- Offer Profile

- The up-to-date development, research and production facilities of JVL employ only the latest technology for the development and production of electronic controls for step- and servo motors. More than 50% of the staff are engineers with a very high degree of experience and competence in the field of motion control. They are all highly motivated and innovative, and we can therefore offer a product program today that includes all the necessary units and components to build up complete motor control systems.

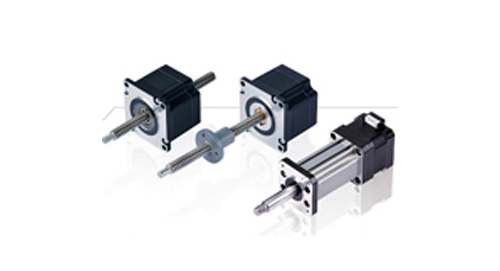

NEW PRODUCTS!

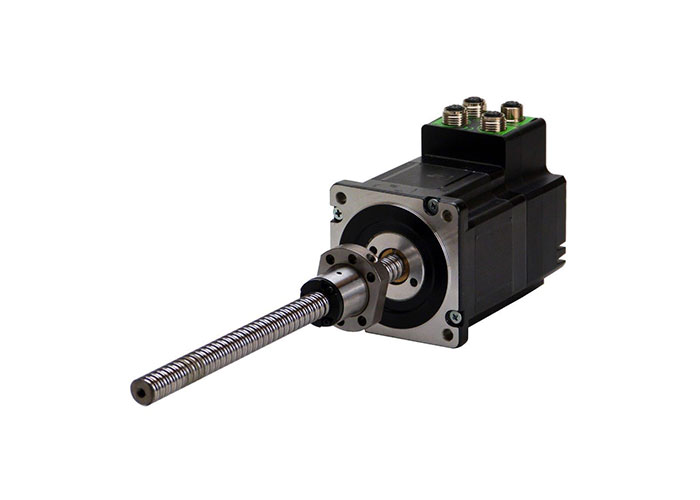

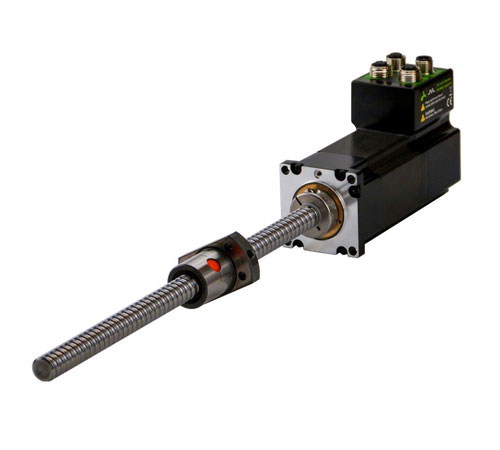

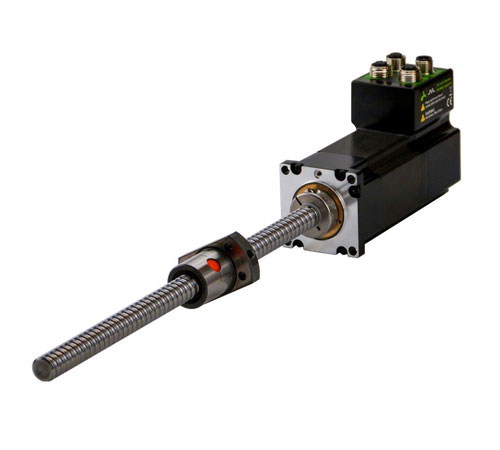

NEMA17 and 23 stepper with ball screw piston captive rod actuator up to 2200N peak

-

Introducing the latest innovation from JVL A/S, a global leader in integrated servo and stepper motors – the ServoStep™ motors line welcomes a groundbreaking addition: the Piston Captive Style Actuator, also known as the Electric Linear Rod Actuator. Engineered with precision and durability in mind, this new actuator boasts a built-in high-quality ball screw and a non-rotating guide, ensuring extended operational lifespan. Unlike traditional setups, the ball screw is seamlessly integrated into the motor shaft, offering an exceptionally compact solution and a shorter actuator length.

Linear stepper motors can reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. It does not only reduce the cost and length but also reduces the failure rate due to fewer components and a simpler construction.

In applications with small radial load ratings a linear guide is not required. The special design and use of ball screw and low friction guide enables long life operation, increased efficiency, or reduced maintenance requirements.

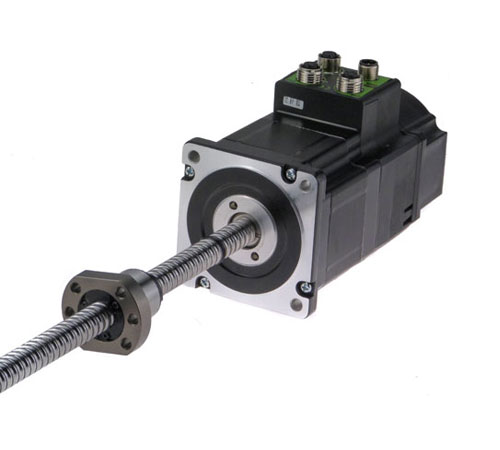

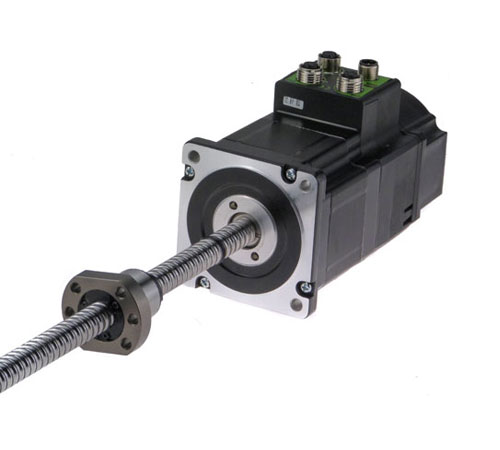

IP65 Integrated linear stepper motor with ball or lead screw NEMA34 up to 4900 N force

-

JVL A/S, one of the world’s leading producers in the field of integrated servo and stepper motors, is announcing yet another addition to its ServoStep™ motors, with integrated spindles featuring either ball screws or lead screws, now equipped with IP65 water and dust protection and operation down to minus 20 degree Celsius.

IP65 motor features with ball or lead screw- Motor coated with special multilayer epoxy paint

- Special Teflon sealing at the motor shaft

- All connectors and openings sealed to prevent water and dust ingress

- Every motor rigorously tested at the factory with certificate

- Optional lead screws suitable for use in dusty and wet environment

- Optional integrated brake

MIS Motor, Integrated Stepper Motors

-

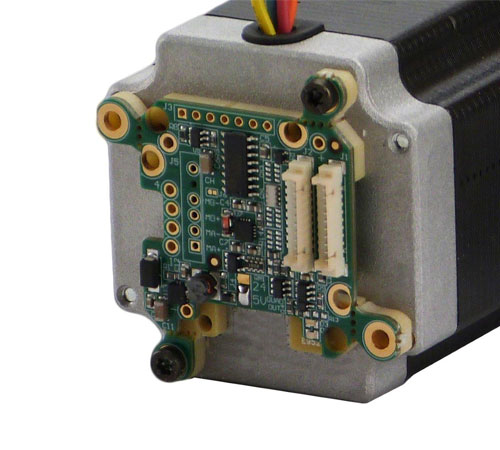

The MIS motor - the complete motion solution Stepper motor with integrated controller All necessary components in one unit

The basic idea of the MIS motor is to minimize the installation costs but also to make a component that is much better protected against electrical noise which can be a problem when using long cables between controller and motor. The stepper motor, hallsensor, encoder and electronics are specially developed by JVL so that they together form an enclosed unit where the power driver and controller are mounted inside the motor in a closed section. The MIS motors can be delivered in sizes of 0.36 to 25.0.

Adapt your motor to your application with firmware

JVL MIS Integrated Servo Motors can be delivered with different numbers of M12 connectors depending on the application. MIS17x and MIS23x motors can be delivered with RS485 interface and PLC built-in and optional CANopen. MIS34x and MIS43x have RS485 and PLC built-in and optional Profinet, EtherCAT, Ethernet/IP, Powerlink or MODBUS TCP/IP interface. All MIS motors have optional magnetic absolute encoder built-in and MIS34x and MIS43 have optional absolute multiturn encoder built-in.

MIS171-MIS176 ServoStep - NEMA17 Programmable Integrated ServoStep Motors with Closed-Loop, Ethernet, multiturn encoder

-

The Integrated ServoStep Motors from JVL. All in one smartmotor with integrated controller. A wealth of possibilities with this new NEMA17 stepper with closed-loop servo-operation up to 3000RPM, It offers the highest microstepping resolution, position/velocity/torque servo-performance up to 0.8Nm.

- MIS171 - 0.36Nm

- MIS173 - 0.56Nm

- MIS176 - 0.80Nm

Available with CANbus, RS485, SSI, Industrial Ethernet Profinet, Ethercat, Ethernet/IP, Powerlink, Ethernet TCP, Sercos III , Absolute multiturn encoder, PLC 8IOA, clock/direction and STO. Velocity resolution 0,01RPM for extreme low speed operation and 409600 step/rev for highest precision. Different shaft diameter, brakes and high IP protection make it ideal for machine adjustment or other demanding applications.

MIS231-MIS234 Quickstep – NEMA23 Programmable Integrated ServoStep Motors with Closed-Loop, Ethernet, multiturn encoder

-

QuickStep, the Integrated ServoStep Motors from JVL. A wealth of possibilities in a NEMA23 series of the world´s most compact stepper motors with the highest micro stepping resolution, closed-loop 3000RPM and up to 3.1Nm.

Available with standard stepper motor or new hybrid stepper motor technology with rare earth magnets in rotor giving +40% more torque in same size.

MIS231-MIS234 QuickStep - Integrated Stepper Motors

-

QuickStep, the Integrated Stepper Motors from JVL. A wealth of possibilities in a series of of the world´s most compact stepper motors with the higest microstepping resolution. 3 sizes are available.

- MIS231 - 1.1Nm

- MIS232 - 1.6Nm

- MIS234 - 2.9Nm

The QuickStep series of Stepper motors with integrated electronics represents a major step forward. All the necessary electronics in a stepper system are integrated in the motor itself. The stepper motor, encoder and electronics are specially developed by JVL so that together they form a closed unit in which the power driver and controller are mounted inside the motor in a closed section with protection up to IP67.

MIS340-MIS343 QuickStep - NEMA34 Programmable Integrated ServoStep Motors with Closed-Loop, Ethernet, multiturn encoder

-

QuickStep, the Integrated ServoStep Motors from JVL. A wealth of possibilities in a series of of the world´s most compact stepper motors with the higest microstepping resolution. 4 sizes are available.

- MIS340 - 3.0/3.0Nm

- MIS341 - 6.1/6.1Nm

- MIS342 - 9.0/7.5Nm

- MIS343 - 12.0/10.0Nm

The QuickStep series of Stepper motors with integrated electronics represents a major step forward. All the necessary electronics in a stepper system are integrated in the motor itself. The stepper motor, encoder and electronics are specially developed by JVL so that together they form a closed unit in which the power driver and controller are mounted inside the motor in a closed section with protection up to IP67, and stainless steel shaft AISI303 as standard on all models.

Choose between wireless Bluetooth, WLAN or Zigbee or Industrial Ethernet Profinet, Ethernet/IP, EtherCAT, Powerlink, MODBUS TCP/IP, RS485 and PLC built-in are standard.

MIS43x - Integrated Stepper Motor

-

QuickStep, the Integrated Stepper Motors from JVL. A wealth of possibilities in a series of the world´s most compact stepper motors with the highest microstepping resolution. 2 sizes are available.

- MIS430 - 10.0Nm

- MIS432 - 25.0Nm

The QuickStep series of Stepper motors with integrated electronics represents a major step forward. All the necessary electronics in a stepper system are integrated in the motor itself. The stepper motor, encoder and electronics are specially developed by JVL so that together they form a closed unit in which the power driver and controller are mounted inside the motor in a closed section with protection up to IP67.

Choose between wireless Bluetooth, WLAN or Zigbee or Industrial Ethernet Profinet, Ethernet/IP, EtherCAT, Powerlink, MODBUS TCP/IP, RS485 and PLC built-in are standard.

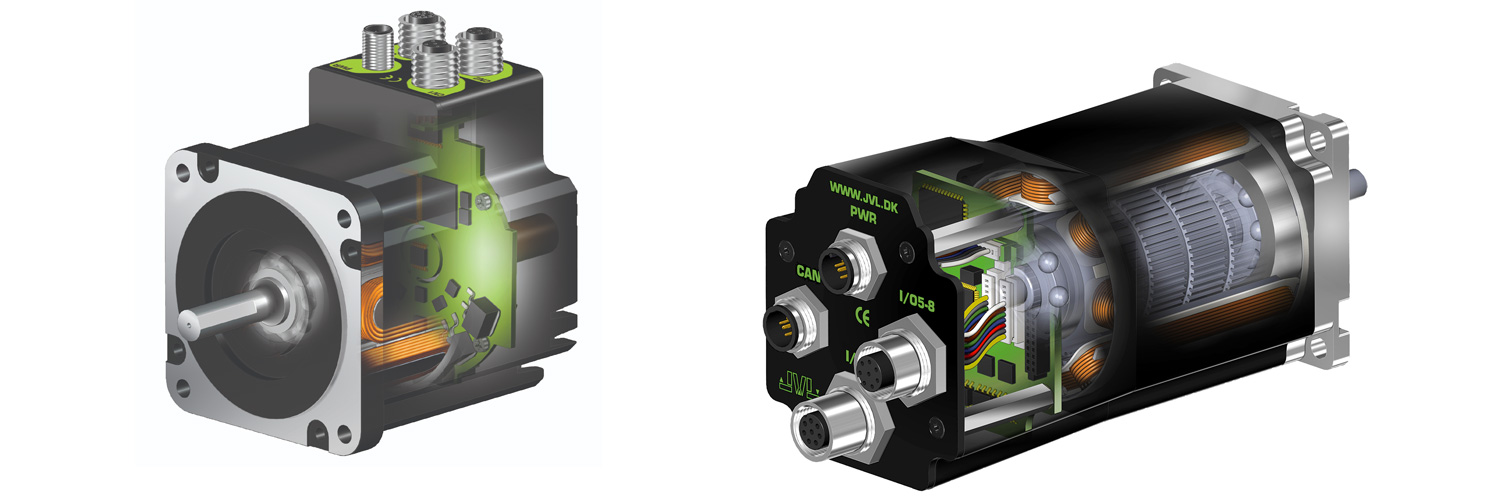

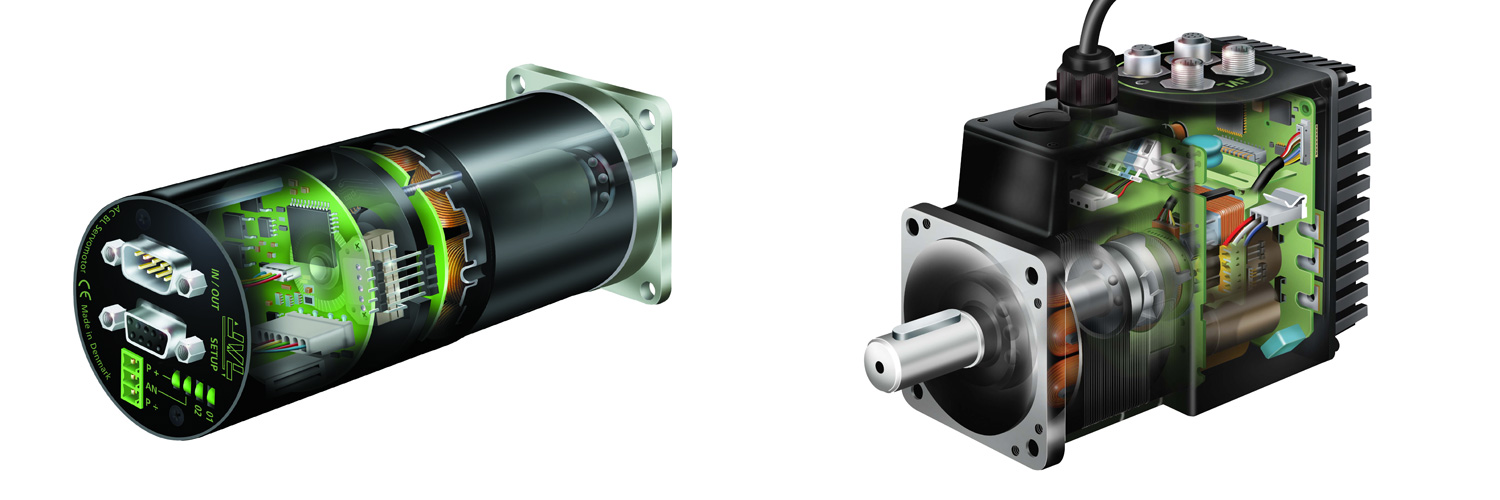

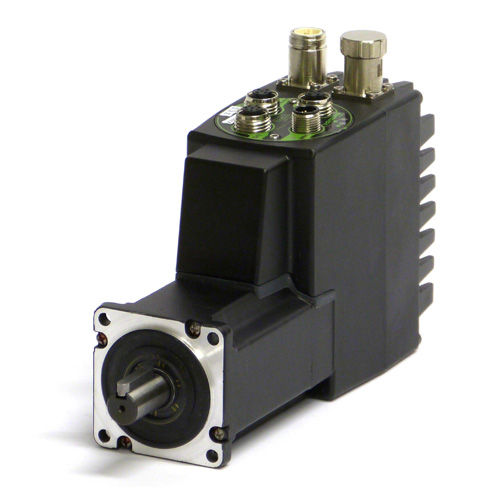

MAC Motor, Integrated Servo Motors

-

The MAC motor - the complete motion solution Brushless servo motor with integrated controller all necessary components in one unit

The basic idea of the MAC motor is to minimize the installation costs but also to make a component that is much better protected against electrical noise which can be a problem when using long cables between controller and motor. The servomotor, hallsensor, encoder and electronics are specially developed by JVL so that they together form an enclosed unit where the power driver and controller are mounted inside the motor in a closed section.

The MAC motors can be delivered in sizes of 50 to 141W, MAC050 to 141 range, 400W, MAC400 motor, 750W, MAC800 motor, 1500-3000W, MAC1500-3000 motor.

Adapt your motor to your application with Expansion Modules

JVL MAC Integrated Servo Motors utilize the unique module concept. Plug-in expansion modulesadapt the motor to the application. You can choose connector type: D-Sub, cable glands or M12 connectors and you can choose freely between Profibus, DeviceNet, CANopen, Ethernet or nano PLC control. High Speed and wireless modules add to the selection. This means that the MAC motor gives you possibilities no other motors on the market can provide. Also important, you only pay for what you need. In addition, if you do not find the features you require, please contact us and we will develop your own customized module.

MAC050 - 141 - Integrated Servo Motors: 0.11-0.48Nm/4000rpm

-

MAC050 to MAC141- the complete solution for lower power ratings.

- Choose between 4 sizes of motor.

- From 50W to 141W.

- Also in IP67 versions.

- Choose Expansion module from the extensive selection for any application.

- Basic Modules

- Programmable Modules

- Field Bus Modules

- High Speed Multi-Axis Modules

- Wireless Modules

MAC400 Integrated Servo Motor 115 to 230VAC: 1.3Nm/3000rpm

-

MAC400 - The complete solution for medium power ratings.

- With built-in mains power supply.

- Choose between model with or without brake.

- Also in IP66 version.

- Absolute multiturn encoder without battery

- Real-time industrial Ethernet: Profinet, Ethernet/IP, MODBUS TCP, EtherCAT, Powerlink and SercosIII

- 2 RS422 channels for encoder in/output and SSI encoder etc.

- 6IO for capture of position, interrupt, counters, enable, timer and PLC functions

- Basic Modules

- Programmable Modules

- Field Bus Modules

- High Speed Multi-Axis Modules

- Wireless Modules

MAC402 Integrated Servo Motor 12-48VDC: 1.3Nm/3000rpm

-

MAC402 - The complete 400W solution for medium power ratings with battery supply 12-48VDC.

- The complete 400W solution for medium power ratings with battery supply 12-48VDC.

- Peak power up to 1200W.

- Choose between model with or without brakes.

- IP55 standard. IP66 optional.

- Wireless, Industrial Ethernet or PLC build in.

New features:

- Absolute multiturn encoder without battery

- Real-time industrial Ethernet: Profinet, Ethernet/IP, MODBUS TCP, EtherCAT, Powerlink and SercosIII

- 2 RS422 channels for encoder in/output and SSI encoder etc.

- 6IO for capture of position, interrupt, counters, enable, timer and PLC functions

Expansion module you can choose between:

- Basic Modules

- Programmable Modules

- Field Bus Modules

- High Speed Multi-Axis Modules

- Wireless Modules

MAC800 - Integrated Servo Motors: 2.4Nm/3000rpm

-

MAC800 - The complete solution for larger power ratings.

- All with built-in mains power supply.

- Choose between model with or without brake.

- Also in IP66 version.

- Choose Expansion module from the extensive selection for any application.

Expansion module you can choose between:

- Basic Modules

- Programmable Modules

- Field Bus Modules

- High Speed Multi-Axis Modules

- Wireless Modules

MAC1200 - Integrated Servo motors: 3.18-3.82Nm/3000rpm

-

MAC1200 - The complete solution for medium power ratings.

- With built-in mains power supply.

- Choose between model with or without brake.

- Also in IP66 version.

- Choose Expansion module from the extensive selection for any application.

- 1182W

New features:

- Absolute multiturn encoder without battery

- Real-time industrial Ethernet: Profinet, Ethernet/IP, MODBUS TCP, EtherCAT, Powerlink and SercosIII

- 2 RS422 channels for encoder in/output and SSI encoder etc.

- 6IO for capture of position, interrupt, counters, enable, timer and PLC functions

Expansion module you can choose between:

- Basic Modules

- Programmable Modules

- Field Bus Modules

- High Speed Multi-Axis Modules

- Wireless Modules

MAC1500 - 3000 - Integrated Servo Motors: 4.5-9.0Nm/3000rpm

-

MAC1500-3000 - The complete solution for larger power ratings. All with built-in mains power supply.

- Choose between model with or without brake.

- From 1.5kW to 3.0kW.

- Choose Expansion module from the extensive selection for any application.

Expansion module you can choose between:

- Basic Modules

- Programmable Modules

- Field Bus Modules

- High Speed Multi-Axis Modules

- Wireless Modules

Most of them available with either cable glands, DSUB connectors and M12 connectors.

MAC1500-Gx to 4500-Gx - Integrated Servo Motor

-

MAC1500-Gx to 4500-Gx - The complete solution for larger power ratings.

- Choose between model with or without brake.

- From 1.5kW to 4.5kW.

- All with built-in mains power supply

- Choose Expansion module from the extensive selection for any application.

- Basic Modules

- Programmable Modules

- Field Bus Modules

- High Speed Multi-Axis Modules

- Wireless Modules

Most of them available with either cable glands, DSUB connectors and M12 connectors.

Stainless steel MACmotor 370W peak, MAC100 and MAC101

-

It's now possible to have a MAC141 in a stainless steel housing and in a IP67 version.

Different modules with M12 connectors can be chosen:- Basic Modules

- Programmable Modules

- Field Bus Modules

- High Speed Multi-Axis Modules

- Wireless Modules

Gears with different ratios can also be chosen for these applications.

Water Resistant Versions of MAC050 - 141

-

IP67 Versions of MAC140 or MAC141

Resistant against rough chemicals- Cost-Effective in harsh wet environment

- Ideal for food processing, pharmaceutical and chemical industries

- A double shaft seal and leak-proof cable entry provide watertight sealing

- A thick protective layer of epoxy surface treatment is bonded to the motor body

- Stainless steel shaft and flange

- For orders more than 50 pcs. the motor can be painted in colors other than green and white.

Integrated Stepper Motors Linear Actuator

- Linear Stepper Motors can dramatically reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduce cost but also reduce failure rate due to the less number of components and more simple construction. In applications with small load ratings a linear guide is also not required. The special design and material of the nut secure long life operations.

MIL17xS NEMA17 ServoStep

MIL17x 2nd generation and MIS17 with hollow shaft for mounting of own or JVL spindle

Linear stepper motors can dramatically reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduces the cost but also reduces the failure rate due to fewer components and a simpler construction. In applications with small load ratings a linear guide is not required. The special design and material of the nut enables long life operation.

Versions available- External linear actuator. Nut are mounted on lead screw.

- Captive

- Rolled ball screw.

MIL232S NEMA23 ServoStep

MIL23xS/W Integrated Stepper Motor Linear Actuator - NEMA23 Programmable with Closed-Loop, Ethernet, multiturn encoder

Linear stepper motors can dramatically reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduce cost but also reduce failure rate due to the less number of components and more simple construction. In applications with small load ratings a linear guide is also not required. New motor technology with large double row ball bearing for axial force 7100N.

Below versions can be delivered- Rolled ball screw up to 3 meter

- Captive version up to 127 mm travel length

- Motor without screw, for mounting of own screws

MIL23xA/B NEMA23 QuickStep

NEMA23 57mm Integrated Stepper Motor Linear Actuator

Linear stepper motors can dramatically reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduce cost but also reduce failure rate due to the less number of components and more simple construction. In applications with small load ratings a linear guide is also not required. The special design and material of the nut secure long life operation.

Below versions can be delivered- Captive linear actuator with built-in guider for linear movements.

- Moving part do not rotate.

- External linear actuator. Nut are mounted on lead screw.

- Captive (will be available for NEMA34 in the future) and External linear actuator in NEMA size 23 and 34 can be delivered with integrated driver or controller.

MIL341x NEMA34 ServoStep

NEMA34 86mm Integrated Stepper Motor Linear Actuator

Linear stepper motors can dramatically reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduce cost but also reduce failure rate due to the less number of components and more simple construction. In applications with small load ratings a linear guide is also not required. The special design and material of the nut secure long life operation.

Below versions can be delivered- Non-Captive linear actuator with nut inside motor. Linear moving part can rotate so it should be fixed.

- External linear actuator. Nut are mounted on lead screw.

- Captive (will be available for NEMA34 in the future) and External linear actuator in NEMA size 23 and 34 can be delivered with integrated driver or controller.

- IP42

- Rolled ball screw, grade C7

Stepper Motor Drivers

- A series of stepper motor drivers that meets almost all the needs for precise control of stepper motors, incuding mini-stepping with up to 25000 ministeps per revolution.

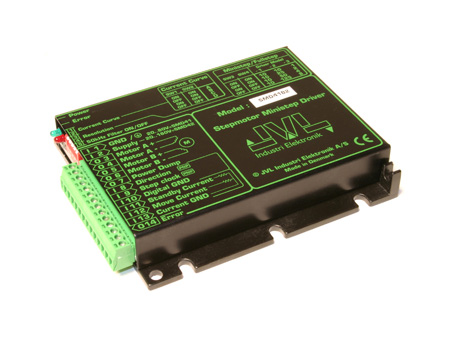

Stepper Motor Ministep Drivers SMD41 and SMD42

-

For particularly smooth motor operation

For particularly smooth and precise motor operation, JVL''s very compact Ministep Drivers are recommended. Model SMD41 operates with 20-80VDC supply voltage while model SMD42 operates with 20-160VDC supply voltage for highly dynamic applications. The drivers are available in 2 basic models, each of which is available in 3A, 6A, and 9A versions. Operating frequency 0 to 800 kHz

- Step resolution 200, 400, 800, 1600, 2000, 5000, 10000 and 25000 ministeps per motor revolution

- Galvanically isolated step-pulse and direction inputs

- "Power dump" output for sinking surplus energy

- Automatic switching between stand-by and operating currents

- Facility for controlling operating and stand-by currents via externally applied voltage 0-2.5V or 0-20 mA

- Small physical dimensions: 100x22x114mm

- Error output for temperature overload and short-circuit

- Thermally protected Filter option at step-pulse input

- Can be connected to both 2 and 4-phase motors

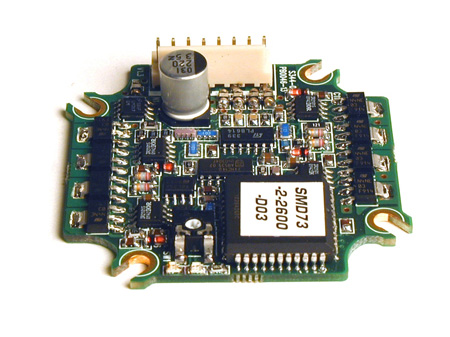

Stepper Motor Driver SMD73

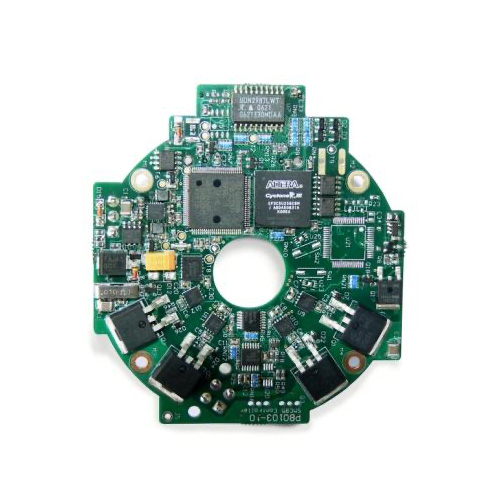

-

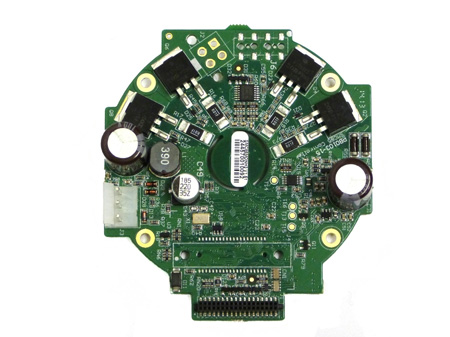

Driver for motor mounting

Step Motor Driver SMD73 is a miniature driver that measures only 52.4x52.4 mm and is ideal for direct mounting onto a step motor. It fits onto most types of high-torque motors, but of course can also be mounted on a surface.

- OEM low-price driver for Step Motors Dimensions only 52.4x52.4x14mm

- Power Supply from 18-28VDC

- LED indicators for error and power on

- Operates in half-step mode,

- 400steps/rev. 200, 800 or 1600 steps/rev. to order

- 3.0 A per phase, other values to order

- NPN/PNP inputs available to order

- Can be mounted on a surface or directly on NEMA23/34 High Torque motors

- Motor control via step-pulse and direction signals

- Can handle up to 50ksteps/sec.

- Also available as DC driver, up to 4A RMS

- Protected against thermal overload, current overload, short-circuit

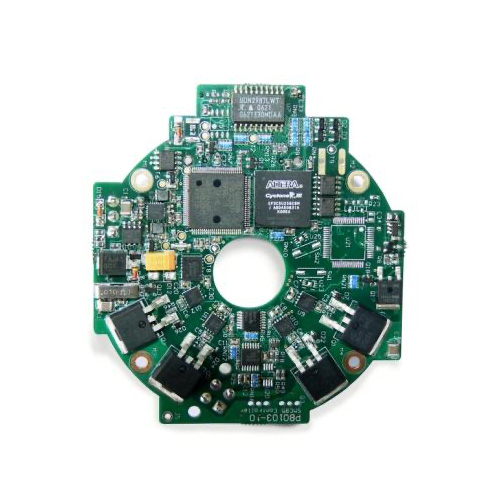

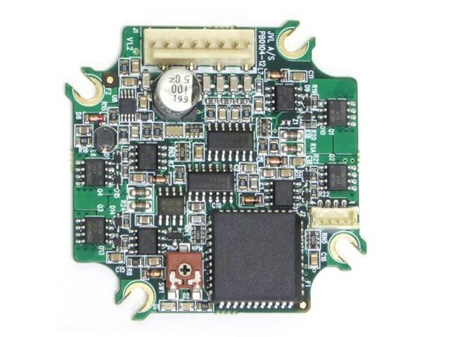

Stepper Motor Driver SMD74

-

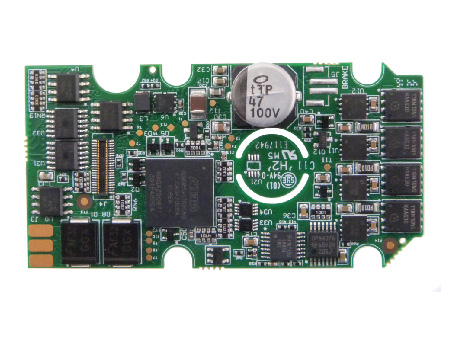

Pulse and direction Driver for motor mounting

Step Motor Driver SMD74 is a miniature driver that measures only 52.4x52.4 mm and is ideal for direct mounting onto a step motor or in a cabinet. It’s can also be used in JVL MIS23x integrated steppermotors and MIL23x linear integrated stepper motors. SMD74 are new and improved version compared to SMD73 that it can replace 100%. Additional features compared to SMD73 are supply voltage up to 48VDC for higher speed and also more efficient driver so it can work up to 85’C degree. Also a 4 pin connector with error output and enable input available. It will work with almost any type of high-torque stepper motors and can be mounted on a plane surface.

- OEM low-price driver for Stepper Motors

- Dimensions only 52.4x52.4x14mm

- Single power supply from 18-48VDC

- Ultra high efficient driver for up to 85’C degree operation.

- LED indicators for error and power on

- 200, 400, 800,1000 or 1600 steps/rev. to order

- Motor current 0,1 to 3.0 Amp RMS to order

- NPN/PNP and 5V inputs can be changed with switch.

- Can be mounted on a surface or directly on NEMA23/34 High Torque motors

- Motor control via step-pulse and direction signals

- Can handle up to 50ksteps/sec.

- Also available as DC driver, up to 4A RMS

- Protected against thermal overload, current overload, short-circuit

- Many cables can be delivered with Molex or M12 connector for easy adaption to own cabinet.

- Can be coated with for environment with eg condensation water.

Multifunction Stepper Motor Driver PA0076

-

Compact step motor driver can replace Parker Compumotor driver

JVL has developed a driver that is compatible with the Parker Hannifin Digiplan driver type SD10, SD12, SM13, SM14, SM15 and SMD15M both functionally and in terms of connectors. The JVL Driver PA0076 does however offer improvements in many areas:

- High-efficiency MOS FET technology ensures less heat generation.

- Single power supply of 12-54VAC or 17-70VDC ensures fewer cables and avoids double supply.

- Built-in potentiometers so that velocity and acceleration can be adjusted on the PCB. This gives lower cost price in external installations and fewer errors.

- Increased options for mini-step operation - up to 4000 steps/rev.

- DIP switch change of modes ensures simpler set-up and fewer errors.

- LED indication for power and error.

- Lower price through the use of latest technology.

JVL has used the PA0076 Driver as a direct replacement for the Parker SD10 series in many projects, and in all cases the JVL Driver has proven to be a more than satisfactory solution for our customers.

Stepper Motor Drivers SMD15 and SMD30

-

A wide selection for any application

JVL Drivers are controlled by either external step- and direction control signals, or by a built-in step-signal generator. The latter can be used, depending on model, to control motor speed and direction using input control signals.The Drivers are equipped with inputs and outputs for clockwise- and counter-clockwise end-of-travel inputs (CW/CCW Limit Inputs), Break, Status, Start and Stop, as well as provision for adjusting start speed, acceleration/deceleration ramps and 2 tops speeds in the same operation.

- Driver stages of 6 and 12 A, and 15-150V

- Top velocity can be controlled using external voltage (0-5/0-10V)

- Phase current can be controlled using external voltage (0-5V)

- Stop input which stops motor operation instantaneously

- Status output which indicates motor is running or stationary

- CW/CCW end-of-travel inputs

- Facility for 2 velocities in same motor operation

- 200, 400, 800 or 1600 steps per revolution (full-, half, 1/4 or 1/8 step operation)

- All in/outputs optically isolated

- Adjustment of stand-by current

- Adjustment of operating current

- External switching between operating and stand-by current

- LED indication of motor operation

- Error-, Step-pulse- and Direction output

Stepper Motor Controllers with PLC, 8IO, analogue, encoder input and CANopen

-

JVL can also deliver pulse/direction drives with PLC and controller on board up to 9Amp and 80VDC. Pulse and direction signal to control motor movement while the PLC program running in the background. A burst of pulses can be sent to the controller which then determines Acceleration and speed in accordance with the PLC program.

Max. 3 Amp Models

Max. 6 Amp Models

Max. 9 Amp Models

Stepper Motor Controllers

- A PCB, small Stepper Motor Controller with PLC, CANopen and 8IO

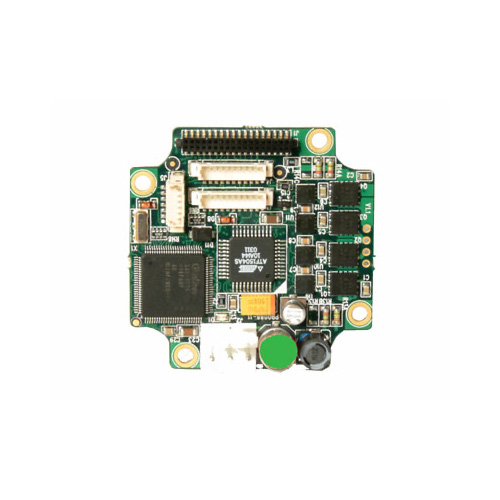

Stepper Motor Controller SMC75

-

Stepper Motor Controller with PLC, CANopen and 8IO

A Stepper Motor Controller with RS485 and CANbus serial interface. 8IO can be configured to input, output or analog input. Can be controlled via nanoPLC and MacTalk. The very compact, 57x57mm, PCB contains everything needed to solve a modern control task as stand-alone or controlled from a PLC or PC. MODBUS RTU and CANopen gives the possibility for easy connection to a PLC. For PC or IPC an ActiveX/OCX driver is available so that interface to LABview, Excel, VB or other Windows-programs is simple.

- NanoPLC with 8IO in 24

- RS485 up to 962kbit

- CANOpen DSP402

- MODBUS RTU

- Resolution up to 1600 step/rev.

- Pulse/Direction mode

- Supply 12-48VDC

- Motor current 0-3Amp RMS

- Dual supply for safe emergency stop

- Active X / OCX driver available

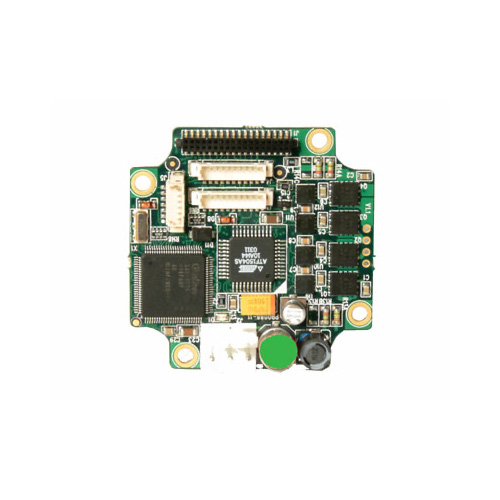

Stepper Motor Controller SMC75 with Housing

-

Stepper Motor Controller with PLC, CANopen and 8IO

A Stepper Motor Controller with RS485 and CANbus serial interface. 8IO can be configured to input, output or analog input. Can be controlled via nanoPLC and MacTalk. The very compact, 57x57mm, PCB contains everything needed to solve a modern control task as stand-alone or controlled from a PLC or PC. MODBUS RTU and CANopen gives the possibility for easy connection to a PLC. For PC or IPC an ActiveX/OCX driver is available so that interface to LABview, Excel, VB or other Windows-programs is simple.

- NanoPLC with 8IO in 24

- RS485 up to 962kbit

- CANOpen DSP402

- MODBUS RTU

- Resolution up to 1600 step/rev.

- Pulse/Direction mode

- Supply 12-48VDC

- Motor current 0-3Amp RMS

- Dual supply for safe emergency stop

- Active X / OCX driver available

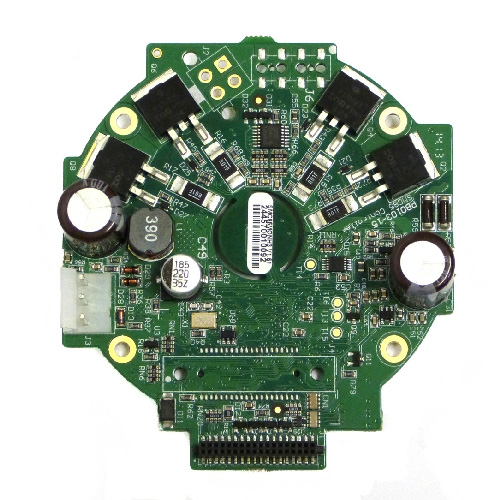

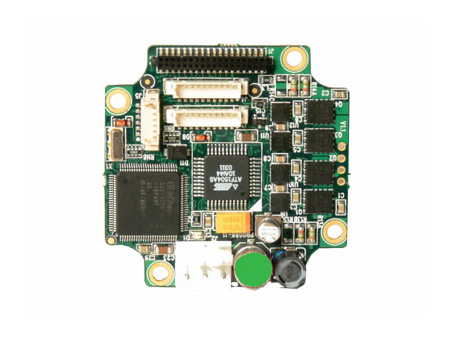

Stepper Motor Controller SMC85 PCB version

-

Stepper motor controller 0-9Amp RMS, PLC build in with 8IOA and RS422. Optional Profinet, EtherCAT, EthernetIP, Powerlink, MOSBUS TCP, Bluetooth, WLAN, Zigbii, SSI or CANopen.

A Stepper Motor Controller with RS485 and CANbus serial interface. 8IO can be configured to input, output or analog input. Can be controlled via nanoPLC and MacTalk. The very compact, 78.4x86.2mm, PCB contains everything needed to solve a modern control task as stand-alone or controlled from a PLC or PC. MODBUS RTU and CANopen gives the possibility for easy connection to a PLC. For PC or IPC an ActiveX/OCX driver is available so that interface to LABview, Excel, VB or other Windows-programs is simple.

- NanoPLC with 8IO in 24V

- RS485 up to 962kbit

- CANOpen DSP402

- MODBUS RTU

- Resolution is 409.600 step/rev.

- Velocity precission 0,01 RPM

- Pulse/Direction mode

- Supply 12-80VDC

- Motor current 0-9 Amp RMS

- Dual supply for safe emergency stop

- Active X / OCX driver available

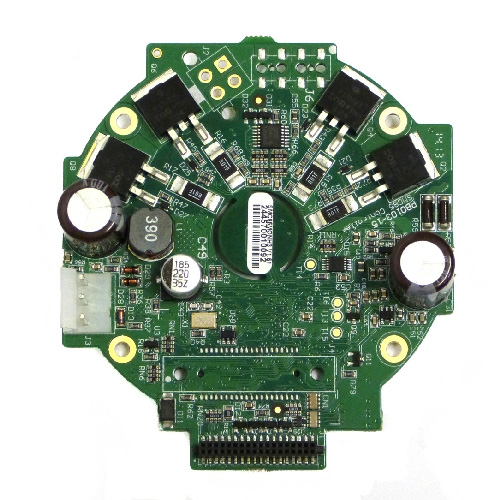

Stepper Motor Controller SMC85 with Housing

-

Stepper motor controller 0-9Amp RMS, PLC build in with 8IOA and RS422. Optional Profinet, EtherCAT, EthernetIP, Powerlink, MOSBUS TCP, Bluetooth, WLAN, Zigbii, SSI or CANopen.

A Stepper Motor Controller with RS485 and CANbus serial interface, also including 6 different Industrial Ethernet protocols. 8IO can be configured to input, output or analog input. Can be controlled via nanoPLC and MacTalk. The very compact, 78.4x86.2mm, PCB contains everything needed to solve a modern control task as stand-alone or controlled from a PLC or PC. MODBUS RTU and CANopen gives the possibility for easy connection to a PLC. For PC or IPC an ActiveX/OCX driver is available so that interface to LABview, Excel, VB or other Windows-programs is simple.

- NanoPLC with 8IO in 24V

- RS485 up to 962kbit

- Compatible with all Ethernet protocols (optional)

- CANOpen DSP402 (optional)

- MODBUS RTU

- Resolution up to 819.200 step/rev.

- Velocity precission 0,01 RPM

- Pulse/Direction mode

- Supply 12-80VDC

- Motor current 0-9 Amp RMS

- Dual supply for safe emergency stop

- Active X / OCX driver available

Stepper Motor Controller SMC66 PCB version

-

Stepper motor controller 0-6Amp RMS, PLC build in with 8IOA and RS422. Optional Profinet, EtherCAT, EthernetIP, Powerlink, MOSBUS TCP, Bluetooth, WLAN, Zigbii, SSI or CANopen.

A Stepper Motor Controller with RS485 and CANbus serial interface, also including 6 different Industrial Ethernet protocols. 8IO can be configured to input, output or analog input. Can be controlled via nanoPLC and MacTalk. The very compact, 33.6x65.3mm, PCB contains everything needed to solve a modern control task as stand-alone or controlled from a PLC or PC. MODBUS RTU and CANopen gives the possibility for easy connection to a PLC. For PC or IPC an ActiveX/OCX driver is available so that interface to LABview, Excel, VB or other Windows-programs is simple.

- NanoPLC with 8IO in 24V

- RS485 up to 962kbit

- CANOpen DSP402

- MODBUS RTU

- Resolution is 409.600 step/rev.

- Velocity precission 0,01 RPM

- Pulse/Direction mode

- Supply 12-80VDC

- Motor current 0-6 Amp RMS

- Dual supply for safe emergency stop

- Active X / OCX driver available

Stepper Motor Controller SMC66 with Housing

-

Stepper motor controller 0-6Amp RMS, PLC build in with 8IOA and RS422. Optional Profinet, EtherCAT, EthernetIP, Powerlink, MOSBUS TCP, Bluetooth, WLAN, Zigbii, SSI or CANopen.

A Stepper Motor Controller with RS485 and CANbus serial interface, also including 6 different Industrial Ethernet protocols. 8IO can be configured to input, output or analog input. Can be controlled via nanoPLC and MacTalk. The very compact, 33.6x65.3mm, PCB contains everything needed to solve a modern control task as stand-alone or controlled from a PLC or PC. MODBUS RTU and CANopen gives the possibility for easy connection to a PLC. For PC or IPC an ActiveX/OCX driver is available so that interface to LABview, Excel, VB or other Windows-programs is simple.

- NanoPLC with 8IO in 24V

- RS485 up to 962kbit

- CANOpen DSP402

- MODBUS RTU

- Resolution is 409.600 step/rev.

- Velocity precission 0,01 RPM

- Pulse/Direction mode

- Supply 12-80VDC

- Motor current 0-6 Amp RMS

- Dual supply for safe emergency stop

- Active X / OCX driver available

Integrated Stepper Motors Linear Actuator

MST/MSW Stepper Motors with Encoder IP42 – IP67

-

These high torque Stepper Motors are now available with mounted encoder. Ranging from Nema08 to Nema23.

- Torque 0.01Nm - 2.6Nm

- Motor and encoder cables

- Encoder RS422 A+,A-,B+,B- Motor 4 wire

- Nema17 and 23 high IP protection

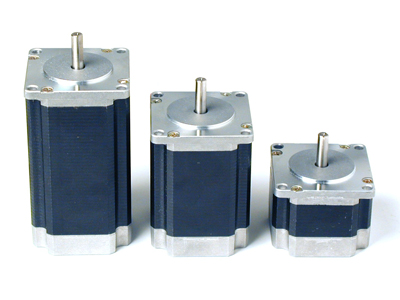

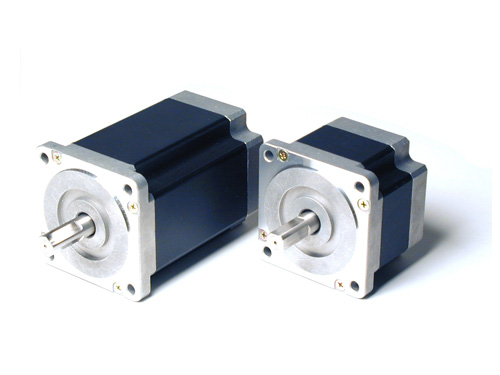

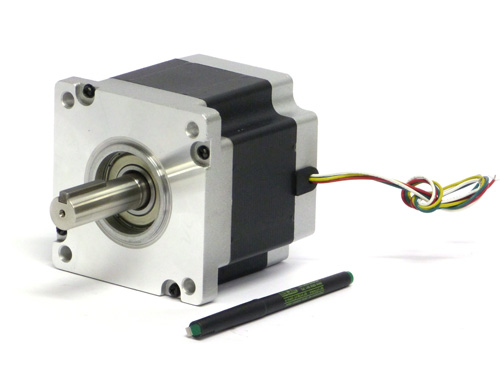

High Torque Stepper Motors

-

High Torque Stepper Motors from 0.01 to 50Nm. NEMA08,NEMA17,NEMA23,NEMA34,NEMA43,NEMA53

A series of step motors that have been designed by JVL for use with the entire range of JVL Step Motor Drivers and Controllers. They are high torque step motors especially made for mini- and microstep operation.

- Highest torque density rating in the industry

- High torque-to-inertia for faster start and stop

- Rugged design and long life bearings

- High power, cooler running, rare-earth magnet design

- Exposed-lamination housing, optimized for high torque and smooth, accurate microstepping

- Standard NEMA08-53 mounting

- Facilities for encoders, double shaft, different shaft types, etc.

- Ground terminal for correct EMC shielding

- High axial and radial shaft load

- Cost-effective alternative to servo motors

- Low noise

- Option for planetary gearhead

- Protection up to IP67

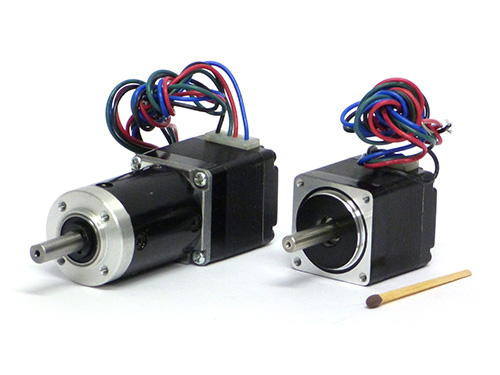

Mini Stepper Motors MST081A03 and MST082A03

-

The small mini step motors MST081A08 and MST082A08 are designed to be used in applications where dimensions and weight must be as small as possible. Both have flanges of only 20x20mm and where MST081 is 33mm in length, MST is 42, but then also includes double shaft. The motors can be connected directly to the range of JVL drivers

Recommended drivers

All JVL stepper motor drivers and controller can be used with the MST081A08 and MST082A08 mini stepper motors. The Step motor drivers SMD41 or the SMD73, which is a compact circuit board, possibly with ready-made cables, can be recommended due to their small size.

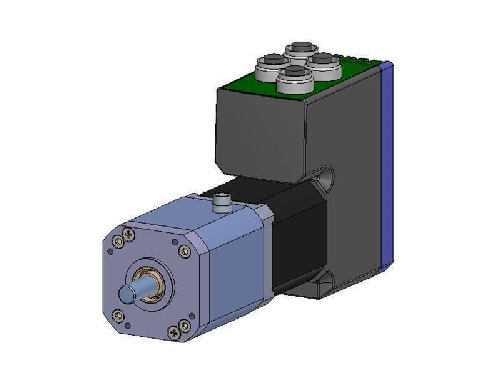

Mini Stepper Motor MST11x - 28mm

-

The small mini steppper motors MST11xA with or without planetary gear are designed to be used in applications where dimensions and weight must be as small as possible. Motor flanges are 28x28mm and motor length 31mm to 50mm. Planetary gear with reductions ratio from 3.71 to 369:1 can be mounted and thereby offer short time torque up to 12Nm.

Recommended drivers

The motors can be connected directly to the range of JVL drivers. The Step motor drivers pulse/direction SMD73 or SMD74, which is a compact circuit board, possibly with ready-made cables, can be recommended due to their small size. If a controller with PLC and IO are needed can SMC75 be used.

High Torque Stepper Motors MST17xxx3 up to 0,8Nm

-

A series of step motors that have been designed by JVL for use with the entire range of JVL Step Motor Drivers and Controllers. They are high torque step motors especially made for mini- and microstep operation.

- Highest torque density rating in the industry

- High torque-to-inertia for faster start and stop

- Rugged design and long life bearings

- High power, cooler running, rare-earth magnet design

- Exposed-lamination housing, optimized for high torque and smooth, accurate microstepping

- Standard NEMA17 mounting

- Facilities for encoders, double shaft, different shaft types, etc.

- Ground terminal for correct EMC shielding

- High axial and radial shaft load

- Cost-effective alternative to servo motors

- Low noise Option for planetary gearhead

High Torque High Precision Stepper Motors MST17xxx2 up to 0,46Nm

-

A series of step motors that have been designed by JVL for use with the entire range of JVL Step Motor Drivers and Controllers. They are high torque step motors especially made for mini- and microstep operation. Compared to the motor MST17xxx3 this motor is produced in higher quality with less mechanical and electrical tolerances making it more suitable for applications that require repetitive and uniform motors. It also offers better protections against water and use better balls bearings etc. This motor is not developed/produced in China.

- Highest torque density rating in the industry

- High torque-to-inertia for faster start and stop

- Rugged design and long life bearings

- High power, cooler running, rare-earth magnet design

Exposed-lamination housing, optimized for high torque and smooth, accurate microstepping

Standard NEMA17 mounting

Facilities for encoders, double shaft, different shaft types, etc.

Ground terminal for correct EMC shielding

High axial and radial shaft load

Cost-effective alternative to servo motors

Low noise Option for planetary gearhead

High Torque Stepper Motors MST23xxx3 up to 2,6Nm

-

Compact, high torque step motors

The step motors MST001A, MST002A and MST234B03 are designed and dimensioned by JVL for use with the entire range of JVL step motor drivers and controllers.

These motors are in particular well-suited for OEM applications. Type MST001A is available in a special version, MST001A-73, for easy back-mounting of the Step Motor Driver SMD73.

High Torque High Precision Stepper Motors MST23xxx2 up to 2,1Nm

-

A series of step motors that have been designed by JVL for use with the entire range of JVL Step Motor Drivers and Controllers. They are high torque step motors especially made for mini- and microstep operation. Compared to the motor MST23xxx3 this motor is produced in higher quality with less mechanical and electrical tolerances making it more suitable for applications that require repetitive and uniform motors. It also offers better protections against water and use better balls bearings etc. This motor is not developed/produced in China.

- Highest torque density rating in the industry

- High torque-to-inertia for faster start and stop

- Rugged design and long life bearings

- High power, cooler running, rare-earth magnet design

- Exposed-lamination housing, optimized for high torque and smooth, accurate microstepping

- Standard NEMA23 mounting

- Facilities for encoders, double shaft, different shaft types, etc.

- Ground terminal for correct EMC shielding

- High axial and radial shaft load

- Cost-effective alternative to servo motors

- Low noise Option for planetary gearhead

NEMA 23/24/34 Stepper Motors with IP67 Protection

-

A series of step motors with IP67 protection have been designed by JVL for use with the entire range of JVL Step Motor Drivers and Controllers. Torque from 0,5Nm to 8,2Nm. Even shaft sealing can be IP67 for harsh industrial operation.

- Special IP67 sealing at rear end and between stator and flanges

- Special Teflon IP67 shaft sealing

- Cost-Effective in harsh wet environment

- Ideal for food processing, pharmaceutical and chemical industries

- A double shaft seal and leak-proof cable entry provide watertight sealing

- The material of shaft is stainless steel SUS303/EN 1.4305/AISI303

- 2 phase motor. 200 step/rev.

- High torque-to-inertia for faster start and stop

- Rugged design and long life bearings

- High power, cooler running, rare-earth magnet design

- Exposed-lamination housing, optimized for high torque and smooth, accurate microstepping

- NEMA23 (57x57mm), NEMA26(60x60mm) and NEMA34 (86x86mm) mounting

- Very short length and very high torque/mm3

- High axial and radial shaft load

- Cost-effective alternative to servo motors

- All motors are D-shaped

High Torque Stepper Motors MST34xxx3 up to 12,5Nm

-

A series of step motors that have been designed by JVL for use with the entire range of JVL Step Motor Drivers and Controllers. They are high torque step motors especially made for mini- and microstep operation.

- Highest torque density rating in the industry

- High torque-to-inertia for faster start and stop

- Rugged design and long life bearings

- High power, cooler running, rare-earth magnet design

- Exposed-lamination housing, optimized for high torque and smooth, accurate microstepping

- Standard NEMA34 mounting

- Facilities for encoders, double shaft, different shaft types, etc.

- Ground terminal for correct EMC shielding

- High axial and radial shaft load

- Cost-effective alternative to servo motors

- Low noise Option for planetary gearhead

High Torque High Precision Stepper Motors MST34xxx2 up to 9Nm

-

A series of step motors that have been designed by JVL for use with the entire range of JVL Step Motor Drivers and Controllers. They are high torque step motors especially made for mini- and microstep operation. Compared to the motor MST34xxx3 this motor is produced in higher quality with less mechanical and electrical tolerances making it more suitable for applications that require repetitive and uniform motors. It also offers better protections against water and use better balls bearings etc. This motor is not developed/produced in China.

- Highest torque density rating in the industry

- High torque-to-inertia for faster start and stop

- Rugged design and long life bearings

- High power, cooler running, rare-earth magnet design

- Exposed-lamination housing, optimized for high torque and smooth, accurate microstepping

- Standard NEMA34 mounting

- Facilities for encoders, double shaft, different shaft types, etc.

- Ground terminal for correct EMC shielding

- High axial and radial shaft load

- Cost-effective alternative to servo motors

- Low noise Option for planetary gearhead

High Torque Stepper Motors MST43xxx2 up to 25Nm

-

A series of step motors that have been designed by JVL for use with the entire range of JVL Step Motor Drivers and Controllers. They are high torque step motors especially made for mini- and microstep operation.

- Highest torque density rating in the industry

- High torque-to-inertia for faster start and stop

- Rugged design and long life bearings

- High power, cooler running, rare-earth magnet design

- Exposed-lamination housing, optimized for high torque and smooth, accurate microstepping

- Standard NEMA43 mounting

- Facilities for encoders, double shaft, different shaft types, etc.

- Ground terminal for correct EMC shielding

- High axial and radial shaft load

- Cost-effective alternative to servo motors

- Low noise Option for planetary gearhead

High Torque Stepper Motors MST51x up to 50Nm

-

This high torque stepper motor can be used for application that demand extreme high torque at low speed. With a flange size 134x134mm and length 270mm can this motor deliver up to 50Nm holding or running torque.

MST511 27Nm 165mm

MST512 40Nm 230mm

MST513 50Nm 270mm- Industrial connector for high IP protection.

- Highest torque density rating in the industry.

- High torque-to-inertia for faster start and stop.

- Rugged design and long life bearings.

- High power, cooler running, rare-earth magnet design.

- Exposed-lamination housing, optimized for high torque and smooth, accurate microstepping.

- Standard NEMA51 mounting.

- High axial and radial shaft load.

- Cost-effective alternative to servo motors.

- Optional with build in controller SMC85 with PLC and Ethernet.

MST/MSW Stepper Motors with Encoder IP42 – IP67

-

These high torque Stepper Motors are now available with mounted encoder. Ranging from Nema08 to Nema23.

- Torque 0.01Nm - 2.6Nm

- Motor and encoder cables

- Encoder RS422 A+,A-,B+,B-

- Motor 4 wire

- Nema17 and 23 high IP protection

- Motor and encoder signal in same cable

- IP67 Protection

- Encoder PNP or NPN signals

- Encoder other resolution

- Absolute multiturn

- Single turn absolute

- SSI and Biss encoder

- Magnetic or optical encoder

- Other pulse resolutions

UL-listed and CSA Certified high torque and high precision Stepper Motors NEMA23 MST23x up to 3.2Nm

-

A series of step motors that have been designed by JVL for use with the entire range of JVL Step Motor Drivers and Controllers. They are high torque step motors especially made for mini- and microstep operation. Compared to motor MST23xxx3 this motor is produced in higher quality with less mechanical and electrical tolerances making it more suitable for applications that require repetitive and uniform motors. It also offers better protections against water and use better balls bearings etc. They are prepared for JVL encoder PCB PA0260 with single or absolute multiturn encoder.

- UL recognized and CSA Certified available from NEMA17 to NEMA43

- Option for rear end magnet encoder from JVL or own encoder PCB.

- Highest torque density rating in the industry

- High torque-to-inertia for faster start and stop

- Rugged design and long life bearings

- High power, cooler running, rare-earth magnet design

- Exposed-lamination housing, optimized for high torque and smooth, accurate microstepping

- Facilities for encoders, double shaft, different shaft types, etc.

- Ground 3mm thread hole for correct EMC shielding

- High axial and radial shaft load

- Cost-effective alternative to servo motors

- Low noise Option for planetary gearhead

- Standard NEMA23 mounting. 200Step/rev

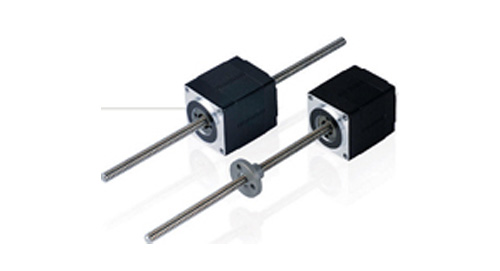

Non-integrated Stepper Motors Linear Actuator

- A wide range of linear stepper motors, from 5 to 2700 N. Size 08(20 mm) to 34(86 mm).

NEMA08 20 mm Stepper Motor Linear Actuators

-

Linear stepper motors can dramatically reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduce cost but also reduce failure rate due to the less number of components and more simple construction. In applications with small load ratings a linear guide is also not required. The special design and material of the nut secure long life operation.

Below versions can be delivered- Non-Captive linear actuator with nut inside motor. Linear moving part can rotate so it should be fixed.

- External linear actuator. Nut are mounted on lead screw.

- Captive (will be available for NEMA34 in the future) and External linear actuator in NEMA size 23 and 34 can be delivered with integrated driver or controller.

- Rolled ball screw, grade C7.

- Different shaft and stroke length

- Special nut design

- Higher IP protection

NEMA11 28mm Stepper Motor Linear Actuators

-

Linear stepper motors can dramatically

reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduce cost but also reduce failure rate due to the less number of components and more simple construction. In applications with small load ratings a linear guide is also not required. The special design and material of the nut secure long life operation.

Below versions can be delivered- Non-Captive linear actuator with nut inside motor. Linear moving part can rotate so it should be fixed.

- External linear actuator. Nut are mounted on lead screw.

- Captive (will be available for NEMA34 in the future) and External linear actuator in NEMA size 23 and 34 can be delivered with integrated driver or controller.

- Rolled ball screw, grace C7.

- Different shaft and stroke length

- Special nut design

- Higher IP protection

NEMA14 35mm Stepper Motor Linear Actuators

- Linear stepper motors can dramatically

reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduce cost but also reduce failure rate due to the less number of components and more simple construction. In applications with small load ratings a linear guide is also not required. The special design and material of the nut secure long life operation.

Below versions can be delivered- Captive linear actuator with built-in guider for linear movements. Moving part do not rotate.

- Non-Captive linear actuator with nut inside motor. Linear moving part can rotate so it should be fixed.

- External linear actuator. Nut are mounted on lead screw.

- Captive (will be available for NEMA34 in the future) and External linear actuator in NEMA size 23 and 34 can be delivered with integrated driver or controller.

- Rolled ball screw, grade C7.

- Different shaft and stroke length

- Special nut design

- Higher IP protection

NEMA17 42mm Stepper Motor Linear Actuators

- Linear stepper motors can dramatically

reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduce cost but also reduce failure rate due to the less number of components and more simple construction. In applications with small load ratings a linear guide is also not required. The special design and material of the nut secure long life operation.

Below versions can be delivered- Captive linear actuator with built-in guider for linear movements. Moving part do not rotate.

- Non-Captive linear actuator with nut inside motor. Linear moving part can rotate so it should be fixed.

- External linear actuator. Nut are mounted on lead screw.

- Captive (will be available for NEMA34 in the future) and External linear actuator in NEMA size 23 and 34 can be delivered with integrated driver or controller.

- Rolled ball screw, grade C7.

- Different shaft and stroke length

- Special nut design

- Higher IP protection

NEMA23 57mm Stepper Motor Linear Actuators

-

Linear stepper motors can dramatically

reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduce cost but also reduce failure rate due to the less number of components and more simple construction. In applications with small load ratings a linear guide is also not required. The special design and material of the nut secure long life operation.

Below versions can be delivered- Captive linear actuator with built-in guider for linear movements. Moving part do not rotate.

- Non-Captive linear actuator with nut inside motor. Linear moving part can rotate so it should be fixed.

- External linear actuator. Nut are mounted on lead screw.

- Captive (will be available for NEMA34 in the future) and External linear actuator in NEMA size 23 and 34 can be delivered with integrated driver or controller.

- Rolled ball screw, grade C7.

- Different shaft and stroke length

- Special nut design

- Higher IP protection

NEMA34 86mm Stepper Motor Linear Actuators

-

Linear stepper motors can dramatically

reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduce cost but also reduce failure rate due to the less number of components and more simple construction. In applications with small load ratings a linear guide is also not required. The special design and material of the nut secure long life operation.

Below versions can be delivered- Non-Captive linear actuator with nut inside motor. Linear moving part can rotate so it should be fixed.

- External linear actuator. Nut are mounted on lead screw.

- Captive (will be available for NEMA34 in the future) and External linear actuator in NEMA size 23 and 34 can be delivered with integrated driver or controller.

- Rolled ball screw, grade C7

- Different shaft and stroke length

- Special nut design

- Higher IP protection

Integrated Stepper Motors Linear Actuator NEMA17 to NEMA34

- Linear Stepper Motors can dramatically reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduce cost but also reduce failure rate due to the less number of components and more simple construction. In applications with small load ratings a linear guide is also not required. The special design and material of the nut secure long life operations.

MIL17x 2nd generation and MIS17 with hollow shaft for mounting of own or JVL spindle

-

Linear stepper motors can dramatically reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduces the cost but also reduces the failure rate due to fewer components and a simpler construction. In applications with small load ratings a linear guide is not required. The special design and material of the nut enables long life operation.

MIS23x Servostep with Double row ball bearing up to 7100N axial load for external ball or lead screw

-

NEMA23 ultra compact and all in one Integrated ServoStep Motors with Closed-Loop, Ethernet, multiturn encoder. Mount external ball or leadscrews directly in hollow shaft with a clamp or a pin.

- Double row ball bearing

- Ultra compact. All in one

- Hollow shaft 8 or 12mm

- Torque pin at 24 or 33,3mm

- Hollow shaft with bottom M5 thread

- High performance driver technology

- Stepper motor with ultra high torque

- IP42 or IP65/67 protection

- Absolute multiturn encoder

- 6 different Industrial Ethernet

- Controller with 8IOA

- Driver 409600 step/rev

- Peak power 177 or 316W

- Closed loop. High efficiency

NEMA23 57mm Integrated Stepper Motor Linear Actuator

-

Linear stepper motors can dramatically reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduce cost but also reduce failure rate due to the less number of components and more simple construction. In applications with small load ratings a linear guide is also not required. The special design and material of the nut secure long life operation.

Below versions can be delivered

- Captive linear actuator with built-in guider for linear movements. Moving part do not rotate.

- External linear actuator. Nut are mounted on lead screw.

- Captive (will be available for NEMA34 in the future) and External linear actuator in NEMA size 23 and 34 can be delivered with integrated driver or controller.

NEMA34 86mm Integrated Stepper Motor Linear Actuator

-

Linear stepper motors can dramatically reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduce cost but also reduce failure rate due to the less number of components and more simple construction. In applications with small load ratings a linear guide is also not required. The special design and material of the nut secure long life operation.

Below versions can be delivered

- Non-Captive linear actuator with nut inside motor. Linear moving part can rotate so it should be fixed.

- External linear actuator. Nut are mounted on lead screw.

- Captive (will be available for NEMA34 in the future) and External linear actuator in NEMA size 23 and 34 can be delivered with integrated driver or controller.

- IP42

- Rolled ball screw, grade C7

Junction Boxes - WI1301 and WI1302 for MAC and MIS

- 2 junctions boxes to help connceting external sensors to either MAC or MIS motors in flange size 17(43mm) to 43 (110mm)

- WI1301 for MAC ( Isolated Digital IO's possible w. ext. PSU )

- WI1302 for MAC and MIS

WI1301-2AM17T01NMB

-

Junction Box for Easy Connection to MAC motor® w/Ethernet. Plug-and-play Junction Box for standard M8-3pin sensors and devices. Just connect the Junction Box to your MAC motor®’s Ethernet module type MAC00-Ex41 and up to 8 local 24 VDC I/Os are available.

Connected I/Os can be read or set from the motors embedded ePLC™ program or via Industrial Ethernet. WI1301 offers easy connection of standard 3-pin M8 connectors typically used for limit switches and home sensor. All the 8 I/Os are available on separate M8 connectors, making it extremely easy to integrate and connect MAC motor® with extended Ethernet module into any machine.

Details:- Power LED

- LEDs for easy monitoring of I/O states

- 8 x M8-3pin Female connectors

- M12-17pin Male connector for the connection to MAC motor®

- 1 meter shielded cable

- IP67 rated

- Multiple mounting options

- Internal or external output supply

WI1302-2AM17T01NMB

-

Junction Box for Easy Connection to ServoStep™ or MAC motor® Plug-and-play Junction Box for standard M8-3pin sensors and devices. Just connect the Junction Box to your integrated servo or stepper motor and up to 8 local 24 VDC I/Os are available

Connected I/Os can be read or set from the motors embedded ePLC™ program or via Industrial Ethernet. WI1302 offers easy connection of standard 3-pin M8 connectors typically used for limit switches and home sensor. All the 8 I/Os are available on separate M8 connectors, making it extremely easy to integrate and connect MAC motor® and ServoStep™ into any machine.

Below versions can be delivered- Power LED

- LEDs for easy monitoring of I/O states

- Built-in 24 VDC supply for sensors

- 8 x M8-3pin Female connectors

- M12-17pin Male connector for the connection to JVL motor

- 1 meter shielded cable

- IP67 rated

- Multiple mounting options

- Automatic output supply when used with ServoStep™ or SMC 66/85 controllers

- Output supply must be provided when used with MAC motor® - see below

Software

- JVL can deliver the software your need. Commissioning software for setup and programming of MAC motor and Quickstep. Additional an OCX/ ActiveX driver (32-bit) is available for programmers of Windows applications. For those who want to make their own interface and send serial data from a PLC, PC or microprocessor a MacTalk protocol analyser and viewer is available.

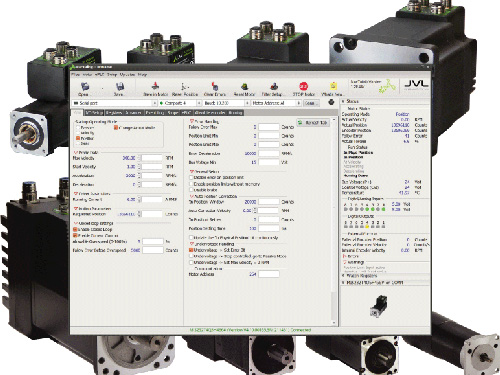

MacTalk Commisioning Tool

-

MacTalk® - One Software for All Motors

MacTalk® is the universal software from JVL for all integrated motor series: MAC motor®, ServoStep® and QuickStep®.

MT is used for setup, monitoring and diagnostics in real time - and for ePLC program development, where the PLC program is embedded and runs locally in the motor. Although advanced functionality is included, all operations are very intuitive and easy to use. MacTalk® allows you to adjust all vital parameters and save them in a file or load them from a file, including any ePLC program.

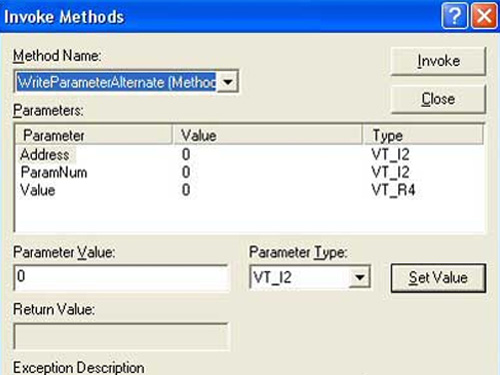

OCX Element/Active X (32-bit): Programming Support

-

OCX / Active X software helps you to interface fast and easily with a PC or industrial PC via RS232 or RS485 serial interface.

This software translates the data to and from the JVL MacTalk protocol so that you don’t have to worry about start and stop byte, checksum and retry. By using this software you do not need to understand the JVL protocol but only have to think about what’s important for you and that is to send data to the correct motor and register. You just send address, register number and value to a function and the driver see to that start and stop byte, checksum calculation and retransmission is done automatically. Additional it helps you with automatic calculation from an internal motor unit to eg. RPM and RPM/s 2. This is very useful when you have more JVL integrated motors like MAC140, MAC800 and MIS232 or the Controller SMC75 on the same serial line. You can interface to the most common software languages like:

- Visual Basic

- Visual C++

- Visual .Net

- Delphi

- Borland C++ Builder

- LabView

- Excel

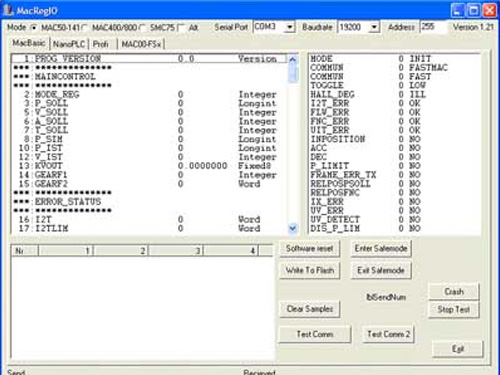

MACREGIO: Expert Tool for Programmers

-

If you would like to learn more about the MacTalk protocol this is the software that you need. When you are using a PLC and would like to send commands to the integrated motor you need to send data in a special format called MacTalk protocol. MacTalk protocol is not ASCII but binary, message-oriented. This means that you can’t use a windows terminal editor to communicate with the motor but need to use MacTalk, MACREGIO or send byte commands.

In the MACREGIO can you see a complete overview with register and description for all MAC motors, QuickStep MIS23x and SMC75. By pressing "R” you can read register´s content and by pressing "W” you can write a value to a register. You can see register value and if a register is a Word, integer or Longint.

As an extra help for the programmer the byte send and received is shown byte for byte so it is easy to see what should be send and what to expect as returned. Thereby implementation and debugging is very easily done.

MotorSizer

-

MotorSizer is a web based software freely available on the Internet 24 hours a day.

MotorSizer makes it very easy to determine the required motor and gear size for a specific task in applications such as machine design, education and research.

MotorSizer enables you to key-in all commonly required parameter values that influence the motor torque or power required in order to achieve the desired motion.

MotorSizer can be used for calculation of the correct motor and gear size for AC-Servo, DC-Servo, and Stepper motors.

MotorSizer is very easy to use. A single screen picture is used for displaying all parameters. Once the known values have been keyed in, simply select CALCULATE to display the results of the configuration.

- Easy to use

- Single screen for all calculations

- Can be used for dimensioning Step, AC-, and DC Servo Motors

- Following parameters can be keyed-in:

- Velocity - Acceleration - Time - Load

- Motor Inertia - Gear Inertia

- Vertical/Horizontal movement - Safety factor

- Can calculate with or without gearing on various drives: Spindle - Drive belt - Disk

- Also ideal for educational purposes

Touch Operator Panels

- Wide range of high quality Human Machine Interface panels for use with the integrated servo and stepper motors from JVL.

Touch Operator Panels for QuickStep and MAC integrated motors

-

Wide range of high quality Human Machine Interface panels for use with the integrated servo and stepper motors from JVL.

JVL now provide a wide range of excellent HMI operator panels for all our integrated motors. Available screen sizes from 4,3" to 15" with resolutions up to 1024 x 768. Enjoy easy creation of operator screens using the EV5000 development software package for Windows.

Highlights:

- Connects to all controller versions of MIS231..234

- Connects to all MAC050..141

- Connects to all MAC400 and MAC800

- Easy and intuitive development software

- All functions that you would ever need, including trend graphs, alarms and recipe handling

- Advanced Timer functions let you mask out individual bits in MAC/MIS/SMC75 registers

- Need very special functionality? Just write a macro in C !

- Ultra fast boot times reduce waiting time after power on. Good connectivity, even the smallest panels have 2 serial ports and an USB-port

Planetary, Robot and Worm Gears

-

Geared motors for any application

Easy connection of your JVL motors to a wide range of gear boxes - worm, low cost planetary, high performance planetary and backlash free robot gear reducers

HSHG Gear for Nema17 Motors

-

Double front flange for optional mounting. Motor flange and front flange is black oxidation. Ring body is spray plastic painting.

Benefit of the the HSHG gear is the output flange is the same size as the input flange, making it possible to easily attach another gear, or brake.

Also the detachable output shaft makes it so the customer can use his own shaft.

HSHG Gear for NEMA23 Motors

-

Planetary gear for NEMA23 motors

The series of HMGH planetary gears are specially designed for JVL. With their NEMA23 standard flanges they can be directly mounted on the MAC 050 to 141 series of integrated motors as well as on a wide range of stepmotors. They also fit directly on the new integrated step motors, QuickStep. Gears with other flanges can also be delivered from this series.

- NEMA23 standard configuration on input and output flange.

- All powder metal gears except adapter.

- Operating temperature range: 0 - 40°C ambient.

- Absolute max. 90°C.

- Maximum input speed: 4000rpm.

- Axial load 34kg max.

- Radial load 34kg max. at 15.8mm from shaft end.

- Very low losses.

- High efficiency.

- Low cost

Low Cost Planetary Gears HMGH

-

Planetary gear for NEMA23 motors

The series of HMGH planetary gears are specially designed for JVL. With their NEMA23 standard flanges they can be directly mounted on the MAC 050 to 141 series of integrated motors as well as on a wide range of stepmotors. They also fit directly on the new integrated step motors, QuickStep. Gears with other flanges can also be delivered from this series.

- NEMA23 standard configuration on input and output flange.

- All powder metal gears except adapter.

- Operating temperature range: 0 - 40°C ambient.

- Absolute max. 90°C.

- Maximum input speed: 4000rpm.

- Axial load 34kg max.

- Radial load 34kg max. at 15.8mm from shaft end.

- Very low losses.

- High efficiency.

- Low cost

Low Cost Worm Gears HFOS

-

Angled worm gears for NEMA23 motors

The HFOS gears are a series of inexpensive, very compact worm gears. By means of an adaptor Kit they can be mounted directly on motors with a NEMA23 standard flange, such as the MAC050-141 series of integrated AC servo motors and QuickStep integrated step motors. They will however also find applications with a wide range of common stepper motors with NEMA23 flanges. These gears offer the advantage over planetary gears that they by nature are angled and gives a very short total length of motor plus gear. The gears can be delivered both right- and left-angled as well as with output shaft to both sides. A wide range of gearing ratios, from 6:1 to 75:1 are available. When ordering, various worm and cogwheel materials can be chosen in order to optimize the gear for the application. On the output side the gears can be delivered with a 30 mm machined recess for centering and 4 M5 threaded mounting holes. A mounting fixture is available for mounting of the motor-gear combination

- Gear ratios from 6:1 to 75:1

- Small build-in length, appx. 73 mm

- Inexpensive solution for many less demanding applications

- Adaptor kit for NEMA23 flanges

- Can be adapted to customer application

- Simpel and robust design

Worm gears HTTW

-

Worm gears in many sizes

This worm gear range allows you to supply compact sized stepper and servo gear motors for applications in many sectors that have limited dimensions and where high torque, hollow shaft and low cost is a necessity.

- Gear ratios from 5:1 to 100:1

- Output torque 12-166Nm. Up to 4KW

- Efficiency 39-91%

- Flanges for all JVL motors

- Assembly in many positions

- Die-cast aluminium housing for worm gearboxes

- Permanent synthetic oil long-life lubrication

- High reliability and space saving

- Many gears on stock

Precision Planetary Gears Type HTRG

-

The HTRG product range of precision planetary gears is the outcome of years of experience in the industry, and is the culmination of a decade-long dedication to performance enhancement. Comprising a wide range of low backlash planetary gearboxes, the units come in a range of precision classes up to 3’, and are available in seven gear frame sizes, with one or more reduction stages for gearing ratios from 1:3 to 1:1000. Double shaft, right angle shaft and right angle output shaft versions are also available. All this, combined with tens of motor mounting adapters held in stock, mean we can quickly respond to the most diverse application requirements of our customers. The gears can be mounted directly or by means of adaptor flanges on most of the JVL integrated servo and stepper motors as well as on the wide range of other motors from JVL. This datasheet shows the HTRG types of gear boxes which JVL normally has in stock for JVL motors and often delivered types. If a special type of gear box, a special ratio, less backlash, angled types etc. is not shown in the datasheet and is needed, then contact JVL A/S and we’ll find a type or a solution.

HTRGxxS Precision inline gears for high radial and axial load

-

The new HTRG-S product range of precision inline planetary gears is the outcome of years of experience in the industry, and is the culmination of a decade-long dedication to performance enhancement.

Features:

- 5 frame sizes

- Torque continues: 20 - 800 Nm

- Torque peak: 30 - 1200 Nm

- Tolerance: 3' - 7' ArcMin

- Stiffness: 12- 500 Nm/ArcMin

- Radial load: 2.400 - 29.000 N

- Axial load: 4.300 - 16.000 N

- Ratio: 3 - 100:1

All this, combined with tens of motor mounting adapters are possible. The gears can be mounted directly on MAC400-3000 depending of size.

Option: For NEMA23 or NEMA34 motors please see HTRGxxU type.

HTRGxxU Precision inline gears for high radial and axial load

-

The new HTRG-U product range of precision inline planetary gears is the outcome of years of experience in the industry, and is the culmination of a decade-long dedication to performance enhancement.

Features:

- 3 frame sizes

- Torque continues: 29 - 155 Nm

- Torque peak: 60 - 360 Nm

- Tolerance: 5' - 12' ArcMin

- Stiffness: xx- xxx Nm/ArcMin

- Radial load: 500 - 2.000 N

- Axial load: 1.100 - 4.000 N

- Ratio: 3 - 100:1

All this, combined with tens of motor mounting adapters are possible. The gears can be mounted directly on MAC400-3000 depending of size and on NEMA23 and NEMA34.

Robot Gears HSPG

-

Features:

- Zero backlash

- Integration of high capacity radial-axial bearings into the reduction gear

- Almost 100% increase of the rated torque

- More than 90% transmission efficiency by rated torque

- Large scale of reduction ratio (31-191)

- High precision performance

- High linearity of the torsion characteristics

- Elimination of the gliding friction from the reduction mechanism

- Very low level of noise and vibration

- Very simple construction

- Decreased external dimensions

- High reliability

- Long service life

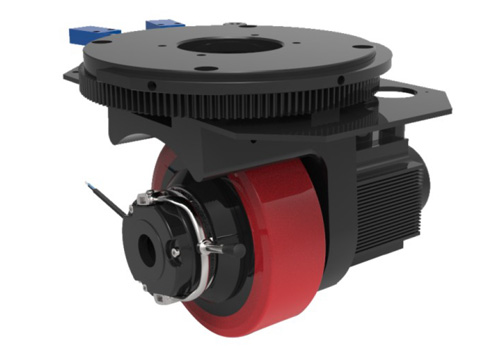

HLMT - Rotary Actuators for ServoStep and MAC motor®

-

Hollow Rotary Actuator

Our new series of Hollow Rotary Actuators, HLMT, offer the easiest possible installation of rotary table applications. Depending on your application you can choose between servo and stepper motors – with or without built-in (absolute) encoders.

Mechanically they are ready to install – and mounting of rotating discs have never been easier. At the same time you gain the usual benefits of JVL’s integrated motors also making electrical installation child’s game.

- Complete Rotary Actuator

- Integrated Step or Servo motor

- Easy point-n-click programming

- All Ethernet protocols

Later we will provide as option the HLMT-SENSOR-KIT: Fork sensor and metal clamp (both for direct mounting onto the turn table) including small bolts. Used for Reference-signal (1 time per rev) or Homing.

Automated Guided Vehicle Gears

-

Automated Guided Vehicle AGV gear for wheel application with integrated stepper or servomotor.

HSHV is a new AGV gear where planetary gear is build inside the wheel for a very compact and short construction in walking and steering applications. Gear is delivered with a polyurethane wheel for harsh industrial application and have proved it worth in many AGV’s . Two angular contact bearing for very high load performance and long lifetime

Features:

- Two angular contact ball bearing for high quality and high load

- Rated output torque up 120Nm

- Radial force up to 6500N

- Axial force up to 850N

- Efficiency 92%

- Standard gear Ø160mm wheel diameter

- Under development 100, 140, 200 mm wheel diameter

- Gear ratio 10,15,30 2stage planetary gear

- Backlash

- Select stepper or servomotor in many different sizes

- Brake option available in motor or front mounted

- Standards flange for MIS34x and MAC40x

- Optional complete walk and steering solution in one unit

Electronic motor Brake for NEMA23 (57mm) and NEMA34 (86mm)

- The electronic brake is designed and produced by JVL to be mounted on stepper- and servo motors that have NEMA23 and NEMA34 flange such as the MAC50-141 series of integrated servo motors and the series of QuickStep MIS23x and MIS34x integrated stepper motors. The brake has zero backlash and no auditory noise. It fits on all step- and servo motors with NEMA23 and NEMA34 flange and can from stock be delivered with different input and output shaft. Connection can be wire or M8 connector. Protection from IP44 to watertight IP67.

NEMA23 57mm Electronic Motor Brake MAB23x

-

Electronic brake for all NEMA23 motors

The electronic brake is designed to be mounted on step- and servo motors, such as the MAC050, MAC095m, MAC140 or MAC141 series of integrated servo motors. Brake can also be used on MIS231,MIS232,MIS234 series of integrated stepper motors and MST23x stepper motors without build in controller.

A high quality electro-magnetic brake is mounted inside the housing. The brake has zero backlash and no auditory noise. Holding torque can be 0,5 to 1,5Nm.

It fits on all step- and servo motors with NEMA23 57x57mm flange and optional 6.35, 8, 10 and 11mm in and output shaft.The brake is used when it is desired to hold the motor shaft fixed at power off, or when the motor is used in a vertical linear application.When 24 VDC is connected, the brake will be deactivated and the motor can turn freely. It is recommended to use the brake only as a holding brake and not as an emergency brake.

NEMA34 86mm Electronic Motor Brake MAB34x

-

Electronic brake for all NEMA34 motors

The electronic brake is designed to be mounted on step- and servo motors, such as the MIS340,MIS341,MIS342 series of integrated stepper motors and MST340, MST341,MST342 series of stepper motors without build in controller.

A high quality electro-magnetic brake is mounted inside the housing. The brake has zero backlash and no auditory noise.

It fits on all step- and servo motors with NEMA3486x86mm flange and optional 9.35mm and 14mm shaft. The brake is used when it is desired to hold the motor shaft fixed at power off, or when the motor is used in a vertical linear application.

When 24 VDC is connected, the brake will be deactivated and the motor can turn freely. It is recommended to use the brake only as a holding brake and not as an emergency brake.

MAB34x, NEMA34 86x86mm 1.7Nm

-

Electronic brake for all NEMA17 motors.

The electronic brake is designed to be mounted on step- and servo motors with NEMA17 flange 42x42mm. Brake itself have NEMA17 mounting dimension but flange size is 46x46mm. Brake can be mounted directly on stepper motor from JVL MST17x and also JVL integrated stepper motor MIS171, MIS173, MIS176 with 5, 6.35 and 8mm shaft. Brake can also be used on any other brand motor that use NEMA17 standard and have 5 , 6.35 and 8mm shaft. Output shaft can be 5 or 8mm. Shaft collars ring with 1 screw is used to tighten brake on motor shaft. A high quality 24VDC electro-magnetic spring brake is mounted inside the housing. The brake use hub connection to brake disc so it can be mounted on motors with axial play. Holding torque is 0.5 to 0.7 Nm.

The brake is used when it is desired to hold the motor shaft fixed at power off, or when the motor is used in a vertical linear application. When 24 VDC is connected, the brake will be deactivated and the motor can turn freely. It is only recommended to use the brake only as a holding brake and not as an emergency brake.

All brake are equipped with M8 4 pin male connector for 24V control voltage.

Encoders

- JVL offers a range of encoders. Both linear and

rotating, Incremental, magnetic, absolute multiturn. SSI and BISS.

JVL is Exclusive distributor for LIKA Electronics and Givi Misure rotational and linear encoders.

JVL Linear and rotating encoders. Absolute multiturn and SSI

-

Typically, absolute-encoders are used when there is a need to continue operation immediately after power is re-applied to a machine or system, without first having to perform a zero-search reset. Thereby the cost for sensor and mounting time is saved Another major reason for using absolute encoders is to correct motor position in relation to the actual physical absolute position measured. All encoders can be mounted on its own connector on the JVL motor, stepper or servo. No need for external power supply or connection boxes, because the encoder is powered via the same cable from the integrated motor.

The SSI interface is used with double or triple reading to secure reading even in noisy environment. The rotational encoder can be delivered as a magnetic based low cost version with 1 degree error or a high precision optical version with 0.05 degree error. Magnetic Linear encoders have precision down to 50µm and can therefore be used for high precision application at a low cost.

Rotating and Linear Encoders

-

Lika Electronics - Italy

Complete program of optical encoders with direct connection to JVL drivers and controllers

Features:

Rotating encoders

LIKA Electronic develops a wide range of absolute and incremental encoders which meet all industrial standards. Wide selection of resolution, cable connection, shaft diameter, IP protection class, voltage connection, Profibus, DeviceNet, CAN Bus interface etc.Encoder resolution from 8 to 65535 pulses per revolution.

Linear Encoders