Opto

- Offer Profile

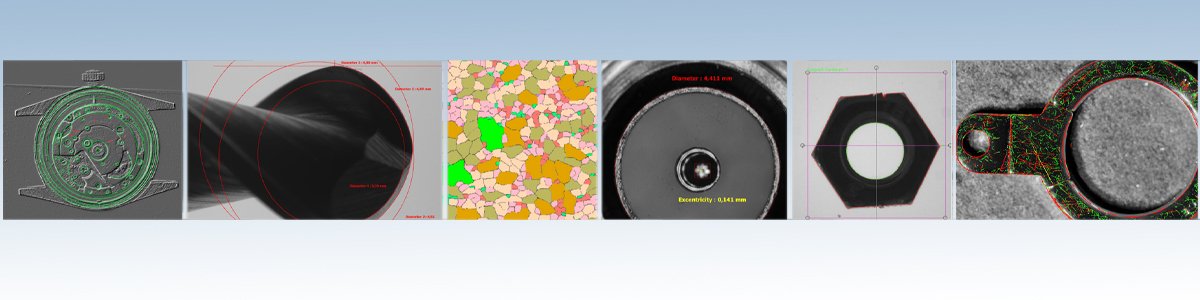

- Opto GmbH has been developing and manufacturing compact imaging modules for industry and medical technology for 40 years. Opto supports device developers and OEM's in the development of their optical requirements - from prototype to series production.

Product Portfolio

Imaging Modules

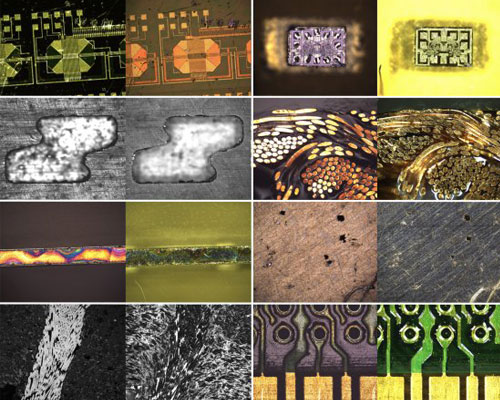

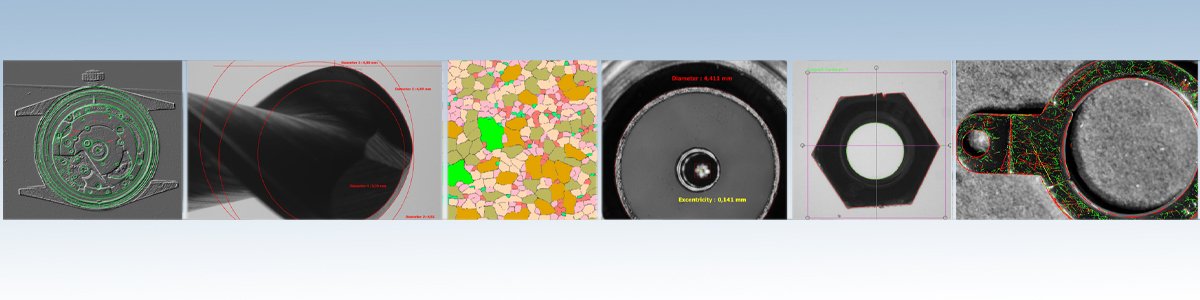

- IM deliver the Image Information that you need “Plug & Play”

Imaging Modules are cameras with integrated optics, illumination and electronics.

Plug & Play (One Wire Concept)

Compact and Robust (Limited Form Factors)

Measurement ready (Many Software Options)

Designed for smart production, and many ‘Industry 4.0’ applications, Opto Imaging Modules bring an unprecedented level of intelligent, easy-to-use, easy-to-integrate, imaging performance to any production environment - from measurement machines to test systems or roundness analysis to bio imaging instrumentation.

Each Module is provided with its own SDK and image acquisition software, making it simple to integrate into any network or system.- Various high resolution, perfectly optimised closed-loop optical designs coupled directly to the latest onboard imaging sensors - no camera needed.

- One wire direct USB3 image output & compati- bility to most machine vision software packages.

- Ultimate imaging performance, simple integration, guaranteed performance first time, every time.

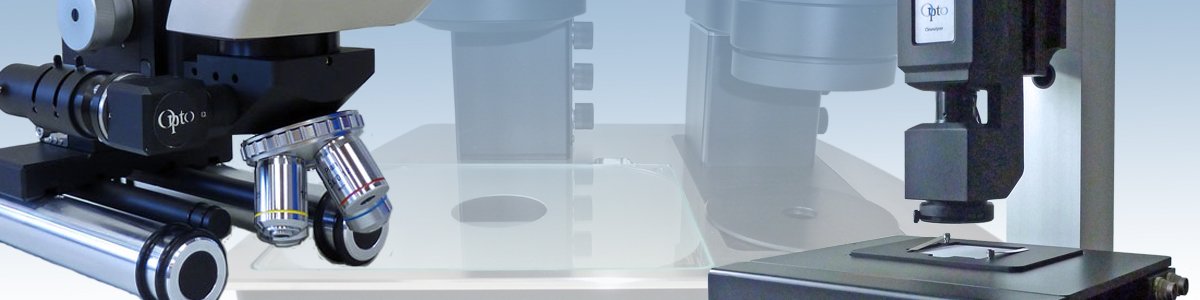

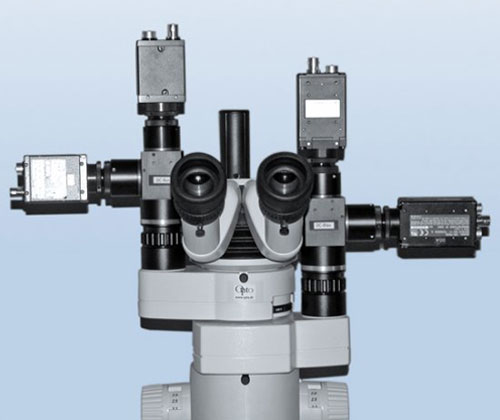

Microscope IM

- Microscope Imaging Modules are pure digital microscopes with no compromise in Quality.

One Microscope for one Application.

They can include in Standard or OEM versions:- Contrast (EPI, Fluorescence, DIC, Phase, DF, BF)

- Cameras (USB, GigE)

- Light (LED, Coax, Ring, Koehler)

- Electronics (Trigger, Controller, Embedded Computing)

- Software (Measure, Analyse, Detect, Computational Imaging, solino)

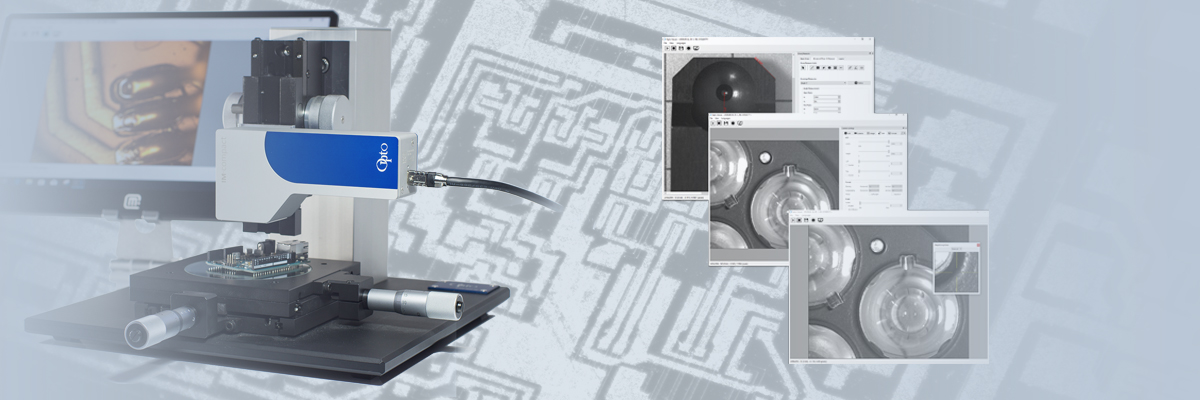

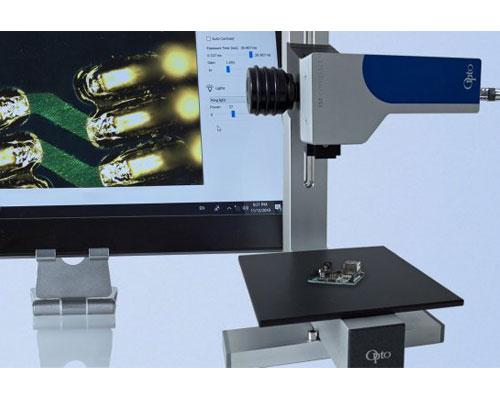

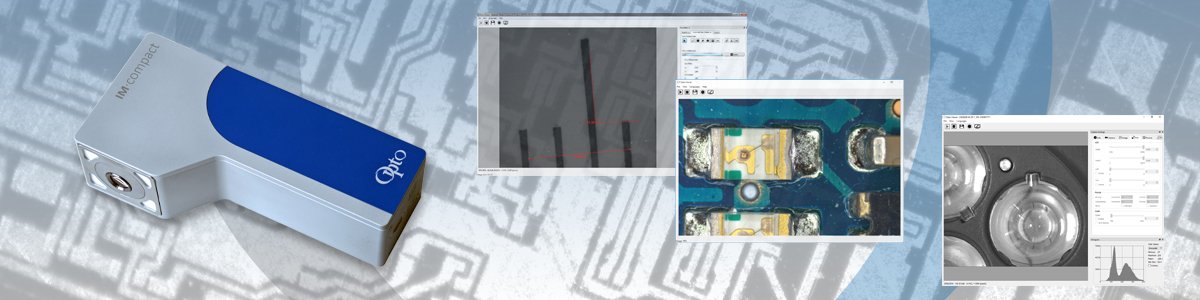

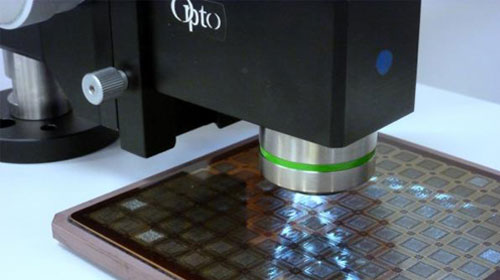

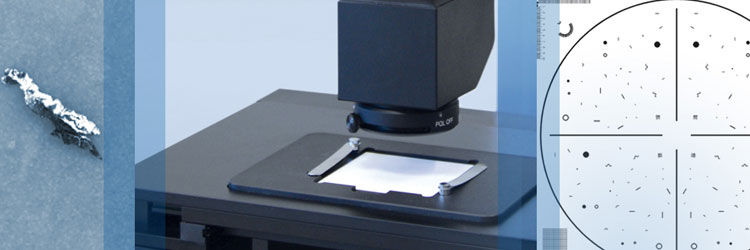

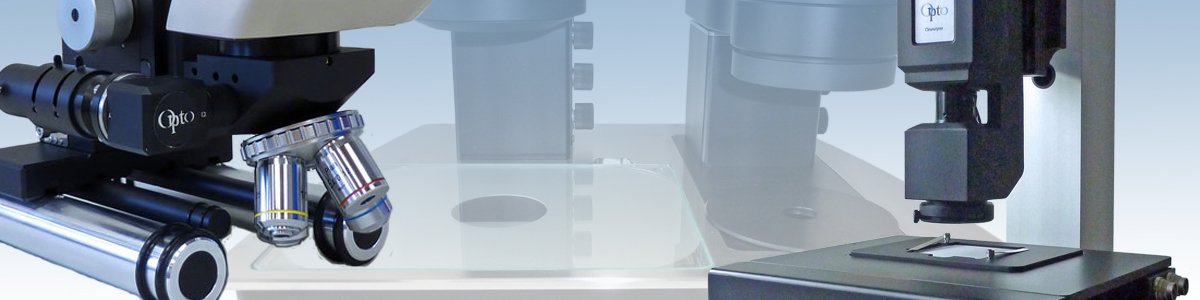

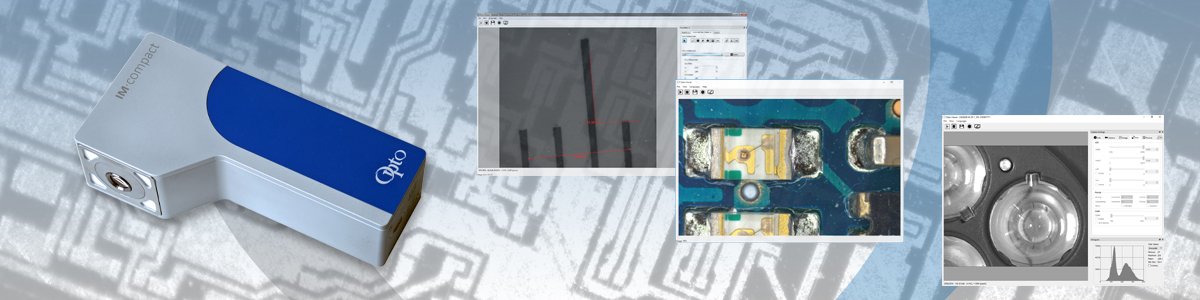

Machine Vision Microscope

- The new Machine Vision Microscope (MVM) is a purely digital microscope with all the features that make a microscope.

It has an apochromatically highly corrected microscope objective and a corresponding tube lens which magnifies each object point to one pixel of the 5MP Sony IMX264 sensor.

In addition, a coaxial incident light and a diffuse ring light have been installed.

The module offers an unprecedented level of user-friendliness. The MVM comes with our own image acquisition software, so it can be easily integrated into any network, system or production environment.

The new digital microscope can thus be easily integrated into measuring devices, analysis systems or bio-imaging systems.- Sub-Micron resolution

- Apo corrected Optics

- LED Coax and Ring-light switchable

- USB 3.1, 5MP colour and B&W camera

- SLWD Optics

- Measurement ready Software

- Pre-Calibrated Memory

- Newest Sony IMX Sensors integrated

- Compact Aluminium Housing

- One Wire USB-C Connector

One Microscope for various applications

The Machine Vision Microscope MVM is one Unit, Plug and Play. A pure Digital Microscope for the following Applications:- Hardness Testing

- Bond Inspection

- SMD Control

- Solar panel Analysis

- Measurements and Documentation

- Surface Analysis

- Rheology

- Scratch Analysis

- Crystal Measurement

- Adjustment Tool

- Micro Connector Measurement

- and much more...

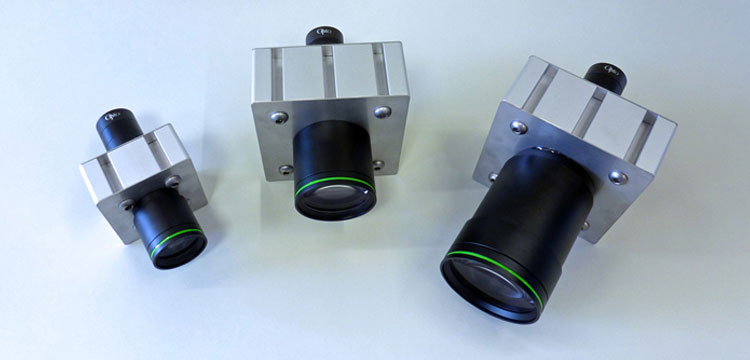

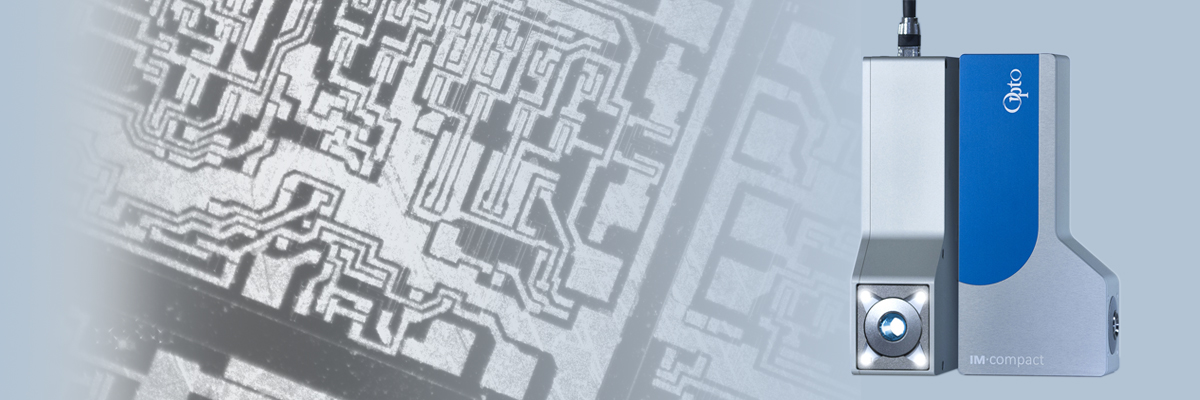

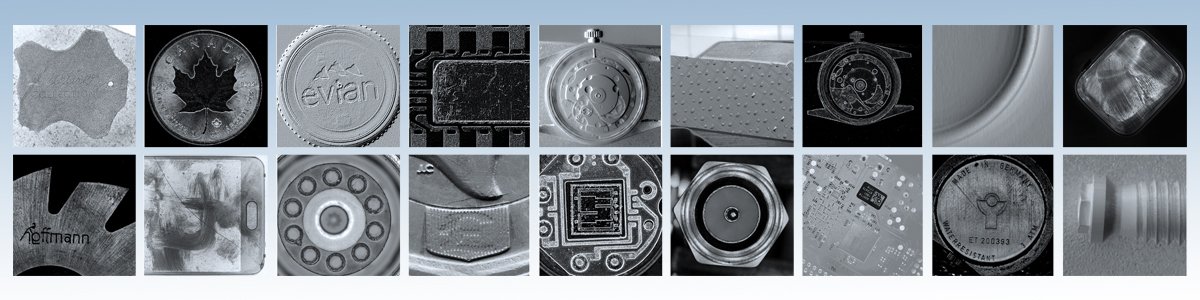

IM•series

The MVM is part of the new Imaging Module family in the 90° IM-compact M design and stable aluminium housing, with a single connection (plug&play).

Imaging Modules are optimized combinations of camera, optics, illumination and electronics for a specific application at the same or lower price than a combination of standard components.

They are not only more robust and better adapted to the application, but also ensure the same configuration when re-ordered.

Machine Vision IM

- Our Opto Machine Vision Imaging Modules are Plug and Play sensors ideal for all Industry 4.0 Applications. They are all:

- Measurement ready

- Robust Fixed

- Magnification so no drift over the time

- One Sensor like the other "pre-calibrated"

Macro Imaging Modules

- Macro Machine Vision Imaging Modules

Our Macro Machine Vision Imaging Modules are imaging a FoV (Field of View) that is normally bigger then 20mmx20mm.

As there is a lot of competition in this market we reduced our offer to selected Modules where we can add significant value.

Black Line Imaging Modules

Our "Black Line" Imaging Modules are designedd to respond to all open requests in Machine Vision.

This includes special megapixel designs or telecentric Imaging Modules where the lens is bigger then Modules itself.

Multi Purpose Machine Vision Sensors

We equip complete Lab stations with Survey, guidance, documentation and assistance functionality.

Out of our own Opto Software frame work we are able to exctract only the needed drivers and plug ins that are needed.- Designed for the digital support of mechanical assembly Work

- Unique Opto Design / Own Manufacturing

- 3D time-of-Light Imaging Modules

- Pick to Light scanner solutions

- 2D high resolution Imaging Modules

- Complete Software Interface and Analysis

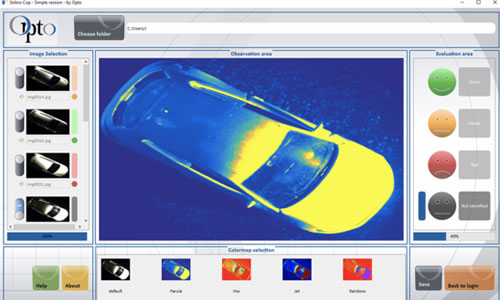

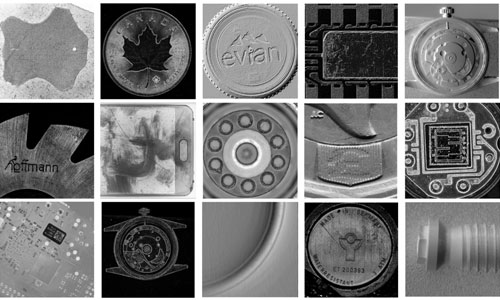

solino Plug & Play sensors

With our own solino Technology we are able to detect all Anomalies on a product with simple Image Aquisition Modules. We assist you in implementing solino in your solution to work as an AI quality control tool.

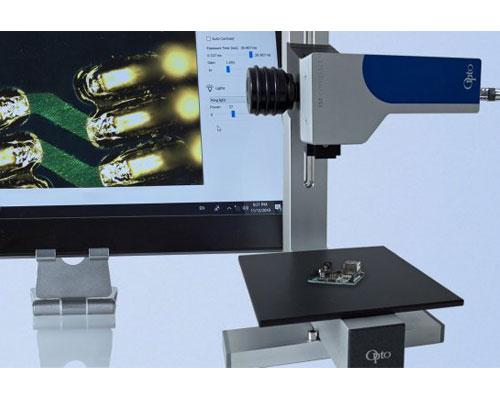

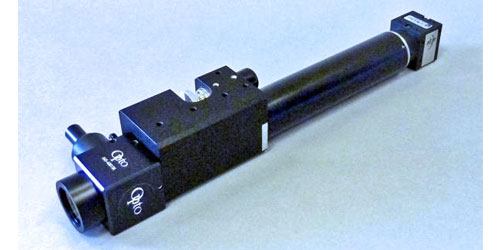

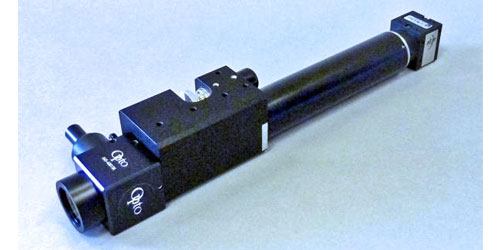

Micro Imaging Modules

- FOV Micro Measurement Microscope 4.0

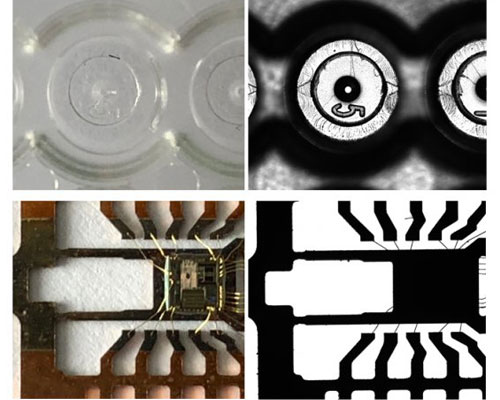

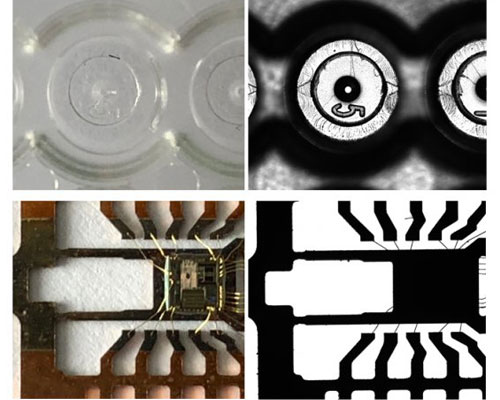

The new ultra-compact digital micro measuring microscope from Opto is the perfect tool for on-site measurements in production.

The image processing microscope digitizes professional quality where it counts.

The sensor design is robust, plug-and-play, easy to operate and equipped with integrated high-end optics and camera.

ith the built-in coaxial LED illumination and ring light, all kinds of features on a product can be visualized, similar to a traditional metallurgical microscope.

With a measurement resolution of 1.8 micrometers per pixel, it enables the analysis of the smallest details.

The free Optoviewer Software presents crosshairs, allows documentation and basic Measurements, whereas the market leading Measurement Software M3 from Metlogix makes it a High End Measurement device with proven functionality.

Specifications:

Digital Machine Vision Microscope- FOV: 4,5x3,8mm

- WD: 31mm

- Resolution: 277 LP/mm Coax and Ring Light

- USB3.0 / 5MP / Color Camera

Ultra compact light weight Stand- Focus Travel range 57mm Size 190x230x350mm

- Weight 2,5kg for easy transportation

OptoViewer 2.0- Simple User Interface

- Camera control for demanding integration tasks

- Pre-calibrated magnification settings

- Illumination adjustment

- One-click image storage

- Standard Measurement functions

- Reticule generator

- Basic Text editor

The Metlogix M3 one Touch Measurement Software performs critical analysis in all phases of your manufacturing process. It is a dependable, intuitive and multi spread tool in the metrology marketplace.- Measuring point acquisition by crosshair, clever video tools Multi touch probe capability

- Measure, construct and define 2D geometries

- Measure polynomes with the blob tool

- Position detection

- Part program with automated measurements

- Automated multiple parts measurement in the field of view

- DXF overlay in live image

- Contour tracking and BestFit

- Integrated Light control of the Opto Imaging Modules

- Tolerance check according to DIN / ISO with tolerance chart

- Launch program with barcode reader

- Image archiving (BMP, JP2, JPG, PNG)

- Program creation from DXF file

- Comprehensive data output as DXF, DXF point cloud, IGS cloud, CSV, TSV

- Q-DAS converter

- and much more ..

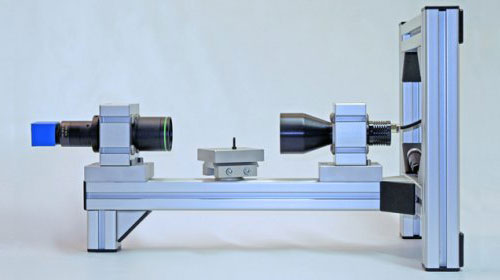

Telecentric Profile Projector

- IM•profile M ECO USB

The Profile Projector IM is a compact all in one telecentric imaging& projection module that delivers a distortion free, perfectly telecentric profile image of a component.

With its high magnification, the Profile Projector module isespecially suited to performing profile measurement of needles, implants, special micro screws or micro tools.

Its highly compact design makes it suited to a variety of integration possibilities, including inline integration, robot arm integration or deep machine integration.- Powerful Plug-and-Play USB Imaging Module

- Telecentric Lighting - White

- Integrated control and measurement software

- Optimized image, through special design

- One Wire concept - to the device

- Compact aluminium housing with many mounting options

- Sony Pregius Sensor IMX264

- Optimized Sony CMOS pixel: 3.45 µm

- High-resolution global shutter sensor: 2456 x 2054 (5.04 MP)

- Ultra compact: 155x145x40mm

Accessories IM

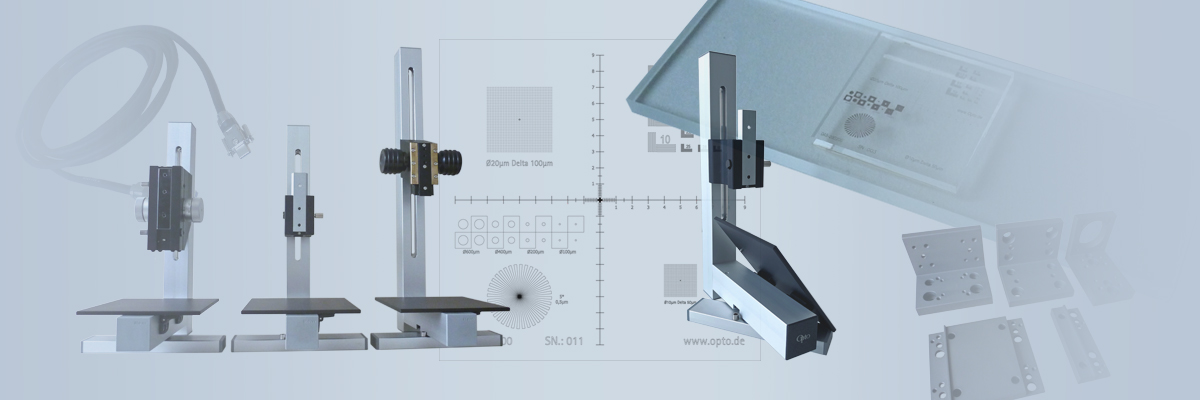

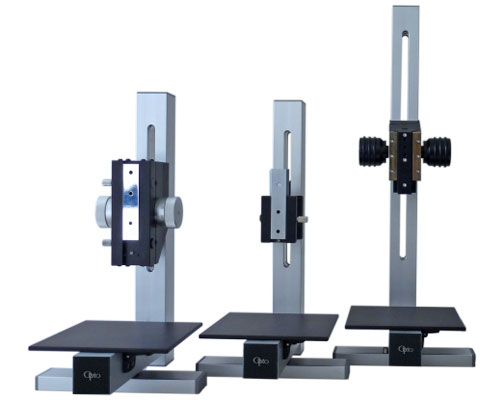

IM Stands

- IM•Stative light

IM•Stative-light_overview Our IM-stand light is specially designed for the Imaging Modules.

As a classic - stationary - tripod it takes up little space and is best suited for single workstations. But these stands are also foldable, for workstations that need to be flexible

Clamps and Mounts

- Mounting brackets

A variety of options are available for fixing the imaging modules:- integrated fastening threads

- Adapters and mounting brackets

- Opto-Dovetail

Cables

- USB 3.1 Gen 1, standard cable, screwable

USB Type-C on USB-A, straight, with the possibility of screwing- Cable: USB 3.1 Gen 1

- Cable type: Standard cable, double shielded in AWG26/28

- Connector: USB Type-C to USB-A, straight and screwable

- Cable length: 3 m

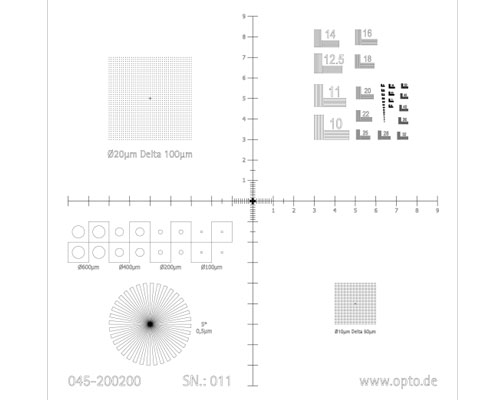

Calibration Targets

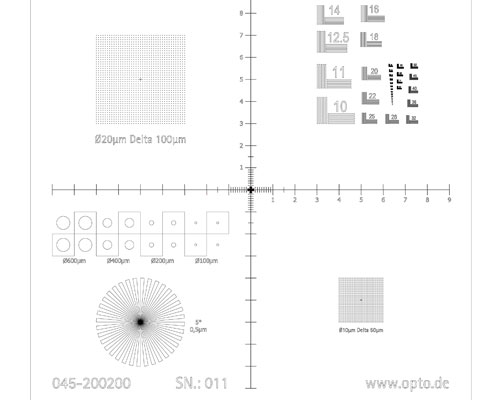

- Calibration Target Micro V1

Optical calibration and resolution testing are critical to understanding and optimizing any optical system

The Calibration Target Micro V1 is unique in that it combines very useful resolution data, combined with ultra-high definition micro-functions that allow efficient and accurate optimization of all optical settings.- Ultra-high definition micro features, compatible with the most demanding optical calibration requirements

- Four unique quadrants that combine resolution targets with measurement scales

- Supplied in a special padded storage compartment

Opto Viewer

- With every Imaging Module there comes the free OptoViewer.

It allows to easily install the Camera, drive the different Light Sources and it includes many additional functions as:- Simple User Interface

- Camera, coaxial & ring light settings

- Settings presets files

- Pre-calibrated magnification settings

- Illumination adjustment

- Flat field correction

- One-click export to image file storage

- Crosshair / grid / scale generator Drawing/Annotations (basic, shapes, bitmaps, text)

- Standard Measurement functions

- Point to Point Distance

- Angle

- Focus

Solutions

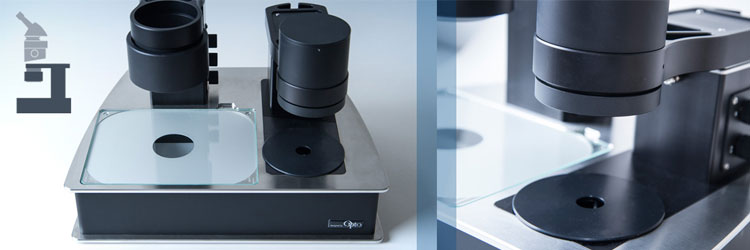

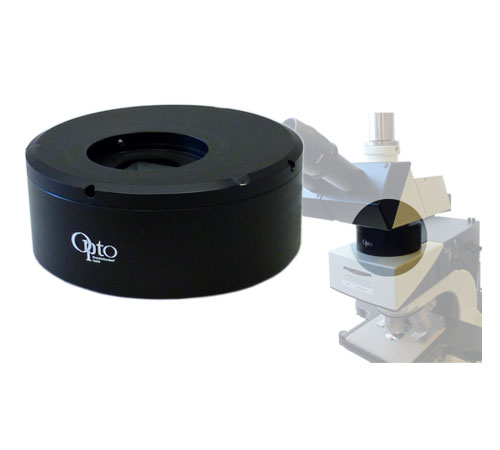

Inverse Controller

- Inverse optical Imaging Module

For instant micro-imaging of a wide variety of samples, Opto offers its bench-integrated inverse imaging unit. This innovative ‘under-bench’ design features integrated camera, high definition optics, LED ring light and optional software for acquisition and measurement.

The optimised design enables production samples to be placed onto the glass plate where it is instantly imaged with no focusing required.

All optical components are housed in a compact metal cover that is designed to be integrated at surface level with your working area.

Optical configuration:- Inverse Optic with fixed focal length

- Digitale Camera (4,92 Mpix resolution, CMOS, USB 3.0)

- LED Ringlight

Micro Measurement

- FOV Micro Measurement Microscope 4.0

The new ultra-compact digital micro measuring microscope from Opto is the perfect tool for on-site measurements in production.

The image processing microscope digitizes professional quality where it counts.

The sensor design is robust, plug-and-play, easy to operate and equipped with integrated high-end optics and camera.

ith the built-in coaxial LED illumination and ring light, all kinds of features on a product can be visualized, similar to a traditional metallurgical microscope.

With a measurement resolution of 1.8 micrometers per pixel, it enables the analysis of the smallest details.

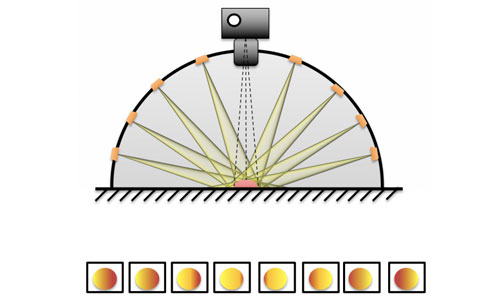

solino Movable Arm

- solino Movable Arm Image Aquisition station L

For R&D work the movable arm design is perfect to simulate every room position of a light source.

It was built to research surface Anomalies in its hole.

As a result there could come designs for complete new segmented solino ring lights or dome setups. Sample size up to 150x150mm

Profile Measurement

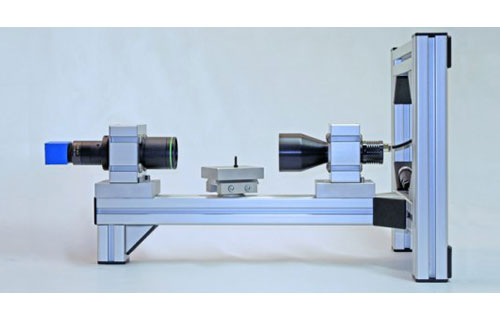

- Telecentric Bench

The combination of a Bi-telecentric lens and a collimated telecentric illuminator ensures optimised resolution and perfect image quality.

The optimum utilisation of the entire 17mm depth of field of guarantees perfect measurement of round objects such as springs, screws, bottles. Transmitted light configuration allows high speed image acquisition Standard aluminium profile construction enables easy machine integration Can be used in horizontal or vertical orientation

Optics

- For more then 40 years we develop and produce High End Optics and optical equipment that are installed in thousends of Machines worldwide

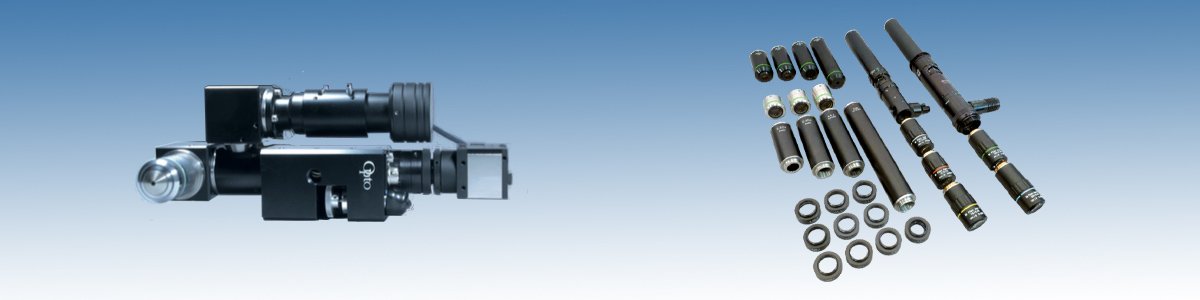

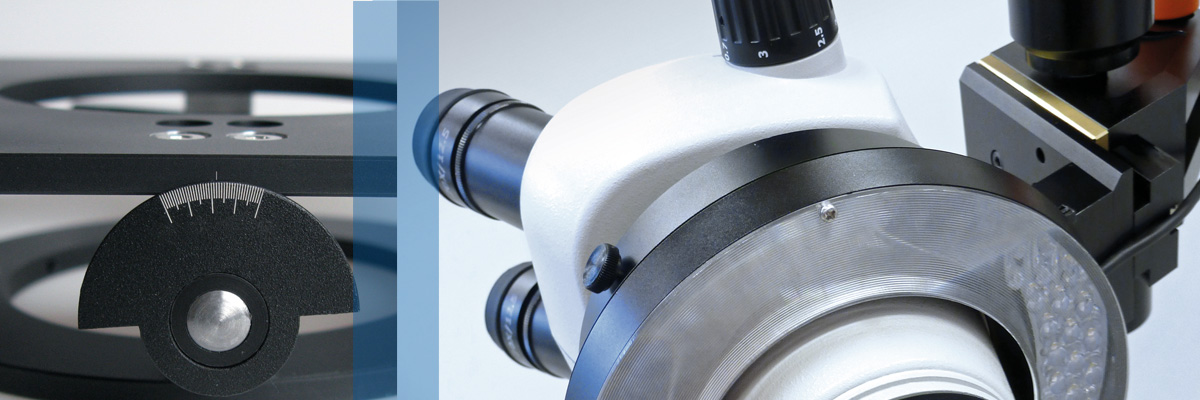

Zoom Objectives

- Motorized Zoom Systems 12:1 , 7:1 from Opto are in hundreds of Metrology-, Photonic-, Bonding-, Biomed- Machineries

7:1 Modulare C-Mount Zoom

- This exceptionally reliable zoom guarantees through it`s modularity a solution for most imaging applications where flexible Magnification is beneficial. All Tubes have diameter 35 mm. Combine your solution with the adapters, tubes, zoom modules, lenses, and lighting necessary for your application..

Selection Guide

The configuration of your system is really simple:- From the overview diagram, you quickly realize the possible combinations of components

- Determine your field (Field of View, FoV)

- Select the required working distance (working distance, WD)

- Go to the Magnification chart and choose your tube and your lens. Tip: Try to use always a higher objective magnification instead of a a higher tube.

- Search in the overview diagram your other components, such as Screening of the zoom, focus, modules, lightingand other adapters

7:1 Motorized C-Mount Zoom

- Featuring the same long-life reliability of our standard zooms, but with the benefits of either stepper or DC encoded motorisation options, our Opto motorised zooms are the optimum solution for high precision, machine integrated measurement tasks. Designed with machine integration in mind, the Opto zoom has much to offer, including a unique square design enabling easy machine integration and setup. A dedicated zoom controller ensures that electronic integration is simple and straightforward. And with our trademark modularity, your configuration remains fully customisable and upgradable at all times.

For volume integration we offer customized versions that fit your mechanical specification and which integrate illumination as a complete OEM package.

Benefits- Modular configuration of working distance, magnification and illumination

- Compact and reliable stepper or DC-motorisation

- Coaxial illumination for unique metallurgical configuration

- Post bond inspection of assembled semiconductors

- Automatic analysis of metallurgical surface defects

- Universal measurement machines

Telecentric Objectives

- No perspective Error for Measurement Applications

With a normal (entocentric) lens, magnification differs when changing the distance from the lens, like seeing with our eyes. Additionally, features which are located at the edge of an image are viewed at a different angle than objects in the centre of the field of view (FoV). This makes the measurement task very difficult.

Telecentric lenses are used for performing exact measurements of objects because they offer images which represent the exact size of an object regardless of its position within the FoV or its distance from the lens.

Bi-telecentric

- All Opto telecentrics are optimized for C-mount cameras with chip sizes up to 2/3“, and represent the ideal solution for measurements of precision components with the best price/performance ratio.

Advantages- Large Field Depth

- No perspective error with three dimensional objects

- Homogeneous image acquisition with high light sensitivity

- High resolution Object- and image side telecentric imaging

- Universal C-Mount

Applications & Markets- Measurement of profiles

- Determination of diameters

- Adjustment of electronic components

- Measurement of objects with large height

- C-Mount cameras supported up to 2/3“ (CCD- or CMOS-chip)

Quadra Mount

- Our bi-telecentric objectives are now even more practical: our new QuadraMount versions are equipped as standard with a 4-sided flat profile, enabling easy installation and setup.

Precision, robust alignment of the optical components in any machine vision setup is crucial to the overall optical performance of the system, and msut be carefully considered during the design of an optical measurement system.

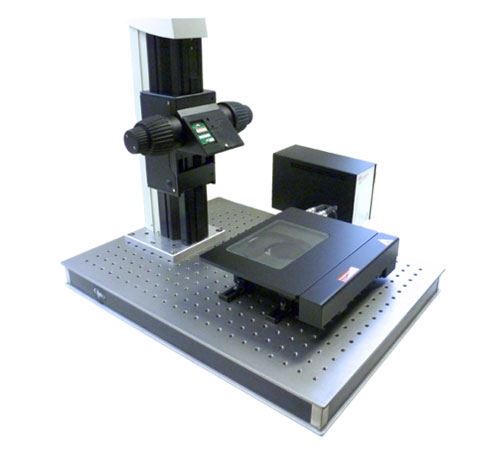

Telecentric test bench

- The combination of a Bi-telecentric lens and a collimated telecentric illuminator ensures optimised resolution and perfect image quality.

The optimum utilisation of the entire 17mm depth of field of guarantees perfect measurement of round objects such as springs, screws, bottles.

Transmitted light configuration allows high speed image acquisition Standard aluminium profile construction enables easy machine integration Can be used in horizontal or vertical orientation

The Features for easy measurement- Optimized for 1 1/8“ and 2/3“ C-Mount Cameras

- FoV with a 2/3“ camera 42x32mm (52mm Image circle)

- Resolution 45% @ 70LP/mm

- Field Depth +/-8mm

- Telecentricity 0,08

- F-No.: F8

- Distortion 0,08

All featuring:- Integrated 0,2x Bi-Telecentric Objective lens

- Telecentric illuminator (Red, Blue, White)

- M12´ type power cable (1m)

- Input Voltage 24V DC

- Forward Current 700mA

- On/OFF Time 300ys

- Maximum trigger Frequency 300Hz

- Manufactured from standard aluminium profile enabling simple integration

- Complete unit can be vertically or horizontally oriented

- Column length: 550mm

- Target Holder carriage for horizontal and vertical position

- Pre adjusted for precise measurements

- Every unit fully tested

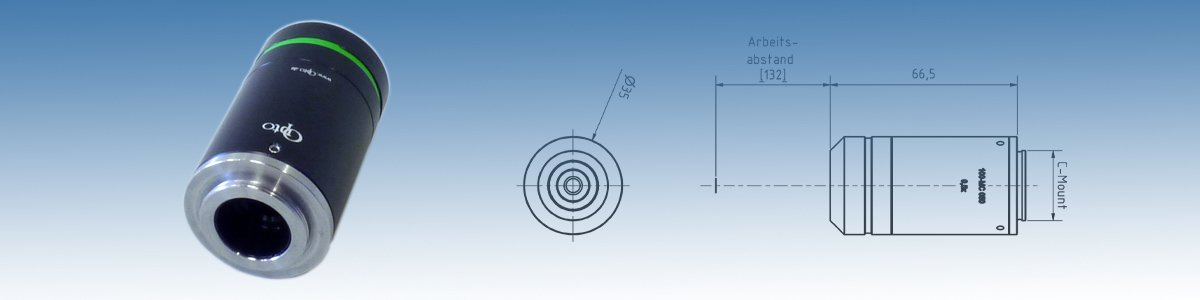

Compact telecentric objectives

- Telecentric lenses are used for performing exact measurements of objects due to their ability to image the exact size of an object regardless of its position within the field of view or its distance from the lens.

With their compact size, ultra low optical distortion and economical price, these lenses are the ideal choice for a wide variety of measurement applications where space is a premium.

Applications & Markets- Dimensional measurement of medical devices

- Biomedical analysis of growth in well plates

- High resolution gauging of mechanical precision parts

- 3D measurements of small objects inside machines

Benefits- Small and compact for OEM integration

- Object side telecentric for precise measurement

- Nearly distortion free with standard C-Mount

Megapixel Objectives

- All type of Lenses for or up to 150 MP Cameras with C-Mount or other Mounts.

Mega Pixel Macro Objektive

- When developing this series of macro lenses, the focus was on imaging small objects with high resolution and very low distortion. SThey are mainly used for the measurement of mechanical parts, electronic components and for the inspection of assemblies. Applications can be found in pressure control, microbiology, forensics and video microscopy.

- Distortion

- Diameter 35 mm

- C-Mount

Multi Megapixel C-Mount Lenses

- We have built up a strong and High Value supply chain for our OEM Business.

We have access to unique and qualified objectives around the world that can assist you in your Machine Vision Integration.

Calibration Targets

- Calibration standards, object micrometers

Image Quality Features

Resolution

The resolution of an optical system indicates the discernibility of two minute structures that can still be perceived separately. The resolution of optical instruments is limited by diffraction. The typical specification is made in line pairs per mm (Lp/mm). The dependence of the resolution from the contrast describes the modulation transfer function.

Modulation Transfer Function (MTF)

MTF (also called contrast transfer function) describes the comparison of the contrast of the edges of a (real) object with the contrast of its image at a certain resolution (MTF = image contrast/object contrast). There will always be some contrast loss.

Contrast

The contrast describes the relationship between light and dark areas of an image, indicated in per cent (%).

Depth of Field

The depth of field (DOF), often erroneously dubbed “field of depth”) describes the expanse of the focussed area (within the object space) in front of and behind the optimal focus level. The smaller the aperture (i.e. the larger the f-number) the greater the depth of field area. The hyperfocal distance is a special instance in which the depth of field area extends to infinity. In case of telecentric lenses, the telecentric area is essentially the depth of field area. Distortion The distortion (or visual distortion) is a geometric image defect (aberration) of lens systems. It leads to different magnifications when the distance to the optical path of the system increases and creates the image of straight lines that do not cross the centre of the image to be reproduced in a bent way. Decreasing magnifications (reductions) with respect to the image field edge are called barrel-shaped distortions (fish-eye effect) with an increasing pulvinate distortion. The distortion is generally indicated in per cent (%).

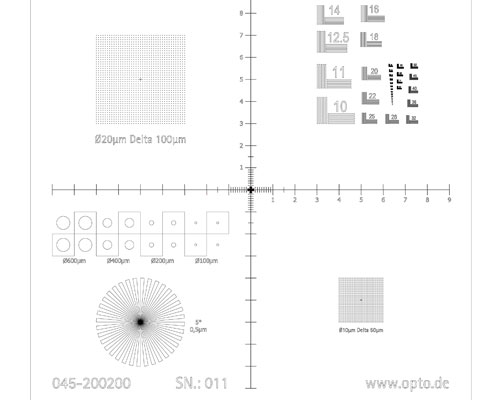

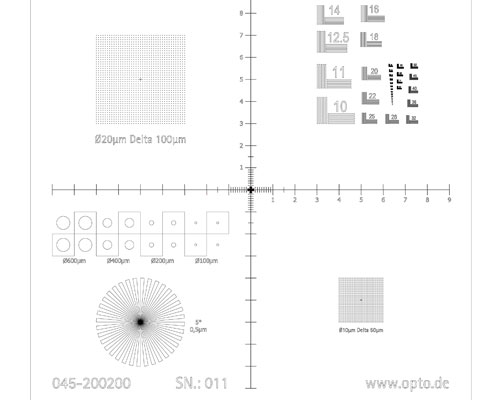

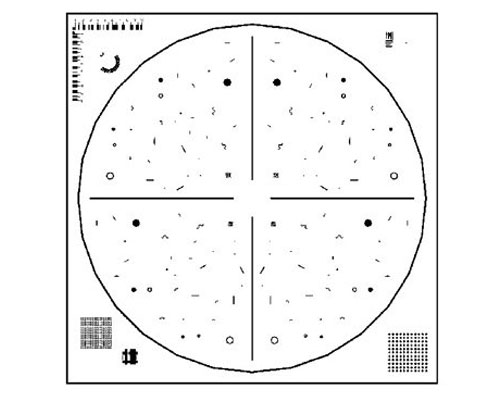

Calibration Target Micro V1

- Optical calibration and resolution testing are critical metrics in understanding and optimizing any optical system.

Calibration Target Micro V1 is unique in that it combines very useful resolution data, combined with ultra-high definition micro features, together enabling efficient and accurate optimization of any optical setup.- Ultra-high definition micro features, compatible to the most demanding optical calibration requirements

- Four unique quadrants combining resolution targets to measurement scales

- Supplied in a dedicated padded storage case

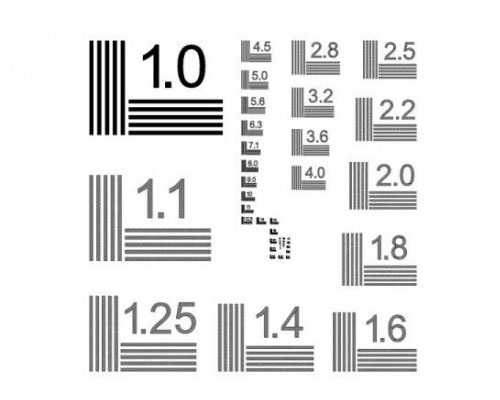

Calibration Target Micro V1 contains defined structures in different shapes and sizes for easy system calibration and distortion detection.- 10 lp/mm to 1000 lp/mm

- Ã20 μm dot matrix 40x40 dots,100 μm grid

- Contrast and Siemens structure

- Ã10 μm dot matrix 40x40 dots, 50 μm grid

- Scale with steps down to 10 μm

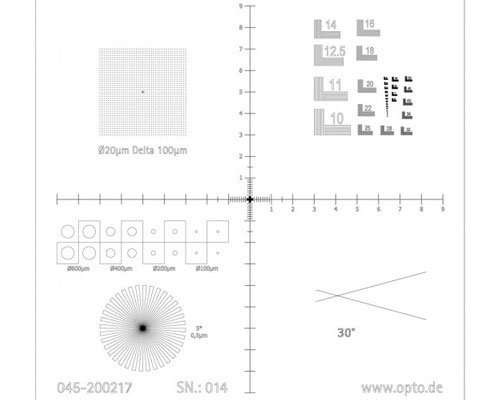

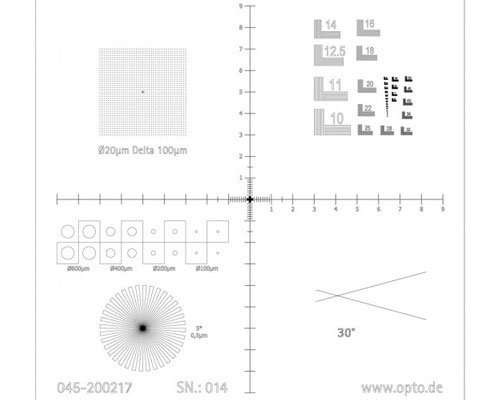

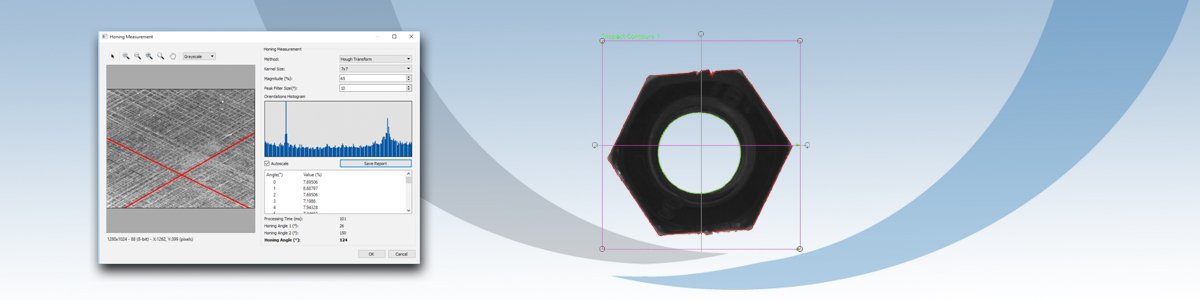

Calibration Target Micro with honing angle

- In contrast to the Target Micro V1, the Calibration Target Mico with honing angle in the 4th quadrant contains a 30° honing angle incl. certificate.

The target contains the following defined structures:

1. 10 lp/mm to 1000 lp/mm

2. Ã20 μm dot matrix 40x40 dots, 100 μm grid

3. positive, negative dots and Siemens star

4. honing angle 30° with certificate

5. scale with steps up to 10 μm

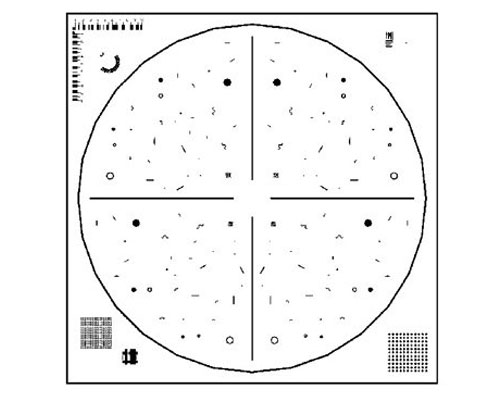

Particle Standard Target

- Particle Standard Target allow the calibration of measurement functions in microscopes through objects in different forms and sizes or of resolution of an optical system measured in Line Pairs per mm.

The Target allows the calibration of measurement functions in microscopes, to analyze particles and measured. A field of objects in different forms and sizes allow the user to check: rectangles, ellipsis, circles, rings and even fibre-shaped objects. To determine optical distortions there are three different sized arrays of cross-targets. The smallest Object is as small as 5μm.

For the calibration of the resolution (magnification) two scale bars in X and Y are applied in a corner of the target.

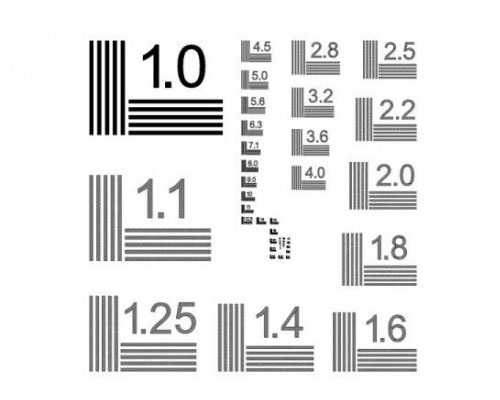

Resolution Test Target

- Test targets (also called test charts, test samples or resolution test patterns) are used to determine the efficiency of optical systems. They are used to determine resolution, MTF, depth of field, distortion and telecentricity.

It is necessary to test and calibrate every single system for comparative measurements, especially when dealing with several measuring systems of the same type.

Resolution pattern 1963A is used in compliance with the National Bureau of Standards (NBS standard 1010A) for this resolution test target.

It is composed of 49 test patterns with five vertical and five horizontal lines each (black lines against transparent background).

The distance of the lines tapers from 1 to 250 line pairs per mm. The lines are twelve times longer than their thickness.

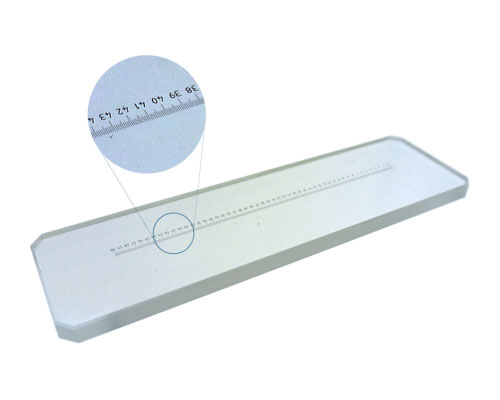

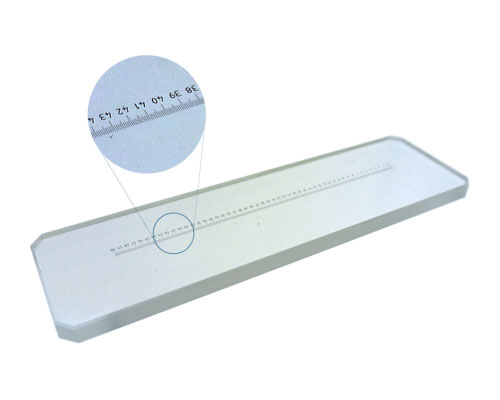

Stage micrometer

- The stage micrometer is a helpfull tool for calibration purposes.

- 50 mm glass scale in 0.1 mm and 0.01 mm

- Calibration of measurement software

The stage micrometer is also available with DKD Certification.

Optical Components

- Selected High End optical Elements with unique specifications and competitive pricing

Opto delivers integrated Imaging Modules to OEM Customers with many single optical components integrated. Due to the volume contracts, we are able to offer them to highest quality standards and perfect pricing.

Selected imaging and microscopy components for machine and product manufacturers. Telecentric, zoom and high resolution Fixobjektive for applications from machine vision and photonics and tripod solutions and positioning for the construction of adapted inspection systems.

Lenses/ Achromats

Achromats are perfect for fluorescence applications, image relay, inspection optics, or spectroscopy solutions.

Prisms/ Mirrors

Prisms are perfect for adjusting the orientation of an image. Mirrors are easy to integrate and perfect for redirecting light.

Beam splitter/ Filter

Beamsplitter are perfect for fluorescence microscopy, interferometry, laser science, BioMed and Semiconductor machinery.

Objectives

Objectives are typically fixed magnification lenses for imaging applications in Machine Vision and Microscopy.

LED Modules

LED Modules deliver intense, even illumination over a specific Field of View. LED Modules are perfect for Machine Integration because of their extra-long lifetime, easy integration and low power consumption. Microscopy

- Microscopy is the heart of Opto. From multi Fluorescence, to ultra compact digital Microscopes we build them to the highest quality, smallest form factor and best price.

Ideal for Machine builder Calibrations Target

- Calibration standards, object micrometers

Image Quality Features Resolution

The resolution of an optical system indicates the discernibility of two minute structures that can still be perceived separately. The resolution of optical instruments is limited by diffraction. The typical specification is made in line pairs per mm (Lp/mm). The dependence of the resolution from the contrast describes the modulation transfer function.

Modulation Transfer Function (MTF)

MTF (also called contrast transfer function) describes the comparison of the contrast of the edges of a (real) object with the contrast of its image at a certain resolution (MTF = image contrast/object contrast). There will always be some contrast loss.

Contrast

The contrast describes the relationship between light and dark areas of an image, indicated in per cent (%).

Depth of Field

The depth of field (DOF), often erroneously dubbed “field of depth”) describes the expanse of the focussed area (within the object space) in front of and behind the optimal focus level. The smaller the aperture (i.e. the larger the f-number) the greater the depth of field area. The hyperfocal distance is a special instance in which the depth of field area extends to infinity. In case of telecentric lenses, the telecentric area is essentially the depth of field area.

Distortion The distortion (or visual distortion) is a geometric image defect (aberration) of lens systems. It leads to different magnifications when the distance to the optical path of the system increases and creates the image of straight lines that do not cross the centre of the image to be reproduced in a bent way.

Decreasing magnifications (reductions) with respect to the image field edge are called barrel-shaped distortions (fish-eye effect) with an increasing pulvinate distortion. The distortion is generally indicated in per cent (%).

Calibration Target Micro V1

- Optical calibration and resolution testing are critical metrics in understanding and optimizing any optical system.

Calibration Target Micro V1 is unique in that it combines very useful resolution data, combined with ultra-high definition micro features, together enabling efficient and accurate optimization of any optical setup.- Ultra-high definition micro features, compatible to the most demanding optical calibration requirements

- Four unique quadrants combining resolution targets to measurement scales

- Supplied in a dedicated padded storage case

Calibration Target Micro V1 contains defined structures in different shapes and sizes for easy system calibration and distortion detection.- 10 lp/mm to 1000 lp/mm

- Ã20 μm dot matrix 40x40 dots,100 μm grid

- Contrast and Siemens structure

- Ã10 μm dot matrix 40x40 dots, 50 μm grid

- Scale with steps down to 10 μm

Calibration Target Micro with honing angle

- In contrast to the Target Micro V1, the Calibration Target Mico with honing angle in the 4th quadrant contains a 30° honing angle incl. certificate.

The target contains the following defined structures:

1. 10 lp/mm to 1000 lp/mm

2. Ã20 μm dot matrix 40x40 dots, 100 μm grid

3. positive, negative dots and Siemens star

4. honing angle 30° with certificate

5. scale with steps up to 10 μm

Particle Standard Target

- Particle Standard Target allow the calibration of measurement functions in microscopes through objects in different forms and sizes or of resolution of an optical system measured in Line Pairs per mm.

The Target allows the calibration of measurement functions in microscopes, to analyze particles and measured. A field of objects in different forms and sizes allow the user to check: rectangles, ellipsis, circles, rings and even fibre-shaped objects. To determine optical distortions there are three different sized arrays of cross-targets. The smallest Object is as small as 5μm.

For the calibration of the resolution (magnification) two scale bars in X and Y are applied in a corner of the target.

Resolution Test Target

- Test targets (also called test charts, test samples or resolution test patterns) are used to determine the efficiency of optical systems. They are used to determine resolution, MTF, depth of field, distortion and telecentricity.

It is necessary to test and calibrate every single system for comparative measurements, especially when dealing with several measuring systems of the same type.

Resolution pattern 1963A is used in compliance with the National Bureau of Standards (NBS standard 1010A) for this resolution test target.

It is composed of 49 test patterns with five vertical and five horizontal lines each (black lines against transparent background).

The distance of the lines tapers from 1 to 250 line pairs per mm. The lines are twelve times longer than their thickness.

Stage micrometer

- The stage micrometer is a helpfull tool for calibration purposes.

- 50 mm glass scale in 0.1 mm and 0.01 mm

- Calibration of measurement software

The stage micrometer is also available with DKD Certification.

Table and Floor Stands

- We have from mobile floor tripods, stationary for a complete work surface, to solutions for very precise measurements, tripods for every need.

IM•Stative light

- Our IM-stand light is specially designed for the Imaging Modules.

As a classic - stationary - tripod it takes up little space and is best suited for single workstations. In addition, we offer this stand as a folding version for workstations that need to be flexible.

Track Stand

- This simple stand-alone solution allows precise vertical movement for high-magnification microscopic solutions or other measurement setups. The combined coarse / fine focusing mechanism and the robust base enable the use of micro lenses up to max. 50x.

Key Features- Based on 50 x 50 mm column format

- Column heights up to 1000 mm

- Focusing path up to 80 mm

- aluminum base

- With mounting diameter 35 mm for TV microscopes

- High-precision design

- Can be equipped with XY stage

Your Benefits- Track-based stand system

- Robust for reliable optical measurements

- Easily adjustable

- Modular with compact footprint

Post Stand

- Economical, Ergonomie, Flexible and Reliable

Our 32mm-column system is the most popular and offered the longest product. Of many thousand units have already been produced and delivered. It stands for the highest quality, reliability and economic support your instruments and is configurable for almost all applications.

Key Features- Based on the column format 32 mm in diameter

- Column heights up to 700 mm

- Focusing path up to 80 mm

- aluminum base

- With mounting diameter 35 mm for TV microscopes

- High-precision design

- Can be equipped with XY stage

Your Benefits- Round pillar-based stand system

- Robust for reliable optical measurements

- Easily adjustable

- Modular with compact footprint

Extended Arm Stand

- With Opto's Extended Arm Stand, the microscope can be effortlessly moved across the entire work surface and fixed in place - even across the work surface.

The system is available with a range of accessories, including an extension of the support arm and a height adjustment. In the column, a light source (or similar) can be mounted so that a flexible inspection without cable clutter is possible.

Key Features- Table, wall or board mounting

- Extremely robust construction

- Easy height adjustment

Benefits- Useable with high magnification microscopes

- Heavy Duty Focus handles safely equipment up to 20 kg

- Modular setup for laboratories and test stations

Our unique Heavy Duty Stands serves two main purposes:

1. In combination with the folding extension arms, it enables a completely clear bench to be maintained, whilst also giving the capability to position your microscope anywhere over your bench area!

2. Using the Heavy Duty Focussing Unit it creates a rock-solid, ultra precise microscopy setup.

Mobile Floor Stand

- For very large samples, or where samples cannot be easily moved, the Microscope needs to be portable. Our Mobile Floor Stand perfectly combines mobility and stability even at high magnifications and long working distances.

Key Features- Stable mobile stand for difficult inspection tasks

- Quick and easy 360° positioning of the microscope

- Lockable wheels and arms

- 4-axis adjustable microscope mount enabling any orientation

Benefits- Flexible and save handling of the microscope

- Use same equipment at different locations

- Table for Light Source completes all in one inspection system

- Compatible with most stereo and video microscopes

The stand base consists of a tripod with fixable wheels. At the height-adjustable column, a practical platform can be mounted on, for example, Light sources or tools can be stored (accommodated).

For easy height adjustment of the optional lever arm can be equipped with an adjustable gas lift mechanism. Normally, the floor stand is used with a stereo microscope, but that can be easily exchanged for another inspection system or even a tool. With our mounting mechanism stereo microscopes can also be flipped be used absolutely secure.

Tilting Stand

- Three-dimensional objects often benefit from a particular angle to see important details. With our tilting stand, it is possible to position and examine your sample at an angle or to tilt and fix it at the desired positions.

Your Benefits:- Very ergonomic inspection status

- Fast and easy 360 ° inspection

- Compatible with all major microscope brands

- Ideal for SMT and PCB rework environments

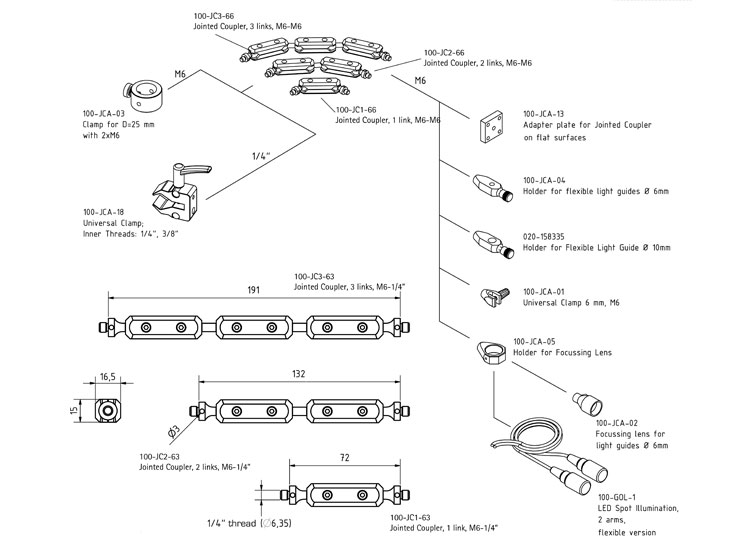

Jointed Couplers

- Jointed Couplers are used for precise attachment of accessories, such as illumination accessories or filters to optical equipment. They are highly resistant to vibration and offer a reliable fixation for your accessories. Equipped with different types of threads they are flexible for mountingfibres, LEDs and cameras. A nickel plated version is available on request. With their new improved design there are now even easier to fix.

Configuration

- A variety of connecting threads ensure that they can always be used flexibly, e.g. for the assembly of optical fibres, LEDs or digital cameras. A nickel-plated version is available on request.

The new revised version is even easier to fix.

Application Microscopes

- Besides our Imaging Modules, Opto has built up for some specific Markets special microscope setups with dedicate Software that will be distributed directly or through selected trained partners.

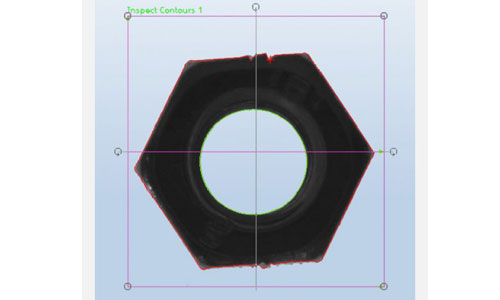

Cylinderinspector

- Cylinder Inner Wall Inspection

CylinderInspector is an all-optical, non-contact inspection and measurement tool designed to inspect cylinder walls. It enables perfect optical inspection of honed surfaces in cast iron and aluminium, as well as the detailed analysis of composition and distribution of silicon crystals in aluminium. With darkfield and brightfield multi wavelength LED illumination, CylinderInspector is perfectly suited to imaging every type of honed cylinder surface - particularly sputter and plasma deposited surfaces.

CylinderInspector has already gained its heritage as the inspection instrument of choice amongst many automobile and engine manufactures internationally.

Key Features- High end optical system with perfectly matched illumination to ensure optimum ‘in-cylinder´ image quality

- Powerful yet easy to use CylinderInspector software suite for measurement and analysis of key parameters including automated hone angle measurement, and crystal distribution

- Available in eyepiece, video, or fully automated versions

- Non contact, self centering mechanisms for easy insertion and removal

- Full 360° rotational view with variable insertion adjustment

- Integrated brightfield and darkfield multi-wavelength LED for textural analysis

- Able to fit wide variety of cylinders ranging from 60mm to 125mm in diameter (dependend on model and configuration)

- Optical zoom and remote focus system allows the user to inspect the surface at different variable magnifications

Benefit- Perfect manual or automated optical inspection of internal cylinder bore walls, honing angle measurement and crystal distribution.

- Standardised inspection process between supplier and customer

- Enables precise and repeatable measurement ofpre-defined parameters – significantly enhancing control over cylinder production processes and ensuring far higher levels of product quality control.

- Totally customisable programming interface and report tool

Cleananalyzer

- Cleanalyzer Professional

Residual pollution analysis system The Cleanalyzer is a high-end analytical system designed to examine particles on filters – a key procedure in performing reliable and reproducible evaluation of component cleanliness.

Precision mechanical parts machined to exact tolerances are susceptible to damage or malfunction caused by particulate contamination. To address this issue, component cleanliness must be measured, and quantified in order to guarantee full function and to avoid failures due to particulate damage. The Cleanalyzer system is a powerful, fully integrated test platform which enables precision measurement, analysis and documentation of this critical cleanliness indicator. Cleanalyzer is fully compliant with all current particulate standards.

The currently valid standards were integrated into the specialized measuring software.

Key Features- High end optical system with perfectly matched illumination to ensure optimum image quality

- Powerful yet simple software interface for automatic measurement, analysis, separation and classification of particles

- ISO 16232 and VDA Vl. 19 standards included, easy creation of user standards

- Measurement of particles down to 35µm, 15µm or 5µm (depending on version)

Benefit- Precise and repeatable statements describing the cleanliness of an item

- Easy to use with super-fast processing times

- Ultimate reliability and repeatability

- Same sophisticated software for all systems providing analysis of single particles, particle classes and particle types

- Easy documentation with freely configurable autoreporting and simple export into excel or other databases

- Individual particle locations can be stored and accessed for closer inspection in live mode or anytime from the database

- Automatic detection of reflecting particles (e.g. metals)

Portable Microscope

- Ultimate portability

The Opto Portable Microscope is designed to offer the ultimate solution in portable microscopy. With its ergonomic design, robust build quality, and perfectly optimised optical configura- tion, the Opto Portable Microscope is ready to take on the most demanding field micrososcopy inspections. Offering cable-free portability and extended long life, the instrument features the very latest in ultra high power coaxial LED technology, with options even for advanced illumination techniques such as Kohler contrast enhancement.

Powerful as standard

Designed to replicate the raw imaging power, magnification and functionality of your lab microscope, the Opto portable scope is the ultimate solution for remote high resolution microscopy. As standard, the instrument is configured with a trinocular head, fitted with high quality infinity corrected objectives, providing 50x, 100x, 200x and 500x optical magnification. A host of configurable illumination options are offered ranging from ultra bright LED battery power to contrast enhancing Kohler options.

Key Features- Objective nosepiece with 4 magnifications

- Integrated coaxial illumination

- Graticule for measurements

- For rolls from diameter 60 mm or flat surfaces

Benefit- Highly stable chassis for high magnifications

- Easy to carry -

- Inspection to go

- Ideal in-field measurement and inspection solution

Dual Station

- Stereo Microscope Stand and Inverse Microscope

Two high resolution magnification ranges in one scope- Reinventing microscopy with a unique easy to use ergonomic user experience.

- Ultra-high contrast macro and micro imaging from the same instrument eliminates the need for 2 separate microscopes!

- Designed for ‘in chamber’ biomed and cell analysis applications such as IVF and other cell engineering applications – no more transferring samples between workstations!

- Fully compatible and retro-fittable to most leading stereo microscopes, and RFID antenna products

The stereo base contains an integrated LED illumination with Opto 'e-mirror' technology to flexibly adjust the brightness and contrast.

The 200x integrated inverse microscope features precision focus and an adjustable LED illumination with embedded special contrast enhancing illumination technology for perfect high contrast structural imaging.

Technical Data:- Stereo Clamp diameter 76mm

- Stereobase with Glass-plate to use also RFID Antenna systems

- Integrated USB 3.0 5 MP Camera with Power supply and cable for PC

- PC-specification: at least WIN 7 and up with USB-3.0 Port

MM Microscope

- FOV Micro Measurement Microscope 4.0

The new ultra-compact digital micro measuring microscope from Opto is the perfect tool for on-site measurements in production.

The image processing microscope digitizes professional quality where it counts.

The sensor design is robust, plug-and-play, easy to operate and equipped with integrated high-end optics and camera.

ith the built-in coaxial LED illumination and ring light, all kinds of features on a product can be visualized, similar to a traditional metallurgical microscope.

With a measurement resolution of 1.8 micrometers per pixel, it enables the analysis of the smallest details.

The free Optoviewer Software presents crosshairs, allows documentation and basic Measurements, whereas the market leading Measurement Software M3 from Metlogix makes it a High End Measurement device with proven functionality.

Specifications:

Digital Machine Vision Microscope- FOV: 4,5x3,8mm

- WD: 31mm

- Resolution: 270 LP/mm

- Coax and Ring Light

- USB3.0 / 5MP / Camera

Ultra compact light weight Stand- Focus Travel range 57mm

- Size 190x230x350mm

- Weight 2,5kg for easy transportation

OptoViewer 2.0- Simple User Interface

- Camera control for demanding integration tasks

- Pre-calibrated magnification settings

- Illumination adjustment

- One-click image storage

- Standard Measurement functions

- Reticule generator

- Basic Text editor

The Metlogix M3 one Touch Measurement Software performs critical analysis in all phases of your manufacturing process. It is a dependable, intuitive and multi spread tool in the metrology marketplace.- Measuring point acquisition by crosshair, clever video tools

- Multi touch probe capability

- Measure, construct and define 2D geometries

- Measure polynomes with the blob tool

- Position detection

- Part program with automated measurements

- Automated multiple parts measurement in the field of view

- DXF overlay in live image

- Contour tracking and BestFit

- Integrated Light control of the Opto Imaging Modules

- Tolerance check according to DIN / ISO with tolerance chart

- Launch program with barcode reader

- Image archiving (BMP, JP2, JPG, PNG)

- Program creation from DXF file

- Comprehensive data output as DXF, DXF point cloud, IGS cloud, CSV, TSV

- Q-DAS converter

- and much more ..

Application Microscopes

- Besides our Imaging Modules, Opto has built up for some specific Markets special microscope setups with dedicate Software that will be distributed directly or through selected trained partners.

LED Illuminations

- Lighting

Coaxial LED-Illumination, white 4000k (3000K) This white light illumination is intended as a light source for the coaxial coupling of light into TV microscopes. It replaces the light guide couplings, which are still often used, with a compact homogeneous LED illumination. Especially for OEM manufacturers, the compactness and the possible power supply via the machine concept is an advantage, since an external light source, which feeds the light guide, is no longer required. The thread fits the compact 35mm coaxial housings with an integrated divider mirror.- Coaxial LED-illumination, white 4000k (3000 K)

- Binder connector 5-pin, cable length 3 m

- For power supply 043-700020 (not included)

- Current max. 800 mA

Coaxial Koehler LED-illumination, white 4000k

Koehler allows homogeneous illumination and increased control over the contrast and depth of field of the image. This is achieved by a system of lenses and irises, which give precise control over the shape of the light entering the microscope.- For microobjectives 20x and higher

- Binder connector 5-pin, cable length 3 m

- For power supply 043-700020 (not included)

- Current max. 800 mA

Homogeneous Spot Light

These unique spots use a beam homogenizer based on chirped micro lens technology to generate extremely homogeneous and sharply delimited spot illumination. For image processing in time-critical applications this feature can eliminate the need for additional shading.

Easy positioning can be achieved using our jointed couplers.

They are available in white, red, green and blue and have a working distance from 200mm (80mm Spot diameter) to 300mm (110mm Spot).

LED Ring Light ID=35 mm

Our ring lights featuring up-to-date LED technology and operate without a fan and are therefore vibration-free.

We do not offer special models due to the rapid advancement of LED technology. We will gladly accommodate any special requirements (colour, pulsed operation, time lags, diameters, brightness, special controls, other geometries, etc.) you may have.

LEDrive

Focus drive C, coarse w / integ. LED ring and 5/8 "pin adapter

The LEDrive with integrated ring light and 5/8 "pin adapter is specially designed for the efficient and ergonomic use of a stereomicroscope to make handling even easier and more flexible

The LEDrive is part of the Opto microscope accessories for stereomicroscopes for all leading microscope manufacturers such as Leica, Nikon, Olympus etc.

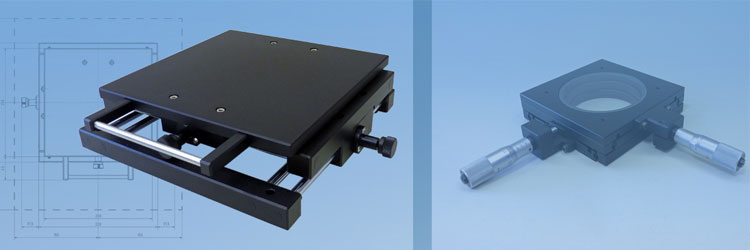

Microscope Tables

- Manual Stages

An alternative to our oblique view adapter and our tilting tables are our measuring stages, as well as our sliding or gliding stages.

For inspection and inspection of large, flat samples, such as electronic assemblies, we can recommend our sliding or gliding stages. These easy-to-use positioning devices significantly increase the effectiveness of your test procedures.

The sturdy construction can be moved easily and precisely and additionally detected in X and in Y. The underside is provided with rubber feet, which ensure a non-slip stand.

Oblique Viewing Solutions

- Oblique Viewing Module

Perfect Flexibility

Our oblique viewing module enables a tilted view of your sample, with full 360 degree viewing around an object or feature, simply by pivoting the module. At the ick of a lever, you can switch instantly between oblique viewing mode and normal vertical mode so you never lose the functionality of your ordinary stereo microscope!

Universally compatible

The clever design of the unit means that it is compatible to an ever increasing range of stereo microscopes. Simply identify the corresponding adapter ring to your microscope, and you are ready to go!

Compact, Fully Integrated Unit

This highly stable and perfectly designed module integrates seamlessly with all major microscope brands. Perfect image quality is guaranteed thanks to the integrated high quality 0.3x achromatic lens. The unit features an integrated, custom developed LED ring light which is fully controllable and is designed to illuminate the sample area with a diffuse, but powerful homogeneous light.

Ideal Repair Station

With working distances of 100 mm in oblique mode, and 115 mm in normal vertical mode, the unit is ideal for a wide variety of repair and rework tasks, being particularly suited to SMT repair work.

Tilting Table

Three dimensional objects often benefit from a specific angle of view in order to reveal key details. With our Tilting Table, it is possible to position your microscope securely at an angle or to tilt and fix your samples at the desired positions.

The entire system from granite slab, stable tripod and microscope mounting adds up to a tilt-proof and ergonomic microscope workstation. Its objects and the microscope can be aligned and fixed to each other at a certain angle.

Your Benefits- Highly ergonomic inspection stand

- Quick and easy full 360° inspection

- Compatible with all major microscope brands

- Perfect for Electronic Board Repair

Key Features- Rock solid stand for many types of inspection

- Inclined viewing

- Easy positioning of objects

Additions

- Optic Cleaning set

Small dust “specks” are annoying, waste time and can interfere with detailed labora- tory work. These tiny particles are dif cult to remove from microscope and camera lenses, view nders and optical instruments. The cleaning kit includes an anti-static lens and optics brush, an anti-static micro bre cleaning cloth, precision cleaning solution to remove oil and residue, and a special tool for picking up dust specks.

Accessories for Leica

- Accessories for Leica microscopes

We have a long history in building and adapting equipment to Leica microscopes. From mechanical adpters to optical extensions, from protective equipment to add-on Functionality.

We develop functional extensions ranging from purely mechanical solutions like stands and adapters to protective glass holders through to optical solutions like gap tubes, or our oblique and direct view modules.

If you have a special requirement or application, simply contact us. We will do our best to help you.

Portable Stand for Leica DMS 300/1000

-

- Usable for roller inspection starting with a diameter of 60 mm or flat samples

- Sensitive positioning of the microscope by x/y stages, travel: 25 mm; spindle pitch: 0.5 mm; scale division: 10 μm; adjustment sensitivity: 5 μm

- Z-axis movement with coarse/fine focusing drive, travel in coarse gear: 70 mm; travel in fine gear: 1.9 mm; fine drive sensitivity 0.001 mm

- Usable objective lenses M-series: 0.5x / 0.63x / 0.8x / 1.0x / 1.25x / 1.6x / 2.0x

- Usable objective lenses Z-series: 0.5x / 0.8x / 1.0x / 2.0x

Stage micrometer

- The stage micrometer in the form of a microscope slide is required for the calibration of microscopes.

- Glass scale 50 mm in 0.1 mm and 0.01 mm

- Calibration of measurement software

The stage micrometer is also available with DKD Certification.

Tilting Stand for highly ergonomic Inspection for Leica column Routine

- Three-dimensional objects often require a certain viewing angle to view critical details. With our ball tables objects can be easily turned and tilted.

The foot-controlled vacuum fixation and the heavy granite plate ensure safe positioning.

The entire system of granite plate, stable tripod and mount microscope combines to create a tilt-and ergonomic microscopy workstation. Its objects and the microscope can be aligned at a certain angle to each other and fixed.

With the 32 mm column, it is optimally designed for a Leica-focus drives.

Objective Adapter

- We offer different lens adapter depending on the microscope.

M50 x 1

Objective adapters with M50x1 thread are for the following Leica microscopes: M3 / MS5 / MZ6 / MZ7.5

These adapters can be used for all microscopes that have an M50x1 thread. This includes: Wild Leica M3B, M3C, M3Z as MS5, MZ6, MZ7,5

M65 x 1,5

Objective adapter with M65x1,5 thread are for following Leica microscopes: M125 / M165 / M205

These adapters can be used for all microscopes that have an M65x1.5 thread.

This includes: Leica M125 / M165 / M205 / MZ 12.5 / MZ 16 / Leica SOM-Microscopes

Image erection ZAB for Leica DM Microscope

- The two-axis image erection module ZAB displays the image in both axes side-correct in the eyepiece and on monitor.

It is quickly and easily positioned between microscope and tube.

The module fits both current DM microscopes and older DML models

Extension for Leica Column 'Routine'

- The drive extension is available in different sizes / distances:

- 15 mm

- 27 mm

- 52 mm

- 72 mm

- 104 mm

- 124 mm

- 144 mm

Extension Tube M-Series 155mm Parallel; 1.0x

- Effective extension 136 mm

- Magnification 1.0x

- Fits to all Leica M- and MZ series microscopes Height 56 mm

- Weight 1.9 kg

Protection Glass Holder D80 mm with Adapter to LED5000

- Adapter to ring light Leica LED 5000 and compatible to stereo objectives with diameter 80 mm.

- Aperture diameter 76 mm

- Clamp diameter 80 mm

- Height 30 mm

- Protection glass thickness 1 mm

Adapter Leica M-Series Research to column Routine

- Connecting stereo M125-165-205 with column M50-60-80 series or Opto focus drive OP No electronic interface Extension 173 mm Not in combination with vertical illumination Dimension 100 x 95 x 85 mm (W x H x D)

Inversion Clamp M60x1 – M60x1

- The Inversion unit clamps the microscope to the carrier 10 450173 and prevents the microscope

from falling out at all inclined viewing angles, such as wall or inverted viewing.

Compatible with M50, M60 and DMS 1000, incl. Distance Ring for M80

Long working distance Objective M600

- The Long working distance Objective M600 is especially designed for Leica stereo microscopes. Depending on the lens, you can extend your working distance up to 1200 mm.

With the appropriate adapters, the M600 can also be used with the Leica M50, M60, M80 and DMS.

An adapter for a ring light is also available.

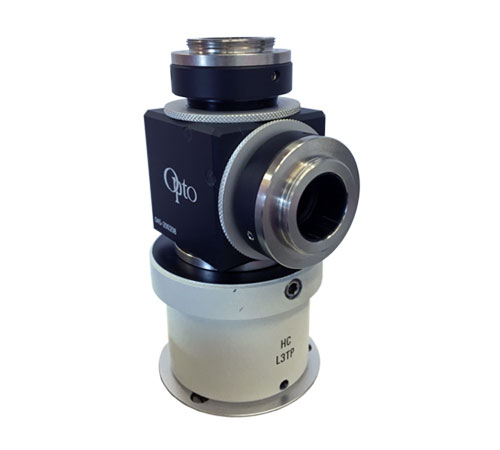

Dual-Camera Coupler 1x for Leica Ergo Tube HC

- Dual-Camera Coupler optimized for VIS splitting ratio 50/50.

- Magnification: 1x

- Adjustment range: ± 2 mm

- Aperture diameter: 18 mm

- Camera interface: C-mount

- Sensor size: max. 1"

Drive Extension 100 mm to Column M-Series Research

- If you need an enlarged working area, simply extend your M-Series column by 100 mm with our drive extension.

- Dimension: 70 x 78 x 102 mm

- Material: aluminium Surface: anodized, natural finish

- Weight: 1.26 kg

Ringlight Adapter ID58-AD80 mm

- Ringlight Adapter for Leica LED 5000 HDI

With the Ringlight Adapter you can connect a Leica Dome LED 5000 HDI to lenses with a diameter of 58 mm.- inner diameter - 58 mm

- outer diameter - 80 mm

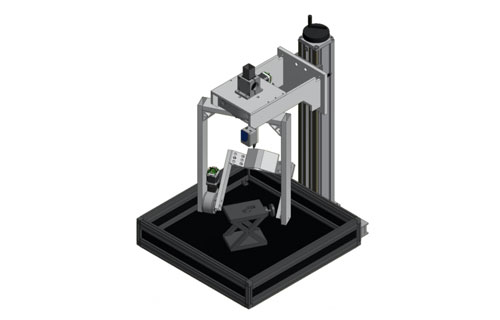

ScanStand - standard, XL

- For "stitching" applications with Leica stereomicroscopes

The Opto ScanStand enables high-precision, automated 3D stitching with Leica microscopes.

The ScanStand consists of a high-precision motorized table and a Z-axis mounted on a high quality table. Depending on your requirements, ScanStand is available in various configurations.

ScanStand is the interface to the Leica "Routine" + "Research" columns and is compatible with all Leica microscopes and a wide range of focusing drives is available to provide compatibility with a variety of scan sizes up to 350mm x 350mm.

Filter Slider

- Filter Slider for Leica M-Series

The Slider filter lets you switch between the neutral density filter and a free field that can be used for a second filter.- Transmission 1 ± 0.5%

- wavelength 400 - 650 nm

Objective Slider for Stereo-Microscopes

- This lens slider allows quick change of two different lenses. This allows you to quickly change two lenses with different focal lengths. You can expand very quickly and easily the magnification range of your microscope.

The stable, yet compact design fits perfectly with any Leica microscope. The M60x1.0 thread fits the Leica microscopes M50 / M60 / M80, DMS 1000 and some Leica SOM microscopes. By using lens adapters, lenses of other series can also be adapted.

Objective protection for LED3000

- Many stereo microscopy applications such as solder rework or bio sample processing can result in debris or unwanted contamination being deposited directly onto the objective lens. This can result in lengthy cleanup operations, or as a worst case, replacement of an objective lens due to excessive contamination.

The Protection Glass Holder from Opto solves this problem by providing the option of securely placing a removable protective glass disc in front of the objective lens. A direct fit to the Leica LED3000 diffusor makes this easy to install, and simple to use. With an optional pack of 5 spare glasses, your customer is well prepared for every eventuality!

Eyepiece Protection

- Eyepiece Cover for Leica Microscopes

The eyepiece cover serves as an effective dust protection and reduces light transmission from eyepiece into camera beam path- to cover both eyepieces

- dimensions: app. 155 x 70 x 105mm (W x H x T)

- integrated elastic securing band anthracite color

- ESD-safe material

- Cleanroom compatible

OEM Microscopes

- For 40 years we build digital Microscopes for Machine Integration

Dedicated modules for machine builders

Business model: custom-specific design and manufacture

Focus on volume and long-term opportunity

Innovative by nature

Stereo Microscopes

- Out of our 40 years Microscopy Experience in designing

special Stereomicroscope solutions and Accessories for and with

Leica, Zeiss, Nikon and Olympus here some results.

If you want to integrate special functionality into your Stereo path or incaet Laser sources, multiple Cameras or others, the chance that we have done it before is quite high.- Refractive eye surgery laser beam delivery

- Multispectral Imaging

- Mobile stereo microscopes

- Table Top Stereo Setup

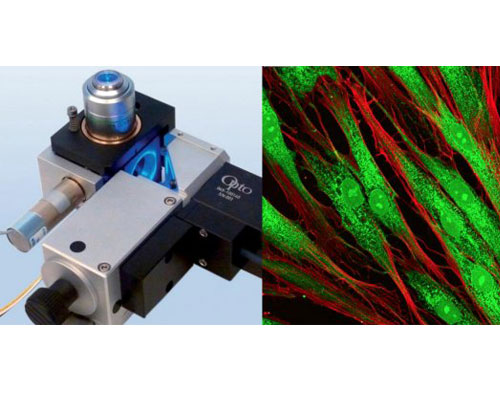

Fluorescence Microscopes

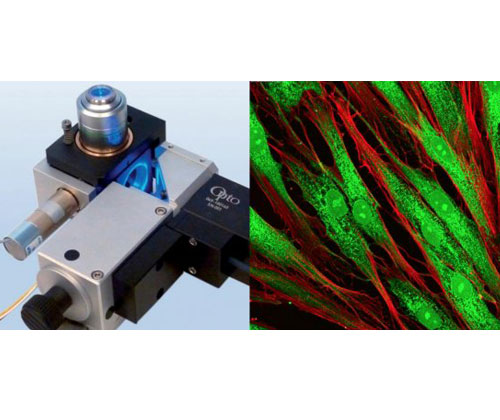

- We design Epifluorescence Microscopes with single fluorescence setups up to

16 fluorescences in some seconds. With standard Cameras or high sensitive sensors inside.

We build our own optics, Filters and ultracompact, high efficent Light-sources as well as the complete Automation.

All in house.

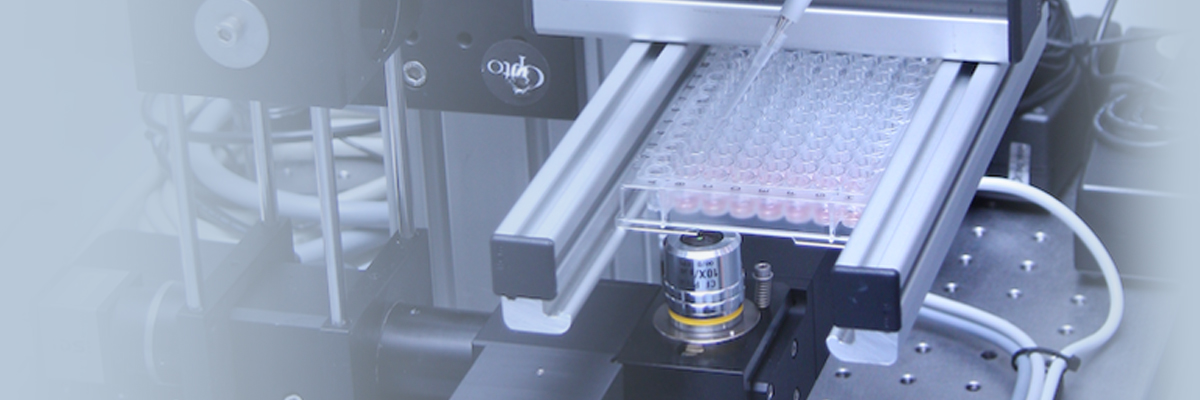

Multi-Fluorescence Screening Cytology Microscope

Working successfully on implementing innovative Microscope Technology in Screening machines and Microfluidics applications.

High throughput multi wavelength Fluorescence Module- Full inverted embedded microscope coupled to ultralight (additive manufactured) spinning filter wheel (8 filters). Strobed multi wavelength LEDs synchronized to high speed camera enables up to 16 different wavelengths to be captured in under a second.

- Supply chain integrated

- Embedded multi-megapixel fluorescence camera

- High speed integrated X-Y-Z well plate positioning

- All controllers and drivers onboard

Special Technieques inside one OEM Fluorescence Microscope

To create an automated Flourescence Module for up to 16 Fluorescences in one Module you need:- Autofocus Z-Axis

- High precision X-Y Movement (We Move the Microscope not the sample)

- Ultra Compact, Multi High Power LED LIght source (Up to 6 LED`s)

- Ultra fast Filter wheel

- Advanced Camera Technology inside

- Compact Controlle Design and Software Framework for the synchronisation

- Plus many more options

Digital Microscopes

- If there is no Imaging Module Solution available we design custom specific compact Digital Microscopes for Machine Integration in Industry and BioMed with unique features like:

- Phase and Hoffmann Contrast

- Scheimpflug and 90° folded

- Autofocus and X-Y Motorized Special CMOS

- Cameras integrated

Scheimpflug solutions

Scheimpflug allows the tilt of the focal plane in orientating the camera towards the optical axis. That enables a sharp obejct field while observing under an Angle. Opto delivers complete solutions with Software to adjust distortion again.

Dual View Microscopes

Dual View means two different Images of one Sample with two optical paths and two cameras with- Two differnt Magnifications

- Two different Colours

- Two different Image aquisition speeds

- Two different Fluorescences

Compact 90° Microscopes

Due to space restrictions we deliver 90° Modules with special Objectives and Tube lenses and compact USB or GigE Cameras with integrated LED Coax light.

LCD pixel inspection Zoom Microscopes

Integrated into QLED TV manufacturing systems, Used for variable magnification pixel inspection.

Objective lens index matched to chamber viewing window

16:1 APO corrected optical zoom with DC motor encoding

Integrated autofocus mechanism

Custom illumination (Köhler)

Full mechanical & electronic machine integration

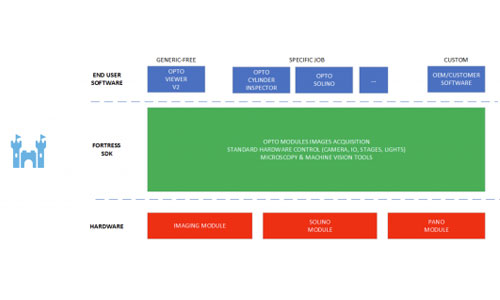

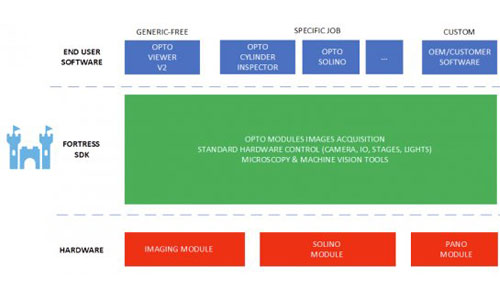

Software

- We design Software to support our Imaging Modules and our OEM Partners.

Imaging Hardware and Software all out of one Hand. Opto Viewer

- With every Imaging Module there comes the free OptoViewer.

It allows to easily install the Camera, drive the different Light Sources and it includes many additional functions as:- Simple User Interface

- Camera, coaxial & ring light settings

- Settings presets files

- Pre-calibrated magnification settings

- Illumination adjustment

- Flat field correction

- One-click export to image file storage

- Crosshair / grid / scale generator

- Drawing/Annotations (basic, shapes, bitmaps, text)

- Standard Measurement functions

- Point to Point Distance

- Angle Focus

Job Solutions

- With every Imaging Module there comes the free OptoViewer.

It allows to easily install the Camera, drive the different Light Sources and it includes many additional functions as:- Simple User Interface

- Camera, coaxial & ring light settings

- Settings presets files

- Pre-calibrated magnification settings

- Illumination adjustment

- Flat field correction

- One-click export to image file storage

- Crosshair / grid / scale generator

- Drawing/Annotations (basic, shapes, bitmaps, text)

- Standard Measurement functions

- Point to Point Distance

- Angle Focus

solino®

- solino is an inspection framework

Opto offers :- solino for inspection assistance

- solino Software licences for quality processing

- solino sensors and modules for quality imaging

- solino and AI-powered development projects

- solino Process Integration service

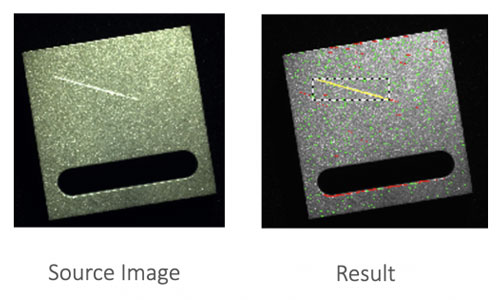

solino enables the right decision making about your product Quality in analysing its fair DATA

What does solino do?

It detects ALL Anomalies as a visual appearance event

Who needs solino?

Where final QC is critical

Why is solino better than other technologies?

It finds Defects beyond the limit of Human perception

What is my ROI with solino?

100% less returns 100% QC possible

100% QC and Process Control possible

The Image Aquisition is very robust to ambient Light conditions and a variation of Light intensity per Image.

solino works with multiple Light sources and positions, dedicated to the sample or within a standard solino Module.

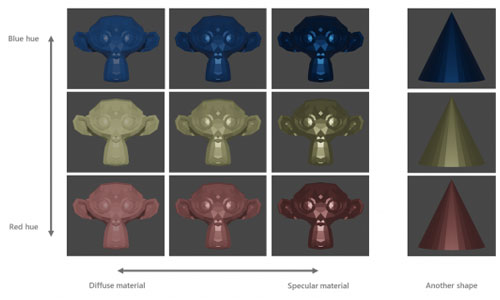

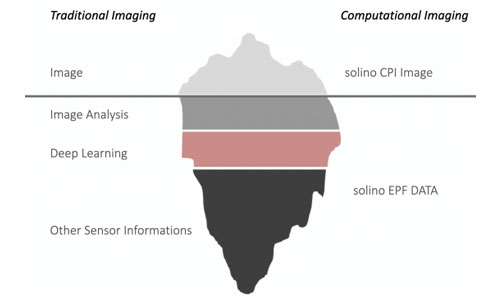

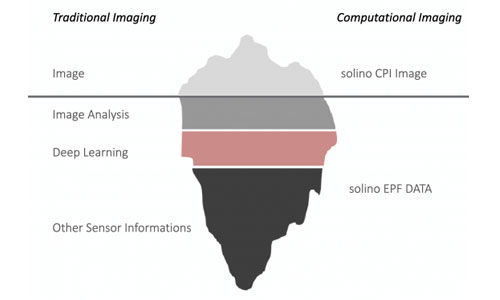

Technology

- solino is based on computational methods to add immediately values to your process and product Quality Control.

We provide tools to build a sustainable visual inspection strategy.

We consider surface appearance as a combination of light and three production parameters such as :- Material

- Shape and

- Hue.

COP Identification

- COP (Classification Of Products)

solino COP is a software solution to execute a first quality survey with the goal to digitize the customer product knowledge with a user-friendly interface.

solino COP is available in differnt levels, depending on the automation degree of use and quality of statistic that it should provide.

To create an AI solution it is critical to correlate in a later stage the product data with the customer Know How about the product. COP is the tool to do this in a strucured way to then be able to do the DATA merge easier and more reiliable.

AQI solino Image Aquisition

- solino is based on images with a direct correlation of the light sources to the Camera.

That means solino works principally with every image.

The more Info about:- The type of source

- The position and Collimation

- The distance and color

the better we can feed the solino Algorithm and the better the Anomalie detection is getting.

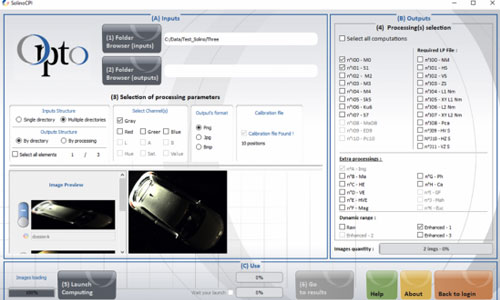

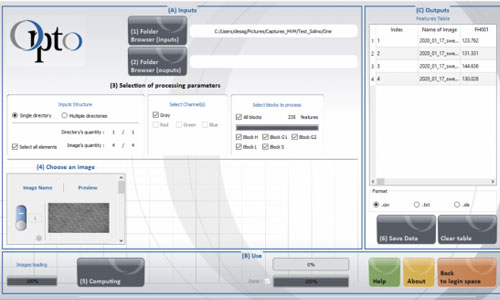

CPI Feature extract

- (Computation of particular Images)

CPI is a software solution to compute one (particular) image from one image set, taking into account the consistency and calibration of the image input.

The acquisition consistency drives to BRDF information and CPI permits to decompose this information in sub-layers, with an image as sub-layer.

Each (particular) image is a result of multiple operations – processing from pixel values distribution.

To improve Quality Control processes CPI provides an image gallery to explore surface anomalies as a first step towards an automated inspection, driven by humans and powered by AI.

EPF Correlation

- Extraction of Particular Features)

EPF is a software solution to compute (particular) features from one image, as a dataset, taking into account the consistency of pixels, from texture or statistical values.- The texture consistency drives to unique signature of an image and is the signature of a surface.

- With image processing, we alocate regions of texture, and each texture has a unique data description.

- A specific combination of regions gives a unique combination of texture, and also a unique digital signature.

- For quality control needs, EPF provides feature sets to explore image content as a surface description, to find correlations with input images in describing the overall quality.

- With this info you can drive a production easily and/or identify product clusters to reveal production behaviors as accidents.

- It is also possible to identify changes in production parameters only from the visual aspects out of the EPF DATA.

VAL Validation

- Validation of the learning rules (VAL Validation and Learning)

For every Product you have Standards (Internal & External) that define the Specification.

Quality Control means to define critical Specs that needed a comparison anginst the Standard with existing Measurment methods. That means only where you have a Measurement tool (normally not only one) you can check the quality.

As a result, what you can`t measure can`t define a quality aspect. That also means that it is quite illosorical to measure all what we as humans define as Quality.

The solino EPF data set is close to have stored most of the aspect we consider to define OK/NOK for a product.

To finally correlate both worlds VAL is checking if we have trained the EPF DATA with the right information. Not more not less.

DEC Decision Making

- Threshold setting for OK/NOK decision making (DEC Decision Making)

The QC could be driven by humans and potentially powered by AI, with explainable image processing for learning of quality behavior and ready to be a reference usable for production management. It could be interesting to be link with data science approach.

Deep Learning and AI

To create an AI solutions it is always important to work closely with the customer to learn and interprete the products to be analysed. So working AI solutions are always project based.

That is why opto uses existing Software Packages from partner companies in its own solino Interface design to set up CNN and Deep Learning.

Opto wants to cooperate with Companies to make solino their AI tool for- Predictive Maintenance

- Quality Inspection and Assurance

- Manufacturing Process Automation

OK / NOK Decision making

This is the most critical Moment in the design of an AI system.

It is time to let the machine make changes in the process.

This is the merge where we only can assist and guide.

This is complete Project driven.

3rd Party Software

- IM compatible 3rd Party Software Packages

The Software focus from Opto is to support the Imaging Modules and not to produce a sellable scalable Software package.

We are happy to promote the following market leading solutions that have integrated the usability of the Imaging Modules perfectly.

We welcome every other Software solution to use the predictable performance of our Imaging Modules to solve the most challenging needs. Software Engineering / OEM

- For System Builders and Machine Manufacturers, we design

OEM ready SW solutions for desktop and mobile use.

Our own Software toolbox "Fortress" allows us to extract quickly custom-made Software solutions for Motion Control, Light Control, Autofocus, Object tracking as well as Memory Management and Big Data analysis.

We program with Vision Builder NI, Open CV, C++, Halcon and more to choose the best solution for you.

With our own solino Technology we are able to serve you with unique and newest computational methods to add immediately value to your product. Software

- We design Software to support our Imaging Modules and our OEM Partners.

Imaging Hardware and Software all out of one Hand.

User Interface Design

- User Interface Design

It is always important to work towards customer usability Interaction.

We design your own identity to work perfectly with all other services inside your Machinery.

We offer this service only to our long term OEM partners to assist the integration of our Imaging devices.

Mobile Interface Design

It is getting more and more important to have also mobile access to the machine and the process especially in the mind of "Predictive Maintenance".

This is why we deliver alos APP designs to drive and read out the Imaging Modules like IoT devices.

Process Control

- Process Recording and Control

WIth our own Fortress framwork we are also able to lead an intellegint workflow process for different applications:- AQT (Assembly / Quality Control / Throughput) Assistance systems

- Lab environment digitisation

Data Management

- DATA and Network Management

DATA Management WIth our own Software Framework we are able to plan and develop easily any new challange around DATA managment and Processing

Image Analysis

- Over the last 40 years we have solved many market driven challenges that we are able to easily integrate in our Opto Framwork to deliver now "Plug and play" Job Modules for you.

Computational Imaging

- Computational Imaging means extracting additional Informations out of standard Images.

Computational Imaging needs a deep understanding of the Application.

We often only assist as an extended development partner.- solino is our own Algorithmic for digitizing the Human Percetion of Products (LINK)

- Super Resolution Effects are possible

- For Computational Microscopy our Imaging Modules are perfect

Deep Learning and AI

- To create an AI solutions it is always important to work closely with the customer to learn and interprete the products to be analysed. So working AI solutions are always project based.

That is why opto uses existing Software Packages from partner companies in its own solino Interface design to set up CNN and Deep Learning.

Opto wants to cooperate with Companies to make solino their AI tool for- Predictive Maintenance

- Quality Inspection and Assurance

- Manufacturing Process Automation

Workflow Management

- In having the internal Hardware and Software design capabilities in house we are able to design for our Partners complete Industry 4.0 stations.

The idea is that many different IoT sensors work together to survey, test, analyse and make decisions to excellerate the Quality, the Throughput and the Documentation to a next level.

OEM

- As a contract manufacturer with our own production facilities, we develop and produce imaging modules, special microscopes in series for manufacturers of industrial and biomedical machines

Custom Microscopes

- For 40 years we build digital Microscopes for Machine Integration

Dedicated modules for machine builders

Business model: custom-specific design and manufacture

Focus on volume and long-term opportunity

Innovative by nature

Stereo Microscopes

- Out of our 40 years Microscopy Experience in designing special Stereomicroscope solutions and Accessories for and with Leica, Zeiss, Nikon and Olympus here some results.

If you want to integrate special functionality into your Stereo path or incaet Laser sources, multiple Cameras or others, the chance that we have done it before is quite high.

Computational Imaging

- Computational Imaging means extracting additional Informations out of standard Images.

Computational Imaging needs a deep understanding of the Application.

We often only assist as an extended development partner.- solino is our own Algorithmic for digitizing the Human Percetion of Products (LINK)

- Super Resolution Effects are possible

- For Computational Microscopy our Imaging Modules are perfect

Deep Learning and AI

- To create an AI solutions it is always important to work closely with the customer to learn and interprete the products to be analysed. So working AI solutions are always project based.

That is why opto uses existing Software Packages from partner companies in its own solino Interface design to set up CNN and Deep Learning.

Opto wants to cooperate with Companies to make solino their AI tool for- Predictive Maintenance

- Quality Inspection and Assurance

- Manufacturing Process Automation

OEM Imaging Modules

- Opto produces specific Imaging Modules with special cameras, Light and Contrast Technologies

Custom Imaging Modules

As we are doing Custom Optics since 40 years it is in our genes to build for our Machine building customers special units.

"reduced to your needs"