- Offer Profile

- Founded in 2002 in Lévis (Québec, Canada), Creaform is a world-class leader in 3D measurement technology as well as 3D engineering services. We develop, manufacture and distribute portable and automated 3D scanning solutions to thousands of clients in over 75 countries. Our innovative technology benefits a wide range of industries such as automotive, aerospace, manufacturing, consumer products, research & education, NDT, heavy Equipment and power generation.

Portable 3D Scanners

-

Discover a new level in performance for 3D measurements.

Creaform develops, manufactures and sells portable 3D measurement solutions, application software platforms, and dimensional metrology services for industrial applications. Thanks to Creaform's innovative R&D, we redefine the boundaries of 3D measurement by constantly pushing the limits of technology.

HandySCAN 3D|BLACK Series

-

When accuracy meets versatility and portability.

Optimized to meet the needs of design, manufacturing and metrology professionals, the HandySCAN 3D|BLACK Series is the premier 3D scanner for accurately and reliably measuring parts of any size, material, or complexity. It delivers results within seconds, anywhere.

Certified based on the most rigorous industry standards, this fast and versatile handheld 3D scanner is easy to use and captures highly detailed measurements—even under challenging environmental conditions and on complex surfaces.

- Accuracy of 0.025mm

- Large Scanning area

- Worldwide support

- ISO 17025

- Scan-to-mesh In seconds

- Patented Technology

Go!SCAN 3D

-

The fastest and easiest 3D scanning experience

The Go!SCAN 3D is our fastest, user-friendly handheld 3D scanner. A powerful tool during the product development phase, the Go!SCAN 3D quickly measures any complex surface making it possible to “get it right” the first time. With its seamless integration to your 3D modelling software and your product life cycle management workflow, it will greatly improve product development, foster innovation and shorten time to market.

Designed to scan any object without need for a set-up, it offers flawless texture and geometry acquisition as well as impressive details in a rich color palette. Just go…and scan!- High level of details

- Accuracy of 0.050mm

- Worldwide support

- Color acquisition

- No set-up required

- Patented technology

HandySCAN 3D|SILVER Series

-

When accuracy meets versatility and portability.

The SILVER Series is part of the HandySCAN 3D™ line-up, the industry standard in portable metrology-grade 3D scanners.

This proven and trusted patented technology captures accurate 3D measurements with an impressive level of detail on any surface finish and in any location.

The HandySCAN 3D|SILVER Series is optimized to meet the needs of technology innovators and engineering professionals looking for a powerful, accessible, and reliable way to improve product development, shorten time-to-market, and reduce development costs.- Accuracy of 0.030mm

- Worldwide support

- Patented Technology

- Proven and trusted solution

MetraSCAN 3D

-

Speed and accuracy combined with versatility

The MetraSCAN 3D optical CMM scanner line-up is specifically designed for manufacturing and metrology professionals who do not want to compromise on quality or efficiency. It can withstand any production environment, including shop floor vibrations, part movements and environmental instability—all while accelerating 3D measurement workflows. This optical CMM scanner has been engineered to perform highly accurate and repeatable metrology-grade measurements and 3D geometrical surface inspections.

When paired with the HandyPROBE, Creaform’s handheld optical coordinate measuring machine (PCMM) with probing capabilities, users can also harness the power of both 3D scanning and probing for complete, end-to-end inspection processes.- Accuracy of 0.025mm

- Certified ISO 17025

- Patented Technology

- Worldwide support

HandySCAN 3D|MAX Series

-

When accuracy meets versatility and portability.

Combining the effect of portability, accuracy, speed, and simplicity, which are inherent to the HandySCAN 3D line-up, the new MAX Series is optimized to acquire highly accurate 3D measurements on large and complex parts typically present in the aerospace, transportation, energy, mining, and heavy industries.

Engineered to capture fine details and scan large volumes equally well, the HandySCAN 3D|MAX Series enables professionals to measure large parts and assemblies in a simpler scanning process, resulting in high-quality 3D scans in just a matter of minutes.- Accuracy of 0.075mm (0.0030 in)

- Scan-to-mesh in seconds

- Large scanning area

- Worldwide support

Automated quality control solutions

-

Fast and accurate 3D scanning solutions for automated quality control

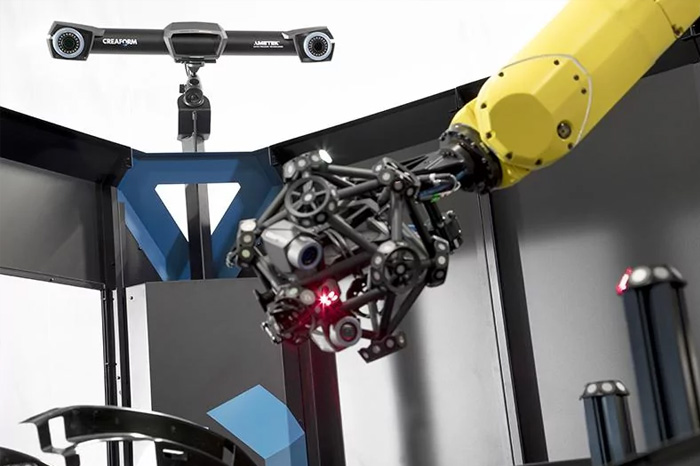

R-Series

-

Detect Quality Issues Faster and Make Better Decisions

Designed for automated quality control applications, the R-Series™ 3D scanning solutions are perfect for manufacturing companies who want to increase their productivity by measuring more dimensions on more parts without compromising on accuracy.

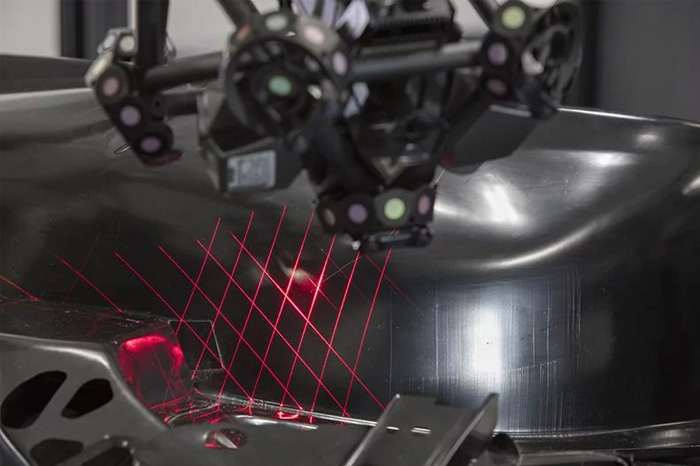

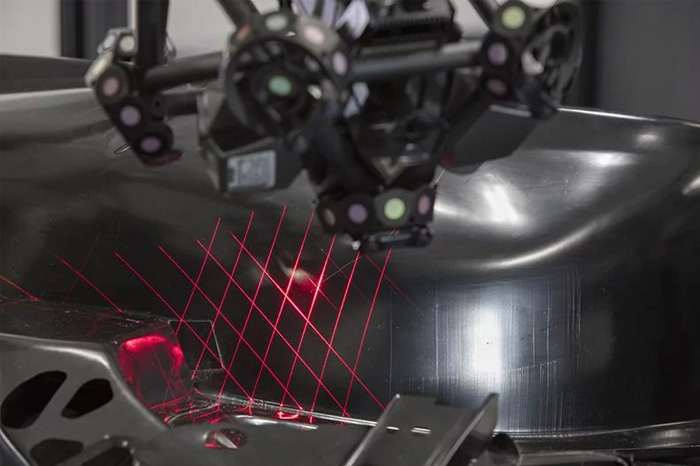

The MetraSCAN 3D-R™ is a powerful, innovative robot-mounted optical CMM scanner that can be seamlessly integrated into automated quality control processes for at-line inspection in mass production. Its cutting-edge technology enables manufacturing companies to detect quality issues faster.

The CUBE-R™ leverages the power of the MetraSCAN 3D-R in a high-productivity industrial measuring cell that has been designed to be integrated into factories for at-line inspections. Compared to traditional CMMs, the CUBE-R is much faster, providing a gain in productivity and better efficiency.- Accuracy of 0.025mm

- Repeatable results

- Worldwide support

- Short cycle time

- Certified ISO 17025

- High resolution

Coordinate measuring machines

HandyPROBE

-

Accuracy and simplicity combined with portability

The HandyPROBE™ line-up is a portable optical CMM specifically designed for use on the shop floor. Thanks to its metrology-grade accuracy and dynamic referencing capabilities, the HandyPROBE delivers unmatched accuracy regardless of the measurement setup, instabilities of the environment and user experience level.

Without the requirements of a rigid measurement setup, the complete measuring system—the part, optical tracker, and wireless probe—can all be moved freely at any time during the measurement sequence.

The HandyPROBE is simply the best metrology solution for measuring geometrical entities on parts of any size directly on the production floor.- Accuracy of 0.025mm

- Worldwide support

- Certified ISO 17025

- Patented Technology

MaxSHOT 3D

-

Elevate your measurement speed and accuracy on large parts

Creaform’s MaxSHOT 3D™, a photogrammetry optical coordinate system, is a game changer for product development, manufacturing, quality control and inspection teams. It is the ideal solution to achieve the highest measurement accuracy and efficiency for large-scale projects and parts from 2 to 10 m. Imagine obtaining accuracy levels better than 0.015 mm/m. Gain peace of mind knowing that your measurements are always right on the dot.

What’s more, thanks to sophisticated, proven user guidance technology and easy-to-use software, technicians of all levels—even non-metrology experts— can use the MaxSHOT 3D. Contrary to traditional photogrammetry, the MaxSHOT 3D features automatic feedback before final measurements captured. Never take a bad image again!

If you consistently work on large-scale projects, the MaxSHOT 3D is your go-to solution to slash budgetbusting measurement mistakes, improve product quality, increase process efficiency, and minimize overall operating costs.- Accuracy of 0.015mm

- Worldwide support

- VDI/VDE 2634 Part 1

- Integrated and streamlined process

3D Scanning Software Solutions

- 3D-Scanning-Softwarelösungen

VXelements

-

The intelligence behind Creaform’s 3D measurement and scanning solutions

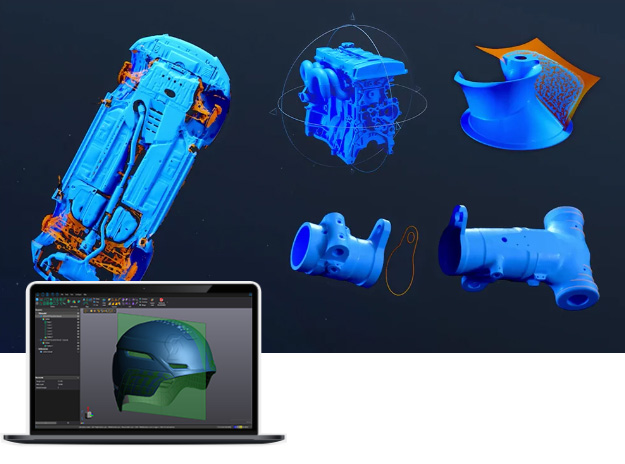

VXelements is a powerful integrated 3D scanning software platform that works in complete synergy with the entire fleet of Creaform’s 3D measurement solutions. It combines both acquisition and application modules into the same simple, easy-to-use interface, providing a complete solution rather than a simple measurement device alone.

Included with all of Creaform’s 3D measurement technologies, VXelements acquisition modules produce superior accuracy and data quality from 3D measurements and provide real-time visualization.

VXelements guarantees you optimal user experience, seamless interaction with your device, and the shortest time to usable mesh or 3D data—everything you need to use your Creaform optical technology to its full potential.- VXmodel

- VXinspect

- VXscan-R

- VXtrack

VXintegrity

- Composed of four software modules designed specifically for the NDT industries, VXintegrity is a powerful NDT software platform that integrates all analytical functions and tools into an intuitive, user-friendly working environment. It combines NDT knowledge and market intelligence to raise the quality of analysis and reporting to a higher level.

3D Measurement Solutions

-

Product Development and Design

- Product development refers to all of the stages involved in bringing a product to market—from inception through conception and engineering design to product development. Computer-aided design (CAD) software is used as a design tool to enhance product development.

As project managers, senior engineers, or engineering directors, you are responsible for finding ideas that lead to new product introduction. Innovation is the essential element that maintains your company’s competitive edge through the development of new technologies, new projects, new angles, and new niches that help you surpass your competitors.

As design engineers or industrial designers, you participate in all of the activities related to product development and implementation. You must first determine if the design intent is feasible and if all of the necessary tools and software to realize the whole project are accessible and available. Then, you design parts (often with complex shapes and geometries) and create 3D models while minimizing iterations in order to shorten the design cycle.

Reverse Engineering

- Reverse engineering is a process that involves measuring a physical object and reconstructing it as a 3D model to recover the design intent—a perfect reconstruction of the original design—in terms of simple analytical surfaces (planes, cylinders, etc.) and freeform surfaces (NURBS) in order to produce a new reference CAD model.

As CAD engineers and industrial designers, you have the critical task of adapting and maintaining parts with shapes that are frequently organic and complex. Since the CAD models are often no longer available or difficult to find, you have to reconstruct the 3D models and integrate them into the design.

The reasons for reverse engineering are multiple: to replace damaged components (for which CAD models are nonexistent), to update obsolete parts, to fit new parts into a current assembly or environment, to generate new manufacturing plans, or simply to analyze competitors’ product features. 3D scanners are generally the preferred technology for extracting dimensional information and representing it as a point cloud or an automatic and instant mesh.

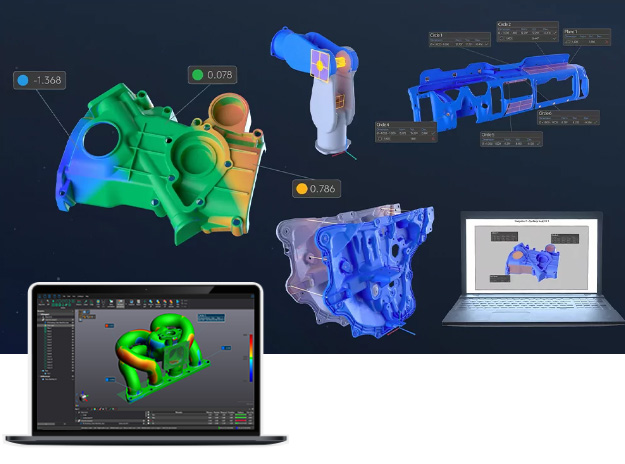

Quality Control and Quality Assurance

- Dimensional quality control (QC) is a process that measures the dimensions of manufactured parts to ensure that they adhere to a defined set of quality criteria and match customers’ requirements. Quality assurance (QA), on the other hand, consists of a set of procedures that prevent mistakes and defects in the different steps of the manufacturing process in order to avoid non-compliance when delivering parts to customers.

As QC managers, you have the delicate task of ensuring—even improving—the quality of the manufactured parts by applying effective controls performed with reliable, fast, and easy-to-use measuring equipment. You are also responsible for testing and validating the true performance of these instruments. Therefore, equipment unavailability, inefficiency, and limitations are obstacles to your work performance.

As QA engineers, you are in charge of investigating the problems raised by QC and production, performing the root cause analysis (often under pressure), and implementing corrective actions quickly to limit downtime. Through this process, you will also look for ways to improve the manufacturing process while minimizing production costs and lead time.

Maintenance, Repair, and Overhaul

- Maintenance, repair, and overhaul (MRO) refers to any action, including tests, measurements, replacements, and adjustments, that helps to maintain or restore products, machinery, tooling, or plants to their working conditions. Planned, predictive, preventative, and corrective maintenance are the main forms of overhaul.

As structure engineers or maintenance managers, you are responsible for the integrity of parts, equipment, or infrastructure. You are in charge of characterizing and repairing defects according to the acceptance criteria detailed in the manufacturer’s manual. To do so, you have to find and apply the right repair methods or contact the OEM to determine if the measured data exceeds the acceptance criteria. Unreliable data and unrepeatable results complicate your work, as do user-dependent measurements. How can you characterize damages and take corrective actions if the measured data on the same structure differs from one operator to another? More importantly, how can you make the right repair decision knowing that important operational and safety issues are often at stake?

Non-Destructive Testing (NDT)

- DNon-destructive testing (NDT) is an inspection and analysis technique used by the oil and gas industry, among others, to evaluate the properties of pipelines without destroying the serviceability of the original system. Surface corrosion, mechanical damages, and cracks are the most common discontinuities detected by visual examinations.

As NDT managers or project engineers working for a service company, you supervise the team of technicians in charge of collecting data during the pipeline inspections. You must verify and analyze the results to provide the pipeline owner with the right diagnosis. For you, inaccurate and unreliable measurements could lead to faulty analysis that can have important consequences.

As integrity managers or engineers working for a pipeline owner, you are responsible for evaluating and maintaining the integrity of aging pipeline networks. The decision to repair a section of the pipeline or to challenge the diagnosis provided by the service company is under your authority. Thus, to ensure the pipeline’s integrity and reliability, you must make the right decision, based on information that you trust.

Science and Education

-

Educational programs that integrate 3D measurement technologies into engineering courses not only demonstrate up-to-date and state-of-the-art expertise, but also offer students the knowledge they need to get the job they are looking for in the industry.

As teachers and researchers, you must show future engineers the fundamentals of engineering based on industry requirements. To do so, you must follow the evolution of technologies and be up to date on the current techniques used in the industry. For students, you are a source of knowledge and a technology expert capable of demonstrating advanced skills.

Nevertheless, the role of professors has one main constraint: lack of time. Between teaching, research, and service requirements, you usually have little time to develop new subjects and integrate them into your classroom curriculum. Thus, how can you stay up to date with the newest technologies and trends, such as laser and white light 3D scanners, in order to capture the attention and interest of your students?

Medical

- Orthotic and prosthetic applications, two medical specialities within the field of healthcare technology, require scanning the human body with non-contact devices in order to design and manufacture orthoses or prostheses.

As prosthetic and orthotic physicians, professionals, or technicians, you want to assist your patients in leading a functionally normal lifestyle with good quality orthoses or prostheses that they find comfortable. Nevertheless, you are not 3D scanning experts. Therefore, you need to find a simple 3D scanning tool and user-friendly software that you can master in just a short period of time and without undergoing extensive training. In addition, to optimize scanning sessions with patients, you should be able to install the tool and be ready to scan in less than 5 minutes in any kind of environment.

Other Applications

- The other applications where 3D scanning provides impressive benefits are multiple. They include heritage preservation, art and architecture, and multimedia.

Heritage preservation is where old objects meet new technologies.

As archaeologists and researchers, you have the delicate task of preserving our cultural heritage. Thanks to non-contact 3D scanning, you can efficiently scan rare objects and artifacts and digitally create 3D models with maximum quality and realism in order to study, restore, or duplicate them, document and classify them into catalogues, repositories, and databases, and share them among the researcher community.