- Offer Profile

- An international family-owned business with a passion for sensor technology, encoders, measuring instruments and components for automated image processing

Our standards – your benefits.

- Passion coupled with expertise – both have made us a sensor pioneer and technology leader

- Our range of services is hard to beat – we have the right product, developed by our own team, for every task

- Inspiring through innovation – a challenge Baumer employees take on every day

- Reliability, precision and quality – our customers’ requirements are what drives us

- Partnership from the start – together with our customers we develop suitable solutions

- Always a step ahead – thanks to our production depth, our flexibility and our delivery reliability

- Available worldwide – Baumer is Baumer everywhere

Object detection

- Sensors, proximity switches and light barriers for object and position detection.

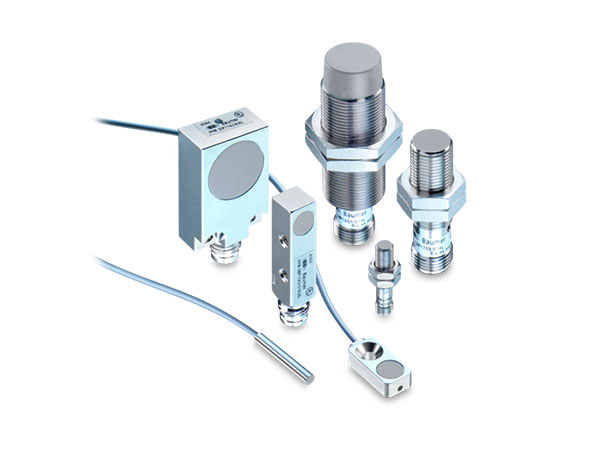

Inductive proximity switches

-

- Non-contact detection of metal objects

- Monitoring presence, movement and position

- Very small sensors with all integrated processing electronics

- Small-sized sensors with large sensing distance

Light barriers and light sensors

-

- Smart & Small – top performance in smallest designs

- Large portfolio

- Easy to set up with teach-in function

- Laser sensors for detection tasks in the 0.01 mm range

Fiber optic sensors and fiber optic cables

-

- Large selection of sensing heads

- Plastic and glass fiber optics

- Fiber optic amplifiers in different versions

- Detecting filling levels or leaks

Capacitive sensors

-

- Non-contact detection of liquid as well as solid objects

- Absolutely reliable even when interfered by ambient conditions

- High switching distance up to 30 mm even through non-metallic walls

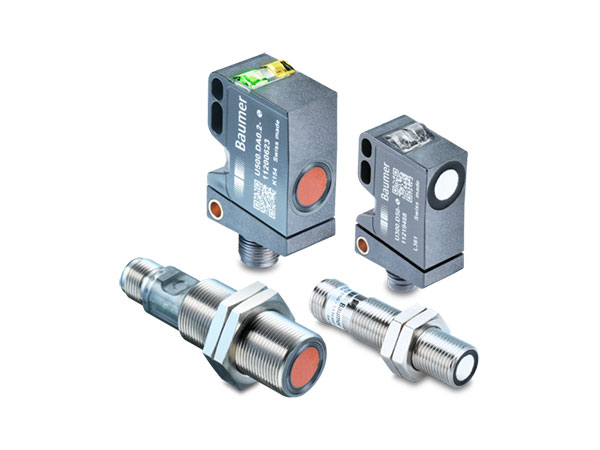

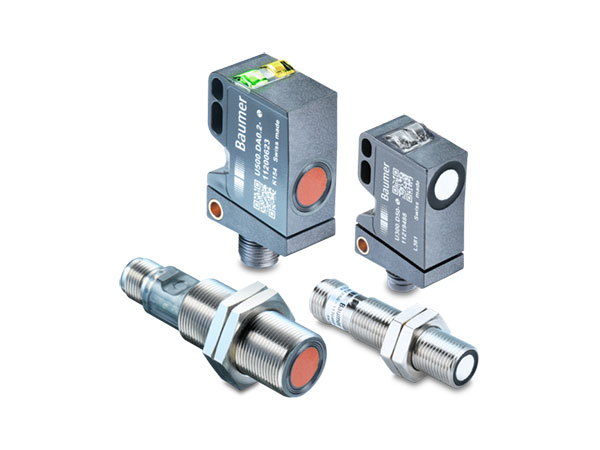

Ultrasonic sensors

-

- Outstanding fast, small and sturdy in one

- Unaffected by object's brilliance, color or transparency

- Immune to dust, moisture or ambient light

Magnetic and cylinder sensors

-

- Large sensing distance up to 60 mm also through metal walls

- Maintenance-free and robust – ideal for outdoor applications

- Fast response time ensures reliable detection

Precision mechanical switches My-Com

-

- Repeat accuracy of 1 micrometer

- Compact design for very confined installation environment

- Mechanical (NC) and electrical (NO) output circuit

Edge measurement and detection

-

- Web edge measurement independent of radial runout

- Edge detection with wide measuring range

- Measurement of edge postions and object widths

- Copy counter

Light-band sensors

-

- Homogeneous, parallel light beams

- Measurement of fast moving objects

- Aluminum housing

- Switching version for detection of small objects

- Measuring range up to 24 mm

Label sensors

-

- Reliable detection of a wide variety of labels and carrier materials

- Precise positioning of labels even at high conveyor speeds

- Photoelectric and ultrasonic sensors

- Auto-teach function

- IO-Link

Accessories sensors

-

- Cables and adapters

- Mounting accessories

- Peripherals

- Reflectors

- Lenses / apertures / glass covers

Distance measurement

- Sensors for detecting distances and distance information from the µm range to over 40 m.

Optical distance sensors

-

- Extensive portfolio of laser and LED distance sensors

- Miniature sensors for use in cramped spaces

- Long ranges of up to 13 meters

- Reliable even on very rough or shiny surfaces

Precise ultrasonic distance sensors

-

- Small and light designs

- Measurements in very small containers or openings

- Large measuring ranges up to 6000 mm

- Sturdy sensors for demanding environments

Radar sensors

-

- Smallest radar sensor on the market (M30 housing)

- Focused beam path

- Measuring range up to 40 m

- Unaffected by environmental conditions and soiling

Inductive distance sensors – AlphaProx

-

- Comprehensive portfolio

- Measuring accuracy down to the nanometer range

- Compact sensors with completely integrated evaluation electronics

- Calibrated for minimum production lot variations

Linear magnetic encoders

-

- MIL10

- Non-contact, wearfree magnetic sensing technology

- Impervious to soiling and resistant against vibration

- Extended life span thanks to robustness and durability in extreme conditions

- Maximized machine and system uptime

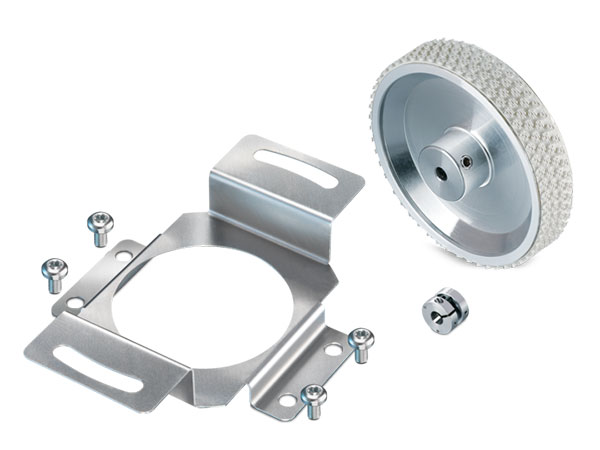

Measuring wheel encoders

-

- MA20 / MR / EIL580P

- Programmable incremental encoders used in conjunction with measuring wheels

- Particularly easy acquisition of position and speed with high flexibility

- Perfect for ink jet and laser printing applications thanks to precise optical sensing

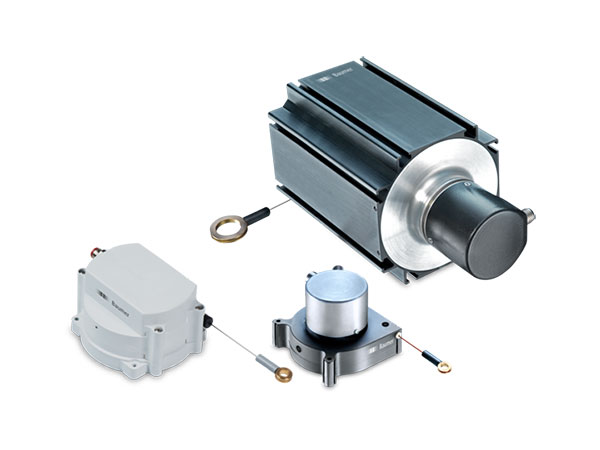

Cable transducers

-

- High linearity throughout the entire measuring range

- Measuring length up to 50 m

- High quality and extremely durable designs

- OEM and retrofit

Accessories sensors

-

- Cables and adapters

- Mounting accessories

- Peripherals

- Reflectors

- Lenses / apertures / glass covers

Smart Vision Sensors

-

Smart vision simpler than ever before

Simple handling and implementation make our smart vision sensors a smart solution for you. For example, parameterization of the new smart profile sensors takes only a few minutes via an intuitive web interface. Featuring an extensive set of integrated measurement functions, they support efficient inline or offline tests without detailed image processing expertise. With the robot-compatible VeriSens vision sensors, the image-based control of collaborating robots from Universal Robots is easier than ever before. This gives you quick and easy access to vision-guided robotics applications.

Smart 2D profile sensors

-

- Smart measurement toolbox

- Web interface for easy parametrization

- Precise up to 5 micron resolution

- Smart connected - IO-Link / Ethernet / and much more.

- 10 models for a wide range of objects

VeriSens vision sensors

-

- Image-based quality control with a single sensor incl. text and code reading

- Automatic object alignment

- 23 powerful feature checks for various inspection tasks

- Configured within a few minutes thanks to VeriSens Application Suite

- Digital inputs and outputs as well as Industrial Ethernet

Easy control of Universal robots

-

- Vision Guided Robotics effectively implemented

- Flexible application solutions with 21 different feature checks

- Fast installation with automated calibration

- Only two new commands (nodes) for easy programming of the robot

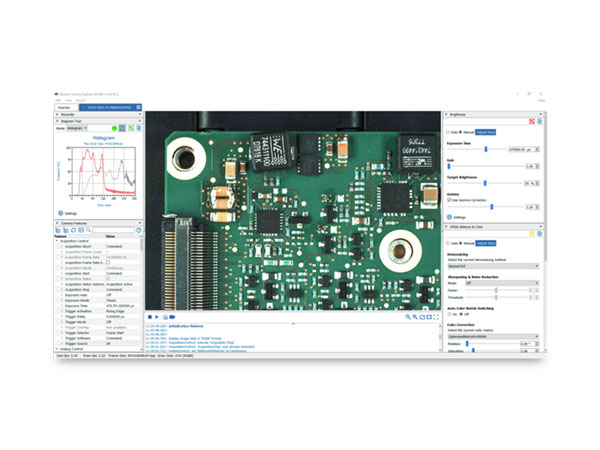

Industrial cameras / image processing

-

Modern image processing faces the challenge of successfully completing complex inspection tasks at top speed. Choosing to use Baumer vision components is the most important step on the way to a reliable solution.

Our high-performance product portfolio – from cameras to vision sensors – with sensor resolution from VGA up to 65 megapixel, always offer exactly the right components for a wide range of applications.

With our VeriSens vision sensors, complex process control tasks can be managed by utilizing image processing technology without a PC. Thanks to the intuitive configuration interface of the vision sensor integration is both easy and rapid.

Baumer cameras with CMOS sensors are the core of high-performance image processing solutions. Your investment in process automation is ensured – whether your goal is maximum speed or precise attention to detail. The portfolio contains robust industrial cameras providing up to 1622 frames/s or resolutions up to 65 megapixel.

Industrial cameras

-

- Up to 65 Megapixel and 1622 fps

- CMOS sensors with global and rolling shutter

- GigE Vision, USB3 Vision and Camera Link interface

Software

-

- Homogeneous, parallel light beams

- Measurement of fast moving objects

- Aluminum housing

- Switching version for detection of small objects

- Measuring range up to 24 mm

Starterkits

-

- Edge detection, width and center measurement

- Measuring field size up to 875 mm

- Precise detection of thin and transparent objects

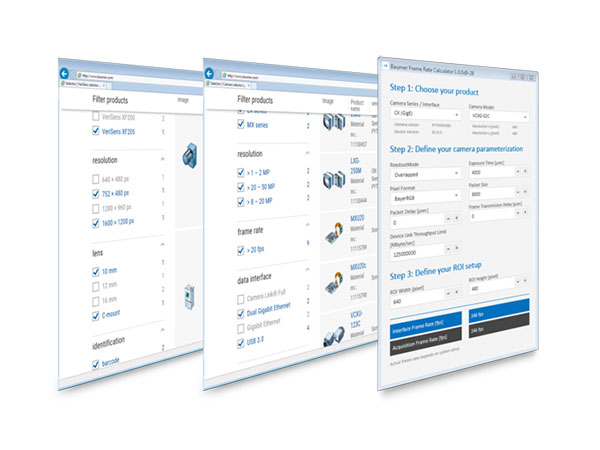

Tools

-

- Frame Rate Calculator

- Lens selector

- Camera selector

- VeriSens selector

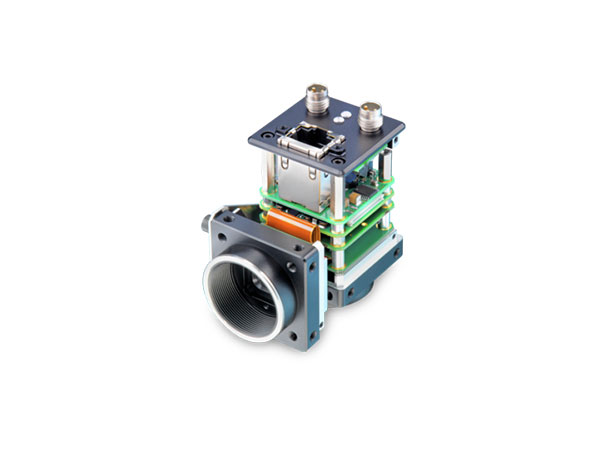

Custom cameras

-

- Modification of standard products

- Tailor-made OEM imaging solutions

- Embedded vision development

- Software and system integration

Accessories image processing

-

- Mountings, cables, power supplies

- Lenses, filter, illuminations

- PCIe interface cards

- Network components

VeriSens vision sensors

-

- Image-based quality control

- Text reader (OCR/OCV)

- Code reader (1D/2D)

- Industrial Ethernet

Identification

-

Our stationary, camera-based 1D/2D code readers reliably detect almost any type of code such as barcodes (1D codes like EAN/GTIN), matrix codes (2D codes like DataMatrix), direct part marking (DPM) or dot-peened codes. In addition to well-known 1D and 2D codes, VeriSens ID code readers also read numbers, characters and symbols of any font, including dot matrix (OCR/OCV).

Our code readers are deployed in many varied industries and applications, such as intra-logistics, assembly technology or the food industry.

Multicode Reader IDC200

-

- Up to 40 frames per second, several codes in parallel

- Reliable even in the presence of reflections, etc.

- Compact housing and smart mounting accessories

- Auto setup and web interface

Text reader (OCR/OCV) with code reading function

-

- Image-based inspection of plain text and 1D/2D codes

- Industry-suited IP 67 metal housing

- Integrated illumination and lenses

- TCP/UDP (Ethernet), RS485, PROFINET, or Ethernet/IP

Starterkits

-

- Edge detection, width and center measurement

- Measuring field size up to 875 mm

- Precise detection of thin and transparent objects

Accessories image processing

-

- Mountings, cables, power supplies

- Lenses, filter, illuminations

- PCIe interface cards

- Network components

Rotary encoders / angle sensors

- Measuring and monitoring of rotary speed and rotary shaft positions at machines, installations and electrical drives

Industrial encoders absolute

-

- Magnetic or optical sensing

- Always the best technology for your application

- All relevant signal interfaces & shaft versions

- Wide and convenient selection

- Compact designs 28 … 58 mm

- Time- & space-saving installation

Incremental industrial encoders

-

- Compact in size

- Robust and modular design

- From 24 mm design on to 85 mm hollow shaft diameter

- Precise optical or robust magnetic sensing

- All common installation options, HTL, TTL and SinCos output signals

Bearingless encoders

-

- Wearfree magnetic sensing technology

- Space-saving short mounting depth

- Reliable especially in most demanding environments

- Incremental and absolute variants

Encoders for synchronous motors

-

- Precise optical sensing – for optimal signal and control quality in your application

- Compact designs of 36 mm minimum save space in installation

- High-performance digital interface

Absolute HeavyDuty encoders

-

- Highly robust HeavyDuty mechanics and innovative technology

- Precise, optical or magnetic scanning

- Extensive interface portfolio and additional incremental signals

- Maintenance-free, energy harvesting HeavyDuty revolution counter – without battery, without gearbox

Incremental HeavyDuty encoders

-

- Unrivalled service life and reliability – the original Hübner Berlin

- Proven HeavyDuty design with double-sided bearing setup

- Precise speed signals for improved process control and process quality

- Minimizing time and cost-intensive downtime

- Benefit from more than 60 years of experience of the world market leader

HeavyDuty tacho generators / resolvers

-

- Unrivalled service life and reliability - the original LongLife from Hübner Berlin

- Proven HeavyDuty design with bearings at both ends

- LongLife commutator with silver track for consistently low contact resistance

- Specific brush design for wearfree and longlife performance

- Ideal in extreme climate and ambient conditions

HeavyDuty speed switches / speed monitors

-

- Unrivalled longevity and reliability – the original by Hübner Berlin

- Proven, robust HeavyDuty design with bearings at both shaft ends

- Mechanical speed switches, electronic and digital speed monitors

- Standalone device or encoder combination, encoder-integrated or for cabinet installation

- Switching speed as factory default or user-configurable by PC software

HeavyDuty combinations

-

- Several different signals for control evaluation generated at one common shaft

- Unrivalled service life and reliability – the original by Hübner Berlin

- Proven HeavyDuty design with bearings at both shaft ends

- Ideal properties for tasks in drive control

- Space-saving design and high torsional stiffness

Real-time Ethernet encoders

-

- PROFINET, EtherCAT, EtherNet/IP, OPC UA (upon request)

- Future-proof for industry 4.0 and IIoT

- High-precision control of the machine in real time

- Operating modes and data provision according to requirements

Programmable incremental encoders

-

- Pulse number, output stage HTL / TTL, pulse sequence and zero pulse programmable

- For end users, wholesalers and system integrators

- For varied and multi-faceted applications

- Cutting down on product variants, downtime, maintenance and inventory cost

Functional safety certified encoders

-

- Protection of human and machine in drive technology, machines and plants

- Certified encoders fulfill the demanding functional safety requirements of DIN 61508 and EN ISO 13849

- Motion control and positioning with ultimate reliability and safety

Rotary encoders for offshore and marine applications

-

- High tightness and corrosion resistance in adverse conditions on deck

- Designed for a long service life and extended maintenance intervals

- Variations with DNV-GL approval for offshore and marine applications

- Rotary encoder solutions for every type of mounting

Accessories

-

- Hollow shaft / solid shaft encoder mounting

- Cables / connectors

- Signal processing

- Programming / diagnostics tools

- Motor grounding devices

- Measuring wheels

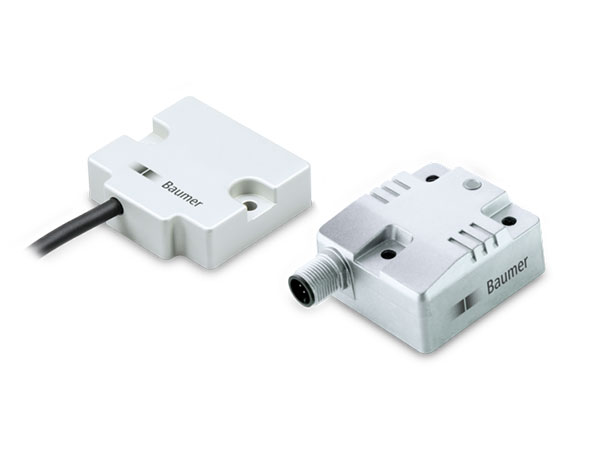

Inclination / acceleration sensors

Inclination sensors - GIM140R / GIM500R

-

- Angle and rotation measurement, particularly where hardly accessible

- Improved safety, for example at cranes

- Robust, encapsulated housing with high IP rating

- For durable use in harsh environment

Dynamic inclination sensors - GIM700DR

-

- Precise position measurement with gyroscope-based motion compensation

- High signal quality and quick response time

- Robust, compact design for the harshest ambient conditions

- Uniaxial and biaxial inclination measurement

Vibration / acceleration sensors - GAM900/GAM900S

-

- Reliable detection of acceleration, vibration and shock levels at machines and facilities

- Transmission of the measured acceleration values to master controller via CANopen or analog interface

- Simple integration of the redundant relay contacts directly into the safety circuit

- Redundant relay output will trip once the factory default limit has been exceeded

- Fast implementation of functionally safe applications up to SIL2 / PLd

Process sensors

- Automation of process technology with transmitters, sensors and measuring equipment for the parameters of pressure, temperature, fill level, flow and conductivity of gaseous, liquid, paste-like and granular media.

Level sensors

-

- Point level detection and continuous level measurement in fluids and bulk media

- For hygienic and industrial applications

- Reliable sensor solutions for high process reliability

- All standard process connections

Pressure measurement

-

- Pressure sensors, pressure transmitters and pressure switches

- Optimum technology for every application

- Relative pressure, absolute pressure and vacuum measurement

- Broad portfolio of process connections and adapters

- ATEX approvals for potentially explosive atmospheres

Temperature measurement

-

- Wide range of measuring technologies and Pt100-classes

- Selectable output signal

- Diverse process connections, adapters and accessories

Flow measurement

-

- Flow measurement for hygienic and industrial applications

- For aqueous media in closed systems

- IO-Link interface

- Various process connections and probe lengths

Liquid analysis

-

- Reliable sensors for conductivity measurements and detection of air and gas bubbles

- Fast and precise measured values for optimum use of resources

- Future-proof thanks to digital IO-Link interface

CombiView DFON touch display

-

- Standardized display concept for all technologies: pressure, fill level, temperature, analysis and flow

- Configurable visual display of measured values

- Easy sensor adjustment straight on site

Accessories process sensors

-

- Cables/Connectors

- Process connections and adapters

- Interfaces

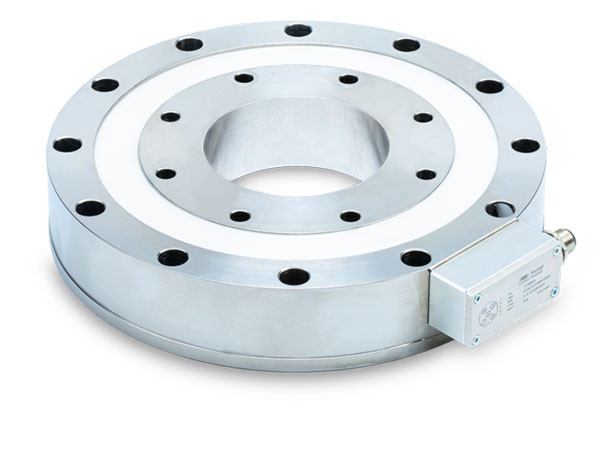

Force sensors and strain sensors

- Force and strain measurement in machines, installations and tools.

Force sensors

-

- Force measurement easily accomplished

- Intelligently designed portfolio for a range of forces and installation options

- For harsh industrial environments

- Durable for cyclical loads in the entire nominal force range

Strain sensors

-

- The clever alternative to force sensors when it comes to measurement of high forces

- One sensor for several force ranges

- Quick and easy implementation in existing machines and facilities

Measuring amplifiers

-

- The measurement electronics for measuring forces

- 3 versions: IO-Link version along with versions with current or voltage output and IO-Link

- Easy parameterization

Customised solutions

-

- Force measurement to over 1000 kN

- Your partner from the development stage to spare part service

- Force measurement optimally integrated in your application

- Professional project management

- Security of investment thanks to long-term product availability

Cavity pressure sensors

-

- Quality monitoring in the injection process

- Improved component quality

- Pluggable version for more flexibility

- Any standard type available

Strain measurement in holes

-

- Cost-effective force measurement using strain probes

- For permanent installations in tiebars of injection molding and die-casting machines

- Robust and maintenance-free

- Suitable for harsh industrial applications

Format adjustment

- Display and adjustment of position of stops and formats in machines and systems

NM170

-

- Two-line backlit LCD display

- Through hollow shaft ø25 mm

- Interface: CANopen®

- 2 x M12 connector, male/female, 5-pin

- Singleturn resolution: 2304 steps

- Multiturn resolution: 4096 / 12-bit

- Protection class IP 55

NM172

-

- Two-line backlit LCD display

- Through hollow shaft ø25 mm

- Interface: CANopen®

- 2 x M12 connector, male/female, 5-pin;

1 x connector M16, female, 12-pin - Singleturn resolution: 2304 steps

- Multiturn resolution: 4096 / 12-bit

- Protection IP 55

- Suitable for connecting DC motors with 4 24 V control inputs (anticlockwise, clockwise, low speed ≤4 rpm, high speed ≤100 rpm)

NM174

-

- Two-line backlit LCD display

- Through hollow shaft ø25 mm

- Interface: CANopen®

- 2 x M12 connector, male/female, 5-pin;

1 x connector M16, female, 12-pin;

1 x flange connector M12, female, 8-pin - Protection IP 55

- Connection for external absolute multiturn encoder with SSI interface

- Suitable for connecting DC motors with 4 24 V control inputs (anticlockwise, clockwise, low speed ≤4 rpm, high speed ≤100 rpm)

Counters / displays

- Acquisition, display and control of process data and measured values such as unit numbers, times, rotational speeds and positions.

Displays

-

- Measuring, monitoring, calculating and controlling various measured values

- Support for standard signals, speeds, temperatures, resistance and strain gauges

- Control of switch and analog outputs

- Wide range of application options by combining with sensors and encoders

Totalizers

-

- Detecting strokes, lengths and revolutions

- Calculating and displaying quantities, volumes and impulses

- Comparing values, determining differences, calculating ratios, outputting control variables

- Wide range of application options by combining with sensors and encoders

Time counters and hour counters

-

- For all time-controlled processes

- For machinery in production areas and for mobile stand-alone devices

- With preselection and control outputs

Preselection counters

-

- Comparing values and identifying differences

- Activating outputs for process control

- Communication with higher-level controls

Accessories for counters and displays

-

- Quick access to the appropriate accessories for counters and displays

- Easy installation

- Protection against dust and moisture

Accessories

- Always the right accessory for your sensor and your application.

Accessories rotary encoders / angle sensor

-

- Quick access to the appropriate accessories for rotary encoders and their application

- Facilitates installation considerably and significantly reduces commissioning time

- Enables full functionality, high precision and long service life

Accessories counters / displays

-

- Quick access to the appropriate accessories for counters / displays

- Facilitate the installation

- Protect against dust and moisture

Accessories sensors

-

- Cables and adapters

- Mounting accessories

- Peripherals

- Reflectors

- Lenses / apertures / glass covers

Accessories process sensors

-

- Cables/Connectors

- Process connections and adapters

- Interfaces

Accessories image processing

-

- Mountings, cables, power supplies

- Lenses, filter, illuminations

- PCIe interface cards

- Network components

Cable/connectivity

-

- The suitable connection option for every sensor

- From standard to special cable solutions

- Cable and IO-Link master for easy sensor connection

- Connectivity in the field, control cabinet, wireless or for USB

Cable/connectivity

Cables and plugs

-

- The matching connection option for every sensor

- From standard cables to special solutions

- Various application areas and certifications, e.g., for cable carriers, food, etc.

- Great variety of versions for your requirement

IO-Link Master

-

- IO-Link master for engineering, field use or control cabinet

- For connection to PROFINET or to the Baumer Sensor Suite

- More interfaces via Modbus TCP and OPC UA

- User-convenient parameterization via web interface

- Simplified sensor replacement thanks to the parameter server function

Baumer Sensor Suite

-

- Evaluation, parameterization and use of smart sensor solutions with IO-Link

- Understanding and exploiting the full potential of IO-Link devices

- Visualization of functions from different sensor manufacturers

- Easy-to-use PC software with clear design and helpful additional information

USB-C CAN Adapter

-

- Fast connection of CANopen devices to a PC

- Power supply via USB-C and switchable termination resistor

- Easy parametrization and testing with Baumer Sensor Suite