- Offer Profile

- Since 1934, the Swiss Stöcklin Group has been your competent partner worldwide for innovative and customer-specific warehouse logistics solutions.

As an experienced, international system integrator for intralogistic systems, we support our customers right from the planning and development phase through to delivery of complete turnkey systems regarding warehouse logistics and automated warehouse management. Our products, produced primarily within our own company, allow us to offer conveying and storage systems for highly varying types of load carriers as well as floor handling equipment and industrial trucks to strengthen our customer's long term, sustainable competitive ability.

Intralogistic Systems

Pallet Conveying System

Stöcklin Logistik is a supplier and manufacturer of pallet conveyor system solutions for fully automated storage and retrievals

The pallet warehouse system acts primarily as a buffer for the replenishment of the picking station. Design and dimensioning is accomplished according to specific requirements in consideration of the required loading aids as well as the desired throughput.Automated Storage

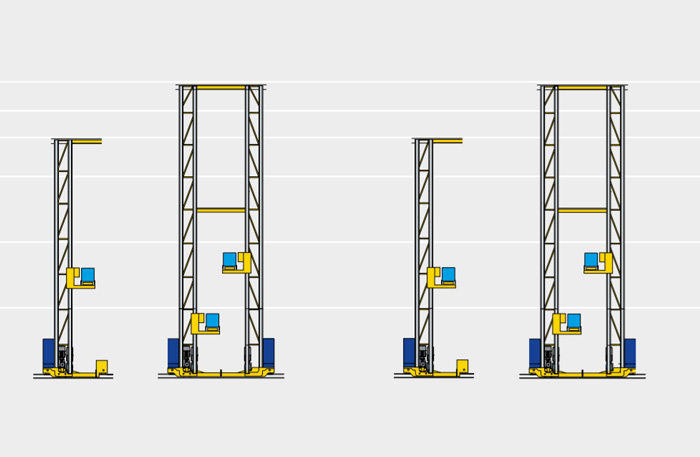

The core element of the pallet conveying system solutions from Stöcklin Logistics are the modular designed stacker cranes of the MASTer series for fully automatic handling of industrial pallets, pallet cages, special load carriers and larger packing units in pallet racks at heights of up to 45 meters. Highly dynamic carriages combined with modular design guarantee maximum performance and high availability.

Advantages of our high bay warehouse system at a glance:- Highest possible storage and retrieval rates

- Maximum availability

- Minimum personnel requirements

- Optimum use of available space

- High operating reliability

Manual Storage

Manually controlled stacker cranes for high racks are particularly suitable for companies with a low flow of goods and simple infrastructure. This is distinguished by its high flexibility and minimum space requirement as well as attractive investment costs.

Pallet Systems

-

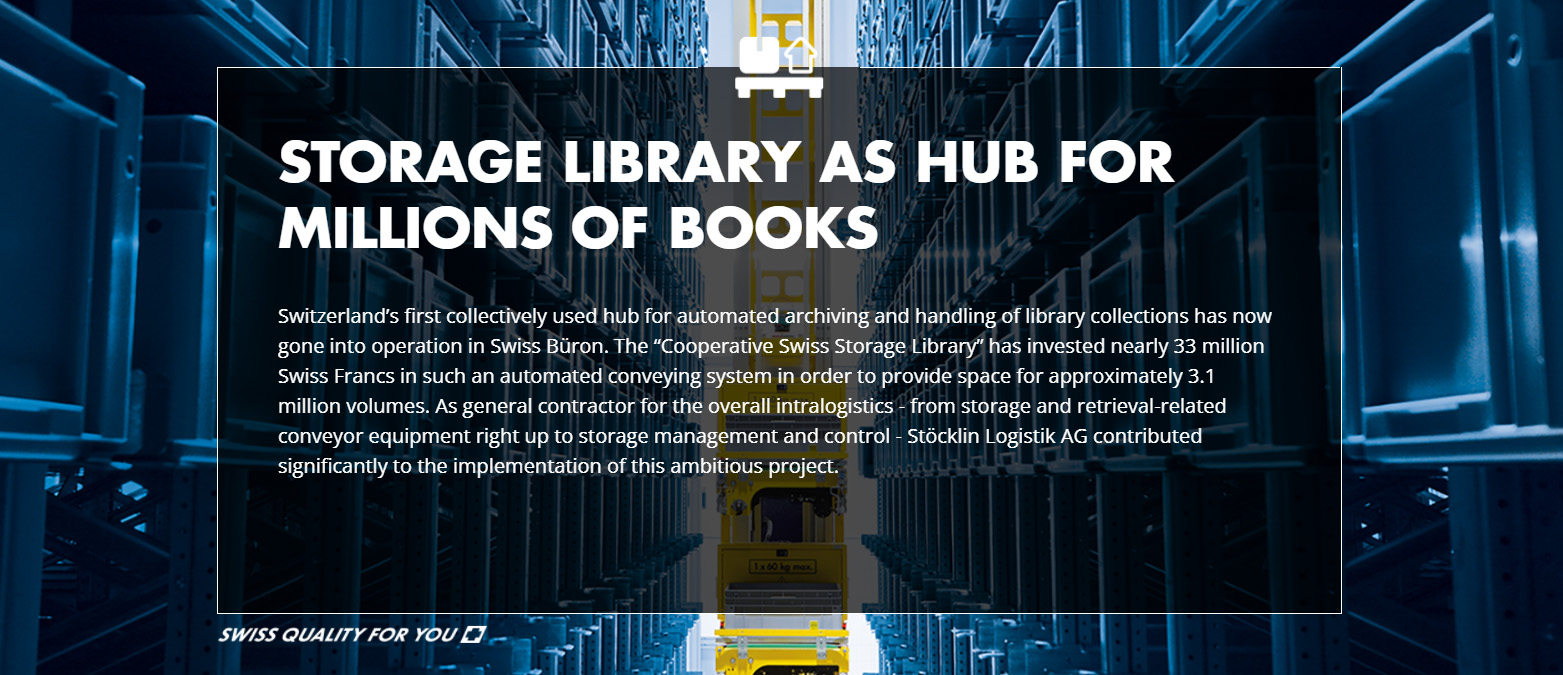

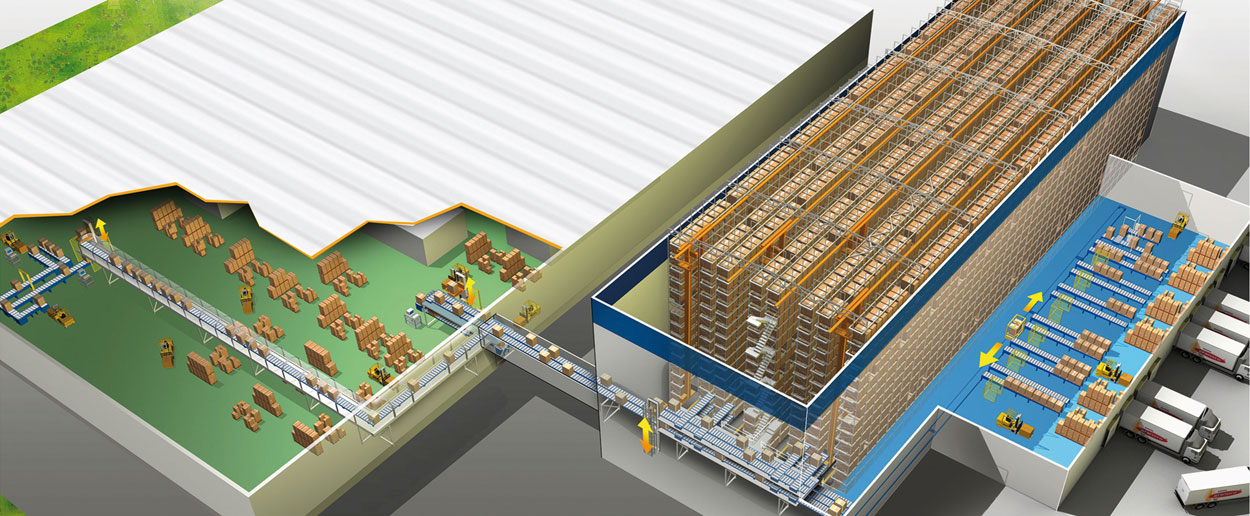

Innovative Complete Solutions

As a supplier of complete systems, we plan, design and realize equipment to meet the distinct and operationally specific requirements of our customers. As a strong partner, Stöcklin supports you with many years of competency and experience in intra-company logistic solutions in all industries.

When we speak of the entire system, we mean more than just smooth interaction between the mechanical, control and material flow systems. Above all, we incorporate all special features of your products, your shop and your economic processes and objectives into consideration.

We support our customers from the planning and development phase right through to delivery of complete turnkey systems. Our many years of experience and great production depth allow us to offer conveying and storage systems for highly varied types of load carriers including floor handling equipment to contribute to your logistic processes as a cost-reducing factor and strengthen your long term, sustainable competitive ability.

We place great emphasis on long term, cooperative relationships with our customers. This means our job is not done when your system is completely installed. This is the point at which another strength reveals itself: We are always there for you with our consulting services. Various service concepts, courses of training, a 24/7 service desk and quick-shipping replacement parts guarantee high availability in your warehouse over the entire life cycle.

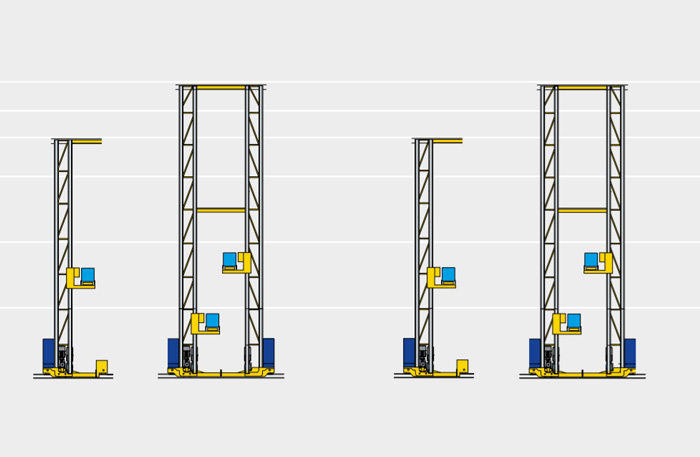

The MASTer — Maximum handling capability and availability

-

Dynamic performance, stable construction

The MASTer: for high-performance and cost-effective fixed-aisle warehouse operation.

In development we combined our decades of experience with leading-edge mast construction and control technology. All units are produced in-house in accordance with Stöcklin’s high quality standards.

A lightweight, torsion-resistant mast design allows rapid acceleration and moving speeds, reducing warehouse cycle

times.The MASTer can be equipped with load handling devices for double/multi-depth storage for even greater handling capacity and high-volume warehousing. Our PowerShuttle is the ideal solution for this.

Optimal visibility and energy efficiency

The MASTer comes in heights of 6 to 45 m. Two operation stands and optional integrated cameras ensure optimal

visibility for storage and retrieval processes, enabling early error detection.

Energy efficiency is part of the equation too, as energy released when lowering the load handler is fed back into the MASTer and used for its drive power.

PowerShuttle

-

Stöcklin PowerShuttle: Space-saving storage in the deep lane warehouse

The ideal solution for goods with limited SKU count and high storage density

A deep lane warehouse and/or compact warehouse is particularly advantageous for efficient storage of goods like

foodstuffs and drinks. Stöcklin has developed the PowerShuttle specially for this purpose. In general, so-called compact warehouses are used when there is a limited range of goods or preferably for single-variety

products.The space allocation takes place according to the instructions of the warehouse management system and thereby takes into consideration the earliest use-by date of the goods, preferably according to the principle of First-Expired-First-Out (FEFO).

The PowerShuttle can also be used in frozen product warehouses with temperatures as low as –30 °C.

The PowerShuttle offers the opportunity to store pallets of various sizes in one lane, whereby the pallets are positioned so that they take up as little space as possible in the lanes. The shuttles can be integrated as load

handling attachments on all stacker cranes.The advantages of our deep lane warehouse system at a glance:

- High level of flexibility (Full Flexible Storage)

- High level of scalability

- Reduced space requirements

- Maximum storage density

- Secure positioning

- Longevity and energy-efficiency

- Low investment, maintenance and operating costs

Automated Small Parts Warehouse

Miniload

Stöcklin is a supplier and manufacturer of system solutions for fully automated small parts storage and retrieval.

Automated small parts warehouse systems (Miniload) from Stöcklin Logistics have proven themselves in storage and distribution systems as well as in production surroundings. In this case the goods are usually stored in containers or boxes containing one specific type. Trays can also be used for storage of mixed articles.

The Stöcklin BOXer series includes variable modules, offering you a complete solution for your automated small parts warehouse. Miniload Cranes from the BOXer series guarantee shortest operation times and maximum handling rates. Small parts shelving storage at heights up to 22 meters is optimized by volume. Innovative and consistent implementation of light-weight design with the BOXer has set new standards for energy consumption.

Advantages of our small parts storage soluations at a glance:- Highest possible storage and retrieval rates

- Shortest access times even with a large variety of articles

- Maximum availability

- Space-saving storage

- Reliable, economical and energy-efficient processes

The BOXer is suitable for standard containers and pallets, as well as for boxes of different sizes and types. Various load handling devices are available for single station as well as multiple station storage. In addition to the classic combination telescopic units, Stöcklin also offers box grippers as well as gripper-type load handling devices.

FSP small parts warehouse shuttle system: A flexible system for all requirements

The FSP (Flexible in Storage and Performance) has been designed for a wide range of fields of applications and therefore enables use with a wide variety of carrier types and dimensions.

Thanks to the flexible modular structure, the system can be freely designed in terms of storage capacity and overall performance. Furthermore, additional factors such as the shape of the building and ambient temperature are also considered.

Because the requirements for intralogistic systems change over the years, later modifications and extensions are essential. We took this into account during the development of FSP. It means you will still have the right system available for future requirements. Last but not least, this guarantees you a high level of investment security as well functionality.

FSP small parts warehouse shuttle system

-

A flexible system that’s always the perfect fit…

The FSP has been designed for a wide range of fields of applications and therefore enables use with a wide

variety of carrier types and dimensions. Thanks to the flexible modular structure,the system can be freely designed in terms of storage capacity and overall performance. Furthermore, additional factors such as the shape of the building and ambient temperature are also considered.Impressive overall package

A tailor-made concept and proven system components guarantee a high level of reliability and availability.

... and if it no longer quite fits - we simply make it fit.

Because the requirements for intralogistic systems change over the years, later modifications and extensions are

essential. We took this into account during the development of FSP. It means you will still have the right system available for future requirements. Last but not least, this guarantees you a high level of investment security as

well functionality.

The BOXer — The technologically superior system

-

The BOXer small parts unit is part of a series of aisle stacker cranes for automated container, tray or box warehouses. Thanks to innovatively and consistently applied lightweight construction, new standards are being set with regard to energy consumption. With a comparable level of system performance, the BOXers are the most lightweight and thus most energy-saving small parts aisle stacker cranes on the market. Stöcklin also offers the BOXer series as a complete turnkey system comprised of stacker cranes, racking, loading equipment (containers, trays), controls and warehouse management.

Highest availability with low maintenance costs

Thanks to the ergonomic and very maintenance-friendly design, the individual components of the mechanics and the

control technology can be changed very quickly. Short downtimes ensure a high level of availability as well as low

maintenance costs.High throughput and vibration reduction

Regulated drives for the chassis and lifting mechanism ensure optimum adjustment of acceleration, propulsion

and braking curves. In sufficiently long aisles, traveling speeds of up to 6 m/s are possible.The proven lightweight aluminum mast construction combined with the smooth propulsion curve permits dynamic, low-vibration operation. Corrective movements for subsequent positioning are generally not required.

Increased reliability

The standard rack gap monitoring function monitors the space between the stacker crane and the rack. If a container or package is identified within the area of movement, the device stops instantly, thus avoiding a collision.

Channel (deep lane) Storage Systems

Stöcklin Logstik is a supplier and manufacturer of compact storage system solutions for fully automated storage and retrieval of warehouse inventory with minimum product mix depth.

Channel and compact storage solutions from Stöcklin Logistics allow multiple depth storage, i.e. a number of load carriers can be stored one in back of the other. This space-saving method is particularly advantageous in the food and beverage industry as well as in the energy-intensive deep freeze sector.

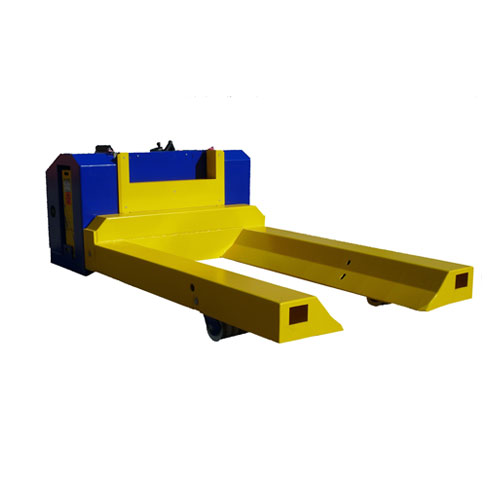

Storage and retrieval are accomplished by the PowerShuttle, developed exclusively by Stöcklin. This carrier vehicle is positioned in front of the shelves by a stacker crane, allowing it to travel horizontally on a rail into the assigned channel where it moves beneath the pallet.Advantages of our compact warehouse systems at a glance:

- High degree of flexibility and scalability

- Minimum space requirement

- Maximum storage density

- Increased redundancy

- Low investment, maintenance and operating costs

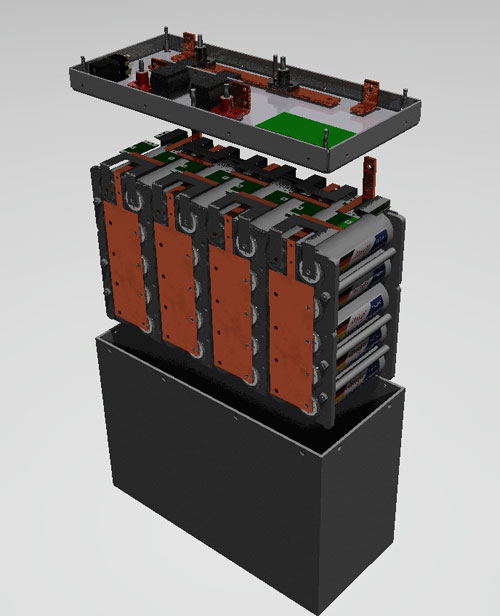

The storage locations are assigned by the warehouse management system in consideration of the minimum best before date of the goods using the FiFo system (First-in/First-out). The PowerShuttle communicates using radio frequency signals and is positioned by means of absolute encoders and sensors. The PowerShuttle is available in one or two-pallet versions (single or double PowerShuttle) and is also suitable for use down to -30 °C.Power Supply

The power supply is a special feature of the Power Shuttle. The PS is driven by a power source with SuperCaps and emergency battery. The double layer capacitors (SuperCaps) are charged after each run within 10 s via pressure contacts on the SCR.

The long service life of 1 million charging cycles is a great advantage of the low-maintenance power source.Deep-freeze storage

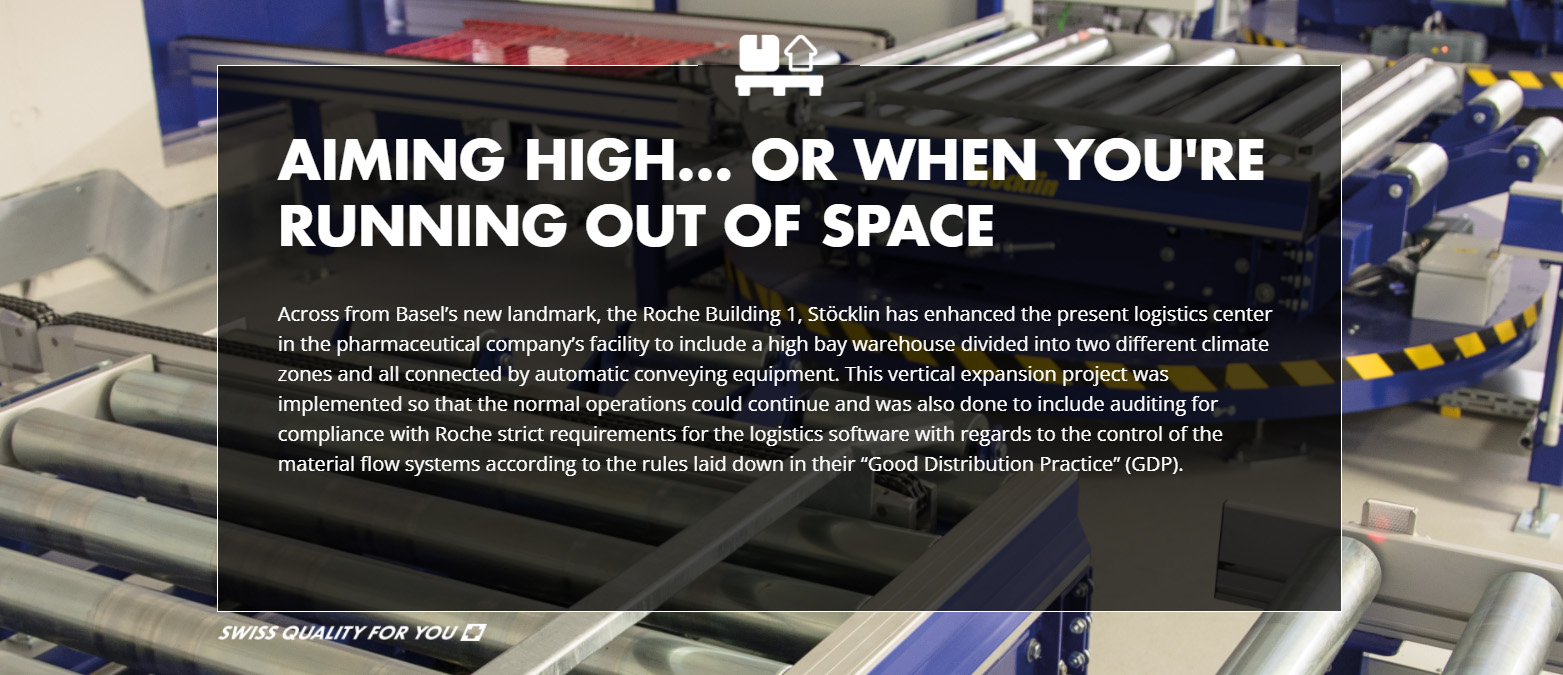

As a manufacturer of cold storage & cold chain technology, Stöcklin also offers you the right intra-company logistics solutions for storage at controlled temperatures. All components in this wide product portfolio are also available for ambient temperatures down to - 30°C.

The change in consumption habits in the foods sector have an impact on food logistics and distribution which has led to massively increased demand for automated deep-freeze storage within the past few years. Stöcklin recognized this trend at an early stage and developed solutions for storing goods in areas with controlled temperature to meet the high requirements of cold chain management by the foodstuffs and pharmaceutical industries.

All standard elements from Stöcklin can be adapted for use in refrigerated storage with temperatures down to -30°C. Naturally, it was not sufficient to only adapt the electrical components, cables, various oils and greases to low ambient temperatures. It was also necessary to use materials suitable for deep-freeze zones in our steel construction.

We guarantee to you the continuous control of the deep-freeze chain from initial storage to picking and shipment. With our experience in intra-logistics and wide range of know-how in product development, we guarantee smooth customer service from planning to after-sales maintenance.Retrofit

Regardless of who supplied your products before, our modular conversion concepts can give your equipment a “second life”.

In the area of retrofitting Stöcklin has its own independent department offering a competent team with many years of know-how, which is very familiar with the desires and requirements of system operators and considers these factors in the planning. Controls and software as well as mechanical components can frequently be retrofitted or converted to meet the increasing requirements of your company, thereby helping you to achieve your set strategic goals.

Our retrofit team is looking forward to using their many years of experience and knowledge to bring your system up to the state of the art for more efficiency, less maintenance and, above all, to ensure that it is always available when you need it. We elaborate and realize solutions with optimum cost/benefit ratio in close cooperation with our customers. The large number of successful realized projects over decades for our customers are the best reference for our competency.Reasons for retrofitting

Our team will be glad to help you evaluate your system to provide you with the right solution to restore efficient and economic operation on the market. Frequent reasons include:- Decreasing availability resulting from malfunctions

- Discontinued product support

- Obsolete higher level ERP and/or WMS systems

- Increased performance requirements

- Noncompliance with apllicable safety standards

- Changes in operating environment

- Increased repair and maintenance costs

- Replace obsolete system components

Driverless transport systems

Transport system solutions for flexibly controlled, driverless material transportation.

In the age of Industry 4.0 driverless transport systems - also known as Automated Guided Vehicles or AGV's - are enjoying increased demand, because they are suitable for transport and secure handling of goods of all types in virtually all branches. This is particularly true in branches, requiring transport or storage and retrieval of unit loads. The vehicles travel along established routes in storage facilities and are controlled by an independent master system or, in large plants, coordinated by a master WMS.

In consideration of the boom in E-commerce, it is essential to adapt AGV's to the changing requirements in production and logistics, by changing the route, for example, without expensive modifications to the floor or to increase the number of vehicles. Automation of intralogistic processes can increase value added for companies, because personnel costs, which add up particularly in multiple shift operation, can be reduced significantly through the use of AGV's.

Stöcklin Logistik is a supplier and manufacturer of automated guided vehicle systems that are based on low-lift transport vehicles, laid out to support weights up to 1,600 kg. These provide robust design and unique price-performance ratio over their entire life cycle.Advantages of our automated transportation management system at a glance

- High user friendliness

- Integrated battery management

- Proven energy efficiency

- Lithium ion technology for maximum availability

- Economical procurement and operation

Putting an AGV fleet equipped with innovative navigation technology is just as simple as integration of further vehicles. An intelligent traffic management system ensures collision-free operation.Intralogistic Software

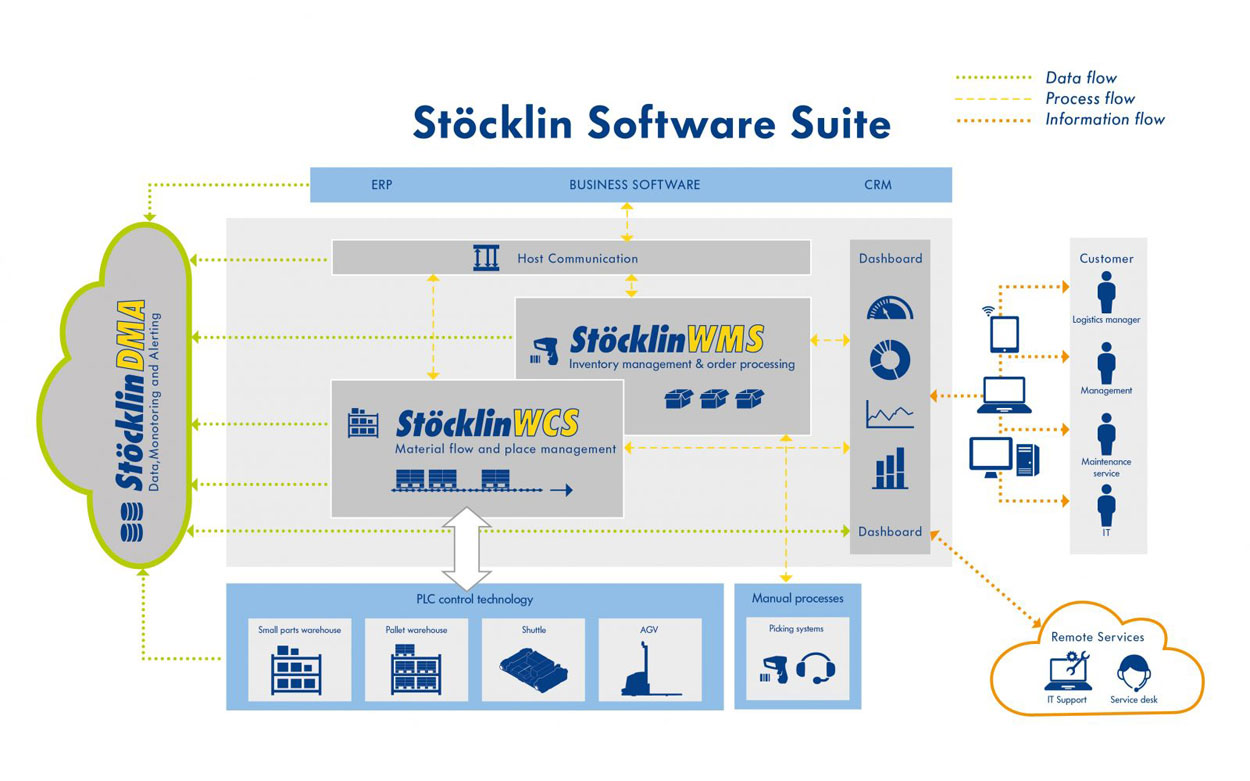

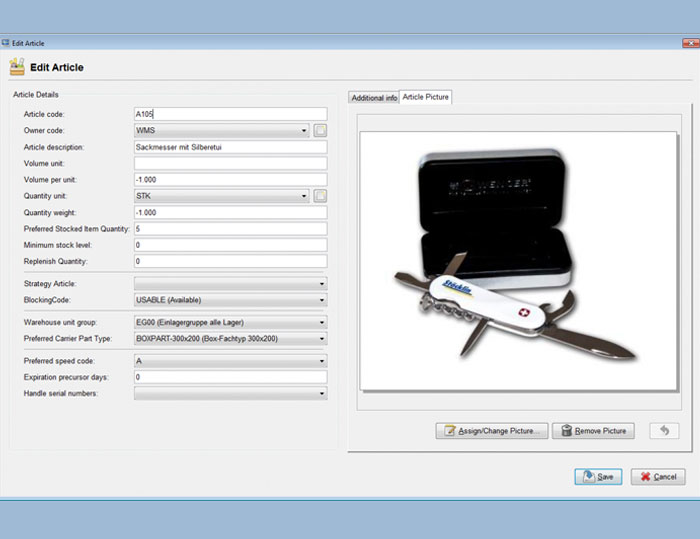

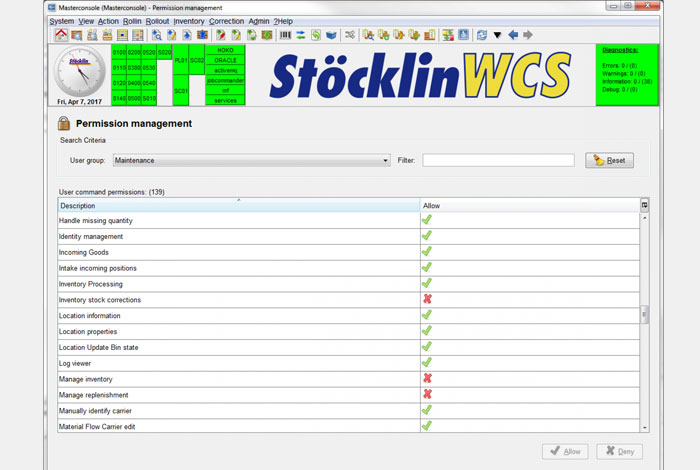

- Stöcklin Logistik is a leading supplier of inventory or warehouse management software. The core modules of Stöcklin’s range of software products include StöcklinWMS and StöcklinWCS, as well as StöcklinDMA, a web-based statistics and monitoring module.

StöcklinWMS (Inventory management & order processing)

StöcklinWMS, a warehouse and order management system, controls all intralogistic processes from receiving to shipping.

During this process it keeps inventory in the storage facilities in which it is installed with optional features such as keeping track of batches, expiration dates and serial numbers.

Moreover it executes retrieval orders specified by the host system depending on the configured material selection strategy and observing the specified provision time. All subprocesses in the retrieval process chain are supported, such as picking, order consolidation, packaging and provision at the ramp.StöcklinWCS (Material flow & place management)

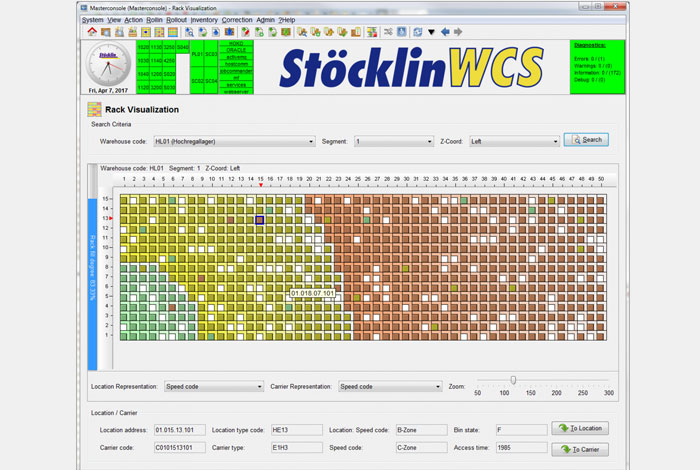

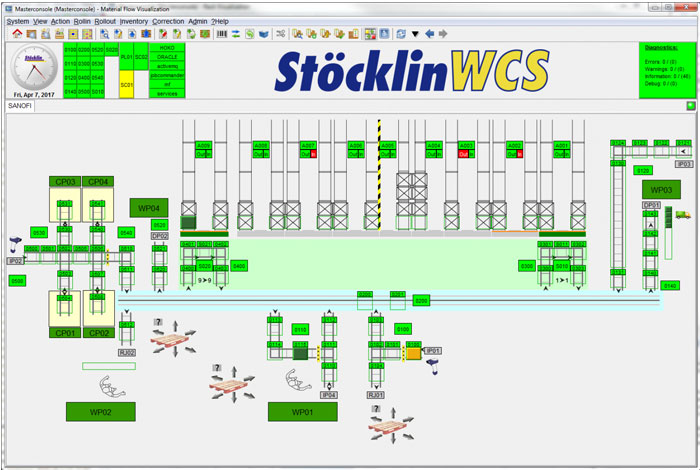

StöcklinWCS, a warehouse management and material flow system for automated storage, can be controlled by the Stöcklin WMS module or directly by a host system using transport orders.

Depending on the system delimitation required, the system can manage all storage locations and optimize its performance using intelligent storage, restorage and retrieval strategies, while guaranteeing any required storage restrictions.

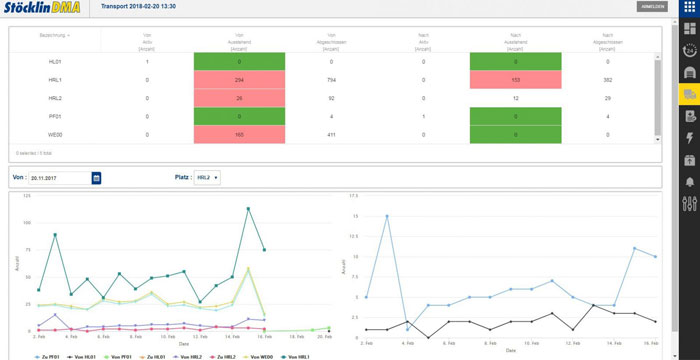

The heart of the StöcklinWCS is a material flow and conveyor control with control center. The material flow control is equipped with a visualization feature for the conveying system, and, in addition to executing transport orders, also optimizes the travel orders based on the sequencing, unavailable routes, priorities, etc.StöcklinDMA (Data, Monitoring & Alerting)

StöcklinDMA includes a web-based statistics and monitoring module. The statistics module assigned logical identification numbers to various peripheral units. The most important system data is logged continuously, allowing many types of evaluation over selected periods of time. The proactive monitoring feature captures and analyzes the states of equipment for all operations, not otherwise subject to logging. For example, this tool, monitors the entire data network for load, failures, etc.

Optimum efficiency and prophylaxis increase system availability. The technologies for Industry 4.0 are ready to go. StöcklinWMS (Inventory management & order processing)

StöcklinWMS, a warehouse and order management system, controls all intralogistic processes from receiving to shipping.

The warehouse and order management system, handles all intra-logistic processes between the receiving department and the shipping department. During this process it keeps inventory in the storage facilities in which it is installed with optional features such as keeping track of batches, expiration dates and serial numbers. The StöcklinWMS handles retrieval orders from the host system selecting the most suited material and observing the specified provision time. Retrieval processes as well as picking, consolidation of orders, packaging and provision at the ramp are supported. The StöcklinWMS can be operated autonomously or controlled by a host system on an order basis.Standardized logistic processes

- Order management

- Stock management

- Client Management

- Strategies for handling serial numbers, expiration dates, batches, quarantined goods, etc.

- Various types of fully automatic picking such as person to goods, goods to person,

- Use of picking aids such as MDE, pick by light, put to light, pick by voice, fork-lift control system

- Standard processes for stock receiving, roll-ins, storage, replenishment, picking, order consolidation, packaging, shipping and inventory

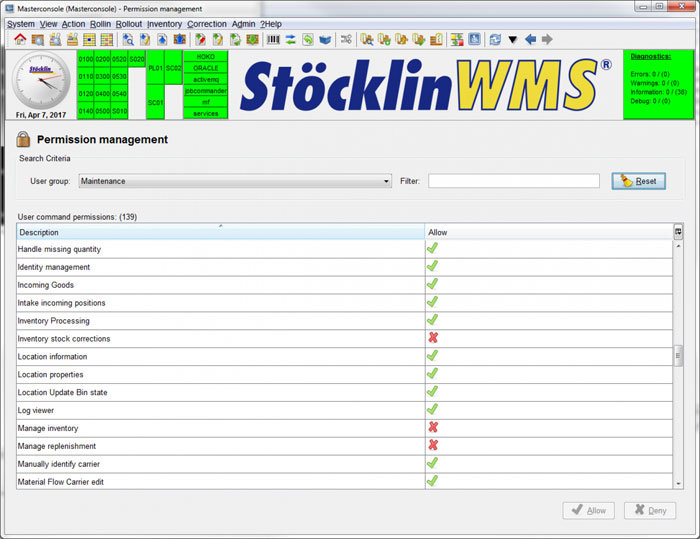

Intuitive User Guidance

- Comprehensive user management

- Multi-lingual

- Interactive user input designed for optimized process control

- Efficient context-related data access

- Continuous logging of process sequences

Optimized realization for new systems as well as for modernization

- Parametrizable processes (adjusting system variables)

- Configurable host interface

- Standardized data acquisition for migration

- Development and realization processes acc. to GAMP

StöcklinWCS (Material flow & place management)

The StöcklinWCS, a warehouse management and material flow system for automated storage, can be controlled by the Stöcklin WMS module or directly by a host system using transport orders.

The StöcklinWCS is located between the host (warehouse management system) and the system controls. Automated communication with the host (warehouse management system) is accomplished by the host communication module in the StöcklinWCS. In addition to storage location management, StöcklinWCS also includes a container management feature as well as the possibility of handling the stored article quantities. If provided in cooperation with the host system, the StöcklinWCS can also take over retrieval strategies in addition to storage strategies.

StöcklinWCS also includes a visualization feature for the storage shelves. This makes it easy to supervise the allocation of each individual storage bay.

As the main user interface, the material flow control has a control center with integrated visualization of the conveying system. The material flow control executes transport orders and confirms their execution to the storage location management or to the host warehouse management system.Intelligent Storage Location Management

- Configurable storage locations

- Zone management within storage facility

- Storage and retrieval strategies with parameterizable strategies for all known storage concepts

- Visualization of storage status with various views

Intuitive User Guidance

- Optimized and intelligent control of material flows on automatic systems

- Inclusion of all conveying and storage operations

- Comprehensive features for energy-optimized operation

- Material flow control for system supervision

Intuitive User Guidance

- Comprehensive user management

- Multi-lingual

- Interactive user input designed for optimized process control

- Efficient context-related data access

- Continuous logging of process sequences

Optimized realization for new systems as well as for modernization

- Parameterizable processes (adjusting system variables)

- Configurable host interface

- Standardized data acquisition for migration

- Development and realization processes acc. to GAMP

StöcklinDMA (Data, Monitoring and Alerting)

- StöcklinDMA includes a web-based statistics and monitoring module. The statistics module assigned logical identification numbers to various peripheral units. The most important system data is logged continuously, allowing many types of evaluation over selected periods of time.

Statistics Module

- A statistics module is available as an option feature for the WMS 5.6. Important data is logged in a separate database partition and compressed at various chronological intervals.

The data for the following main features is logged for statistical purposes:- Storage allocation

- Stocks

- Inventory

- Transport operations

- Stock receiving

- Order picking

- Outgoing goods

- Management of empty containers

- System availability

- Energy Management

The statistics check can be called using a web browser (depending on client security regulations in Intranet only or also in the Internet). In addition to predefined site views, custom site view can also be created. A filter can be used on the observations periods to define the desired data. It is also possible to download the site view as an xml file.

Proactive Monitoring Module

- Optimum efficiency and prophylaxis increase system availability. Proactive monitoring detects pending problems early, preventing down times.

- Different infrastructure technologies offer various access possibilities for logging, collection and intelligent evaluation of data and information.

- Industry 4.0 is on the rise. StöcklinDMA offers the possibility of automatically monitoring intra-logistics, production and IT globally using a tool and outputting alarms according to predefined rules.

Floor Handling Equipment

Hand pallet trucks

The best hand pallet truck in the world!

The robust and economical solution for moving pallets. Special version also available for paper rolls, cable bobbins, etc.

SHR 2000/3000

- High speed lift truck

2-speed hydraulic system for high speed hoisting with optimum force/travel ratio.

Special models:- SHR «Frosty» model for deep freeze applications

- SHR «Silent» model with special noise attenuation for use in residential areas

- SHR «Inox» model: All parts stainless steel (including bearings)

- Special widths and lengths.

Features:- Load capacity up to 3000 kg 2-speed hydraulic system for high speed hoisting with optimum force/travel ratio.

- Switch-over from high speed to normal hoisting is accomplished directly during pumping operation without additional drawbar travel.

- Pumping once is sufficient to raise even heavily loaded pallets allowing them to be moved immediately!

- Full travel with only 3 ½ pumps in high speed hoisting range.

Advantages at a glance:- Optimum running properties

- Long service life

- Low wear on shafts, bolts, bearings, etc.

- Not a throw-away device - repair can extend product life.

SHR 2000 Waage

- High speed lift truck with weighing system

SHR 2002-W and SHR 2004-W:- Weighing capacity: 2000 kg

- Weighing accuracy: 0.1% with display 0.5 kg

- Automatic zeroing

- Gross/net weight readings

- Taring or tare weight entry

- With totalling memory

- IP 65 version

- Battery has plug-in module

Features:- Load capacity up to 2000 kg 2-speed hydraulic system for high speed hoisting with optimum force/travel ratio.

- All hydraulic functions such as high speed switch-over and gradual lowering are incorporated in the Stöcklin valve cartridge; hydraulic system for hoisting with optimum force/travel ratio

- Steering wheels: Aluminium wheels with solid rubber rims

- Steering angle 240°

- Load rollers: Dual polyurethane

- Robust chassis

Sealed bearings

- Shafts running in maintenance-free bushings

Advantages at a glance:- «Ravas» system

- Automatic zeroing

- Automatic power switch-off

- Taring and other functions

- IP 64 moisture protection

SHR 2000 SF

- High speed lift truck for underfloor chains

Towing front operable from both sides with central actuation of driver bolt; also foot control Upon approaching an obstacle, the bolt is lifted out of the driver chain; after clearing the obstacle, the truck moves on automatically. This safety device functions in the vicinity of the floor as well as over the entire surface of the guard plate - even when pallets hang over. Driver bolts can rotate and are hardened in the engagement area. With pitched towing front the truck can be used as a normal high speed lift truck in handling area.

Features:

Load capacity up to 2000 kg

2-speed hydraulic system for high speed hoisting with optimum force/travel ratio.- Steering wheels: Solid rubber rimmed aluminium wheels

- Steering angle 240°

- Load rollers: Single polyurethane

- Robust chassis, sealed bearings

- Shafts running in maintenance-free bushings

- Surface powder coated

- Color: yellow

Advantages at a glance:- Optimum force ratio for high speed operation

- No idle stroke when shifting hydraulic stages

- Low wear

- Long service life

MS 1000

- Manual high lift truck

Very compact, in spite of robust design. Supporting capacity of 1000 kg at 600 mm from center of gravity Lifting heights: 700, 900 and 1200 mm.

Features:- Stroke heights up to 1.2 m

- Load capacity up to 1000 kg

- Stöcklin high speed hydraulic hoisting unit.

- Travel approx. 30 mm (empty) per pump stroke.

- Polyamide (nylon) steering and load rollers for optimum running properties.

- Steering angle 360° Parking brakes on both steering rollers.

- Grate cover on hoisting platform

- The spring force holds the drawbar in the upright position automatically.

- Additional hand rails for moving unit.

- Very compact, in spite of robust design

Advantages at a glance:- Minimum space requirement

- Maximum stability

- Minimum rolling resistance

- High serviceability

- High speed lift

- Can also be moved in raised position

HS 1000

- Manual high lift truck

Minimum dimensions combined with maximum user friendliness.

Features:- Stroke heights up to 1.7 m

- Load capacity up to 1000 kg

- Compact hydraulic assembly with integrated safety valve and manual valve for lifting and infinitely adjustable lowering.

- 12 V battery with built-in charger and retractable, 220V charging cable.

- Steering wheels (solid rubber) and load wheels (nylon) from hand pallet truck line.

- Two additional support wheels d = 82 mm.

- Optimum running properties and 180° steering angle.

- Optional parking brake on steering wheels.

- Very compact design, while still providing optimum accessibility.

Advantages at a glance:

Can be charged from any electrical outlet

Maximum stability

Minimum rolling resistance

Minimum space requirement

High serviceability

Low lift trucks

Simple transport from A to B

For transporting loads over short distances as walk-along or with platform for longer distances.

EDP 16 mini

- Electric palett truck

Minimum dimensions guarantee optimum handling. Perfect as on-board unit for overland trucks.

Features:- Load capacity up to 1600 kg

- Three-phase wheel hub drive

- The center drive with two lateral spring mounted support rollers ensures high stability and optimum traction in material handling.

- Drive unit and the wheels are integrated in the chassis.

- Freely programmable microprocessor controller.

- Minimum dimensions guarantee optimum handling.

- All components are arranged for easy access in spite of compact design.

- Safe lithium 24V/50A with display and mobile app.

- Ideal on-board unit for overland trucks

- Minimum space requirement

- Fast handling

- Ideal handling

- High degree of flexibility

- Safe handling even on slopes

- Careful transport of materials and reduced vehicle wear

- High serviceability

- Optimum response at all times even under changing requirements

- Best quality and long service life

- Three-phase drive

EDP 20

- Drawbar low lift truck

Developed from a new complex modular system with multiple use of standard components. Very rugged despite compact design. Stainless steel axle and bolts for load wheels and hoisting gear. EMERGENCY STOP button, combination operating time counter, battery controller with error code indicator. Built-in charger 30A/230V. Battery 24V − 250 Ah.

Features:- Load capacity up to 2000 kg

- Maintenance-free, smooth-running three-phase AC motor with high torque at lowest speed

- Power recovery during electronic brake application.

- The center drive with two lateral spring mounted and damped carrier rollers ensures high stability and optimum traction in materials handling.

- The centered steering handle provides more agility due to an exceptional of freedom of movement.

Advantages at a glance:- Higher productivity

- Ideal handling

- High degree of flexibility A.C. drive motor with CAN bus technology

- Safe handling even on slopes

- Careful transport of materials and reduced vehicle wear

- Optimum response at all times

- Power saving

- Emergency motion system

- Best quality and long service life

- High serviceability

- Optimum price/benefit ratio

- Rational prices for spare/replacement parts

EDP 2001-P

-

Low lift truck with platform

Minimum dimensions guarantee optimum handling even in extremely close spaces. Vehicle width 680 mm.

Features:- Load capacity up to 2000 kg

- The lateral drive and lateral support rollers (4-point support) ensure high stability and optimum traction for material handling.

- The three-phase drive unit and wheels are integrated into the chassis, where they are protected from damage.

- All wheels made of durable Vulkollan.(polyurethane)

- Double steering rollers ensure sturdiness and easy turning.

Advantages at a glance:- Minimum space requirement

- Fast handling

- Ideal handling

- High degree of flexibility

- Safe handling even on slopes

- Careful transport of materials and reduced vehicle wear

- High serviceability

- Optimum response at all times even under changing requirements

- Best quality and long service life

- CAN BUS technology

- Three-phase drive

EMP 30

- Low lift truck with platform

Simply ingenious - ingeniously simple:

The EMP 30 is an extremely sturdy platform unit for hard use on ramps. The spring mounted, adjustable center drive as well as platform with triple springs, offers excellent operating safety as well as high operating comfort.

Features:- Load capacity up to 3000 kg

- Spring mounted, adjustable center drive

- Triple spring platform

- Servo-steering, standard feature

- AC travel drive

Advantages at a glance:- Developed for use on ramps

- Best quality and long service life

- High serviceability

- Power saving

- Ergonomic side bars or side walls

- Safe handling even on slopes

- Optimum response at all times

EHP 2000 / 3000

- Drawbar low lift truck

Including maintenance-free three-phase motor (2.2 kW) as standard feature. Advantages: Maximum torque at minimum speed, smooth operation. The lateral drive and lateral support roller ensure optimum driving stability. Initial lift for maximum ground clearance. Suitable for loading trucks and picking up pallets cross-wise.

Features:- Load capacity up to 3000 kg

- Maximum ground clearance

- Including maintenance-free, three-phase motor (2.2 kW) as standard feature.

- The lateral drive and lateral support roller ensure optimum driving stability.

- The motor is attached in a stationary position eliminating cable motion when steering.

Advantages at a glance:- Minimum aisle widths

- Suitable for block storage

- Suitable for block storage

- Efficient and rapid handling

- Best quality and long service life

- High serviceability

- Strong drives for high performance

- Three-phase drive

EHP 2000-P / 3000-P

- Low lift truck with platform

Including maintenance-free three-phase motor (2.2 kW) as standard feature. Advantages: Maximum torque at minimum speed, smooth operation. The lateral drive and lateral support roller ensure optimum driving stability. Initial lift for maximum ground clearance. Suitable for loading trucks and picking up pallets cross-wise. With stand-up operator's platform for long distances.

Features:- Load capacity up to 2000 kg

- With stand-up operator's platform

- Including maintenance-free three-phase motor (2.2 kW) as standard feature.

- The lateral drive and lateral support roller ensure optimum driving stability.

- The operating characteristics (acceleration, deceleration, speed) can be adapted to the specific customer requirements. The motor is attached in a stationary position eliminating cable motion when steering.

- All wheels made of durable Vulkollan.(polyurethane)

Advantages at a glance:- Minimum aisle widths

- Suitable for block storage

- Optimum handling

- Efficient and rapid handling

- Best quality and long service life

- High serviceability

- Strong drives for high performance

- Three-phase drive

EFP 2000 / 3000

- Low lift truck with seat

Multi-function handle for all control functions The high standard of human engineering also includes electric steering, an adjustable shock-cushioning seat and padded arm rests with stowage compartments. A further standard feature is the floor platform with adjustable height.

Features:- Load capacity up to 2000 kg

- With seat, suitable for block storage

- Lateral drive and one lateral support roller guarantee optimum traction and operating stability in combination with the terrain compensation integrated into the initial stroke.

- The three-phase drive motor is mounted vertically in a stationary position eliminating cable motions while steering.

- The output of 2.2 kW allows a maximum speed of 12.0 km/h.

- Minimum space requirement

- Fast handling

- Ideal handling

- High degree of flexibility

- Safe handling even on slopes

- Careful transport of materials and reduced vehicle wear

- High serviceability

- Optimum response at all times even under changing requirements

- Best quality and long service life

- CAN BUS technology

- Three-phase drive

ESP 2000 / 3000

- Stand-up low lift truck

Lateral drive and one lateral support roller guarantee optimum traction and operating stability in combination with the terrain compensation integrated into the initial stroke. With width of 800 mm, this truck is also ideal for block storage and loading/unloading overland trucks.

Features:- Load capacity up to 3000 kg

- Stand-up unit

ESP 20 / 30

- Stand-up low lift truck

Lateral drive and one lateral support roller guarantee optimum traction and operating stability in combination with the terrain compensation integrated into the initial stroke. With width of 800 mm, this truck is also ideal for block storage and loading/unloading overland trucks.

Features:- Load capacity up to 3000 kg

- Stand-up unit, suitable for block storage

High lift truck

High stacking can be so simple.

Loading trucks quickly and efficiently, storage in shelves with heights up to 6.3 m - all this is quickly solved with our high lift trucks.

EDS 10 / 12

- Drawbar high lift truck

The side-mounted drawbar provides good visibility for handling and storing loads. The ergonomically designed tiller allows for precise handling even with working gloves. The large rocker switches allow finely controlled, proportional lifting and lowering. Handling in narrow spaces even with vertical steering handle due to the additional bridging switch.

Features:- Stroke heights up to 4.2 m

- Load capacity up to 1000 kg

- Maintenance-free, smooth-running three-phase AC motor with high torque at lowest speed

- User-programmable microprocessor controller

- Optimum serviceability in spite of minimum dimensions

Advantages at a glance:- Higher productivity

- Ideal handling

- High degree of flexibility

- A.C. drive motor with CAN bus technology

- Safe handling even on slopes

- Careful transport of materials and reduced vehicle wear

- Optimum response at all times

- Power saving

- Emergency motion system

- Best quality and long service life

- High serviceability

- Optimum price/benefit ratio

- Rational prices for spare/replacement parts

EDS 14 / 16

- Drawbar high lift truck

Minimum dimensions, maximum user friendliness, state-of-the-art electronic control and rugged Swiss quality!

Features:- Stroke heights up to 4.8 m

- Load capacity up to 1400 kg

- Maintenance-free, smooth-running three-phase AC motor with high torque at lowest speed

- The manual programming console makes it easy to adapt the operating response and other parameters to the customer’s specific requirements.

- Designed with 3D-CAD for compact layout.

Advantages at a glance:- Higher productivity

- Ideal handling

- High degree of flexibility

- A.C. drive motor with CAN bus technology

- Safe handling even on slopes

- Careful transport of materials and reduced vehicle wear

- Optimum response at all times

- Power saving

- Emergency motion system

- Best quality and long service life

- High serviceability

- Optimum price/benefit ratio

- Reasonable prices for spare/replacement parts

EDI 12 / 14 / 16

- Drawbar high lift truck with initial lift

Minimum dimensions, maximum user friendliness, state-of-the-art electronic control and rugged Swiss quality!

Features:- Stroke heights up to 4.8 m

- Load capacity up to 1600 kg

- Maintenance-free, smooth-running three-phase AC motor with high torque at lowest speed.

- User-programmable microprocessor controller

- The side-mounted drawbar provides optimum visibility for handling and storing loads

Advantages at a glance:- Higher productivity

- Ideal handling

- High degree of flexibility

- A.C. drive motor with CAN bus technology

- Safe handling even on slopes

- Careful transport of materials and reduced vehicle wear

- Optimum response at all times

- Power saving

- Emergency motion system

- Best quality and long service life

- High serviceability

- Optimum price/benefit ratio

- Reasonable prices for spare/replacement parts

EMI 16

- High lift truck with platform

Simply ingenious - ingeniously simple:

The EMI 16 is an extremely sturdy platform unit for hard use on ramps. The spring mounted, adjustable center drive as well as platform with triple springs, offers excellent operating safety as well as high operating comfort.

Features:- Stroke heights up to 3.9 m

- Load capacity up to 1600 kg

- Spring mounted, adjustable center drive

- Triple spring platform

- Servo-steering, standard feature

- AC traction drive / steering drive

- Speed-regulated stroke

- Double tier use up to stroke height of 1,800 mm

Advantages at a glance:- Developed for use on ramps

- Best quality and long service life

- High serviceability

- Power saving

- Ergonomic side bars or side walls

- Safe handling even on slopes

- Always optimum traveling and lifting characteristics

- Lithium ion battery technology

EDD 12

- Double tier high lift truck

Minimum dimensions, maximum user friendliness, state-of-the-art electronic control and rugged Swiss quality!

Features:- Stroke heights up to 2.4 m

- Load capacity up to 2000 kg

- Double tier stacker

Advantages at a glance:- Higher productivity

- Ideal handling

- High degree of flexibility A.C. drive motor with CAN bus technology

- Safe handling even on slopes

- Careful transport of materials and reduced vehicle wear

- Optimum response at all times

- Power saving

- Emergency motion system

- Best quality and long service life

- High serviceability

- Optimum price/benefit ratio

- Reasonable prices for spare/replacement parts

EDD 1001-P

- Double tier high lift truck with platform

Minimum dimensions, maximum user friendliness, state-of-the-art electronic control and rugged Swiss quality!

Features:- Stroke heights up to 2.6 m

- Load capacity up to 1200 kg

- Double tier with platform

- The three-phase drive unit and wheels are integrated into the chassis, where they are protected from damage.

- User-programmable microprocessor controller

Advantages at a glance:- Fast handling

- Ideal handling

- High degree of flexibility

- Safe handling even on slopes

- Careful transport of materials and reduced vehicle wear

- High serviceability

- Optimum response at all times even under changing requirements

- Best quality and long service life CAN BUS technology

- Three-phase drive

EHS 1600 / 2000

- Drawbar high lift truck

These standard free view hoisting platforms are available in various overall heights (optionally with full free travel).

Features:- Stroke heights up to 5.2 m

- Load capacity up to 2000 kg

- Including maintenance-free three-phase motor (2.2 kW) as standard feature

- User-programmable microprocessor controller

- These standard free view hoisting platforms are available in various overall heights (optionally with full free travel).

Advantages at a glance:- Minimum aisle widths

- Suitable for block storage

- Optimum handling

- Efficient and rapid handling

- Best quality and long service life

- High serviceability

- Strong drives for high performance

- Three-phase drive

EHI 1600 / 1800

- Drawbar high lift truck with initial lift

Compact and easy to handle

Features:- Stroke heights up to 5.2 m

- Load capacity up to 1800 kg

- Initial lift for maximum ground clearance. Suitable for loading trucks and picking up pallets cross-wise.

- Combined, user-programmable microprocessor controller for drive and hydraulic system.

- All wheels made of durable Vulkollan.(polyurethane)

Advantages at a glance:- Minimum aisle widths

- Suitable for block storage

- Fast handling Ideal handling

- High serviceability

- Optimum response at all times even under changing requirements

- Best quality and long service life

- Strong drives for high performance

- CAN BUS technology

- Three-phase drive

EHI 1600-P / 1800-P

- High lift truck with platform

Minimum dimensions, maximum user friendliness, state-of-the-art electronic control and rugged Swiss quality!

Features:- Stroke heights up to 5.2 m

- Load capacity up to 1800 kg

- Including maintenance-free three-phase motor (2.2 kW) as standard feature

- Combined, user-programmable microprocessor controller for drive and hydraulic system.

- The center-mounted drawbar with free-view masts provides good visibility for handling and storing loads.

Advantages at a glance:- Minimum aisle widths

- Suitable for block storage

- Fast handling Ideal handling

- High serviceability

- Optimum response at all times even under changing requirements

- Best quality and long service life

- Strong drives for high performance

- CAN BUS technology

- Three-phase drive

EFS 1600 / 2000

- High lift truck with seat

Minimum dimensions, maximum user friendliness, state-of-the-art electronic control and rugged Swiss quality!

Features:- Stroke heights up to 6.3 m

- Load capacity up to 1600 kg

- Crosswise seating

- Lateral drive and one lateral carrier roller guarantee optimum traction and operating stability

- Combined, user-programmable MOS microprocessor controller for drive and hydraulic system.

Advantages at a glance:- Minimum aisle widths

- Suitable for block storage

- Fast handling Ideal handling XXL version available for large operators High serviceability

- Optimum response at all times even under changing requirements

- Best quality and long service life

- Strong drives for high performance

- CAN BUS technology

- Three-phase drive

EFI 16 / 18

- High lift truck with seat and initial lift

Minimum dimensions, maximum user friendliness, state-of-the-art electronic control and rugged Swiss quality!

Features:- Stroke heights up to 5.2 m

- Load capacity up to 1800 kg

- Lateral drive and one lateral support roller guarantee optimum traction and operating stability in combination with the terrain compensation integrated into the initial stroke.

- The operating characteristics (acceleration, deceleration, speed) can be adapted to the specific customer requirements.

- Multi-function handle for all control functions

Advantages at a glance:- Minimum aisle widths

- Suitable for block storage

- Fast handling

- Ideal handling

- High serviceability

- Optimum response at all times even under changing requirements

- Best quality and long service life

- Strong drives for high performance

- CAN BUS technology

- Three-phase drive

ESS 1600 / 2000

- Stand-up high lift truck

Minimum dimensions, maximum user friendliness, state-of-the-art electronic control and rugged Swiss quality!

Features:- Stroke heights up to 6.3 m

- Load capacity up to 2000 kg

- Stand-up platform for operator

- Lateral drive and one lateral carrier roller guarantee optimum traction and operating stability

- With width of 800 mm, this truck is also ideal for block storage.

Advantages at a glance:- Minimum aisle widths

- Suitable for block storage

- Optimum human engineering

- Efficient and rapid handling

- Handling characteristics matched to operation

- Best quality and long service life

- Three-phase drive

ESI 1600 / 1800

- Stand-up high lift truck with initial lift

This truck is an HFS series product designed consistently using the module principle. Various openings and an ingenious, hinged mechanism allow easy access to all areas requiring maintenance. A roll-out mechanism is provided for operation with interchangeable batteries. Various mast versions with partial or full free stroke are available for selection. In addition to the tandem load rollers, an EMERGENCY OFF Button and combination operating time counter/battery monitor are included as standard features.

Features:- Stroke heights up to 5.2 m

- Load capacity up to 1800 kg

- Stand-up platform for operator with initial lift

- Lateral drive and one lateral support roller guarantee optimum traction and operating stability in combination with the terrain compensation integrated into the initial stroke.

- Combined, user-programmable microprocessor controller for drive and hydraulic system.

Advantages at a glance:- Minimum aisle widths

- Suitable for block storage

- Optimum human engineering

- Efficient and rapid handling

- Handling characteristics matched to operation

- Best quality and long service life

- Three-phase drive

ESI 12.5

- Stand-up high lift truck with initial lift

Developed from a new complex modular system with multiple use of standard components. Very rugged despite compact design. Stainless steel axle and bolts for load wheels and hoisting gear. Various fork-lift frames available from stock. Battery change from side. EMERGENCY STOP button, combination working time meter, battery controller with error code indicator. Battery 24V – 465Ah.

Features:- Stroke heights up to 2.4 m

- Load capacity up to 1250 kg

- Stand-up platform for operator with initial lift

- Maintenance-free, smooth-running, three-phase AC motors with high torque at lowest speed.

- User-programmable microprocessor controller

Advantages at a glance:- Higher productivity

- Ideal handling

- High degree of flexibility

- Three-phase drive and steering system with CAN bus technology

- Safe handling even on slopes

- Careful transport of materials and reduced vehicle wear

- Optimum response at all times

- Power saving

- Emergency motion system

- Best quality and long service life

- High serviceability

- Optimum price/benefit ratio

- Rational prices for spare/replacement parts

EHS 1600-P / 2000-P

- High lift truck with platform

These standard free view hoisting platforms are available in various overall heights (optionally with full free travel).

Features:- Stroke heights up to 5.2 m

- Load capacity up to 2000 kg

- User-programmable microprocessor controller

- The width of 800 mm is ideal for block storage

- The center-mounted drawbar with free-view masts provides good visibility for handling and storing loads.

Advantages at a glance:- Minimum aisle widths

- Suitable for block storage

- Optimum handling

- Efficient and rapid handling

- Best quality and long service life

- High serviceability

- Strong drives for high performance

- Three-phase drive

Picker

Picking is easy as pie

With our equipment with its ergonomic workstations picking is easy as pie.

ESPK 20 / ESPK 20-H

- Electric, stand-up picker

Optimum for tight spaces with an overall width of 800 mm. Very rugged despite compact design.

Features:- Load capacity up to 2000 kg

- High operating speed: 14 km/h

- All wheels (load rollers inclusive) made of durable Vulkollan.(polyurethane)

- User-programmable microprocessor controller

Advantages at a glance:- Low, simple access

- Ideal handling

- High degree of flexibility

- Three-phase drive and steering system with CAN bus technology

- High operating speed: 14 km/h

- Operation outside vehicle also possible

- Emergency motion system (LOS)

- Best quality and long service life

- High serviceability

- Optimum price/benefit ratio

- Rational prices for spare/replacement parts

ESIK 12.5 A18

- Electric, stand-up picker

Optimum for tight spaces with an overall width of 800 mm. Very rugged despite compact design.

Features:- Stroke heights up to 1.8 m

- Load capacity up to 2000 kg

- Cantilever forks

- Maintenance-free, smooth-running three-phase AC motors with high torque at lowest speed and extremely smooth operation.

- User-programmable microprocessor controller

Advantages at a glance:- Low, simple access

- Ideal handling

- High degree of flexibility

- Three-phase drive and steering system with CAN bus technology

- High operating speed: 12 km/h

- Operation outside vehicle also possible

- Optimum stability at all times

- Emergency motion system (LOS)

- Best quality and long service life

- High serviceability

- Optimum price/benefit ratio

- Reasonable prices for spare/replacement parts

Explosion protection equipment

ATEX/IECEx certified and type tested.

Our decades of experience in the field of explosion protection ensure safety in your company. Choose Stöcklin as a certified manufacturer and designer of a wide range of floor handling equipment with explosion protection.

EXP 20

- for ATEX Zone 1 (2G) and 21 (2D)

Stöcklin Logistik AG is certified as a manufacturer of explosion protection floor handling equipment for the European market by ATEX and also has IECEX certification, which is recognized worldwide. Our model for explosion hazard zones 1/21 is approved by ATEX as well as IECEX.

Features:- Load capacity up to 2000 kg

- AC travel drive

- AC lift motor

- CAN-BUS technology

- II 2G Ex de IIB+H₂ T4 Gb

- II 2D Ex tb IIIB T135°C Db

Advantages at a glance:- Dimensions and appearance same as standard unit

- Ideal handling

- High degree of flexibility

- Safe handling even on slopes

- Always optimum traveling and lifting characteristics

- Power saving

- Best quality and long service life

- High serviceability

EXS 16

- Drawbar high lift truck for ATEX Zone 1 (2G) and 21 (2D)

Stöcklin Logistik AG is certified as a manufacturer of explosion protection floor handling equipment for the European market by ATEX and also has IECEX certification, which is recognized worldwide. Our model for explosion hazard zones 1/21 is approved by ATEX as well as IECEX.

Features:- Stroke heights up to 4.8 m

- Load capacity up to 1600 kg

- AC travel drive

- AC lift motor with speed control

- CAN-BUS technology

- II 2G Ex de IIB+H₂ T4 Gb

- II 2D Ex tb IIIB T135°C Db

Advantages at a glance:- Dimensions and appearance same as standard unit

- Ideal handling

- High degree of flexibility

- Safe handling even on slopes

- Always optimum traveling and lifting characteristics

- Power saving

- Best quality and long service life

- High serviceability

EXI 16

- Drawbar high lift truck for ATEX Zone 1 (2G) and 21 (2D)

Stöcklin Logistik AG is certified as a manufacturer of explosion protection floor handling equipment for the European market by ATEX and also has IECEX certification, which is recognized worldwide. Our model for explosion hazard zones 1/21 is approved by ATEX as well as IECEX.

Features:- Stroke heights up to 4.8 m

- Load capacity up to 1600 kg

- AC travel drive

- AC lift motor with speed control

- CAN-BUS technology

- II 2G Ex de IIB+H₂ T4 Gb

- II 2D Ex tb IIIB T135°C Db

Advantages at a glance:- Dimensions and appearance same as standard unit

- Ideal handling

- High degree of flexibility

- Safe handling even on slopes

- Always optimum traveling and lifting characteristics

- Power saving

- Best quality and long service life

- High serviceability

EXG 035 Barrel tipping clamp

- Barrel tipping clamp with drawbar for ATEX zones 1 (2G) and 21 (2D) with pantograph feed option

Stöcklin Logistik AG is certified as a manufacturer of explosion protection floor handling equipment for the European market by ATEX and also has IECEX certification, which is recognized worldwide. Our model for explosion hazard zones 1/21 is approved by ATEX as well as IECEX.

Features:- Stroke heights up to 4.8 m

- Load capacity up to 350 kg

- AC travel drive AC lift motor with speed control

- CAN-BUS technology

- II 2G Ex de IIB+H₂ T4 Gb

- II 2D Ex tb IIIB T135°C Db

Advantages at a glance:- Dimensions and handling same as a standard unit

- Traction always good thanks to center drive

- Clear, sensitive levers for the 4 hydraulic functions

- All plastics electrically conductive Internal self-monitoring

- Maximum maintenance friendliness thanks to brushless AC motors

- Also available with the patented LITHIUM Ex "LiTex", a world first

EHI 1600

- Drawbar high lift truck for ATEX Zone 1 and 2

Stöcklin has produced forklifts for use in explosion hazard areas for over 30 years, providing a wealth of experience for this sensitive application.

Features:- Stroke heights up to 5.2 m

- Load capacity up to 1600 kg

- The center-mounted drawbar with free-view masts provides good visibility for handling and storing loads.

- Including maintenance-free three-phase motor (2.2 kW) as standard feature

- Combined, user-programmable microprocessor controller for drive and hydraulic system.

- Ex 2G/3G acc. to Atex (Zone 1 and 2)

Advantages at a glance:- Minimum aisle widths

- Suitable for block storage

- Fast handling

- Ideal handling

- High serviceability

- Optimum response at all times even under changing requirements

- Best quality and long service life

- Strong drives for high performance

- CAN BUS technology

- Three-phase drive

SHR 2000

- High speed lift truck

- Explosion hazard 2G IIC T6

- 2D IIIC T85 °C

Features:- Load capacity up to 2000 kg

- 2-speed hydraulic system for high speed hoisting with optimum force/travel ratio.

- All hydraulic functions such as high speed switch-over and gradual lowering are incorporated into the Stöcklin valve cartridge.

- Steering wheels: Solid rubber rimmed aluminium wheels

Advantages at a glance:- Optimum force ratio for high speed operation

- No idle stroke when shifting hydraulic stages

- Low wear

- Long service life

- «Ravas» system

- Automatic zeroing

- Automatic power switch-off Taring and other functions

- IP 64 moisture protection

SHR 2000 SCALES

- High speed lift truck with weighing system

EEx ia IIB T4 explosion protection version

Features:- Load capacity up to 2000 kg

- 2-speed hydraulic system for high speed hoisting with optimum force/travel ratio.

- All hydraulic functions such as high speed switch-over and gradual lowering are incorporated into the Stöcklin valve cartridge.

- Steering wheels: Solid rubber rimmed aluminium wheels.

Advantages at a glance:- Steering wheels: Solid rubber rimmed aluminium wheels.

- No idle stroke when shifting hydraulic stages

- Low wear

- Long service life

- «Ravas» system

- Automatic zeroing

- Automatic power switch-off

- Taring and other functions

- IP 64 moisture protection

INOX equipment

For use in foodstuffs industry (meat / cheese) and pharmaceutical industry

Our Inox stackers are constructed entirely of stainless steel so that they are absolutely rust-free and have an extremely long service life. They are perfect for use in wet areas or for companies in the pharmaceutical branch. On request, we can also provide many of our other floor handling equipment partially or completely in INOX stainless steel.

SHR 2000 INOX

- Stainless steel rapid pallet truck

INOX 100% stainless steel parts - incomparable quality

Features:- Load capacity up to 2000 kg

- 100% stainless steel high speed lift truck

- All hydraulic functions such as high speed switch-over and gradual lowering are incorporated into the Stöcklin valve cartridge

- 2-speed hydraulic system for high speed hoisting with optimum force/travel ratio

Advantages at a glance:- Optimum force ratio for high speed operation

- No idle stroke when shifting hydraulic stages

- Long drawbar reduces forces required

- Minimum maintenance requirements

- Optimum running properties

- 100% stainless steel parts for long service life Low wear on shafts, bolts, bearings, etc.

- Not a throw-away device - repair can extend product life.

EDP INOX

- Electric low-lift pedestrian truck

- All construction parts stainless steel

- Completely hygienic

- Electronic circuitry protected against moisture

- Surface cleaned and glass-bead blasted Supporting capacity 2,000 kg

Features:- Load capacity up to 2000 kg

- All construction parts stainless steel

- The center drive with two lateral, spring mounted support rollers (three point support) ensures optimum traction for material handling.

- User-programmable MOS microprocessor controller.

Advantages at a glance:- Minimum space requirement

- Fast handling Ideal handling

- High degree of flexibility

- Completely hygienic

- Safe handling even on slopes

- Careful transport of materials and reduced vehicle wear

- High serviceability

- Optimum response at all times even under changing requirements

- Best quality and long service life

- Three-phase drive

EDD INOX

- Double tier

- All construction parts stainless steel

- Completely hygienic

- Electronic circuitry protected against moisture

- Surface cleaned and glass-bead blasted

- Supporting capacity 1,200 kg

Features:- Stroke heights up to 2.4 m

- Load capacity up to 1200 kg

- All construction parts stainless steel

- Double tier

- Combined, user-programmable microprocessor controller for drive and hydraulic system

Advantages at a glance:- Minimum space requirement

- Fast handling

- Excellent visibility for easy handling

- High degree of flexibility

- Safe handling even on slopes

- Careful transport of materials and reduced vehicle wear

- High serviceability

- Optimum response at all times even under changing requirements

- Best quality and long service life

EHS INOX

- Electric walkie high lift truck

- All construction parts stainless steel

- Completely hygienic

- Electronic circuitry protected against moisture

- Supporting capacity up to 1250 kg

Features:- Stroke heights up to 5.2 m

- Load capacity up to 1250 kg

- All construction parts stainless steel

Automated guided vehicles (AGV)

The way to driverless Industry 4.0

Stöcklin is the right partner for meeting the high demands placed on driverless transport vehicles - also known as automated guided vehicles or AGV's. We offer one-stop shop solutions covering a wide range of applications, from simple transport orders to complex automated systems including WMS interface.

Eagle-Ant 0

- Driverless floor handling equipment

This is a simple, long life transport vehicle for transporting pallets and similar cargo from A to B without interruptions. Single and autonomous or in complex network with many vehicles.

Features:- Load capacity up to 1600 kg

- Innovative navigation technology - the ANT lite from BlueBotics

- From simple single order entry to complex WMS link

- Clever traffic management for numerous vehicles

- Quick integration of further vehicles

- Building scanning and teach-in tour for quick and simple IBS

- Speed up to 1.6 m/s

Advantages at a glance:- Well protected laser scanner for safety and navigation

- Order and position control with WiFi communication

- New, intelligent lithium ion battery

- Problem-free route modification

- Supported 24/7 by Stöcklin HELP DESK available

Eagle-Ant 1

- Driverless high lift truck

Derived from its brother Eagle-Ant 0 with short hoisting platform. Two safety scanners for all round safety. Ideal machine for integration into logistics process. Link to high-bay warehouse, infeed conveyors, etc.

Features:- Stroke heights up to 1.2 m

- Load capacity up to 1200 kg

- Innovative navigation technology - the ANT lite from BlueBotics

- From simple single order entry to complex WMS link

- Clever traffic management for numerous vehicles

- Quick integration of further vehicles

- Building scanning and teach-in tour for quick and simple IBS

Advantages at a glance:- Well protected laser scanner for safety and navigation

- Order and position control with WiFi communication

- New, intelligent lithium ion battery

- Problem-free route modification

- Supported 24/7 by Stöcklin HELP DESK available

Automated guided vehicles (AGV)

The way to driverless Industry 4.0

Stöcklin is the right partner for meeting the high demands placed on driverless transport vehicles - also known as automated guided vehicles or AGV's. We offer one-stop shop solutions covering a wide range of applications, from simple transport orders to complex automated systems including WMS interface.

Eagle-Ant 0

- Driverless floor handling equipment

This is a simple, long life transport vehicle for transporting pallets and similar cargo from A to B without interruptions. Single and autonomous or in complex network with many vehicles.

Features:- Load capacity up to 1600 kg

- Innovative navigation technology - the ANT lite from BlueBotics

- From simple single order entry to complex WMS link

- Clever traffic management for numerous vehicles

- Quick integration of further vehicles

- Building scanning and teach-in tour for quick and simple IBS

- Speed up to 1.6 m/s

Advantages at a glance:- Well protected laser scanner for safety and navigation

- Order and position control with WiFi communication

- New, intelligent lithium ion battery

- Problem-free route modification

- Supported 24/7 by Stöcklin HELP DESK available

Eagle-Ant 1

- Driverless high lift truck

Derived from its brother Eagle-Ant 0 with short hoisting platform. Two safety scanners for all round safety. Ideal machine for integration into logistics process. Link to high-bay warehouse, infeed conveyors, etc.

Features:- Stroke heights up to 1.2 m

- Load capacity up to 1200 kg

- Innovative navigation technology - the ANT lite from BlueBotics

- From simple single order entry to complex WMS link

- Clever traffic management for numerous vehicles Quick integration of further vehicles Building scanning and teach-in tour for quick and simple IBS

Advantages at a glance:- Well protected laser scanner for safety and navigation

- Order and position control with WiFi communication

- New, intelligent lithium ion battery

- Problem-free route modification

- Supported 24/7 by Stöcklin HELP DESK available

Special construction / custom design

We build everything physically possible.

Custom tailored products are frequently the only solution for your logistic challenges, whether you have unusual loads, changing ambient conditions or other special requirements for your loads.

Our optimized module system allows special solutions at reasonable prices. Stöcklin offers partially standardized branch solutions and guarantees long term availability of parts by using as many standard equipment parts as possible.

High loads

- Low lift trucks for loads up to 5,000 kg with fork dimensions for European pallets with single drive and up to 10,000 kg with custom twin drive adapted to specific client requirements. Unique high lift trucks for loads up to 3,000 kg for Euro pallets and custom versions for higher loads.

Features:- Load capacity bis 10,000 kg

- Euro-pallets up to 5,000 kg

Advantages at a glance:- Custom solutions

- Use of standard components from series vehicles

- Long term availability of parts

- Long term availability of parts

Paper and printing industry

- Special low lift trucks

We have many years of experience with branch solutions, for example, for the printing industry. Hard operating conditions, dusty atmospheres and high loads. Whether horizontal transport of paper rolls or special manipulation devices, we can find the right solution for you.

Features:- Roll transport

- Transport of printing shop cartridges

Advantages at a glance:- Custom solutions

- Use of standard components from series vehicles

- Long term availability of parts

- CE conformity

Hydraulic attachment equipment

- Secure handling for your applications. Units with barrel tipping clamps, fork adjustment mechanisms, side pushers right up to pallet turners can be laid out and built to meet your requirements. With us, you are also in good hands for meeting your requirements for explosion protection.

Features:- For example: 180° barrel tipping clamps

- For example: 180° barrel tipping clamps

Advantages at a glance:- Custom solutions

- Use of standard components from series vehicles

- Long term availability of parts

- CE conformity

Cantilever fork tines

- Trucks with straddle chassis are perfect for high loads with remaining supporting capacity or low pallet entry heights. When wheel arms interfere with your applications, we offer solutions with counter-weight forklifts.

Features:- Straddle chassis up to 4,000 kg

- Counterweights up to 1,500 kg

Advantages at a glance:- Custom solutions

- Use of standard components from series vehicles

- Long term availability of parts

- CE conformity

4-way forklifts

- We offer 4-way drawbar units to solve your problems with transporting long goods or when the passage is very small. As an option, the trucks can also be produced with additional telescopic forks when it is not possible to move beneath the rack during storage.

Features:- Up to 3000 kg

- Stroke up to 5,200 mm

Advantages at a glance:- Custom solutions

- Use of standard components from series vehicles

- Long term availability of parts

- CE conformity

Special load carriers and equipment

- Do you have a special load to handle or move under particular conditions of use? We can work out a suitable solution in cooperation with you.

Features:- Laid out to costumer specifications

- Custom solution

- Use of standard components from series vehicles

- Long term availability of parts

- CE conformity

Other equipment

- If you require completely custom tailored equipment, checking with us is worthwhile. We can design a custom tailored solution to meet your specific needs. We lay this equipment out to meet CE standards and also confirm its conformity.

Features:- For custom requirements

Advantages at a glance:- Custom solutions

- Use of standard components from series vehicles

- Long term availability of parts

- CE conformity

Hyundai electric forklift trucks

Zero emissions - full power

Emission-free and quiet is the perfect description for Stöcklin’s high performance electric forklifts with supporting capacity of 1,000 to 8,000 kg.

10 / 13 / 15BTR-9

- Electric forklift truck

Your satisfaction is our utmost priority!

Positive points for the newly developed 3-wheel electric forklifts with counterweight and rear wheel drive are excellent handling, higher productivity and simple maintenance.

Features:- Stroke heights up to 6.0 m

- Load capacity up to 1500 kg

- 3-wheel electric forklift truck (24V) LSP 500 mm

- The closed drive and pump motor with AC technology are distinguished by their high performance, long maintenance intervals and excellent durability.

Advantages at a glance:- Maximum performance

- Spacious operator cab

- Control with miniature joystick (optional)

- Weight display (optional)

- Safety system prevents overloading (optional)

- Side loading system for battery

- Wet brakes as standard feature

15 / 18 / 20BT-9

- Electric forklift truck

Your satisfaction is our utmost priority!

Positive points for the newly developed 3-wheel electric forklifts with counterweight and front wheel drive are excellent handling, higher productivity and simple maintenance.

Features:- Stroke heights up to 7.0 m

- Load capacity up to 2000 kg

- The driver protection roof fulfills and even exceeds all CEE and ANSI requirements, while providing an excellent panoramic view.

- LSP 500 mm

- When lowering the forks, the lowering valve regulates the lowering speed

Advantages at a glance:- Maximum performance

- Spacious operator cab

- Miniature joystick (optional)

- Weight display (optional)

- Safety system prevents overloading (optional)

- Side loading system for battery

- Curve control system

16 / 18 / 20B-9

- Electric forklift truck

Your satisfaction is our utmost priority!

The advantages of the newly developed four-wheel electric forklift truck with counterweights include convenient operation, higher productivity and simple maintenance.

Features:- Stroke heights up to 7.0 m

- Load capacity up to 2000 kg

- 4-wheel electric forklift truck (48V)

- LSP 500 mm

Advantages at a glance:- Maximum performance

- Spacious operator cab

- Miniature joystick (optional)

- Weight display (optional)

- Safety system prevents overloading (optional)

- Side loading system for battery

- Curve control system

22 / 25 / 30 / 32 / 35B-9

- Electric forklift truck

Your satisfaction is our utmost priority!

The advantages of the newly developed four-wheel electric forklift truck with counterweights include convenient operation, higher productivity and simple maintenance.

Features:- Stroke heights up to 7.9 m

- Load capacity up to 3500 kg 4-wheel electric forklift truck (48V) LSP 500 mm

- The closed drive and pump motor with AC technology are distinguished by their high performance, long maintenance intervals and excellent durability.

Advantages at a glance:- Maximum performance

- Spacious operator cab