- Offer Profile

-

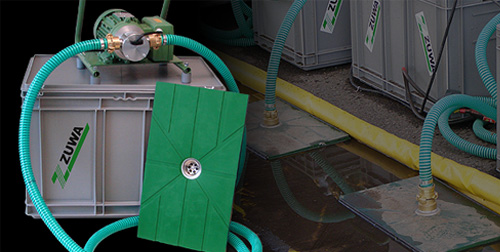

The family run enterprise ZUWA-Zumpe GmbH has been manufacturing high quality pumps and innovative pump systems for more than 70 years. The ample experience in designing and producing high end products enables us to offer a wide range of different devices.

The entire product range consisting of pumps, fuelling stations, plant protection systems as well as charging and flushing stations is in high demand all over the world. ZUWA is working in accordance with the ISO 9001:2015 quality management system, regularly controlled by TÜV SÜD. Process safety and constant quality is guaranteed.

The close contact with our customers provides us with proposals and impulses to improve and further develop our products. in house production and shop floor enable us to meet customer specific requirements, manufacture custom made products and complete repair jobs. Competent contact persons and lean management make for quick and reliable service.

OUR NEW PRODUCTS

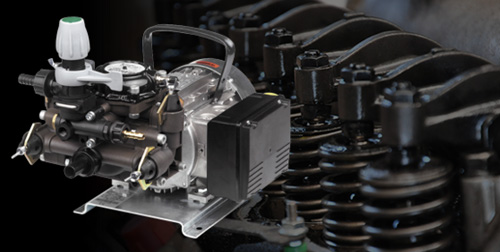

Impeller pump Acostar

-

FOR A WIDE VARIETY OF APPLICATIONS IN THE CHEMICAL SECTOR

Perfect for fluids with various viscosities plus agressive acids, bases and solvents. Using top quality seals and Impellers made of VITON provide excellent operation safety. Various motors (220, 400 V; 1.400, 2.800 U/min; 50, 60 Hz). Star knobs make for quick and simple replacement of the Impeller. The Ceramic sleeve to protect the motor shaft comes as standard equipment. Using a frequency converter permits to adjust the pump speed or rotation direction.

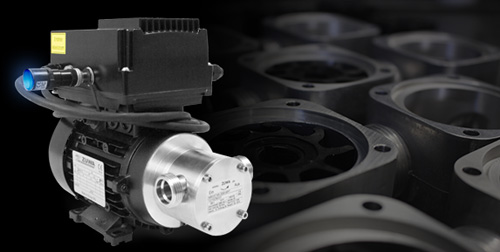

Frequency Converter

-

REGULATE YOUR ZUWA FLEXIBLE IMPELLER PUMPS BY USING YOUR SMARTPHONE

The efficiency of machinery used is an important factor for plant operators, as increasing operating costs have become a topic of focus. By using a frequency inverter, the motor speed is continuously adjustable to allow the regulation of capacity during the filling and dosing process. The adjustment can be made with the keypad of the frequency inverter, via software with a LAN connection, or with an app using the Bluetooth connection of a smartphone or tablet.

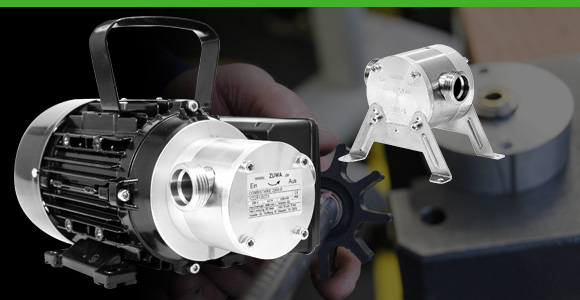

Nirostar 2000-C PLUS

-

MORE POWER, GREATER ADAPTABILITY, LESS DOWNTIME

The plus model NIROSTAR 2000-C flexible impeller pump is particularly distinguished by the fact that the pump can be opened without any tools. Not only does this shorten cleaning time for the pump, but also simplifies changing out the impeller. The new design offers the possibility to rotate the pump head in 45 increments, thereby allowing easy adaptation for difficult installation requirements. Capacity range has been increased, as the plus model NIROSTAR 2000-C achieves a delivery rate of 120 l/min over the standard versions 90 l min. The ZUWA NIROSTAR 2000-C plus is available with 230 V and 400V drive.

PUMPS

THE MOST SUITABLE PUMP FOR ANY APPLICATION. DISCOVER OUR VAST PRODUCT RANGE.

Our wide selection of electric pumps and a wide range of accessories allow you to create the optimal pump for your application. ZUWA pumps convince not only by their comprehensive selection and the resulting application possibilities, but also by their robust construction, their longevity and the maintenance-friendly construction. Whether you are looking for pumps for home or garden use, hobby, or professional craft, agricultural, construction, or industrial applications: ZUWA offers pumps for quick application.

ADVANTAGES OF ZUWA PUMPS

More than seven deacedes of experience in developing and distributing pumps makes us a reliable and strong partner. As a manufacturer we are able to customize and refine our pumps constantly. Also, thanks to our own workshop, we can repair products in a timely manner.

WE HAVE THE BEST PUMP FOR YOUR UTILISATION!

You want to move a certain liquid under dificile conditions? We help to chose the most suitable pump or solution for you. Take profit out of our more than 70 years of experience, comprehensive expertise and competent consulting and advice from ZUWA, a leading PIUSI distributor and pump producer in Germany. In our wide product range you can chose solutions with different drives for different fluids and pumping technologies: impeller pumps, centrifugal pumps, PTO pump, diaphragm pumps, drum pumps, pumps for oil, diesel, gasoline or urea ( AdBlue ) and many more. Choose between a self-priming pump, a dry self-priming pump and a not self-priming pump.IMPELLER PUMPS

-

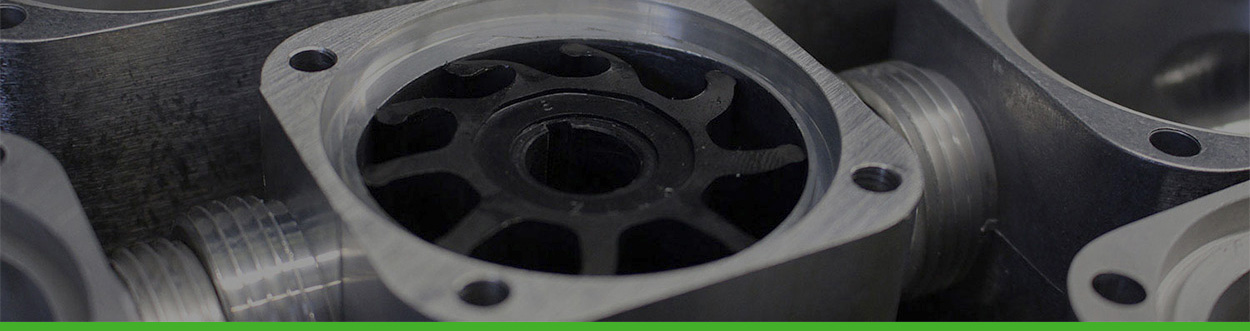

DRY SELF-PRIMING UNIVERSAL PUMP FOR MANY LIQUIDS

Impeller pumps by ZUWA are especially easy to maintain and cheap to run. Thanks to the flexible impeller the pumps are capable to move solid content or convey highly viscous fluids.

The running wheels (impellers) in our impeller pumps are available in different, always flexible materials to meet the requirements of many fluids. The impellers are not arranged centered in the elliptical housing. Due to the rotation of the impeller and therefore the bending of the impeller's blades a vacuum is created which sucks in the liquid. Because our impeller pumps are self-lubricating, only a rather short dry run is possible. After utilisation a longer dry-run is possible, but not recommendable.

ZUWA impeller pumps are available in several sizes with several drives and are made drom stainless steel, aluminum or plastic. We provide impellers made from NBR, EPDM, CR, FKM, FPM and TPU.

Our impeller pumps can be used with different drives: electric motors, air motors, belt drive, hydraulic motors, with a power drill or a cordless drill with an adapter.

Where impeller Pumps are being used

- electroplating

- biotechnology

- heating and sanitary

- workshop, machine shop

- agriculture and horticulture

- food and beverage industry

- boating, marine engineering

- water and sewerage treatment

- manufacturing, industrial plants and construction

- chemical, pharmaceutical and cosmetics industry

DRY SELF PRIMING FROM A DEPTH OF THREE METERS

-

What makes impeller pumps outstanding – they do not need to be fi lled prior to operation. Impeller pumps are dry self priming from a depth of three meters. Pre-filling is required for a suction depth of three metres and more. The suction depth is max. 7 metres.

The flexible impeller turns within an eccentrically formed casing creating a suction via the flexing of the impeller blades, which draws the fluid into the pump casing. The medium itself acts as a lubricant between the blades and the casing, therefore minimizing friction and allowing smooth fluid transfer. In order to avoid possible damages to the pump it is recommended to install dry run protection to each flexible impeller pump by ZUWA.

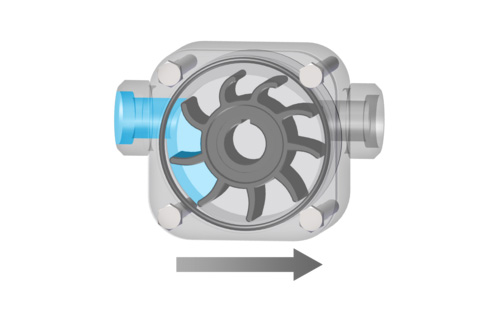

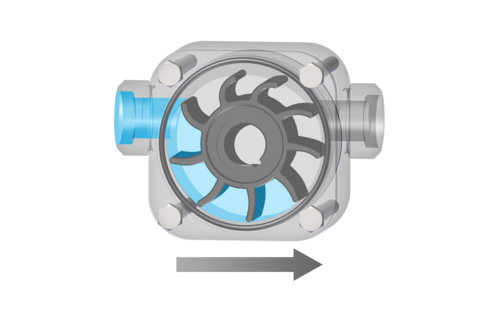

1. SUCTION

- On the suction side the blades begin to straighten. The chamber space between each blades enlarges and creates a vacuum pulling the fluid into the pump.

2. TRANSPORT

- With the turning of the impeller the fluid is positively displaced from the inlet to the outlet. Small particles are also able to be pumped freely through the chambers.

3. PRESSURE

- On the pressure side the blades of the impeller begin to flex causing the chambers to shrink, therefore forcing the fluid in a constant flow out of the pump.

PORTFOLIO

IMPELLER PUMP UNISTAR

-

A multi-purpose pump designed for transferring clean or contaminated liquids. Not suitable for handling abrasive or corrosive fluids.

DRY SELF-PRIMING UNIVERSAL PUMP FOR MANY LIQUIDS

ZUWA-Impeller pumps are easy and inexpensive to maintain. They are insensitive to solid content in the fluid due to the flexible impellers and can even promote high-viscosity fluids.

The pump series UNISTAR is made of aluminum and suitable for all non-abrasive and non-corrosive media. Below for liquids like:

- water

- Diesel and biodiesel

- vegetable oil

- Antifreeze

- coolants

The maximum delivery rate is between 15 and 90 liters / min.

IMPELLER PUMP COMBISTAR

-

This pump is particularly suitable for all fluids containing abrasives. It is an economic alternative to the NIROSTAR series for transferring abrasive or slightly corrosive fluids.

DRY SELF-PRIMING UNIVERSAL PUMPS FOR A WIDE VARIETY OF LIQUIDS.

Our COMBISTAR consists of a material mix. All wetted parts are made of stainless steel. The pump body is made of aluminum. Therefore suitable for all liquids which also contain abrasives.

This type of pump offers a low-cost alternative to the NIROSTAR series to promote abrasive or slightly corrosive media such as contaminated fluids and debris.

IMPELLER PUMP NIROSTAR

-

A high quality stainless steel pump with numerous applications in industrial plants and production facilities, the appropriate choice for transferring corrosive fluids.

DRY SELF-PRIMING UNIVERSAL PUMPS FOR A WIDE VARIETY OF LIQUIDS.

As a manufacturer of impeller pumps, we pay special attention to quality. They are particularly easy to maintain and inexpensive to maintain. They are due to the flexible wheels insensitive to solids in the medium and can promote even highly viscous liquids.

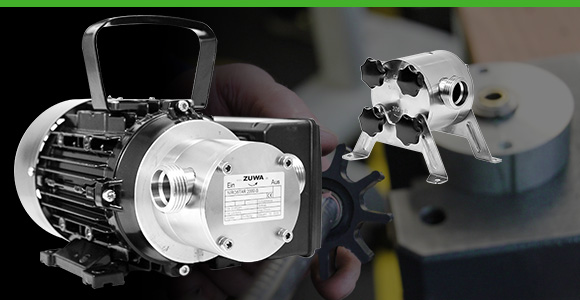

IMPELLER PUMP ACOSTAR

-

The synthetic impeller pump is for a wide variety of applications in the chemical sector. Perfect for fluids with various viscosities plus agressive acids, bases and solvents.

FOR A WIDE VARIETY OF APPLICATIONS IN THE CHEMICAL SECTOR

Perfect for fluids with various viscosities plus agressive acids, bases and solvents.

Using top quality seals and Impellers made of VITON provide excellent operation safety. Various motors (220, 400 V; 1.400, 2.800 U/min; 50, 60 Hz). “Star knobs” make for quick and simple replacement of the Impeller.

The Ceramic sleeve to protect the motor shaft comes as standard equipment. Using a frequency converter permits to adjust the pump speed or rotation direction.

Drill Powered Pumps

- The pump series 2001-A and 2001-B are ideally driven with a drill. The shaft can easily be fixed to the chuck of each regular electric or cordless drill and screwdriver.

FEATURES

- ZUWA makes efficient pump power available everywhere. All ZUWA pumps of the 2001 series can be powered with any regular electric or cordless drill and screwdriver, at any time, at any place.

- Connect the shaft of the pump with the chuck. The depth stop of the drill fully stabilises the system and ready you are. Contrary to similar pumps on the market this pump is truly self priming. It has a metal body instead of plastic and a shaft with top quality ball bearing which guarantees a long lifetime.

- All ZUWA impeller pumps are dry self priming from a depth of 3 metres, no pre filling required. The flexible impeller easily copes with solids in stained liquids.

UNISTAR 2001-A WITHOUT MOTOR

UNISTAR 2001-B WITHOUT MOTOR

UNISTAR 2001-C WITHOUT MOTOR

COMBISTAR 2001-A WITHOUT MOTOR

COMBISTAR 2001-B WITHOUT MOTOR

NIROSTAR 2001-A WITHOUT MOTOR

NIROSTAR 2001-B WITHOUT MOTOR

Pumps and refuelling systems for diesel

- EFFICIENT DIESEL PUMPS, DRUM PUMPS, REFUELING SET, TRANSFER TANK AND STORAGE TANKS FOR DIESEL WITH MATCHING ACCESSORIES

You are looking for a high quality diesel pump, a storage tank for diesel, a drum pump or a refueling set for diesel? In this section you will find all products of our cast product range referring to the medium diesel. Matching to the products you find professional and inexpensive accessories. Our diesel pumps are available in several variants according to the use and thus are versatile.

We offer electric driven pumps for diesel with different voltages. A 230V pump is suitable as a fuel transfer pump for larger amounts of diesel. These pumps are ideally used where you find a standard wall socket. For mobile utilisation we provide diesel pumps and refueling sets which are driven by 12V or 24V motors. They are typically supplied by batteries or a car's onboard power system. If you are interested in mobile fueling station, refer to our section. For several diesel pumps we also offer a three phase motor propulsion. They have a voltage of 400V and are consequently called high voltage pumps.

With a diesel pump you can fill up construction machinery, agricultural machinery, motorboats and yachts with diesel or bio diesel. Just as well the diesel pump can be used as transfer pump for aspirating or decanting diesel fuel oil.

Especially for the commercial utilisation in small and medium sized businesses diesel pumps can be a handy aid. It is possible to transfer diesel from any vehicle to another or into a tank or from a mobile or stationary fuel tank to a car.

REFUELING KITS FOR DIESEL

- ZUWA refueling sets are complete, ready-to-install units, easy to install on the wall or directly on the tank - optionally with or without counter.

STATIONARY COURT FILLING STATIONS

- Small units for wall mounting or complete dispensers, also for multiple users with access control.

DIESEL PUMPS

- rugged diesel pumps for refueling constructiony machinery, trucks, agricultural machinery, motor boats

STORAGE TANKS AND DIESEL TANKS

- discover our range or fueling stations and storage tanks with diesel pumps

BARREL- AND HAND PUMPS

- fuel and impeller pumps - also with battery power supply for mobile application

Oil Pumps

- OIL PUMPS FOR HEATING OIL, VEGETABLE OIL, LUBRICANT OIL OR ENGINE OIL

We offer oil pumps for many different viscosities, kinds of oil and with several drives.

There are many different kinds of oil, since oil only describes the viscosity of a liquid and its characteristics of being hydrophobic (immiscible with water) and lipophilic (miscible with other oils). Generally speaking there are mineral oils, organic oils and synthetic oils. They are used for food (oil from pressed oilives for example), fuel (e.g., heating oil), lubrication (e.g., transmission or engine/motor oil), manufacturing of plastic products, paint or other materials or medical purposes.

OIL PUMPS WITH ELECTRIC MOTOR

- our oil pumps can be propulsed with different electric motors, from 12V to 400V, with 50Hz or 60Hz

MOBILE OIL CHANGING STATIONS

- Mobile service center to empty and pour clean and used fluids. Easy handling: Avoid carrying heavy canisters and spilling fluids.

FIXED FILLING STATIONS FOR OIL

- Plate mounted unit with pump, nozzle and flow meter for wall or tank attachment. The stationary ServiceCenter is ideal for changing motor oils in large machines and plants and to be employed with a diversity of fluids as well.

FILTROLL

- MOBILE FILTERING UNIT WITH DIESEL PUMP

- filtering diesel in two steps: 30 for absorbing water, 5 for absorbing contamination

- automatic stop in case of clogged filter

- rugged construction with large wheel

- suction hose with integrated foot valve

- 230V electric drive

SMALL OIL TANK STATION

- Easy to install unit consisting of tank, suction kit, pump and delivery hose. Perfectly suitable for enterprises, farm yards or construction sites.

DIAPHRAGM PUMPS WITH PNEUMATIC DRIVE

- The construction of the rugged ZUWA double piston diaphragm pumps provides a constant transport of fluids. The pumps work in a medium pressure range and offer excellent intake capacity. These pumps are used for the conveyance of herbicides, pesticides or aggressive substances, also with small solids or fluids containing gases. High efficiency, good self priming capabilities along with good dry run characteristics make this pump type a very versatile device.

PNEUMATIC BARREL PUMPS

- Professional equipment for body shops for lubrication grease. ZUWA offers the right air driven pumps to handle lubrication jobs efficient and cost saving.

AdBlue Pumps

- Pumps, as well as tanks and tank facilities, for refilling or refueling commercial verhicles and passenger cars with AdBlue (Diesel Exhaust Fluid, DEF, Urea, AUS-32).

PUMPS AND REFUELING SETS FOR ADBLUE ENSURE AN EASY AND SECURE REFUELING WITH UREA.

To reduce our impact on the environment with the emissions of diesel internal combustion engines, in some trucks and cars SCR catalytic converters are installed. In order to work properly these converters need diesel exhaust fluid, standardised as AUS-32 in ISO 22241. Here you will find all pumps, refueling sets, tanks and accessoires for DEF/AdBlue.

Diesel engines emit, due to their design, NOx. Those nitrogen oxides are relevant for the ozone depletion. In order to reduce these climate damaging emissions, limits were enshrined in laws, which are known in the EU as EURO 5 and EURO 6. To reach the goal of not exceeding the emission limits most of the modern diesel engines are equipped with SCR catalytic converters. Prior to the SCR catalytic converter AUS-32 is injected which reacts with about 90% of the emitted NOx to harmless N2 (Nitrogen), water and little amounts of carbon dioxide.

FUEL TRANSFER KITS FOR ADBLUE

- refueling sets and dispensing systems for AdBlue (AUS 32, urea). Here you will find the right solution.

MOBILE TANK SYSTEMS FOR ADBLUE

- Different versions of mobile fueling systems for dispensing diesel, AdBlue (AUS 32, Urea), and gasoline are available.

ADBLUE SERVICE STATIONS

- service stations for AdBlue with fuel data acquisition

ELECTRONIC ADBLUE PUMPS

- Pumps for AdBlue (AUS 32, urea). Perfect for use with trucks and cars.

HAND PUMPS FOR ADBLUE

- Hand-operated pumps for pumping AdBlue.

Gasoline Pumps

- Browse through our range of products for gasoline and discover pumps for gasoline, refueling sets or storage tanks for gasoline. All products are ATEX certified under ATEX directive 2014/34/EU.

GASOLINE PUMPS

- pumps for gasoline with ATEX certification

TANKS AND TANK SYSTEMS FOR GASOLINE

- we offer gasoline tank systems for refueling in different styles

FUEL TRANSFER UNITS FOR GASOLINE

- fuel transfer units for gasoline and other highly flammable liquids (ATEX certification)

Barrel- and Hand Pumps

- RELIABLE AND HIGH QUALITY BARREL PUMPS - MANUALLY OPERATED OR ELECTRICALLY DRIVEN

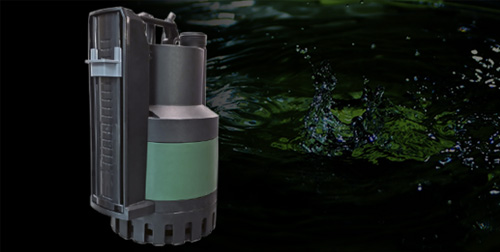

Barrel pumps are perfectly good for filling and refueling with oil or propellants like diesel and gaosline or, in motor sports kerosene. A drum pump provides a lot more of flow pressure which leads to an increase of the flow volume. This allows a much quicker and more convenient process in comparison to letting the fluid run out of the higher stored barrel or container just with gravity. WASTE WATER PUMPS

- HIGH QUALITY SEWAGE WATER / WASTE WATER SUBMERSIBLE PUMPS

Waste water pumps are some of the most widely spread submersible pumps used for many applications. Suspended particles of a size up to 5cm in the water are no problem for pumps of this kind. Advice: To prevent damage by sucking in larger particles like stone, submersible pumps can be placed in baskets.

The float switch mounted to the waste water pump ensures that the pump is switched on and off automatically, depending on the water level. That is why submersible waste water/sewage water pumps are commonly used for draining soakaways or dead wells after heavy rain. Please note, that our submersible waste water/sewage water pump always leave a bit of water, as they are not able to suck water in very shallow water. Only our model VELO is working as a flat suction pump. If you are looking for flat suction pumps, have a look at our products in this section. The housing and the rotating wheel of our submersible waste water pumps are made of grey cast iron. For aggressive fluids like salt water or fluids in chemical sector we offer a wide range of stainless steel waste water submersible pumps.

CENTRIFUGAL PUMP WITH OPEN IMPELLER

- the alternative to conventional pumps for dirty water: centrifugal pumps with open impeller

WASTE WATER PUMP VORTEX

- waste water pumps for conveying polluted water with suspendes particles

WASTE WATER PUMP NIRO

- waste water pump made from stainless stell for aggressive fluids

WASTE WATER PUMP VELO UP

- waste water pump with flat suction technique made from stainless steel for continous operation

WASTE WATER PUMP SUPERSAND

- waste water pump for polluted water with sand or stones

WASTE WATER PUMP ATEX

- waste water pump for the use in explosion endangered areas

Side Channel Pumps

- The main principle of a side channel pump is a combination of the displacement pump and a centrifugal pump. Therefore side channel pumps are self priming when they are pre-filled with fluid and are, as versatile multi purpose pumps, capable of conveying liquids with gases and vapours.

SIDE CHANNEL PUMPS AS SOLUTION FOR SPECIAL APPLICATIONS Our side channel pumps are available in stainless steel and bronze. Depending on the material they are more or less suitable for different special applications. Expecially the food industry, including the dairy industry and the chemical industry as well as large agricultural facilities and industries use side channel pumps for many different purposes.

The electric motors (only 230 V) for our side channel pumps are equipped with a toggle switch, which enables the user to chose in which direction the pump is conveying. To control the flow rate there is option to equip the pump with a bypass valve.

SIDE CHANNEL CENTRIFUGAL PUMPS WITH MOTOR - BRONZE

SIDE CHANNEL CENTRIFUGAL PUMPS WITHOUT MOTOR - BRONZE

SIDE CHANNEL CENTRIFUGAL PUMPS WITH MOTOR - STAINLESS STEEL

SIDE CHANNEL CENTRIFUGAL PUMPS WITHOUT MOTOR - STAINLESS STEEL

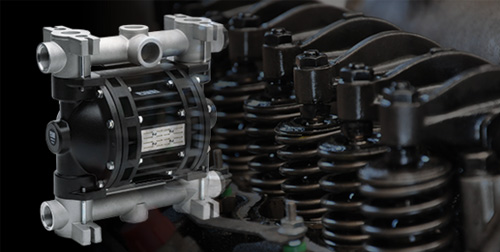

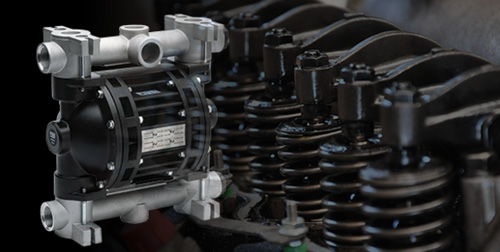

Diaphragm Pumps

- DIAPHRAGM PUMPS: PUMPS PROPULSED WITH COMPRESSED AIR

Diaphragm pumps are characterized by their spatial segregation of propulsion and pumping mechanics. This makes diaphragm pumps very long lasting. They are very popular in industry and agriculture where mediums are used which could, if they are encountered by the propulsion, could do harm to the technics. Due to this self-priming diaphragm pumps can be used for abrasive, acid alkalic or other aggressive fluids.

Diaphragm pumps are rank amongst displacement pumps. The movement of the membranes creates alternating positive and negative pressure. Through the entry valve the fluid in question to convey is sucked in. As soon as the pressure starts rising again, the fluid is pressed through the outlet valve. Electric diaphragm pumps can vary the pressure and therefore create a very steady and pulsation free flow.

ADVANTAGES OF A DIAPHRAGM PUMP

Diaphragm pumps have a high pressure but a relatively low flow rate. That is why they are very popular within agricultural and gardening applications. The main use is to convey plant and crop protection as well as pesticides and insecticides or detergents for spraying and spreading. Thank to the pressure control valve the frequency of positive and negative pressure is adjustable whereby flow rate and flow pressure can be controlled infinitely variable.

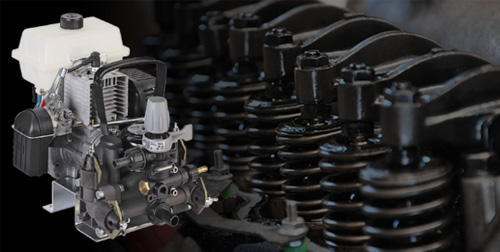

DIAPHRAGM PUMPS WITH GASOLINE MOTOR

- diaphragm pumps with a air-cooled two stroke or four stroke engine

DIAPHRAGM PUMPS WITH ELECTRIC MOTOR

- application in gardening, agriculture and industry - special versions for acids

DIAPHRAGM PUMPS WITH PNEUMATIC DRIVE

- The construction of the rugged ZUWA double piston diaphragm pumps provides a constant transport of fluids. The pumps work in a medium pressure range and offer excellent intake capacity. These pumps are used for the conveyance of herbicides, pesticides or aggressive substances, also with small solids or fluids containing gases. High efficiency, good self priming capabilities along with good dry run characteristics make this pump type a very versatile device.

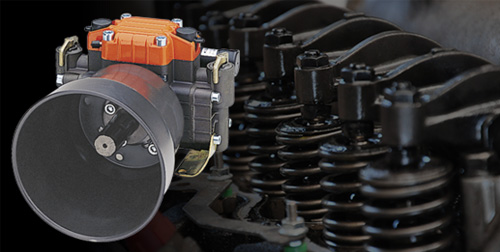

DIAPHRAGM PUMP FOR P.T.O SHAFTS

- easy to mount diaphragm pumps for P.T.P. shafts

PTO Pumps

- PTO pumps are used in numerous areas. Predominantly in the agricultural and municipal sector, the very reliable PTO pumps are used even under the most adverse conditions. In many cases, the cast iron pumps with PTO connection are used for irrigation and drainage of non-abrasive and corrosive liquids or for washing equipment and machinery.PTO pumps with stainless steel housings are available for pumping liquids such as herbicides, insecticides, fungicides and liquid fertilizers.

PTO PUMPS Basic Line

-

Irrigation, flushing, plant protection

PTO Pumps from ZUWA are ideal to convey water and pesticides. They are self-priming and sturdy.

The PTO 20 and 25 are fully equipped. For PTO 300 accessories are to be ordered separately.

Hand Pumps

- Hand operated pumps usually are vane pumps or reciprocating pumps. They are generally used when mediums of low viscosity have to be conveyed quick and easy. ZUWA offers various types of pumps for this purpose, starting with a good value plastic pump up to a high quality stainless steel version.

The main advantages are:- cost-effective

- straightforward and easy to use

- minimal maintenance

HVAC FILLING AND FLUSHING PUMPS

- Flushing, venting and filling heat transfer medium into solar systems in one process. The latest member of the ZUWA filling stations family: small, easy to transport, fits upright into the trunk of a Volkswagen Golf/ Rabbit!

SOLARCHECK MOBILCENTER UNISTAR

- Dry self-priming impeller pump with a pressure relief valve

FLUSH PRO MOBILE CENTER P80

- Solar system filling station with self-priming centrifugal pump

SOLARCHECK MOBILCENTER P90

- High pressure version with max. 9 bar

FLUSH PRO MOBILE CENTER 60/30 KOMPAKT

- The FLUSH PRO KOMPAKT is ZUWA's most mobile unit for professional use.

FLUSH PRO MOBILE CENTER 90/55

- SP MC 90/55 filling and flushing station with 55l container and the UNISTAR 2000-C pump.

FLUSH PRO MOBILE CENTER 90/120

- Suitable for Filling, Flushing and Venting of earth probes or rather geothermal probes.

Descal Mobile Center

-

DECALCIFY WARM WATER TANKS AND HEAT EXCHANGER

The DESCAL Mobile Center is a decalcifying unit for professional use to flush warm water tanks and heat exchangers with descaler. In several industrial processes diverse fluids like process water, glycolic coolant, cooling lubricants and other fluids are used.

- increases running time and process reliability

- reduces costs and downtimes

DESCAL MOBILE CENTER PLUS

- The DESCAL MC Plus has additional connectors and characteristics.

DESCAL MOBILE CENTER KOMPAKT

- To decalcify collectors we developed the Descal Mobilcenter.

ACCESSORIES FOR HIVAC FILLING AND FLUSHING PUMPS

- ACCESSORIES FOR HIVAC FILLING AND FLUSHING PUMPS

Cleaning Mobilcenter

- THE MOBILE FLUSHING STATION

Different media are used in industrial applications. Among them are process water, glycol based coolants, and cooling lubricants.

The effectiveness of the process can deteriorate over time due to aging of the machinery, or impurities in the media that accelerate the wear of components. Foreign debris, sediment, and corrosion can impede the process, and cause unexpected downtime. Filtering the media, flushing and cleaning of the respective equipment on a regular basis is important to avoid such trouble.

Cleaning Mobile Center - Tank 55 l Flushing Station w. COMBISTAR 2000-B , 230 V, 1400

- Impellerpump Combistar 2000-B

- flow rate max. litres 60 l/min

- flow rate max. m 3,6 m/h

- max. pressure 5 bar

- Inlet/outlet 1" mt

- Impeller Perbunan (NBR) Bush material Polyamid

- Perbunan (NBR)

- Material pump housing stainless steel 1.4404, aluminium AlMgSi1

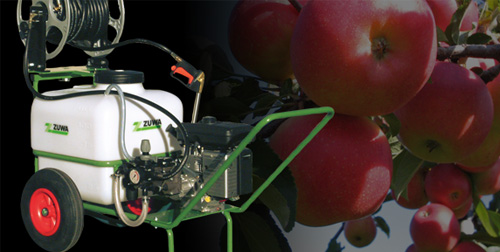

PLANT PROTECTION

-

PLANT PROTECTION EQUIPMENT, SPRAYERS FOR CROP PROTECTION, PLANT CARE AND FERTILIZATION

Sprayers & Irrigation Devices

- Battery powered sprayer for watering larger flower or vegetable beds.

MOUNTED SPRAYERS

- individual field sprayers meeting your tractors specifications

CART AND TRAILER SPRAYERS

- spraying devices with handle drawbar, container (50 - 300 l)

WATERING UNIT

- for watering and fertilizing larger areas, battery powered

MORE PRODUCTS

-

WE OFFER AN ASSORTMENT OF PUMPS TO FULFILL YOUR APPLICATIONS REQUIREMENTS. HAVE A LOOK AROUND!

DOMESTIC WATER

- Centrifugal pump with pump control for domestic water supply and garden irrigation, self-priming.

POND CLEANING

- The dry self-priming impeller pump guarentees an easy and successfull pond cleaning

FLAT SUCTION SYSTEMS

- The flat suction system removes fluids completely on large areas and is applied in many situations.

ACCESSORIES

WE OFFER A WIDE RANGE OF ACCESSORIES AND SPARE PARTS FOR OUR PUMPS AND SPRAYERS

ACCESSORIES FOR IMPELLER PUMPS

ACCESSORIES FOR HVAC FILLING AND FLUSHING PUMPS

NOZZLES

FLOW METERS

HOSE REELS

FREQUENCY CONVERTER

PUMP CONTROL SYSTEMS

HOSES

FILTERS

SOLUTIONS

FLAT SUCTION SYSTEM

- Simple and effective. Flooded areas are due to the flat suction mat almost complete dry! We have a suitable solution for the most varied demands.

SOLAR AND HEATING TECHNOLOGY

- For a solar thermal system to produce the desired yields, maintenance is an important process. Our product range offers important tools for flushing, filling and venting.

FUELING SYSTEMS FOR ADBLUE

- AdBlue neutralizes climate-damaging nitrogen oxides that diesel engines emit by up to 90%. Zuwas fueling systems offer perfect solutions for your requirements.

PUMPS FOR BIOGAS PLANTS

- No matter what area of your biogas plant. We have the right and professional pump solutions for you. From the water supply to the filling of the cooling circuit.

PLANT PROTECTION

- Sprayers for plant protection, cultivation and fertilization: Tanks in different sizes, Durable diaphragm pumps, Pressure regulation with bypass, All-terrain carts.

DRILL POWERED PUMPS

- Small, lightweight and portable - always usable. This is our drill powered pump. Make your standard drill or cordless screwdriver to a mobile pump.