- Offer Profile

- For over 45 years, Geppert Rührtechnik has stood for quality and reliability in agitator construction. We develop, manufacture, and distribute innovative agitators for all applications in the materials processing industries, such as the chemical, pharmaceutical, biotechnology, and food industries, as well as in water and wastewater treatment.

Geared agitators

- We manufacture robust geared agitator solutions featured with helical geared, worm geared, parallel shaft geared, helical bevel geared as well as variable speed geared drives to match every application in the materials processing industries, such as, the chemical, pharmaceutical, biotechnological, paper and pulp industries, as well as in water and wastewater treatment.

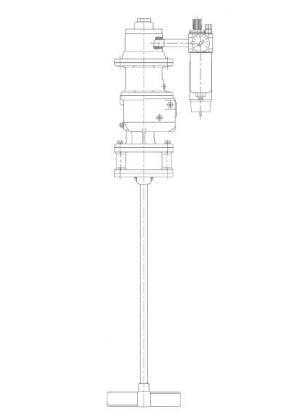

GRS – Geared agitator with helical geared drive

-

The GRS geared agitator is equipped with a helical geared drive suited for a wide range of applications thanks to shaft lengths of up to 2,000 mm and drive ratings of up to 7.5 kW. The

GRS series agitators have a standard output speed of 10 to 500 rpm.

The shaft mounting options available include sleeve coupling, flange coupling, quick-change coupling or precision-change coupling. The agitator shafts are balanced for concentric run after assembly of the mixer.- Upon request, we supply the GRS series with frequency controlled drive.

- Depending on the specific mixing task, the GRS can be supplied with matching mixing elements and various seals.

- Type test certificate for explosive zone 0.

GRF – Geared agitator with parallel shaft geared drive

-

The agitator shaft of the GRF series geared agitator is directly mounted in the hollow shaft of the parallel shaft geared drive. Thus, no additional bearing housing is necessary. The gear bearings are adequately dimensioned and fully adapted to the requirements.

The GRF series is suited for a wide range of applications thanks to shaft lengths of up to 6,000 mm and drive ratings of up to 75.0 kW. It has a standard output speed of 1 to 400 rpm. The agitator shafts are balanced for concentric run after assembly of the mixer.- Upon request, we supply the GRF series with frequency controlled drive that has drive ratings of up to 7.5 kW.

- Type test certificate for explosive zone 0.

GRW - Geared agitator with worm geared drive

-

The GRW series is suited for a wide range of applications thanks to shaft lengths of up to 3,000 mm and drive ratings of up to 5.5 kW. It has a standard output speed of between 10 and 200 rpm. Low installation height thanks to horizontal position of the drive.

The agitator shaft of the GRW series geared agitator is directly mounted in the hollow shaft of the worm geared drive. Additional flanged or clamp couplings can be implemented upon request. The agitator shafts are balanced for concentric run after assembly of the mixer.- According to the specific mixing task, the GRW can be supplied with matching mixing elements and various seals.

- Upon request, we supply the GRW series with frequency controlled drives.

GRK - Geared agitator with helical bevel geared drive

-

The GRK series geared agitator equipped with a helical bevel geared drive with reinforced bearing can be used for a wide range of applications due to its low installation height. This ow installation height can be achieved thanks to the horizontal position of the drive.

The agitator shaft of the GRK series is directly mounted in the hollow shaft of the gear and, upon request, this agitator shaft can be divided by flanged coupling. After assembly of the mixer, the agitator shafts are balanced for concentric run.

The GRK series features shaft lengths of up to 6,000 mm and drive ratings of up to 75.0 kW. It has a standard output speed of 1 to 250 rpm.- According to the specific mixing task, the GRK series can be supplied with matching mixing elements and various seals.

- Upon request, we supply the GRK series with frequency controlled drives that have drive ratings of up to 7.5 kW.

- Type test certificate for explosive zone 0.

GRV - Geared agitator with variable speed gear unit

-

The GRV series can be used in versatile manner. It is equipped with a mechanically variable speed variation drive with drive ratings of up to 11.0 kW. Furthermore it can be supplied with geared drives that have a standard output speed of between 1 and 1,750 rpm.

The speed is adjustable with a hand wheel. The agitator shaft of the GRV series geared agitator is directly mounted on the shaft of the mechanical speed variator or with additional speed reduction (all before mentioned solutions possible).

The agitator shafts are balanced for concentric run after assembly of the mixer.- According to the specific mixing task, the GRV series can be supplied with matching mixing elements and various seals.

GRP - Pneumatic agitator

-

The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal.

Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling.- Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures.

- Compressed air expanding in the air engine cools the agitator drive.

- The pneumatic agitators are explosion proof and overload proof until standstill.

- Type test certificate for explosive zone 0.

KRK - Coaxial agitator

-

KRK coaxial agitator features two different impeller systems for parallel mixing. The KRK has two interdependent agitator shafts with a different number of revolutions that move in opposite directions. The faster agitator shaft is supported in the slower hallow shaft of the geared mixing unit.

- The KRK series is primary suitable for the dispersing of highly viscous media. The heat transfer is promoted.

- Explosion-proof series certified to ATEX Directive 2014/34/EU zone 0 and zone 1.

Industrial agitators

-

Industrial agitators are suitable for all applications in the materials processing industries. They are used in the chemical, pharmaceutical, biotechnological, paper and pulp industries, food industries as well as in water and wastewater treatment.

Features- Agitator shaft borne within robust bearing housing

- Highly versatile in application for shaft diameters of up to 130 mm

- Compatible with all common drives, seals and agitator elements

- Agitator shafts balanced for concentric run in our in-house test field

LRE - Simple top-entry agitator

-

The LRE is the most simple solution of an industrial agitator. It consists of a hollow shaft geared drive (worm geared, parallel shaft geared or helical bevel geared drive) and a rigid cast steel bearing housing. Due to this construction high torques are achieved. The agitator shaft is borne within the gear box and the bearing housing and is divided by a flanged coupling below the mounting flange.

- According to your tank size, the LRE series agitator is available in four different frame sizes. Shaft diameters of 40 mm to 130 mm with lengths of up to 12,000 mm are realized.

- Sealing housings supplied with shaft seals in various materials are feasible, stuffing boxes or mechanical seals are an alternative.

- Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3).

LRD - Top-entry sealed agitator

-

The LRD series top-entry sealed agitator can be used for mixing in closed containers with a mechanical seal. It is designed with a coupling housing. The agitator shaft is borne in the bearing housing and the mechanical seal (single- or double-acting). The seal can be exchanged without dismantling the mixer from the tank (also in case of a side entry).

Drives with shaft journals for LRD series:- Three-phase motor

- Helical geared drive unit

- Parallel shaft geared drive unit

- Variable speed geared drive unit

- Helical bevel geared drive unit

- According to the tank size, the LRD series agitator is available in four different frame sizes. Shaft diameters of 30 mm to 90 mm and shaft lengths of up to 10,500 mm are feasible.

- Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3).

- Pharmaceutical version with FDA and GMP feasible.

LRK - Top-entry agitators for rigorous requirements

-

The top-entry agitator LRK is used to meet rigorous requirements regarding both bearing and smooth-running. In addition to its rigid cast steel bearing housing, this agitator series features a coupling housing with an elastic coupling to connect the drive with a shaft journal. Thus, the

LRK can be supplied as a fast running agitator with long shafts. The agitator shaft is borne within the bearing housing and is divided by a flanged coupling below the mounting flange.

- According to your tank size, the LRK series agitator is supplied in six different frame sizes. Shaft diameters of 40 mm to 130 mm with lengths of up to 12,000 mm can be realized.

- Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3).

- Bearing housings with shaft seals of different materials are feasible, alternatively with stuffing boxes or mechanical seals.

NRK - Compact top-entry agitator

-

The NRK series is a compact top-entry agitator that can be used to meet high requirements regarding both surfaces and cleaning inside and outside of the tank. Due to its’ compact design, agitator shafts with diameters of 25 mm and lengths of up to 1,200 mm can be realized, making the

NRK the ideal mixer for small tanks in food and drug industry.

- The NRK series agitator has an integrated bearing and coupling housing with flexible coupling to connect drives with shaft journals.

- The NRK can be supplied with radial shaft seal rings for non-pressurized operation or with liquid-lubricated mechanical seals on pressurized tanks.

- Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3).

GLP - Peumatic top-entry agitator

-

The GLP is a pneumatic top-entry series agitator that is used for homogenizing, dispersing, emulsifying and suspending in vessels and for viscosities up to 500 mPas for instance in wastewater treatment, chemical and cosmetics as well as in food industries.

The agitator speed adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight. Power transmission via elastic coupling in the bearing housing. The agitator shaft has a double bearing in an aluminum housing separated from the drive.

Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air, expanding in the air engine cools the agitator drive.

Includes filters, pressure reducers with pressure gauge that indicates the secondary pressure.

Available with a vessel clamp to fix the GLP on a drum.- The pneumatic agitators are explosion proof and overload proof until standstill.

- Explosion proof series certified to ATEX Directive 2014/34/EU zone 1.

SPR - Standard-propeller-agitator

-

The direct driven agitator SPR is Geppert Rührtechnik’s solution for all industrial mixing tasks that demand a turbulent mixing with high peripheral speeds. It is driven by a three-phase-motor with poles between 2 and 8 as well as drive ratings between 0.25 kW and 75.0 kW. The SPR could also be equipped with a frequency inverter upon request (up to 7.5 kW).

The agitator shaft is directly connected at the shaft journal of the drive via sleeve or flange coupling. Solutions with quick-change or precisions-change coupling are also feasible for lower drive ratings of up to 3.0 kW. The standard agitator element is a propeller. Other mixing elements according to the mixing task upon request.- The SPR can be mounted as a stationary unit or – at a weight of up to 25 kg – it can also be mounted directly onto the open tank via a vessel clamp

- Up to motor size 112, all SPR series agitators can also be provided with reinforced shaft.

- Type test certificate numbers for zone 0 (category 1).

PDR - Side-entry agitator

-

The PDR is a simple side-entry-agitator for mixing below the liquid surface. The PDR is recommended for applications where low viscous liquids are mixed turbulently in high tanks and where a top-entry mixer would be too heavy due to its shaft length and –diameter.

The sealing between the agitator and the vessel is done by means of a single-acting, internal mechanical seal which is lubricated by the mixing product or an additional fluid The agitator shaft is connected to the drive directly with a flange coupling inside the seal housing. By default, this agitator series is supplied with marine type propellers. Other mixing elements according to the mixing task upon request.- Solutions correspond to those of the SPR, additionally mechanical seal in sealing housing.

- Other solutions for this series upon request.

Drum mixers

-

Our drum mixers are literally all-rounders that can be used for all applications in the materials processing industries. We provide you with the optimal solution for open or closed 200 l drums, low to high viscous media or either electric or pneumatic applications.

For applications in the food and pharmaceutical industry, we manufacture in all available steel and stainless steel grades, in the required surface qualities or coatings- ground and electro polished.

FR - Electric drum mixer

-

The FR series is a fast running electric drum mixer that can directly be mounted on 200 l steel drums with a 2“ bung hole. The mounting on the drum is done with a 2” threaded adapter with which the agitator is screwed into the bung hole.

The agitator shaft is connected to the drive shaft by means of a sleeve coupling. Folding propellers are used as mixing elements, which can be inserted into the drum through the 2” bung hole when being folded.- The FR series mobile mixer is delivered as a turn-key solution with an on-/off-switch with low voltage breaker and connection cable.

- Upon request, the FR series mixer can also be supplied with an integrated frequency inverter.

- Additionally we can provide you with a vessel clamp applicable for open lid drums.

FR-LX - Lightweight mixer

-

Lightweight electric mixer with direct screwing into 2“ bung hole.

The FR-LX series mixer stands for easy handling. Aluminum being the material of the housings and the adapters, this is a lightweight solution with a total weight of only 10 kg.

The agitator is screwed directly onto the on-top 2” bung hole of the tank thanks to either a 2”-steel or a 2”-fluoroware coupling. Therefore, this agitator can not only be screwed onto steel tanks but also onto plastic tanks with bung hole.- The mobile mixer FR-LX is by default equipped with an on-/off-switch with low voltage breaker and connection cable.

- The FR-LX could also be equipped with a frequency inverter upon request.

- Additionally, we can supply your open lid drums with a traverse bridge or a vessel clamp.

FR-HX - Highly viscous media

-

Electric drum mixer for highly viscous media.

The FR-HX is Geppert Rührtechnik’s drum mixer for highly viscous media of up to 5,000 mPas. The foldable mixing elements with a diameter of 200 mm demand a non-vertical installation in the tank. This installation is realized due to a traverse with a welded 2”-socket. Additionally the traverse allows the use of the agitator when the drum is open.- The mobile mixer FR-HX is by default equipped with an on-/off-switch with low voltage breaker and – upon request – with a connection cable. .

- The FR-HX could also be equipped with a frequency inverter upon request.

- Explosion-proof design after ATEX (2014/34/EU) for operation in ex-zones 0-2 for gases and zones 20-22 for dusts (Device group II, category 1-3).

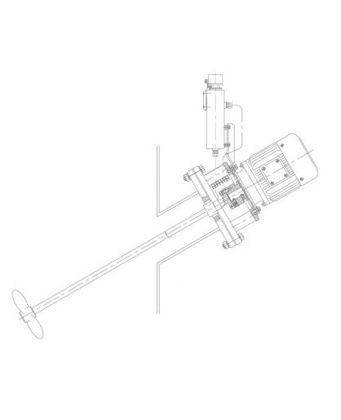

FRP - Pneumatic drum mixer

-

The FRP is Geppert Rührtechnik’s fast running pneumatic air mixer that can be directly mounted on 200 l steel drums with a 2“ bung hole. The

FRP is mounted onto the drum with a 2” threaded adapter. The agitator is screwed into the bung hole.

We do offer one drive especially adapted for low viscous media and one drive especially adapted for medium viscous media of up to 1,000 mPas. The agitator shaft is connected to a bearing shaft within the drum mixer housing by means of a sleeve coupling. This bearing shaft is connected to the drive shaft. Folding propellers are used as agitator elements, which can be inserted into the drum through the 2” bung hole when being folded. As a mobile mixer, the FRP can be delivered as a turn-key machine with a service kit for the lubrication of the compressed air and a noise muffler.- Additionally we can provide you with a vessel clamp applicable for open lid drums.

FRP-LX - Lightweight mixer

-

The pneumatic FRP-LX mixer series has been designed for easiest operation. Aluminum being the material of the housings and the adapters, it has a weight of only 6 kg.

The agitator is screwed directly onto the on-top 2” bung hole of the tank thanks to either a 2”-steel or a 2”-fluoroware coupling. Therefore, this agitator can not only be screwed onto steel tanks but also onto plastic tanks with bung hole.

The mobile agitator FRP-LX is by default equipped with a maintenance unit for the oiling of the pressurized air and mufflers.- Additionally we can provide you with a vessel clamp applicable for open lid drums.

FRP-HX - Highly viscous media

-

Pneumatic drum mixer for highly viscous media.

The FRP-HX is Geppert Rührtechnik’s drum mixer for highly viscous media of up to 5,000 mPas. The foldable mixing elements with a diameter of 200 mm demand a non-vertical installation in the drums. This installation is realized due to a traverse with a welded 2”-socket. Additionally the traverse allows the use of the agitator when the drum is open.

The mobile mixer FRP-HX is by default equipped with a maintenance unit for the oiling of the pressurized air and mufflers.- Special solution for highly viscous liquids of up to 5,000 mPas.

- Explosion-proof design after ATEX (2014/34/EU) for operation in ex-zones 0-2 for gases and zones 20-22 for dusts (device group II, category 1-3).

Vessel clamp

- By means of a traverse or a vessel clamp, the drum mixers could also be used for open drums.

Tote tank mixers

- Geppert Rührtechnik has designed tote tank mixers for all plastic and stainless steel IBCs. They are delivered including traverse with rapid clamping system for plastic IBC. The mixing elements fit to all filling holes of a minimum diameter of 150 mm. Versions with explosion protection for the explosive zones 0 or 1 are also available.

CR-E - electric tote tank mixer for plastic IBCs

-

The tote tank mixers CR-E are designed for operation on plastic containers with filling openings of 150 mm and volumes from 600 l up to 1,200 l. The customer may choose between various viscosity-related basic versions of fast-running and slow-running mixers with electric drives. The agitator shafts are connected to the drive shafts with sleeve couplings or borne within the gear’s hollow shaft (worm gears). The agitator shafts are balanced for concentric run after assembly.

The mixer is mounted on a container traverse bridge, which is included in the scope of supply and clamped with a rapid fixing system to the cage frame of the IBC. The plastic bulk of the container is therefore not harmed by any static or dynamic loads by the agitator. The fixing of the traverse bridge is adjustable for various container models.- The impellers are designed to fit through the filling opening 150 mm when being inserted.

- The electric container mixers are delivered with on-/off-switches with low-voltage breaker. The electric container mixers can also be supplied with frequency converter drives.

CRP-E - Pneumatic tote tank mixer for plastic IBCs

-

The tote tank mixers CRP-E are equipped with a pneumatic drive. It has been especially designed for plastic IBCs with filling openings of at least 150 mm and volumes from 600 l up to 1,200 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive.

The mixer is mounted on a container traverse bridge, which is included in the scope of supply and clamped with a rapid fixing system to the cage frame of the IBC. The plastic bulk of the container is therefore not harmed by any static or dynamic loads by the agitator.- Folding propellers that fit through the filling opening DN 150 mm are used for geared agitators.

- The agitator shafts are connected to the drive shafts with sleeve couplings or borne within the gear’s hollow shaft (worm gears). The agitator shafts are balanced for concentric run after assembly.

- Explosion-proof mixers are also feasible.

CR-M - Electric tote tank mixer for stainless steel IBCs

-

The tote tank mixers CR-M are designed for operation on stainless steel containers with filling openings of DN 400 mm and mixing volumes from 400 l up to 1,500 l. Depending on the viscosity of the mixing material, CR-Ms with fast running or gear reduced drives are available. The agitator shafts are connected to the drive shafts with sleeve couplings or borne within the gear’s hollow shaft (worm gear). The agitator shafts are balanced for concentric run after assembly.

The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening DN 400 when being inserted.- The electric container mixers are delivered with on-/off-switches with low-voltage breaker. The electric container mixers can also be supplied with frequency converter drives.

All CR-M series mixers can be supplied as follows:- Lid

- Explosion-protection design

CRP-M - Pneumatic tote tank mixer for stainless IBCs

-

The CRP-M tote tank mixers are featured with a pneumatic drive and were designed for the application in stainless steel tanks with filling openings of at least 400 mm and mixing volumes of 400 l to 1,500 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive.

The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening of at least 400 mm when being inserted.

All CRP-M series can be supplied as follows:- Lid

- Muffler

- Explosion-protection design

LRK-C mit Antrieb LRK-A

-

The LRK-C series tote tank mixer and their drive units LRK-A are a special solution designed for operation on stainless steel containers with filling openings of at least 400 mm and mixing volumes from 400 l up to 1,500 l. The customer may choose between various viscosity-related basic versions of fast-running and slow-running mixers with electric drives.

The mixing unit that remains in the container is connected to the drive unit with a bayonet coupling and a clutch. The drive is dismountable so that one drive unit can be used for several mixer units interchangeable. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring.

The agitator shafts are borne in a bearing housing, which is welded into the container lid on the product side.

The impellers are designed to fit through the filling opening DN 400 when being inserted.- If required, the electric tote tank mixers are delivered with on-/off-switches with low-voltage breaker.

- The electric container mixers can also be supplied with frequency converter drives.

- Explosion-proof design after ATEX (2014/34/EU) for operation in ex-zones 0-2 for gases and zones 20-22 for dusts (device group II, category 1-3).

Equipment for tote tank mixers

-

Equipment for tote tank mixers for plastic IBCs

- Traverse bridge

- Lifting lug for cranes

- On-/off-switch without ex-protection

- On-/off-switch with ex-protection

- Frequency inverter controlled drive

- Maintenance unit for pneumatic drive

Equipment for tote tank mixers for stainless IBCs- Container lid

- Lifting lug for cranes

- On-/off-switch without ex-protection

- On-/off-switch with ex-protection

- Frequency inverter controlled drive

- Maintenance unit for pneumatic drive

Tripod Agitators

- Geppert Rührtechnik offers a multitude of popular standard solutions for tripod agitators that meet all of your expectations. For us, an easy handling as well as the compliance to safety regulations are a matter of course. We will be happy to discuss the details with you!

SRW - Floor stand mixer

-

Rigid stand with H-foot for tanks that range in volume from 100 l. Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching mixing elements. Mixer powers from 0.37 kW to 7.5 kW and support loads up to 100 kg - by means of a reinforced stand loads up to 300 kg - can be realized.

The agitator is positioned on a telescope sleeve that is moved via the spring-suspended lid connected to the stand. The lift is done by a geared hand-wheel or electric with a lift drive and chain drive. The mixer is positioned on a cantilever beam which is fixed to a support slide that is moved on the stand column. The electric or pneumatic supply is guided through a laterally mounted energy chain.- The floor stand mixer SRW is available in two standard sizes that are particularly designed for the processing of exchangeable vessels such as drums and IBCs.

- Various tank sizes upon request.

FRW - Mobile stand mixer

-

Mobile stand with H-foot for tank volumes from 100 l. The mobility of the tripod is ensured by using castors and fixed castors. The tripod can be moved due to The lift is done by a geared hand-wheel or electric with a lift drive and chain drive. Mixer powers from 0.37 kW to 7.5 kW and support loads up to 100 kg can be realized (with ex-protection only realizable to a limited extend). Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching mixing elements.

The mixer is positioned on a cantilever beam which is fixed to a support slide that is moved on the stand column. The FRW is equipped with fixed and steerable wheels for mobility. The electric or pneumatic supply is guided through a laterally mounted energy chain.- The mobile stand mixer FRW is available in two standard sizes that are particularly designed for the processing of exchangeable vessels such as drums and IBCs.

- Various tank sizes upon request.

WRW - Wall mounted stand mixer

-

Rigid stand for wall-mounting for tank volumes from 100 l. Mixer powers from 0.37 kW to 7.5 kW and support loads up to 100 kg can be realized. Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching agitator elements.

The lift is done by a geared hand-wheel or electric with a lift drive and chain drive. The mixer is positioned on a cantilever beam which is fixed to a support slide that is moved on the stand column. The electric or pneumatic supply is guided through a laterally mounted energy chain.

The stand WRW is available in two standard sizes, thus enabling the processing of various tank sizes. The standard sizes are particularly designed for the processing of exchangeable vessels such as drums and IBCs.

WRW/SRW – Double column

-

Double column wall mounted stand mixer/floor stand mixer

Rigid stand for wall-mounting or floor stand for mixers from 100 kg. The stand consists of 2 u-shaped columns with a ball-borne support slide with a cantilever beam for the mixer. The double-column stand allows the processing of tank volumes up to 4 m3, depending on the tank dimensions.

Mixer powers up to 75.0 kW and support loads up to 1,000 kg can be realized. Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching agitator elements.

The lift is done electrically by a lift drive and chain drive. The electric supply is guided through a laterally mounted energy chain.- Customized solutions for instance a stand mixer with H foot or stand equipped with coaxial agitator type KRK are feasible.

SV 30 - Small stand mixer

-

The SV 30 is a small stand mixer with manual stroke adjustment and spring suspended lid for small batches that range in volume from 20 l up to 100 l and agitator drives of up to 1.5 kW. It is supplied with helical gear agitators of up to 0.75 kW or fast running agitators of up to 1.5 kW and the suitable mixing elements.

Thanks to the H stand as well as two hook blocks, the SV 30 can be moved. The weight is balanced by means of a counterweight positioned in the stand column itself. The pneumatic supply is guided through a laterally mounted energy chain.- Explosion-proof design ATEX 2014/34/EU feasible.

Safety + Equipment

Safety

-

The tripod agitators are equipped with electric and mechanic safety devices after EC guideline for machinery 2006/42/EG which prevent the mixer from accidental starting and prevent access to moving parts. We provide you with extensive risk analysis for each tripod agitator to consider all possible sources of danger. Thus, our whole range of tripod agitators is CE-certified

Mechanical safety equipment

The stand mixers can be protected against access to moving parts with a shaft protection sleeve when used in open tanks which are big enough or with a spring-suspended lid when the tanks are small or tanks with various heights are used. The lift way is covered by bellows and the mixing tank is clamped in mixing position or checked by a limit switch arm.

According to the customers’ requirements, the spring suspended lid could be supplied with level sensors, and various nozzles and hubs for filling.

Electric safety equipment

The stand mixer is delivered with an electric safety control which allows operation of the mixer only when the mixer is in mixing position and when a vessel is positioned below the mixer.

Examples for Safety Control Boxes- Single safety switch for manual stroke adjustment

- Single safety switch for electric stroke adjustment

- Ex-proof safety switch for manual stroke adjustment

- Ex-proof safety switch for electric stroke adjustment

- Ex-proof safety switch (Control box outside of area with potentially explosive atmosphere, handling in this area)

- Pneumatic mixers feature a pneumatic safety switch with pneumatic limit switch.

Equipment

-

Depending on the standard models, our tripod agitators can be equipped with a wide range of options and special features. Geppert Rührtechnik engineers this product line to your individual mixing task.

DrivesDrives with fixed speed

Drives with special voltage

- Drives with thermistors for fc inverter operation

- Drives with integrated fc inverters

- Drives with helical gear box

- Drives with parallel shaft gear box

- Drives with worm gear box

- Mechanical variable speed geared drive

- Pneumatic drives

- Pneumatic gear drives

Wetted parts

- Stainless steel (1.4571) without surface treatment

- Ground and polished surfaces with recess-free transitions between single compounds

- Plastic covers (PP, PVDF)

- Coating with E-CTFE or PFA

- Special steels (1.4462, 1.4539, Hastelloy)

- For applications in the field of food and drug industry or clean room technology, the stand mixers can be manufactured completely in stainless steel with the lift mechanism being completely encased. The casing and the stand frame can be ground and polished.

Lift

- Manually with geared hand-wheel

- Electrically with lift drive and chain drive

Tank positioning

- Manually with laterally movable brackets

- Laterally movable brackets with hand wheel and threaded spindle

- Limit switch arm for containers with plate switch

- Folding for use in drums or container

Protection from rotating parts

- Basic grip protection sleeve from perforated sheet for fixed agitator shaft couplings

- Grip protection sleeve with flap and limit switch for exchangeable agitator shafts

- Spring-suspended lid with bellow

- Spring suspended lid with telescope sleeve

Spring suspended lit

- Basic closed design with short lift way for single, open vessels and drums

- Basic closed design with long lift way for open vessels with various heights

- Limit switch-controlled filling and inspection flap (also as part of the lid)

- Nozzles and hubs for filling, pumps, aspiration, level sensors

Explosion protection

Depending on the process requirement our tripod agitators feature an explosion-proof design to ATEX RL 2014/34/EU for operation in rooms classified as ex-zone 1 and 2 and tanks classified as ex-zone 0 - 2.

- Drives with thermistors for fc inverter operation

Applications

- We develop, manufacture, and distribute innovative agitators for all applications in the materials processing industries, such as the chemical, pharmaceutical, biotechnology, and food industries, as well as in water and wastewater treatment.

Chemical & Petrochemical

-

Variable and diverse

Mixing of substances and chemical reactions are closely interconnected. The way in which different reagents are mixed together can have a significant influence on product quality, product yield, or even on the resulting product itself.

Stirred reactors are used in the chemical industry for a range of applications. They can be used for reaction, extraction, distillation, crystallization, and other processes. Depending on the reactor process and operating mode (continuous, semi-batch, or batch operation), the agitators used can be subjected to varied demands.

In the petrochemical industry, emulsification, absorption, desalination, alkylation, or neutralization processes are commonly found; lubricating oils must be homogenized or sludge oils suspended.

For this wide variety of mixing tasks, Geppert offers tailor-made agitators to satisfy operational and customer requirements.

Fields of application

All stirring and mixing tasks in the chemical and petrochemical industry, for the production of:

basic chemicals, hydrofluoric acid chemicals, fine chemicals, specialty chemicals, plastic resins, plastic materials, adhesives, ethoxylation and hydrogenation, chlorination, and many more.

Materials

We have the ability to construct our agitators from conventional or special materials, in the surface quality desired. We use all available stainless steels, titanium or tantalum, as well as a wide range of plastic coatings. We select materials according to the process requirements and customer preferences.

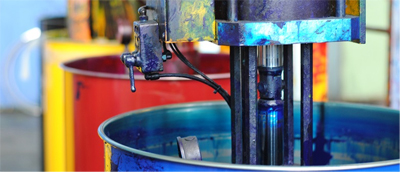

Paints & Coatings

-

Dispersion and Homogenization

Paints and coatings play a significant role in our lives. Without them, life would be dull and even monotonous. But they don't just provide color. They perform a multitude of other tasks as well. For example, they protect objects or structures from corrosion and deterioration, thus contributing to the sustainable use of resources. Equally, special coatings can contribute to a reduction in flow resistance, or create a pearled finish that makes objects easier to clean and reduces contamination.

Paints and coatings generally consist of binders, fillers, pigments, solvents, resins, and perylene, as well as additives. These substances must be mixed together homogeneously during the production process. Various agitators are used to achieve this, for example dissolvers, depending on the process step and according to the boundary conditions.

Different agitators can be used for this task. Low-shear mixers in storage tanks ensure that the coating does not separate. Paints and coatings frequently require stirring even during transport to their point of use. Geppert offers optimized mixing concepts for this too.

Our product range extends from agitators for drums, roll containers and IBCs¹, through tripod agitators, right up to agitators with retractable stirring elements. Regardless of whether mixing is required in open or closed containers, or during storage or transport of paints and coatings – Geppert has the solution to suit your application.

Fields of application

Open or closed stirred tanks for paint and coating manufacture, storage containers and tanks

Materials

Geppert agitators for the paint and coatings industry are manufactured from high quality stainless steel or from a wide variety of special materials where desired.

Pharma & Biotech

-

Specialized and challenging

The pharmaceutical and biotech industry involves a wide range of mixing tasks, for which precision and consistence are of utmost importance.

Particles must be evenly suspended and homogenized in liquids for filling processes. In some cases, multiple processes, such as for example heat transfer, rapid mixing, or material transport, must take place simultaneously within one reactor. Specific requirements are often placed on the drives, if for example production is carried out under clean room conditions. The surface quality of the stirring elements must always meet the highest standards; they are therefore usually electropolished.

Our agitator solutions for the pharmaceutical and biotech industry are engineered and manufactured to customer-specific requirements. Selection of the agitator, as well as of the drive and sealing concepts, depends on the process and customer specifications. We will provide all the necessary design calculations, or simulate the mixing process.

Fields of application

All applications in the pharmaceutical and biotech industry, such as pharmaceuticals, enzymes, yeasts, proteins and amino acids, vitamins, cell cultures, substrate production, sterilization of fermentation media, aerobic and anaerobic fermentation, synthesis, cell disruption, product concentration and purification, crystallization, or hydrogenating applications.

We supply in accordance with FDA* and GMP** requirements.

Materials

We manufacture in all available steel and stainless steel grades, in the required surface qualities or coatings. Surface qualities range from Ra 0.8 to Ra 0.2 – ground and electropolished. All sealing materials are supplied with the relevant FDA certificates of conformity.

Food & Beverages

-

Food grade compliant and efficient

Mixing technology is particularly wide-ranging in the food and drinks industry. From simple suspension and homogenization tasks in storage or transport containers, right through to complex reduction tasks, during which mixtures can be exposed to only the lowest of shear forces – you will find it all in the food and beverages industry.

High food sensitivity and the multitude of fields of application for agitators require close process coordination with the customer, in order to design, construct, and finish the agitators in the optimal manner with the widest variety of mixing elements.

In addition to its popular standard mixers, Geppert also has special stirring elements within its portfolio, capable of being extremely gentle on the product while remaining highly efficient. All agitators have the relevant food approvals and can also be supplied with clean room drives and special sealing systems.

Fields of application

Food and beverages production applications, such as milk, juice, soft drinks, syrups, beer, wine, spirits, sauces, ketchup, soups, desserts, chocolate, sugar, or honey.

Material

We manufacture in all the usual stainless steel qualities and with food-compliant plastic coatings.

Water & Wastewater Treatment

-

Multifaceted and challenging

In the treatment of drinking water, whether done conventionally or via seawater desalination, agitators are used for rapid mix, precipitation and flocculation processes. Precipitation and flocculation processes require low shear, slow-running agitators. For pH adjustments and rapid mixing faster running agitators that can blend reactor content in a flash are required.

Wastewater treatment also requires a multitude of application options for agitators. In anaerobic and anoxic tanks for nitrogen removal, slow-running agitators are used to suspend and homogenize activated sludge flocs. In aeration tanks, mixer/aerators can be used for efficient oxygenation and mixing.

Where waste water is purified, sludge is generated. This sludge is generally conditioned using polymers, dewatered, and then digested in anaerobic sludge digesters to generate biogas. Special agitators are required for both polymer introduction and for digested sludge mixing.

For water and wastewater treatment also, Geppert can offer a multitude of specially developed agitators. From energy-saving hyperboloid mixers for anaerobic and anoxic tanks, to hyperboloid mixing and aeration systems for aeration tanks, or digested sludge agitators with gas seal and explosion-proof drives. Geppert has the solution, experience, and supplies complete systems from a single source.

Fields of application

Precipitation and flocculation, flash mixing, anaerobic and anoxic tanks, oxygenation in aeration tanks, polymer introduction, digested sludge mixing.

Materials

In addition to all the usual stainless steels, for the water sector we also offer agitators and shafts made from fiber-reinforced plastic. These are lightweight and corrosion-resistant.

Paper & Pulp

-

Reactive and complex

Despite the increasing level of digitalization, an ever-increasing demand for paper and pulp products can be observed. However, a shift is taking place from print paper qualities to packaging paper and cardboard.

The wide range of paper products requires a variety of production processes. These include mechanical and chemical processes which, depending on the form and variant, produce different pulp qualities. Stirring and mixing are essential unit processes in all types of paper and pulp production. Mixing tasks range from liquid/liquid or gas/solid/liquid mixtures, through mixing of complex liquids, and include mixing of chemically reactive components.

Improving and optimizing mixing processes in the paper and pulp industry can lead to end product improvements; such as increased strength, improved luster, or significant energy or chemical savings. Such process optimizations require precise analysis of the process conditions, a clear definition of the objective, and an understanding of not just process, but also fluid mechanics. Geppert offers a range of proven agitators for all applications in the paper and pulp industry, with which you can achieve such improvements and savings.

Fields of application

Dilution and make-up of bleaching solutions, melting of saline solutions, oxidation of alkalis, chemical recovery, preparation of paints and coatings, polysulfite production, paper pulp suspension.

Materials

Depending on the application, we use stainless steels (316Ti grade or higher), bare or in some cases with abrasion resistent coatings.

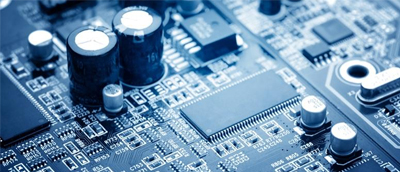

Semiconductor Technology

-

Progressive and innovative

In the manufacture of semiconductors, agitators are mainly used in conditioning of polishing and cutting suspensions, etchants and other auxiliary chemicals, cleaning solutions, or in chemicals recycling. Requirements placed on stirring systems are extremely demanding.

Almost always, clean room conditions prevail, meaning that drives and seals must be designed with no abrasion or leakage. Parts that come into contact with the medium, such as the shaft and stirring element, often have to be produced with metalfree surfaces due to the aggressiveness of the media and the purity requirements.

Also in this area, Geppert Rührtechnik can look back on a very successful history. All well-known chip manufacturers belong to our client base, as well as the manufacturers of the specialty chemicals used in this field. In addition, our agitators are used in broad solar cell production areas. Geppert supplies a significant proportion of agitators to a group of satisfied customers, year after year, for both chip and solar cell manufacture.

Fields of application

Manufacture of high purity chemicals, treatment of cutting and polishing agents, treatment of etchants and auxiliary chemicals, acid supply.

Design

Leak-proof and wear-free sealing systems, metal-free surfaces, highest purity, acid resistance, flush-fit construction, gentle product stirring and mixing, state-of-the-art drive and control technology, fully enclosed drive systems with laminar flow extraction, emission-free.

Material

Stainless steel coated with perfluoralcoxy (PFA), polytetrafluoroethylene (PTFE), or ethylene chlorotrifluoroethylene (ECTFE).