- Offer Profile

LINEAR ROBOTICS BY EXPERTS AND CREATORS

A conventional jointed-arm robot is often not sufficient for many industrial applications. Our two managing directors have decades of experience in complex mechanical engineering, coupled with an extensive knowledge of the problems and hurdles that can arise in production processes with industrial robots.

We started to develop a solution where no higher-level measurement technology was needed to achieve the required high-precision kinematics. Our solution had to be lean, efficient, and easy to use. Does this seem impossible? Not for us. We managed to simply achieve all these requirements with our linrob.

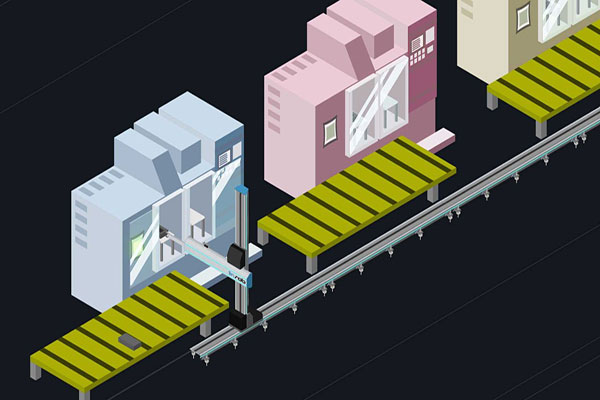

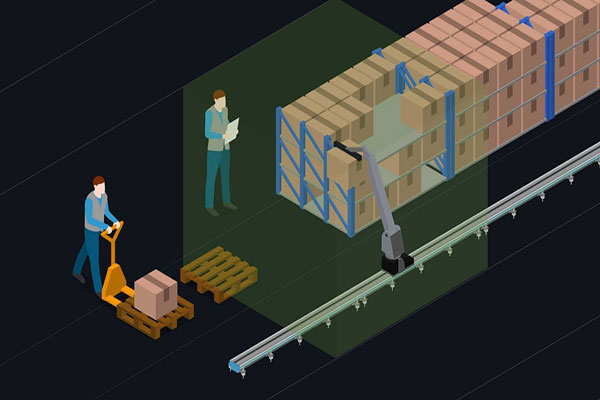

The result is a linear robot that covers all areas of large-format automation.

LINEAR ROBOTS TAILORED TO YOUR SPECIFICATIONS

-

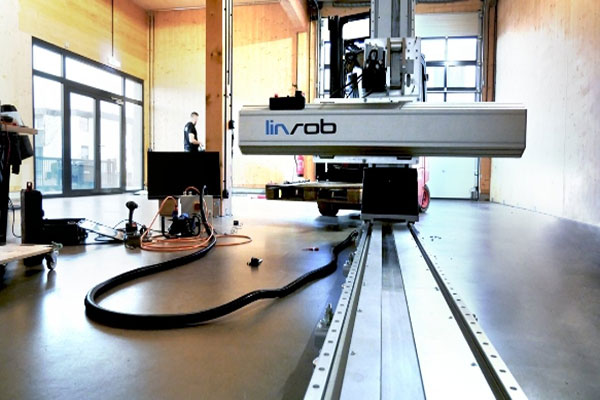

Requested within minutes, delivered within days, set up within hours

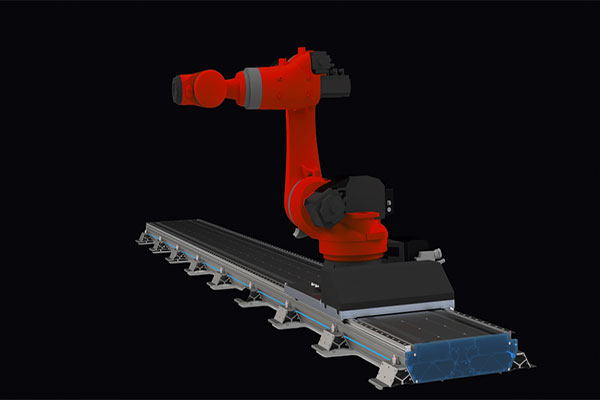

Our linrob Range Extender and linear robots provide the ideal basis for your industrial application. Simple and flexible, scalable up to 80 meters, allowing three-dimensional application and, thanks to its simple integration, compatible with every cobot on the market.

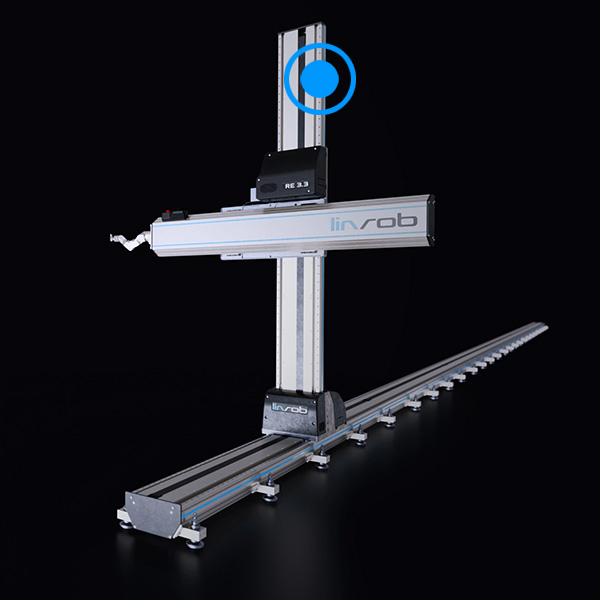

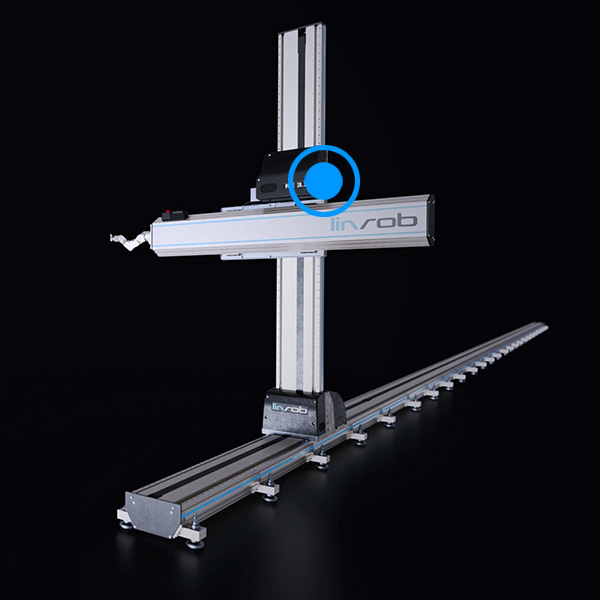

Linrob Range Extender

- Our linrob Range Extender and linear robots provide the ideal basis for your industrial application. Simple and flexible, scalable up to 80 meters, allowing three-dimensional application and, thanks to its simple integration, compatible with every cobot on the market.

Modular linrob axes

Expand your existing applications with our modular linrob axes. This opens up completely new fields of application for your cobot.

Plug & Work solution

Discover our Plug & Work solution.

Linrob Linear Robots - All Components At A Glance

-

Simplicity, flexibility and short delivery times on axes scalable up to 80 meters

You don't have enough space on the floor of your shop floor for a long axle? You want to avoid expensive idling in your production process? Together we can solve this situation. After all, linrob's range extenders and linear robots provide the ideal basis for production and manufacturing tasks. Even three-dimensionally or as ceiling or wall mounting. We think outside the box when it comes to linear robotics, are partners at eye levels and strife to find the perfect solution for you. Find out for yourself how our modular linear robotics designs can benefit you.

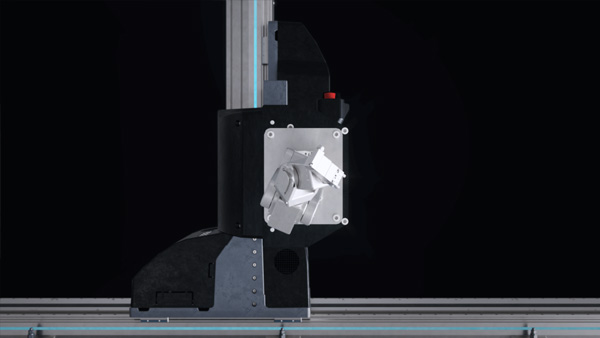

Precision Guiding

- Our guideways are maintenance-free due to lifetime lubrication. All running surfaces are made of steel wire. And bimetal effects are avoided by the base body made of aluminum.

Backlash-Free Precision Drives

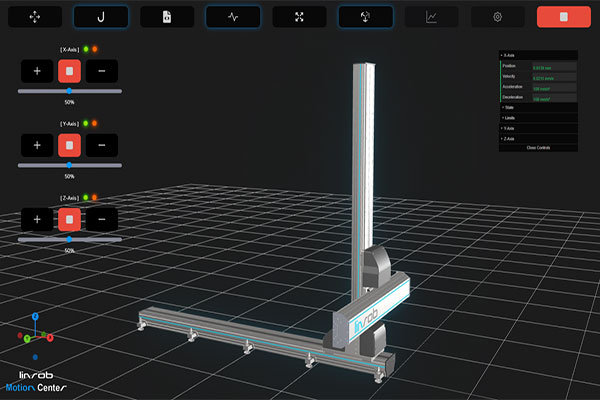

A compact unit consisting of a combination of motor, gearbox and controller is installed in our system axles. In addition, a linrob has linear scales for absolute position determination.

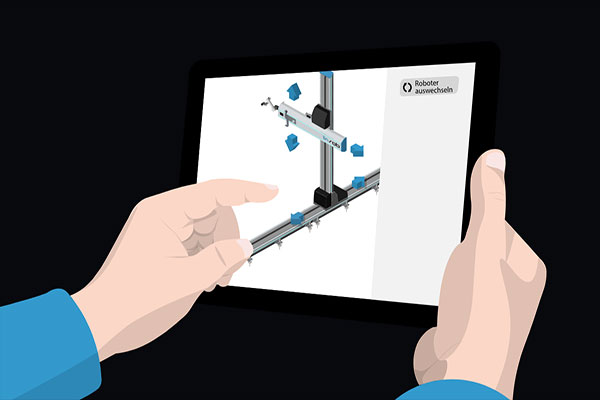

3D-Control (SPACEMOUSE)

Instead of programming the machine with software, manual programming with a SpaceMouse is also possible. With this, the entire system is very easy to operate and an effortless and intuitive movement to any position in the working area is possible.

Precision Aluminum Extrusions

Our FE-supported profile design enables us to achieve extremely high rigidity. With the help of T-slots, any peripheral equipment can be easily adapted.

Internally Routed Cables

We have laid all the cables that a linrob needs inside the axle, which significantly reduces the risk of errors. The only two cables leading to the machine are a 230V power cable and a data cable. You therefore only need a conventional power socket to put a linrob into operation.

Integrated Control

Our control system has a TCP/IP interface for the integration of peripheral devices. Thanks to the OPC/UA interface, a linrob is Industrie 4.0 and IIoT capable. In addition, the control still has programmable digital inputs and outputs.

Multi-Color LED Bar

Each LED is individually programmable, providing visual feedback on the current machine status.

Quick and Easy Installation of the Axles

Thanks to the connecting plates matched to the profiles, stretchable line connections and the cast slides, our axles can be easily plugged together, avoiding incorrect assembly.

What Distinguishes LINROB From Other Linear Robots & Range Extenders

Infinity Range

Achieve more than ever before. Thanks to expandable axle design, LINROB adapts to your requirements at any time. When it comes to the basic axle, we can achieve an application range of up to 80 meters.

Easy-of-Use

We offer you unprecedented simplicity, whether in terms of configuration, installation, or daily use. Programming your linrob is simple, too, via your web browser or a fully integrated app, such as URCap.

Ready-to-Go

Waiting weeks or even months for your linear system? Not with linrob! Thanks to our series production based in Germany, we are able to deliver within a very short time. The fact that our axes are delivered ready-to-work allows for an easy assembly and commissioning in just a few hours.

Safety Integrated

Safety is a top priority at linrob. Our simple plug-and-play system makes integrating safety sensors simpler than ever and enables coworking of cobot and human without a safety fence. A brake is built into the lift axle by default. Each linrob is based on 48V technology.

Digital Services

You are not sure if your application can be realized? We will provide you with a simulation of your application in advance (proof of concept). With linrob, you also don't have to wait for days for support when there is a bug in the system. With the included digital twin and our remote services, we can simply provide help remotely.

Seamless Integration

You want to increase the application range of your cobot? Thanks to common interfaces, you can simply integrate any cobots and small robots with our range extender. linrob can be seamlessly integrated as a base-of-arm product. Even if you want to run several different systems/robots on one axle.

From Request To Assembly

1. Consultation

Remotely or in our showroom in Mannheim. We discuss your configuration with you and advise you before you decide to work with LINROB

2. Manufacturing

Immediately after your order, our production starts with the construction of your axes.

3. Delivery

Within 14 days, your order will be delivered ready-to-go.

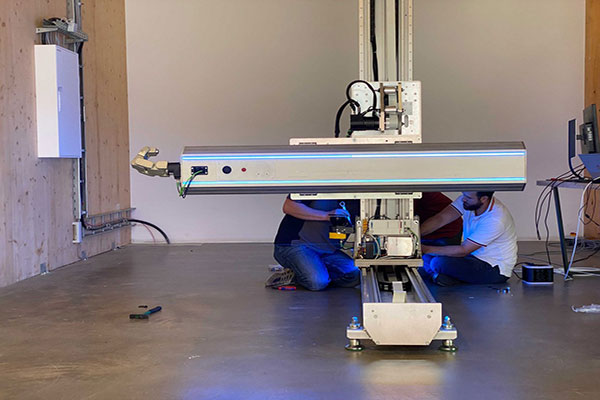

Assembly At Your Site

- Since our axle system only needs to be plugged into place on site, the entire system can be set up within a few hours. Of course, we will assist you in the process.

News

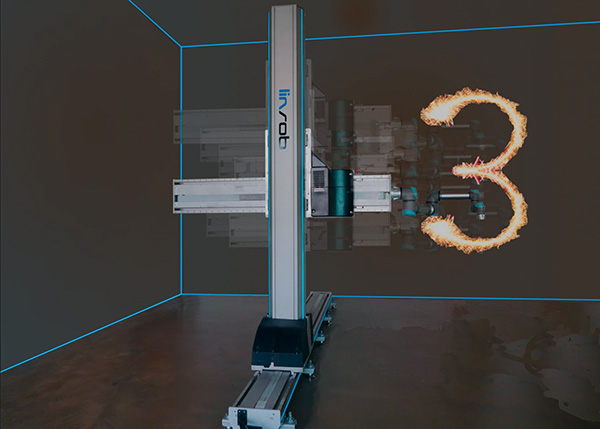

linrob GmbH celebrates its third birthday

- More than 10 years ago, our two company founders already worked together. At that time, Andreas was still manufacturing design milling machines and Rainer was selling high-precision laser measuring technology. Even then, they both noticed that the wrong technology is often used for many applications. Most people reflexively turn to large articulated-arm robots for large-volume applications. However, these have poor repeatability and positioning accuracy. In addition, large robots often get in their own way and cannot properly approach positions at short distances. The use of the more inefficient technology is still regularly observed today. For this reason, Andreas and Rainer set themselves the goal of simply making robotics better.

Doosan Integration

-

Together with Niederrhein Automation, we have worked on making our linrob linear axles compatible with the Doosan software. This means that any Doosan cobot can be easily connected to any possible configuration of our linrob axles and the entire automation sequence can be programmed within a few minutes.

First, we mounted a Doosan cobot on our linrob RE 3.3 and coupled them together. Within a very short time, it was possible to operate the cobot and the linear robot with the Doosan control system.

Linrob in MRK-Blog

- In his fascinating article, Guido Bruch explains how linrob linear robots can help to implement robotics applications as simply as possible and thus enable automation.