Yelo

Videos

Loading the player ...

- Offer Profile

- Yelo is a leading

manufacturer of automated test equipment for the Photonics and Electronics

industries.

We specialise in manufacturing equipment that tests the reliability of laser devices which are used in Photonic Integrated Circuits (PIC's). These laser devices are used in Data Centers and in Telecommunications to carry information.

Product Portfolio

Laser Diode Testing

Low Power Laser Diode Burn-in Selection Guide

-

The low power series of burn-in and life test systems are designed to test the

reliability of low power laser diodes up to 1 Amp in current. The modular design

means they can test up to 2,048 lasers, however due to the flexibility of the

system, it can be adapted to suit both low volume R&D environments and high

volume production environments.

BURN-IN

The system performs burn-in stress tests on all laser diodes. The data from these tests can be used to identify and remove defective devices from reaching the end customer.

LIFE TEST

The system can also perform life testing on a representative sample of laser diodes from a wafer. This test data can be used to establish the long term reliability of the laser.

Which system is for you?

There are 3 systems in Yelo's Y1000 series;

- Y1000S (the standard system)

- Y1000D (the system most suited for R&D Environments)

- Y1000P (the system most suited for Production Environments)

Y2000H HIGH POWER

-

Laser Diode Reliability Life Test and Burn In System

Easily test the reliability of your high power laser devices with the Y2000H burn-in and life-test system. It will quickly identify defective laser devices so you can prevent them reaching your customers. Y2000H's full automation and expandable capacity helps you work through your tests more productively. And its user-friendly software makes testing your devices easier than ever.

LASER DIODE LIV TEST INSTRUMENT

- The Yelo LIV test instrument allows LIV measurements to be taken from laser devices loaded into a Yelo module. This module can also be used with the Yelo Y1000L Low Power Burn-in system. The LIV test instrument has been designed for easy operation. Once powered on, and with laser supply enabled, the touch screen can be used to initiate, monitor and review measurements of laser devices.

Y1000L LOW POWER

-

Laser Diode Reliability Life Test & Burn In System

Easily test the reliability of your low power laser devices with the Y1000L burn-in and life-test system. it will quickly identify defective devices so you can prevent them reaching your customers. Y1000L's full automation and expandable capacity helps you work through your tests more productively. And its user-friendly software makes testing your devices easier than ever.

TEMPERATURE CONTROL CHILLER

-

The Yelo Chiller is designed to work with the Y1000L to increase thermal management accuracy. This is achieved through providing faster cooling temperatures. The benefits of improved thermal management can lead to higher levels of productivity and enables LIV testing at ambient temperatures.

Benefits- Its free-standing compact chassis ensures that it doesn't take up valuable floor space.

- "Burned in" and quality tested at our facility with a Y1000L rack before shipment.

- Connection plugs, wiring and piping that is designed for the Y1000L internal air cooling architecture.

- Fully controlled by the Y1000L's control station, making temperature management simple and easy.

- Lower cost when bought directly from Yelo compared to a third party chiller system.

- Fully supported both for maintenance, repairs and calibration under the same support program as the Y1000L.

- We provide a rental scheme that allows for extra flexibility, perfect for specialised testing, short term projects or prototyping.

- Suited to a range of climates and working environments, with adaptable plug fittings and pipe work suitable for your country or facility.

PCB AUTOMATED TEST EQUIPMENT

- Yelo manufacture and design a variety of custom automated test equipment for printed circuit boards. Our test equipment architecture provides systems capable of both pre-functional and post functional testing for PCBs and final-assembled products. We design custom mechanical and pneumatic test fixtures using traditional bed of nails testing. These are controlled by our bench top Testpoint station. We also manufacture a rack based PXI test system which uses off-the-shelf test equipment and instrumentation.

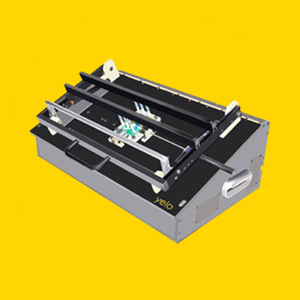

PCB Functional Tester

-

Functional testing of printed circuit boards, sub assemblies and finished products

A compact bench-top system, the Yelo Testpoint combines bed of nails in-circuit testing with functional testing to validate that your product hardware is free of defects. It has easy-to-use software that allows you to program and monitor your own test, making it the most convenient and flexible product tester on the market.

YELO PIXI

-

PXI Functional Test System

The Yelo Pixi is an off-the-shelf PXI based functional test system with in-circuit, continuity and functional test capability. Built into a free standing 19" rack is a PXI chassis, mass interconnect fixture interface, PC, flat screen and space for additional instruments if required.

Hardware Features- Operator ergonomics

- In-built safety systems

- Analogue in-circuit capability and guard capability

- Uncommitted space for user selected instruments

YELO TEST FIXTURES & JIGS

- A test fixture or test jig is the component containing the bed of nails used for testing the PCB or assembled product. It is powered and controlled by the Yelo Testpoint system which has test cards capable of providing multiple test conditions. This system also controls the probes used in the bed of nails, and relays test information back to the Testpoint system to be analysed.

YELO TEST ENVIRONMENT V5.0

-

What is Yelo Test Environment?

The Yelo Test Environment (YTE) is an automated test environment developed by Yelo. Test sequences can be developed for multiple products and are tailored to customer needs and specifications. Flexibility in testing is a key benefit of the YTE and is provided to the user by allowing management of test sequence order. There is also the ability for the user to change the test limits or parameters for more or less stringent testing depending on requirements.

BESPOKE TESTING SOLUTIONS

-

Why choose Yelo?

Yelo has over 30 years experience creating and developing bespoke testing solutions. We have a strong in house team of electronic engineers, mechanical design engineers, software developers and test engineers. We can ship internationally as well as offering international support and commissioning. Automated LP Heating Control Unit Tester

-

About: This system was designed for Schneider Electric and programmed and performed functional tests on the LP model heater control units at a rate of about one every 15 seconds. The units were transported through a conveyor belt system which routed passed or failed units.

Result: "Yelo provided us with a reliable Automated LP Tester. It's now in production and achieving a throughput of 1,400 units per day. We look forward to working with Yelo again and we would recommend them for similar projects."

- Paul Pady (Schneider Electric)

Functional Tester for D38 Aircraft Reading Light

-

Functional Tester for D38 Aircraft Reading Light

About: This system was designed for Nitronica and programmed and performed functional tests on the D38 Reading Light at PCB level and also at completed assembly level as final functional test.

Result: "Yelo provided us with a fully functional Production Test solution, on time, and meeting the Test specification for the most recent D38 Test Solution. Support was also very good in commissioning.

We would recommend Yelo for Electrical Test Solutions."

- Noel Irwin (Quality Manager)