- Offer Profile

-

QUALITY, LONGEVITY AND EXCELLENT PRODUCTS ARE OUR PHILOSOPHY.

The range of JDT lashing equipment in the quality grades 10 (ENORM) and 12 (MAXNORM) offers you the best possible securing of a load - an absolute legal requirement.

By optimising the points relating to weight and ergonomics, JDT components ensure user-friendly handling and safe operation.

Industry

Chain Sligns

Chain sling with hook grade 8

Chain sling with hook and shortening clutches grade 8

Chain sling with hook grade 10

Chain sling with hook and shortening clutches grade 10

Chain sling with terminal link grade 8

Chain sling with terminal link grade 10

Endless sling grade 8

Endless sling grade 10

Grade 8

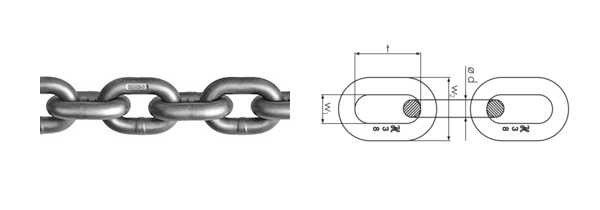

Round link chain

-

Medium tolerance chain for chain slings EN 818-2

Master links

- Master links with and without clevis attachments

Connecting assemblies

- Shackle(TVS) / Eye-Connector with shackle(TGVS) / Coupling(TBS) /

Eye-Connector(TGV) / Special swivel – ball bearing(WG/WGÖ)

Hooks

-

Clevis sling hook(GH) / Self locking clevis hook(AHG) / Automatic-hook(AHÖ) /

Automatic-hook with swivel(TCLE) / Reinforcing-mash-hook(TMH)

Hooks

- Hook with strong safety latch(TOE) / Standard hook(TSiH) / Foundry hook(TGH) /

S-Hook with eye(TRH) / S-Hook(TFH)

Clevis shortening clutches

Attachment points

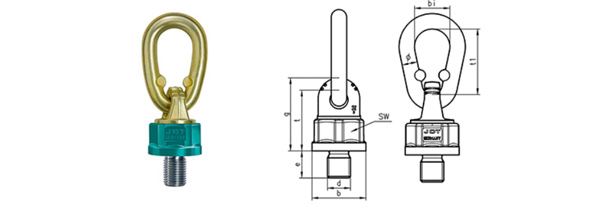

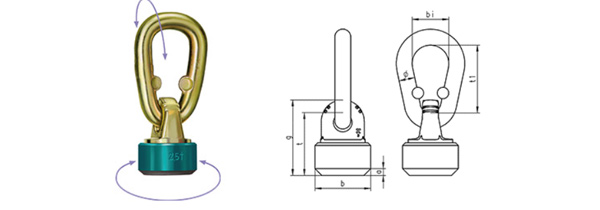

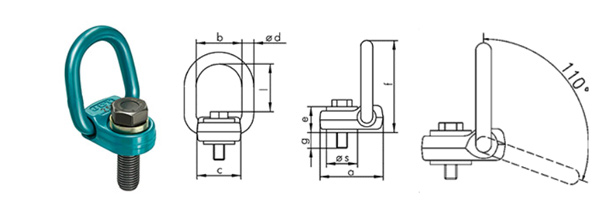

THEIPA Point TP

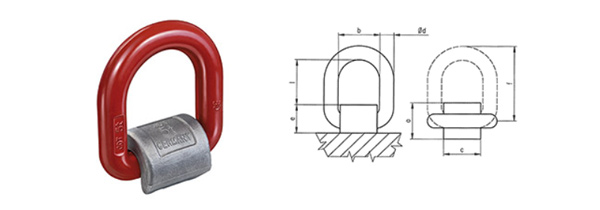

THEIPA Point TP-F

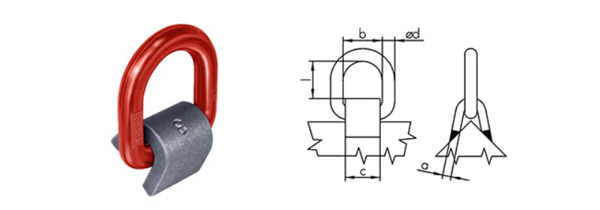

THEIPA Point TP-S

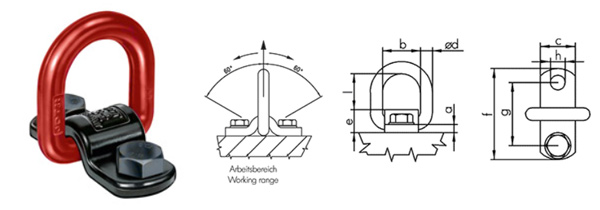

ENORM - flat point - enormously flat and good

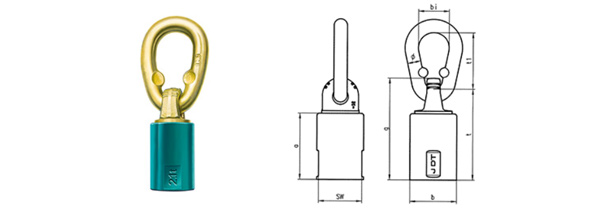

TAPS - Attachment-point, weld-on type

TAPSK - Attachment-point, weld-on type - edge fastening

TAPG - Attachment-point, bolt-on type

TPB - Attachment-point, bolt-on type

Robotics

-

DT has been using industrial automation for more than 10 years. Why not incorporate the systems developed and tested by JDT in your company, and use them for your success. We provide you with advice on the planning, and develop individual concepts in line with your company.

Tailor made automation

Automation using robots that is customary in the trade could not and cannot meet the requirements of JDT’s operations. In conjunction with the company managers and employees on site, JDT and a number of qualified engineers therefore developed systems for the company’s own industrial automation.

Turning, milling, painting, grinding and assembling are applications that are part of the “rough” daily routine at JDT and were automated. Experience was gained over years and was incorporated in optimising the systems. The advantage is obvious – as a user and manufacturer we are familiar with our manufacturing processes and operating sequences.

These systems have been so successful that now as JDT Robotics we would like to offer them to you too. Let the industrial automation systems from JDT Robotics work for you, and permanently improve your production processes.

Review the conditions of use and options at JDT on site yourself, and make use of our know-how for your own company.

Standard Robot Cell (SRC)

- The Standard Robot Cell (SRC) is extremely robust and suitable for continuous use in systems such as turning, drilling or milling machines. It can also be linked to measurement and testing systems.

Flexible Robot Cell (FRC)

-

The Flexible Robot Cell (FRC) can be relocated by just two persons from one workplace to another place of use. There it is fixed to the ground to guarantee secure mounting.

The advantages of this system are:

- Quick assembly and setting at different locations

- Easy to use

- Minor change-over work

- Easy programming

Special Robot Application

-

The Special Robot Application. In this case JDT Robotics develops special solutions for special requirements.

Provide us with a description of your requirements – we’ll find the perfect solution.