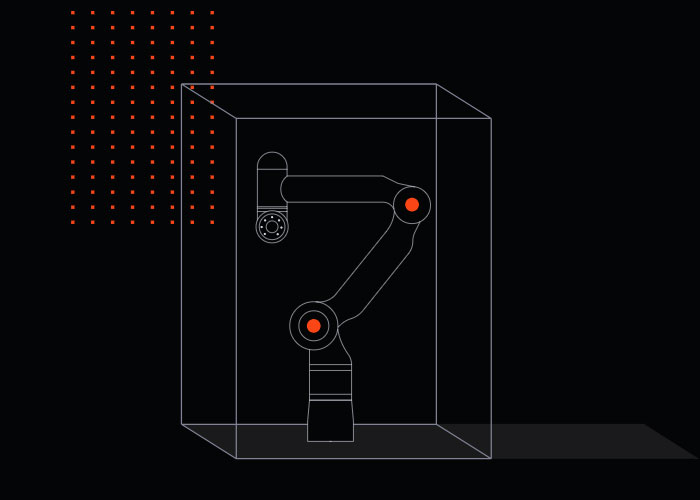

All Kassow robots are “lightweight articulated robots” – i.e. robots with a single arm and rotating joints. Depending on a risk analysis, they can be used directly in industrial production with minimal or even no additional safety measures.

What makes our robots special: Unlike other robot manufacturers, whose portfolios usually feature only six-axis models, we exclusively make robots with 7 fully controlled axes. These 7 axes give you much more flexibility, as they enable our robot arms to far better replicate the movement of a real human arm.

This means that Kassow robots can not only move an object in a straight line from A to B, but can also follow a curved path at a specified speed. This offers real advantages, for instance when it comes to tasks such as welding, painting and gluing, or where particular manoeuvrability is required (e.g. when loading machining centres in confined spaces). Outsmart the competition

Reach new dimensions

-

Our 7-axes cobot offers a greater range of motion, increased payload capacity, and improved precision. It can access hard-to-reach areas with ease, handle heavier objects, and perform delicate tasks with greater accuracy, making it an ideal solution for a wide range of industrial tasks.

- Enhanced precision

- Increased reach

- Improved payload capacity

- Advanced safety features

Safety is our priority

- Our cobots are equipped with sensors that detect overload, ensuring that they can operate safely in shared workspaces without the need for special safety measures. This expands the range of possible applications, including repetitive, dangerous, and dirty tasks, making our cobots an efficient and versatile solution for a variety of industrial applications. Risk assessment analyze has to be done before anything.

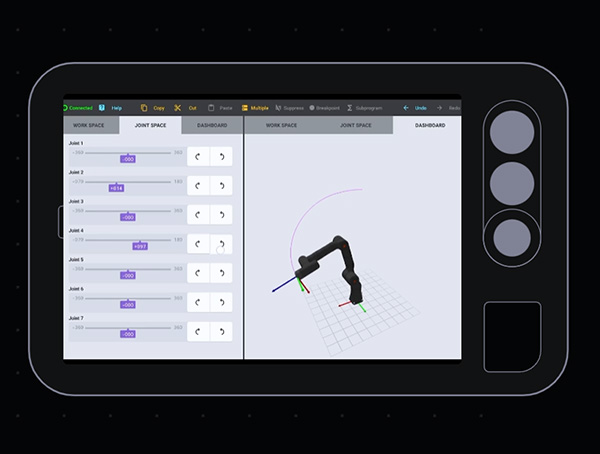

Intuitive user interface

-

The key feature of our robots. The modern-tablet based interface is using all benefits of the powerful Android System to help user build their applications.

- Split screen concept

- Block based programming

- Optimised for robot applications

- Responsive and intuitive environment

- Dynamic content support, native 3D engines

Powerful technology made simple

-

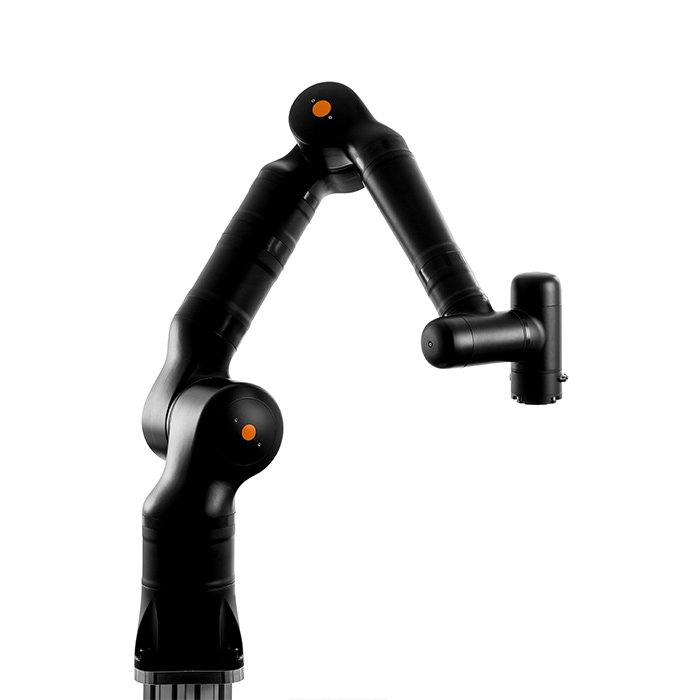

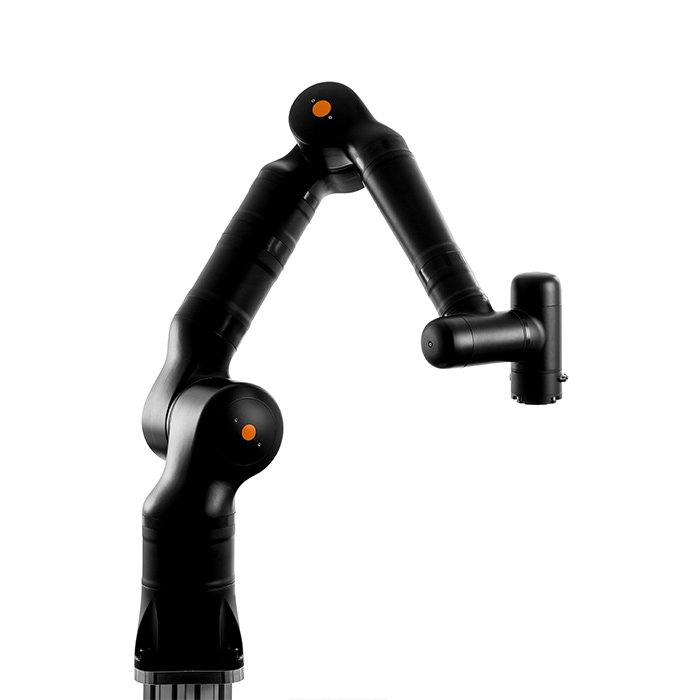

Meet the 7-axes cobot.

Experience a new level of accuracy. An unique combination of the 7th axis, payload & reach. Our range of 5 models allows to reach around the corners, and undertake the most demanding manufacturing tasks.

Long Reach, High Payload

-

Experience unmatched flexibility, precision, and speed for loads ranging from the smallest to the heaviest, regardless of your application - no matter what your application is.

Strong, Light & Durable

-

Solid construction reflected by an all-aluminum surface and very strong materials. Our five models offer an exceptional durability, ensuring optimal performance in any setting.

Easy Relocation & Great Versatility

-

Designed to make set-up and programming easy and efficient. Our lightweight cobots can seamlessly be relocated and redeployed to different areas and applications. Even in super confined spaces thanks to its small footprint.

Cost Effective Automation

-

Our cobots quickly pay for themselves and can solve a multitude of challenges. From automating your repetitive or complicated tasks to assisting your employee’s ones in order to generate more value.

Our Full Range

Kassow Robots - KR Series

KR810

- Strong and fast industrial cobot with a reach of 850 mm and a payload of 10 kg. Simple programming thanks to our special intuitive Kassow user interface.

Specifications:- Payload: 10 kg

- Reach in all directions: 850mm

- Weight: 23.5 kg

- Degrees of freedom: 7

- Repeatability: +/- 0.1mm

- Joint speed (deg / sec): 225

- IP specification: IP54

KR1018

- A strong lightweight robot (payload: 18 kg, reach: 1000mm, weight: 34 kg) for repetitive precise pick & place tasks, which requires great strength. Intuitive user-interface and plug & pay design.

Specifications:- Payload: 18 kg

- Reach in all directions: 1000mm

- Weight: 34 kg

- Degrees of freedom: 7

- Repeatability: +/- 0.1mm

- Joint speed (deg / sec): 170/225

- IP specification: IP54

KR1205

- Fast and flexible industrial cobot with a reach of 1200 mm and a payload of 5 kg. Simple programming thanks to our special intuitive Kassow user interface.

Specifications:- Payload: 5 kg

- Reach in all directions: 1200mm

- Weight: 25 kg

- Degrees of freedom: 7

- Repeatability: +/- 0.1mm

- Joint speed (deg / sec): 225

- IP specification: IP54

KR1410

- A true power pack: Fast industrial cobot with an especially long reach of 1400 mm and no compromise on strength. Payload of 10 kg. Simple programming thanks to our special intuitive Kassow user interface.

Specifications:- Payload: 10 kg

- Reach in all directions: 1400mm

- Weight: 35 kg

- Degrees of freedom: 7

- Repeatability: +/- 0.1mm

- Joint speed (deg / sec): 170/225

- IP specification: IP54

KR1805

- Fast industrial cobot with an especially long reach of 1800 mm and no compromise on strength. Payload of 5 kg. Simple programming thanks to our special intuitive Kassow user interface.

Specifications:- Payload: 5 kg

- Reach in all directions: 1800mm

- Weight: 38 kg

- Degrees of freedom: 7

- Repeatability: +/- 0.1mm

- Joint speed (deg / sec): 170/225

- IP specification: IP54

APPLICATIONS

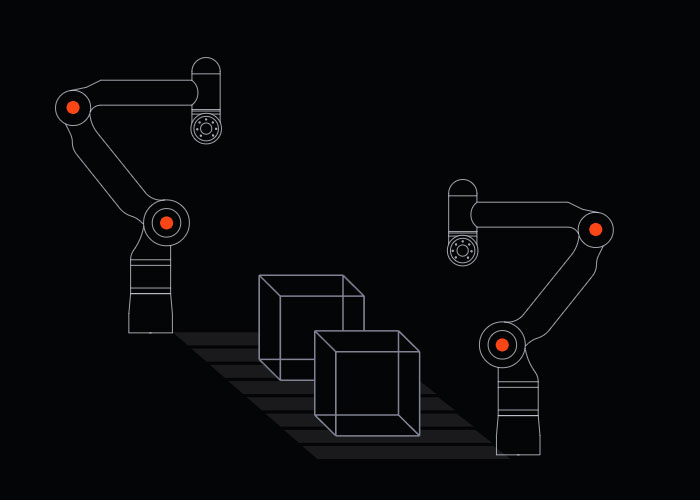

- Our 7-axes robot arms can make the difference and ensure more efficient processes. The cobots areable to even grab around the corner. On top, they can be easily programmed and are very fast. Our collaborative robots help you automate thousands of applications.

ASSEMBLY

- The assembly process is an essential part of many manufacturing industries, where individual parts are put together to form a final product. Automation plays a critical role in streamlining the assembly process and improving productivity. Cobots have become increasingly popular in assembly applications due to their flexibility, safety features, and ease of use. With the ability to work alongside human operators, cobot arms can perform repetitive and labor-intensive assembly tasks, freeing up workers to focus on more complex and high-value tasks.

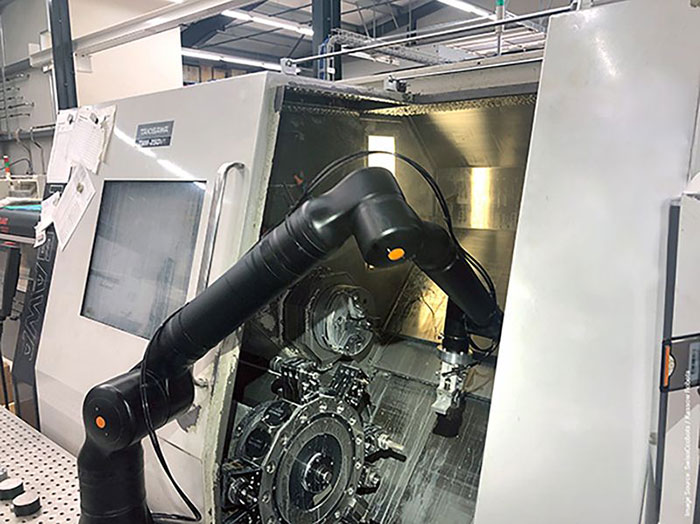

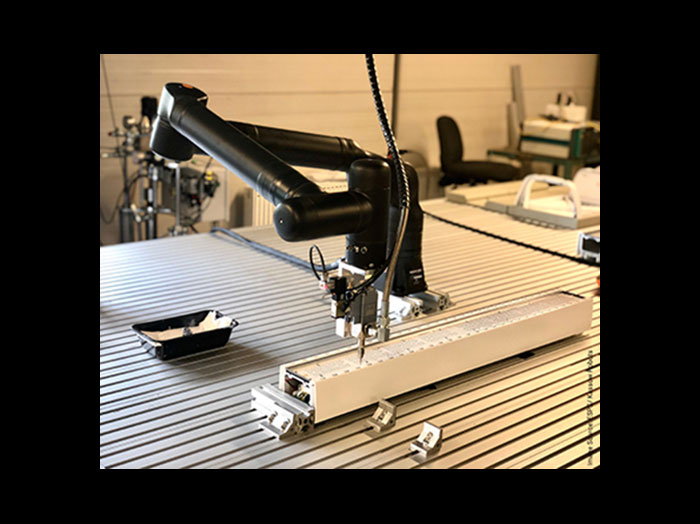

CNC MACHINE

- A 7th axes cobot arm can be beneficial for CNC (Computer Numerical Control) machine applications in several ways. The cobot arm can handle various tasks such as loading and unloading of raw materials, moving finished parts to other workstations or storage, and tool changes. The cobot's compact size and flexibility allow it to work in tight spaces, increasing efficiency and reducing production time. Finally, integrating a cobot arm with a CNC machine can reduce errors and minimize waste, leading to cost savings in the long run.

PALLETIZING

- The 7th axis cobot is an excellent choice for palletizing applications due to its versatility and flexibility. With its increased range of motion, the cobot can pick up and place items on pallets with greater accuracy and precision, reducing the risk of damage to the items being palletized. Thanks to his collaborative capabilities it also makes it an ideal solution for palletizing tasks that require human supervision or decision-making.

PACKAGING

- A 7th axes cobot arm is an excellent choice for packaging applications due to its versatility, flexibility, and collaborative capabilities. With its increased range of motion, the cobot can pick and place items with greater accuracy and precision, reducing the risk of damage to the products being packaged. The cobot's collaborative capabilities also make it an ideal solution for packaging tasks that require human supervision or decision-making. The cobot can work alongside human workers to perform tasks that require human expertise, such as quality control or product inspection.

PICK AND PLACE

- The 7th axis cobots are ideal for pick and place applications due to their flexibility, high precision, and ease of integration with other systems. They can handle a wide range of products and can be programmed to perform a variety of tasks, making them a versatile and efficient solution for pick and place operations. Additionally, their collaborative capabilities enable them to work safely alongside human operators, improving overall productivity and reducing the risk of workplace injuries.

DISPENSING

- A 7th axis cobot arm can be highly beneficial for dispensing applications, as it allows for precise and consistent dispensing of fluids or other materials. With the additional axis of motion, the cobot arm can reach further and move more freely, increasing its range of motion and allowing it to access difficult-to-reach areas. This level of precision and accuracy is crucial for dispensing tasks, where even minor errors or inconsistencies can have significant consequences. Additionally, the cobot arm can be programmed to perform repetitive dispensing tasks with speed and efficiency, freeing up workers to focus on other areas of production.

CASE STORIES

-

Our 7-axis robot arms can make the difference and ensure more efficient processes. The cobots areable to even grab around the corner. On top, they can be easily programmed and are very fast. Ourcollaborative robots help you automate thousands of applications.

Dramatically increase the productivity of CNC machining

-

Key technical facts:

- 7-AXES COBOT: KR1410

- COMPANY: JULES BERTSCHINGER AG (SWITZERLAND)

- SECTOR: CNC MACHINING

- KR PARTNER: SWISSCOBOTS GMBH

Labelling in tight space with the KR810

-

The 7 axis KR810 Process – Applying Labels Effeciently in Limited Spaces

Key technical facts:

- 7-AXES COBOT: KR810

- COMPANY: WALTER RAU NEUSSER ÖL UND FETT AG

- SECTOR: FOOD

- KR PARTNER: PROJECT SERVICE & PRODUKTION GMBH

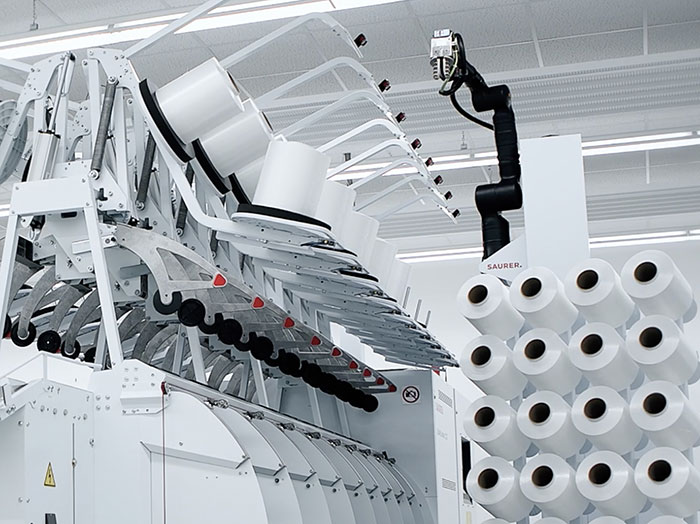

Restocking of cabling machines

- KR1018 in tandem with AGV: Restocking cabling machines with bobbins

Key technical facts

- 7-AXES COBOT: KR1018

- COMPANY: CLIENT OF SAURER TECHNOLOGIES GMBH & CO. KG

- SECTOR: TEXTILES

- KR PARTNER: PROJECT SERVICE & PRODUKTION GMBH

7 Axes cobot for securing cutting edge gluing

- KR1205 in action: 8 steps towards better output and quality in gluing and sealant

Key technical facts:

- 7-AXES COBOT: KR1205

- COMPANY: AP (NETHERLANDS)

- SECTOR: ELECTRICAL INDUSTRY

- KR PARTNER: ESPS BV