- Offer Profile

-

GRIP specializes in automatic and manual tool changers (EOAT) standardized feed-throughs and pneumatic grippers such as parallel grippers for robots and cobots.

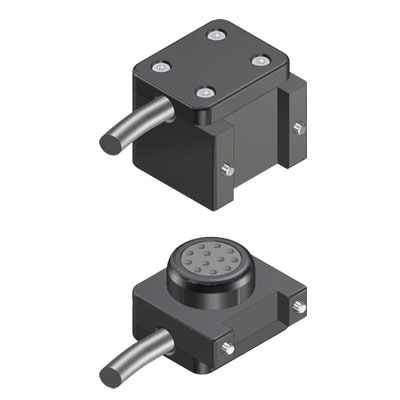

Manual tool changers - One connection - 1000 possibilities

SHS Connector

- The SHS Connector – the original one with the blue hand lever can be purchased directly from the manufacturer. The thrust lever system was developed by GRIP over 10 years ago and is among the most popular manual tool changers in the world. It is available for immediate delivery.

SHW-P Connector

- The SHW-P Connector is an evolution of the SHW Connector. The SHW-P Connector has integrated pneumatic feed-throughs which allow it to be used in wider variety of applications. The new SHW-P tool changer is 100% compatible with the standard SHW Connector.

SHW Connector

- The SHW end of arm tool changer consists of a cylindrical bolt which locks the upper and lower assembly together. A centering disc can be installed on both the upper assembly (robot side) and lower assembly (tool side) of the robot and ensures that the end of arm tools are correctly aligned with the robot arm.

MGW Connector

- The MGW is our universal tool changer for almost every application and we have made it even better! The new system is of higher quality and offers more safety and accuracy. The innovations are a response to the current requirements of our customers. A centering disc can be installed on both the upper assembly (robot side) and lower assembly (tool side) of the robot and ensures that the tools are correctly aligned with the robot arm.

SWS Connector

- The SWS Connector is our tool changer for applications with increased force and torque loads. The semi-cylindrical bolt accurately joins the upper and lower assembly without play. A centering disc can be installed on both the upper assembly (robot side) and lower assembly (tool side) of the robot and ensures that the tools are correctly aligned with the robot arm.

SWA Connector

- The SWA Connector has a very low-profile tool changer for applications with limited space. The transverse screw clamps the upper and lower assembly of the SWA with two wedge-shaped locking flanges, creating a form-fit without any play.

Base Connector

- The GRIP Base Connector allows quick and easy removal of the entire robot arm. The robot arm is bolted to a special tool changer which is bolted to a table or cell. This manual tool changer system allows companies to use the same robot in multiple different cells without having to unscrew the robot every time. The pull of a lever releases the robot from its current position and allows it to be moved to a new position. The entire process takes only a few seconds. It enables companies to be more flexible with the robots that they have and optimizes the use of their resources.

Automatic tool changers

The Auto Connector

-

The Auto Connector is a fully automatic mechanical end of arm tool changer. The system is composed of an upper assembly and a lower assembly. The upper assembly houses the locking mechanism, which ensures a precise and form-locking fitment between the upper and lower assembly. The locking and unlocking mechanism is activated through the robots own movement. Trays make it possible to park multiple types of end of arm tools. An external energy source is not required for the Auto Connector to perform its automatic tool change.

Auto Connector advantages- Fully automatic end of arm tool changer

- Interface according to DIN EN ISO 9409-1

- High repeatability < 0.02 mm

- Durable – withstands over 1,000.000 changing cycles

- Withstands high loads with low dead weight

- The robot’s own movement activates the locking and unlocking mechanism

- No external energy such as compressed air or electric are required

- Integrated pneumatic feedthroughs

- Module for electric actuated tools is optional

- Machined out of high strength aluminum and anodized

- A spring actuated pin ensures additional safety during operation

Feeding through

SEK Energy Coupling

- The SEK Energy Coupling is a SHW Connector accessory that enables the transmission of energy, air and vacuum.

MEK-PM Multi-Energy-Coupling

- The MEK-PM Multi-Energy Coupling is a further development of our MEK series. The inlets and outlets for the pneumatic and electrical lines are horizontally arranged. This reduces the height profile of the MEK-PM. Pneumatic hoses can be connected to the coupling by means of push-in fittings (connection M5).

MEK Multi-Energy-Coupling

- The MEK Multi-Energy-Coupling is an MGW Connector accessory to that enables the transmission of energy, air and vacuum.

MEK-R Multi-Energy-Coupling

- The MEK-R Multi-Energy-Coupling is a further development of our MEK series. The four air feedthroughs are equipped with check valves on the robot side. This allows the MGW-R coupling to be released under activated compressed air. In addition, the electrical contacts on the MEK-R have been replaced with spring contacts.

Pneumatic grippers

-

Our pneumatic grippers are at the heart of many automated processes that require precision, speed and reliability. Designed to support a wide range of applications across multiple industries, our grippers offer a unique combination of strength, flexibility and control.

The G-GP parallel grippers and G-GZ angular grippers are characterized by their compact and robust design. The grippers are available in five different sizes.

Since 2009, we have offered our pneumatic internal grippers G-GI and the G-GIS since 2016. These grippers are available in one mm increments from 5 to 20 mm for a total of 16 different sizes. The internal grippers are a unique industrial handling technology.

GRIP grippers have proven themselves for 35 years at well-known companies.

GP Parallel gripper

-

GRIP's parallel grippers operate via an efficient linear jaw movement that enables precise handling. These grippers are powered by a double-acting cylinder that is operated by compressed air. This system ensures a reliable and powerful movement of the gripper jaws - ideal for a variety of applications.

The special feature of these grippers lies in the unique way that they convert movement: two angled springs that grip into the grooves of the bolts play a key role. This design makes it possible to convert the vertical movement of the cylinder into a precise opposing horizontal movement of the gripper jaws. This innovative mechanism ensures exceptionally fine control and precision during the gripping process.

The combination of compressed air operation and mechanical conversion, enable GRIP's parallel grippers to offer an optimal solution for applications that require both strength and sensitivity.

GZ Angular Gripper

-

The Angular grippers are driven by a double-acting cylinder that is activated by compressed air. This configuration ensures a powerful yet precise drive movement that is suitable for a wide range of applications.

A unique feature of our angular grippers is the implemented eccentric mechanism. This not only ensures an extraordinarily long service life of the components, but also ensures a constant gripping strength. This is essential for applications where consistent performance and reliability are a priority.

In contrast to our parallel grippers, which use an opposing horizontal movement, the gripping force lock on the angular grippers is exclusive to the closing version. This feature allows the gripping force to be maintained even in the event of a loss of pressure or other malfunction, providing an additional measure of safety.

GI Internal Gripper

-

The inflatable bellows gripper is specially designed for internal gripping applications and has a unique functionality. The gripper plunges into bore holes and uses innovative technology to securely grasp objects.

The functionality of the GI internal gripper is based on a silicone membrane that expands when pressure is applied. This expansion increases the outer diameter of the gripper and enables it to adhere to an inner wall through the use of friction. This method allows objects to be gripped safely and without damage, which is particularly advantageous in precision-critical applications.

Another outstanding feature of the GI internal gripper is its ability to automatically retract when air pressure is removed. The elastic properties of the silicone membrane cause it to automatically retract into the gripper housing. This ensures a smooth transition between gripping and releasing, making the use of the gripper particularly efficient and user-friendly.

The GI internal gripper from GRIP is the ideal choice for applications where precision, safety and protection of the materials are crucial.

GIS Internal Gripper Short

-

Imagine if you had an alternative to the proven GI internal gripper that can dive deeper into the borehole - our GIS, internal gripper short, from GRIP allows that. This further development is characterized by a specially designed gripping zone for more demanding applications.

Just like the proven GI internal gripper, the GIS internal gripper also plunges into bores and increases its outer diameter by expanding a silicone membrane as soon as pneumatic pressure is applied to it. This intelligent design allows the gripper to frictionally adhere to the bore wall and thus grasp objects safely and precisely.

The modified gripping zone of the GIS internal gripper makes it possible to dive deeper into the borehole, which is particularly advantageous for complex or heavier pieces.

Accessories

ZS Centering disc

-

A centering disc can be installed on both the upper assembly (robot side) and lower assembly (tool side) of the robot and ensures that the tools are correctly aligned with the robot arm.

ZS Centering disc advantages:

- Ensures precise centering

- Installation on both the upper assembly (robot side) and lower assembly (tool side) possible

- Compatible with MGW, SHW and SWS Connectors

- Easy to remove due to the central threaded hole

Y-Adapter

-

The Y-Adapter connects two tools to a robot flange.

Y-Adapter advantages:

- Allows two tools to be connected to a robot arm at the same time

- Interface according to DIN EN ISO 9409-1

- Available in four sizes

- Pitch circle diameter 50 mm

- Universal Robots UR3, UR5, UR10, UR16

- Compatible with FANUC, YASKAWA, OMRON..

RSGU - Signal transmitter with LED

-

We recommend the RSGU signal transmitter as an accessory for our GP and GZ Grippers. The electronic magnetic switch enables the piston position to be queried and thus the status of the gripper. For example "open" or "closed". It is designed as PNP-closer and is compatible with all our Gripper sizes. The sensor is inserted into the prepared grooves on the Grippers. The switching position can then be fixed via a set screw.

The signal transmitter with LED is available in two versions:- The ZG-RSGU-01 has a 2 meter long and open end cable

- The ZG-RSGU01-300-M8 has a 300 mm long cable with an M8 connector

VKS

- The Square Socket Key is the optimal operating tool for our SWS Connector. It is required when using the safety lock device VS2. By inserting the key, the spring-loaded flap of the safety lock is disengaged.

VS2

- The VS2 Safety Lock is the optimal accessory for our connectors SWS050, 063, 080, 100, 125. For sizes SWS160, 200, 250 the VS2 Safety Lock is standard and comes premounted.

DP Tray Extension

- The DP Tray Extension is an extension of the AC Tray, for a highly flexible and adaptable storage system. The Auto Connector lower assembly and respective tool are securely held.DP Tray Extension advantages:

- Provides secure support for storage plate, car connector and tools

- The storage position is flexible and adaptable

- Compatible with all common robotic tools on the market

- Creates additional space for larger tools and attachments

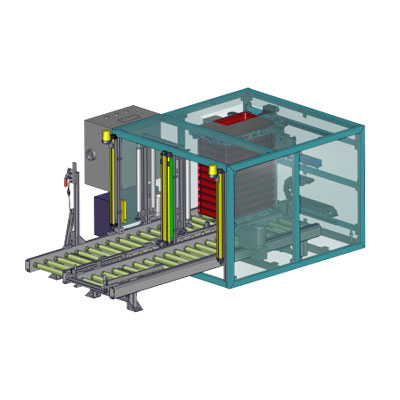

Automation

Jig / Fixture Construction

-

GRIP is your expert for cross-industry, high-quality solutions in the field of fixture construction. Regardless of whether it is tool making, clamping devices, assembly devices or testing devices - we develop your device to increase the quality and efficiency in your production.

Advantages

- Decades of cross-industry, experience

- Custom made solutions

- High level of vertical integration using only high-quality components

- Reliable point of contact throughout the entire project

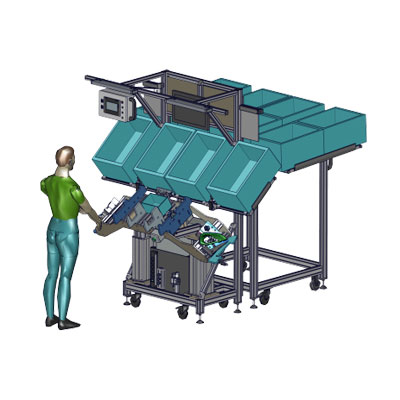

Custom made Grippers

-

If you want to modify existing system, handle new components or want to improve your gripper technology - GRIP will build the optimum gripper for your task. Cross-industry experience, task-specific solutions with integrated sensors and valve technology for all types of drives (pneumatic, hydraulic, electrical or mechanical).

Advantages

- Cross-industry experience

- Custom made solutions with integrated sensors and valve technology

- Pneumatic, hydraulic, electrical or mechanical

- Process optimization, light-weight and durable

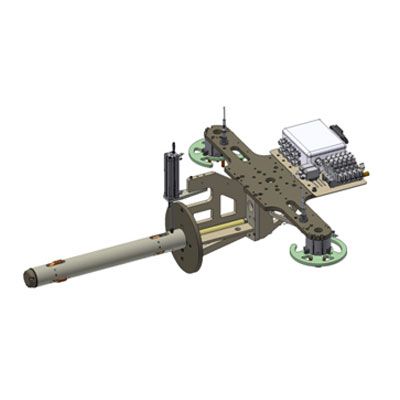

Robotic Tools

-

Gripping, sucking, cutting, milling – we offer various technologies, for multiple materials from a single source. Our high-quality, custom-made solutions are compatible with all major robots and cobots. - durable and made in Germany.

Advantages:

- Our solutions are as varied as our customers' tasks

- Experienced project team to develop the optimal tool

- Longevity and flexibility are the focus of our work

- Reduction of process costs and process chains

Hand tools

-

Do you want to make your assembly processes safer, more ergonomic, and more economical? Our hand tools allow you to assemble and reliably monitor the assembly process at the same time: We offer tools that can be equipped with different, custom-made holders that document your assembly process.

We offer a complete line of clamps, expanding rivets, rings, pads, etc. that will optimize your tools Do you require a different setting movement, multiple shots, without signal generation, etc.? No problem, we have the solution for your production and are happy to offer you a custom-made solutions.

Advantages

- Specialists in the development and production of hand tools

- tailored to your needs

- Consultation, support and optimization of your production processes

- Reduction of process chains and process costs

Robotic solutions

-

We offer you the right robot solution for every task - with the same point of contact from conception to turnkey solution. Depending on the project, we use cobots or industrial robots from our partners ABB, Kuka, Fanuc and UR. Other manufacturers available upon request.

Range of services

- Concept creation and budget planning

- Creation of robot simulations all the way to concept verification

- Planning of the safety concept and the control technology

- 3D design and mechanical manufacturing

- assembly and commissioning in-house and at the customer's site

- Documentation and training

Your advantages

- Increasing quality and reducing defects

- fast implementation and the same point of contact

- economical solution with fast amortization

- Increased safety and worker satisfaction

Services

-

GRIP offers complete robotics solutions from a single source: Regardless of whether you want to convert your existing system or are planning to automate it - we will help you in all stages of the project. From programming services to consulting and concept creation.

Range of services

- Programming services, consulting, concept creation, feasibility studies

- Optimization of applications, processes and procedures

- Prototype plant construction

- Comparisons between robot solution or full automation, industrial robot or cobot

- Simulations of robot movements, accessibility and cycle time analyses

- Construction of the entire system or just individual components

- Advice on the creation of the system and safety concept

Your advantages

- Experienced project team with same point of contact

- Productivity increase and market competitiveness

- Quick, safe and uncomplicated planning of your project

- We will optimize your solution