URACA

Videos

Loading the player ...

- Offer Profile

URACA - Innovative solutions with high-pressure technology

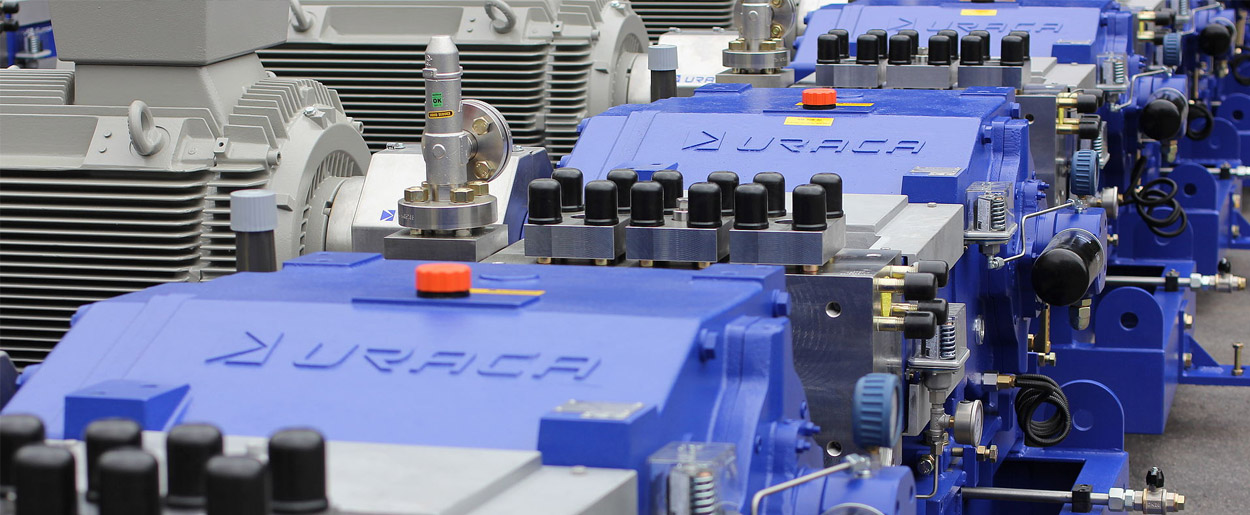

Based in Bad Urach in the heart of the Swabian Alb, URACA is one of the pioneers in the field of high-pressure motorized pumps. Since its founding in 1893, the experts have been dealing with this topic and delivering quality "Made in Germany".

URACA offer a wide range of high-quality products. The core is a series of high pressure plunger pumps for operating pressures up to 3,000 bar / 43,500 psi and drivÂing powers up to 2,600 kW / 3,485 HP.

Product Portfolio

Applications

- Wherever it comes to absolutely reliable and powerful high-pressure technology, professionals worldwide trust in URACA. From standard products to complex solutions, URACA is happy to advise you at any time. We have listed exemplary applications here, and many other applications are conceivable.

Process and Industrial applications with high pressure

CO2 Extraction

- Liquid carbon dioxide is used as solvent in extraction processes. Special plunger pumps supply the processes with liquid CO2 and operate at pressures of up to 1,000 bar.

Descaling

- High-pressure water enables reliable descaling in continuous casting and rolling processes. URACA provides the ideal pump technology for generating the required pressures.

Fiber Spunlacing

- Spunlacing solidifies individual fibres by means of high pressure water to a mat of fibres with special properties. URACA pumps are used successfully worldwide for this technology.

Urea production

- In urea production, URACA pumps reliably deliver liquid ammonia and carbamate. The high-pressure plunger pumps ensure an economical and safe production process.

Hydrostatic Bearing Lubrication

- In hydrostatic sliding bearings, an oil film that has been actively built up before the start of the movement ensures lubrication. URACA high-pressure pumps always ensure reliable oil supply to the bearings.

Coal Liquefaction

- For the process of coal liquefaction, URACA offers suitable high-pressure technology that meets the high requirements of highly abrasive and rapidly sedimenting coal-oil suspensions.

Oil and Gas Production

- URACA pump technology of the highest quality. The sophisticated solutions meet extreme requirements in terms of operational safety and reliability in oil and gas production.

Press drive

- Highly efficient URACA plunger pumps either charge an accumulator or serve in the direct press drive for reliable pressing operations with high pressure.

Chemistry and Petrochemistry

- In process technology for the chemical and petrochemical industries, high-quality, individually tailored solutions are required. Thanks to many years of experience, URACA finds the ideal solution for every application

Spray Tower Feeding

- In the pharmaceutical, hygiene and food industries, the spray-drying process is widely used. URACA supplies high-pressure pumps adapted to the media for spraying tower supply.

Reverse osmosis

- Reverse osmosis is used, for example, for the desalination of seawater. URACA supplies pump technology that can be individually adapted to the various applications.

Cleaning with high pressure

Container and reactor cleaning

- Well-designed container and reactor pipe cleaning systems from URACA clean where no people can reach and effectively prevent downtimes – an advantage for every production

Filter cloth cleaning

- High-pressure cleaning of filter cloths maintains the functionality of filter presses. URACA supplies the right technology for manual or automatic filter cloth cleaning.

Industrial parts cleaning

- The basic requirement for functioning industrial processes is clean parts and workpieces. URACA offers high-quality technology for efficient parts cleaning by means of high-pressure water.

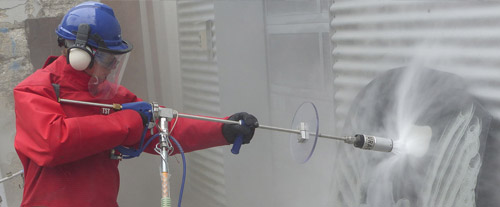

High pressure water jets

- High-pressure cleaning by high-pressure water jetting is an effective and gentle method for removing residues. URACA offers a wide range of pumps and tools.

Tanker cleaning

- In tank wagons, tank cars and truck mixers residues are formed, which are to be removed regularly. URACA offers a wide range of cleaning solutions for many different industries.

Cleaning pipes and sewers

- Around the world, professionals rely on the high performance cleaning pumps from URACA. They ensure that blockages are effectively removed. This keeps everything flowing in your pipe and sewer.

Heat exchanger cleaning

- Heat exchangers can be found in many applications. URACA offers suitable, energy-efficient high-pressure solutions for manual, semi-automatic or fully automatic heat exchanger cleaning.

Remove materials and work with high pressure

Paint stripping and deburring

- Deburring and stripping with high-pressure water jet technology is a highly efficient process. URACA offers ideal systems, units and tools for various applications.

Casting core removal

- High-pressure casting core removal ensures clean, high-quality cast products. URACA supplies suitable solutions for thorough and fast cleaning and coring with high pressure technology.

Road marking removal

- Thoroughly and gently remove road markings with high pressure! High pressure water up to 2,800 bar ensures efficient cleaning. URACA provides the necessary technology.

Surface preparation

- High-pressure technology enables surface cleaning and processing of almost all materials. URACA supplies reliable complete solutions consisting of high-pressure units and accessories.

Renovation

- The renovation of floors, facades and concrete with the highest-pressure water technology offers many advantages. URACA offers the right high-pressure solutions for demanding refurbishment work.

Component Refinement

- Production processes in the automotive sector rely on clean reprocessed parts. URACA offers high-performing and affordable solutions for component refinement that uses high-pressure technology.

Water jet cutting

- Water jets efficiently and precisely cut different materials through very high pressure. URACA supplies the pump technology to generate the required operating pressures.

Testing/Supplying with high pressure

Pressure testing

- Containers and piping used in industry must be checked regularly to ensure that the processes run smoothly. URACA pressure testing units fulfill this task.

Drinking water supply

- URACA plunger pumps supply higher elevations with drinking water in an energy-efficient and safe manner. The pumps are characterized by high efficiencies and constant flow rates.

Systems & Products

- URACA offers a wide range of high quality products. The core is formed by high-pressure plunger pumps for operating pressures up to 3,000 bar and drive capacities of up to 3,500 kw. The program is supplemented by coordinated high-pressure components, complete units and individually developed systems.

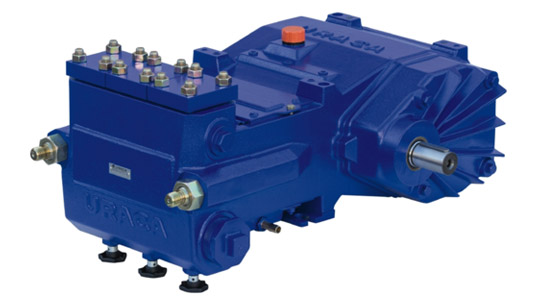

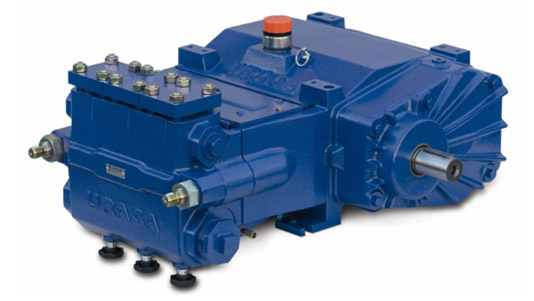

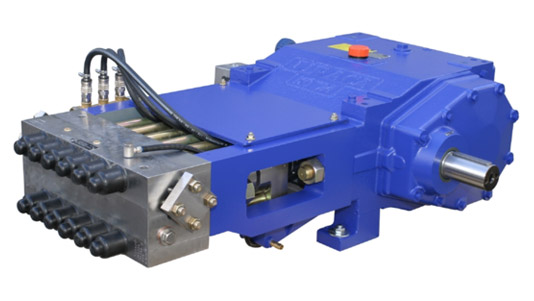

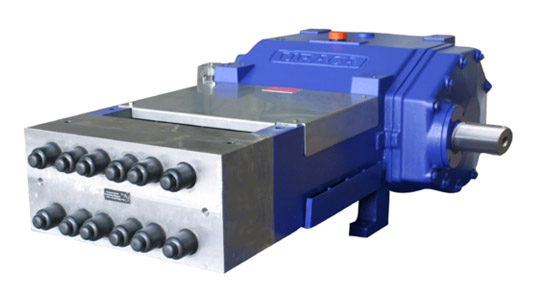

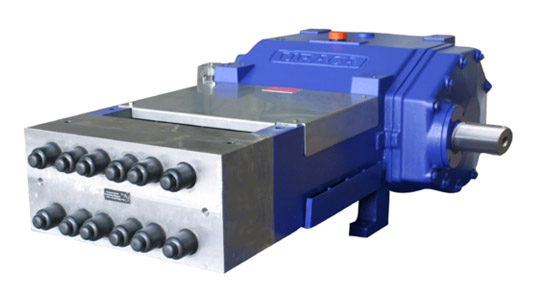

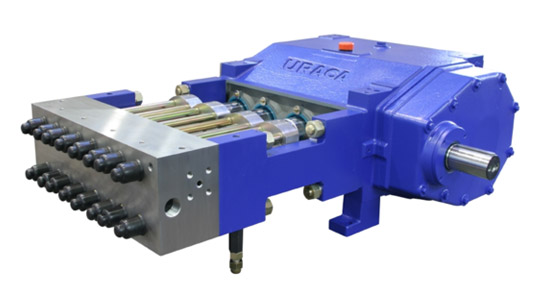

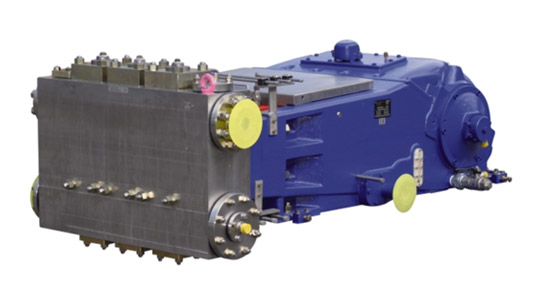

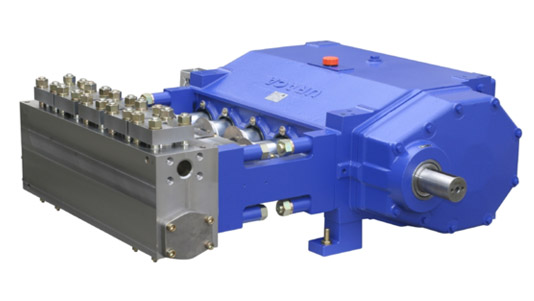

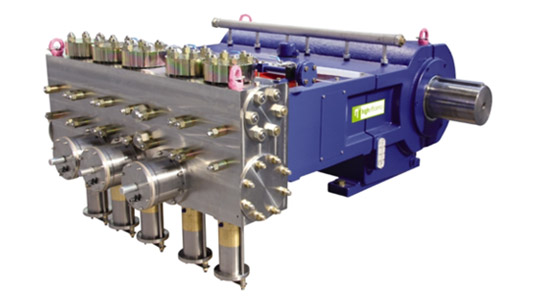

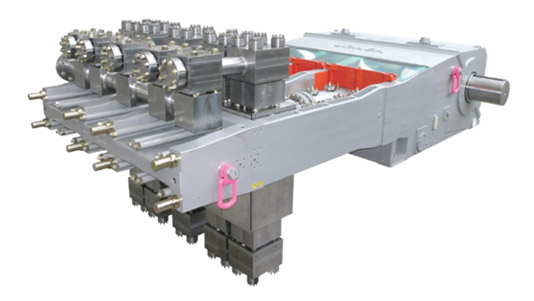

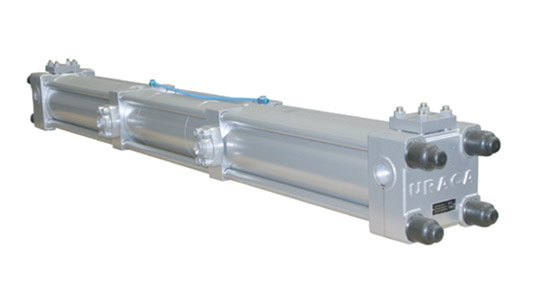

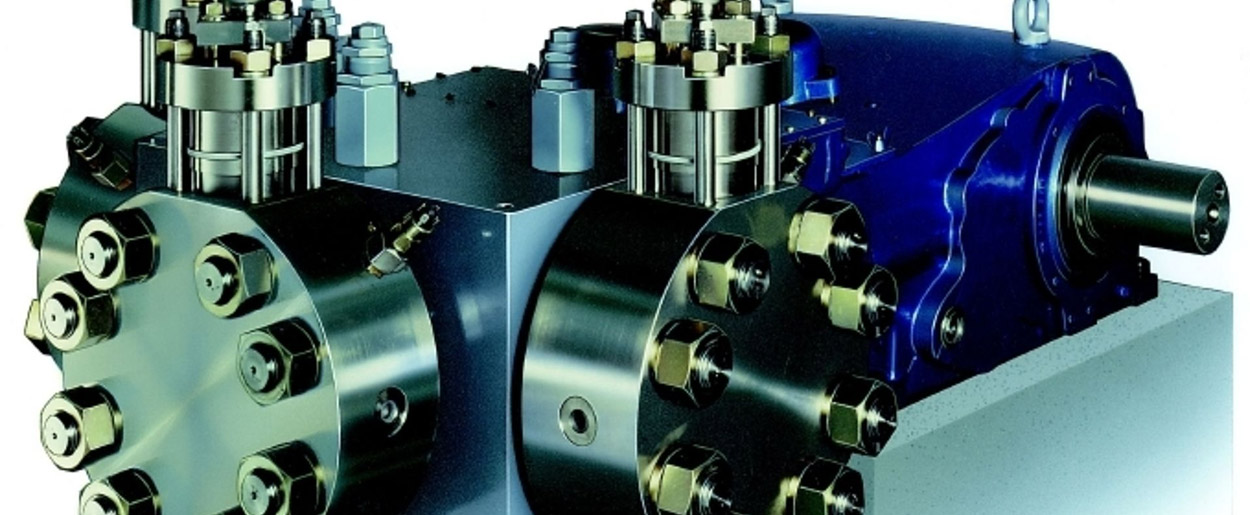

High pressure pumps

with high mechanical efficiencies

The URACA high-pressure pumps are in operation worldwide and supply the required delivery pressure and flow rate for industrial applications. In addition to the bare-shaft high-pressure plunger pumps, URACA offers units and suitable accessories for stationary or mobile cleaning applications. In addition to simple hand operated plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

Benefits of URACA high-pressure pumps- sophisticated design solutions

- robust pump desig

- displacement pumps in different versions

- low energy consumption

- high mechanical efficiencies

- low-wear operation

- long operating times up to several decades

- can be used in almost all branches of industry

- high pressure up to 3,000 bar

- tailor-made, customized solutions

- secured long spare parts supply

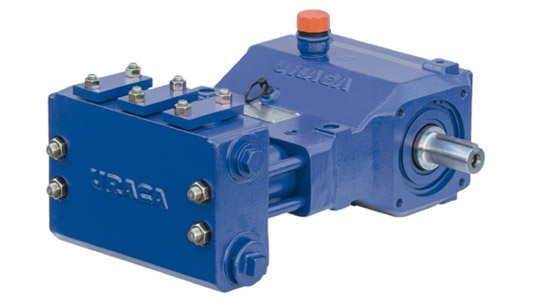

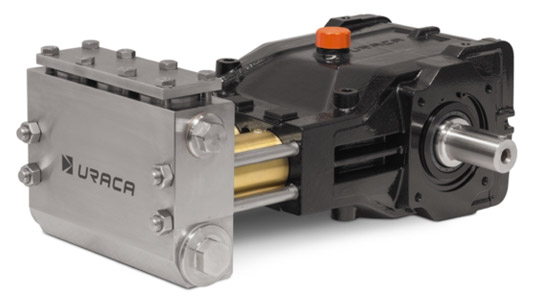

High Pressure Triplex Plunger Pump P3-08

- Power rating: up to 30 kW

- Operating pressure: up to 200 bar

- Flow rate: 20-163 lpm

High Pressure Triplex Plunger Pump P3-10

- Power rating: up to 38 kW

- Operating pressure: up to 2000 bar

- Flow rate: 2,2-163 lpm

High Pressure Triplex Plunger Pump P3-15

- Power rating: up to 55 kW

- Operating pressure: up to 250 bar

- Flow rate: 12-229 lpm

High Pressure Triplex Plunger Pump KD708

- Power rating: up to 75 kW

- Operating pressure: up to 1200 bar

- Flow rate: 12,1-295 lpm

High Pressure Quadruplex Plunger Pump P4-20

- Power rating: up to 75 kW

- Operating pressure: up to 100 bar

- Flow rate: 9,5-652 lpm

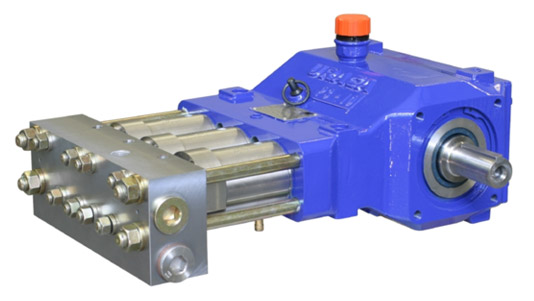

High Pressure Triplex Plunger Pump KD718

- Power rating: up to 110 kW

- Operating pressure: up to 530 bar

- Flow rate: 37,5-432 lpm

High Pressure Triplex Plunger Pump KD719

- Power rating: up to 110 kW

- Operating pressure: up to 2800 bar

- Flow rate: 8,2-335 lpm

High Pressure Triplex Plunger Pump P3-45

- Power rating: up to 135 kW

- Operating pressure: up to 250 bar

- Flow rate: 162-483 lpm

High Pressure Triplex Plunger Pump KD724

- Power rating: up to 170 kW

- Operating pressure: up to 3000 bar

- Flow rate: 12-615 lpm

High Pressure Quadruplex Plunger Pump P4-45

- Power rating: up to 180 kW

- Operating pressure: up to 250 bar

- Flow rate: 216-631 lpm

High Pressure Triplex Plunger Pump KD725

- Power rating: up to 270 kW

- Operating pressure: up to 2800 bar

- Flow rate: 19-720 lpm

High Pressure Triplex Plunger Pump P3-70

- Power rating: up to 330 kW

- Operating pressure: up to 2800 bar

- Flow rate: 23-910 lpm

High Pressure Quadruplex Plunger Pump P4-70

- Power rating: up to 440 kW

- Operating pressure: up to 2800 bar

- Flow rate: 23-910 lpm

High Pressure Triplex Plunger Pump KD822

- Power rating: up to 450 kW

- Operating pressure: up to 820 bar

- Flow rate: 13-2080 lpm

High Pressure Quintuplex Plunger Pump P5-70

- Power rating: up to 550 kW

- Operating pressure: up to 2800 bar

- Flow rate: 39-1550 lpm

High Pressure Triplex Plunger Pump KD823

- Power rating: up to 650 kW

- Operating pressure: up to 820 bar

- Flow rate: 25-3248 lpm

High Pressure Triplex Plunger Pump P3-80

- Power rating: up to 680 kW

- Operating pressure: up to 1600 bar

- Flow rate: 14-3780 lpm

High Pressure Quintuplex Plunger Pump P5-80

- Power rating: up to 1120 kW

- Operating pressure: up to 1600 bar

- Flow rate: 23-6300 lpm

High Pressure Triplex Plunger Pump KD825

- Power rating: up to 1200 kW

- Operating pressure: up to 675 bar

- Flow rate: 60-4550 lpm

High Pressure Triplex Plunger Pump KD827

- Power rating: up to 2000 kW

- Operating pressure: up to 650 bar

- Flow rate: 123-5040 lpm

High Pressure Quintuplex Plunger Pump P5-96

- Power rating: up to 2600 kW

- Operating pressure: up to 360 bar

- Flow rate: 405-10970 lpm

Pressure Intensifier UD200

- Power rating: 20-190 kW

- Operating pressure: 70-200 bar

- Flow rate: 350-550 lpm

Test pumps

for pressure testing

Test pumps from URACA are used wherever systems have to work reliably under pressure. Whether routine seal testing or locating leaks, URACA test pumps and pressure testing units have been developed for unsparing use on site and are used successfully worldwide. They withstand even the toughest conditions of extreme heat,cold, dust and dirt.

URACA test pumps show almost unlimited possible uses. The most varied plant operators in the manufacturing and cleaning industry, as well as experienced workers, have been relying on the superior technology from Bad Urach for generations.

Benefits of the URACA test pumps- absolute reliability with every use

- varied purposes through flow rate

- high functionality

- robust and long-lasting design with stable containers

- simple and ergonomic handling on site

- coordinated, high performance units available

- mobile design versions available for mobile use

HP140

- Operating pressure: up to 30 bar

- Flow rate: 62 cm³/stroke

UX60

- Operating pressure: up to 60 bar

- Flow rate: 11 cm³/stroke

HP220

- Operating pressure: up to 100 bar

- Flow rate: 15 cm³/stroke

HP300

- Operating pressure: up to 60 bar

- Flow rate: 28 cm³/stroke

HP500

- Operating pressure: up to 200 bar

- Flow rate: 79/8 cm³/stroke

HP32-12

- Operating pressure: up to 630 bar

- Flow rate: 28/3,4 cm³/stroke

HP32-12 VA

- Operating pressure: up to 630 bar

- Flow rate: 28/3,4 cm³/stroke

HP32-8

- Operating pressure: up to 1000 bar

- Flow rate: 28/1,5 cm³/stroke

HP20-5

- Operating pressure: up to 3000 bar

- Flow rate: 11/0,5 cm³/stroke

EP601 W/100

- Power rating: up to 1,5 kW

- Operating pressure: up to 100 bar

- Flow rate: 5 lpm

EP601 D/160 Ex

- Power rating: up to 3 kW

- Operating pressure: up to 160 bar

- Flow rate: 5 lpm

EP601 D/200

- Power rating: up to 3 kW

- Operating pressure: up to 200 bar

- Flow rate: 5 lpm

EP602 D/200

- Power rating: up to 11 kW

- Operating pressure: up to 200 bar

- Flow rate: 30 lpm

EP602 D/350

- Power rating: up to 11 kW

- Operating pressure: up to 350 bar

- Flow rate: 15 lpm

EP602 D/500

- Power rating: up to 11 kW

- Operating pressure: up to 500 bar

- Flow rate: 10 lpm

VP602 G/200

- Power rating: up to 8,2 kW

- Operating pressure: up to 200 bar

- Flow rate: 15 lpm

VP602 D/200

- Power rating: up to 7,5 kW

- Operating pressure: up to 200 bar

- Flow rate: 15 lpm

Pump units - Diesel units

- The URACA pump units complete the pumps to entire

solutions. They can be equipped with different drives and controls for

example. Suitable for the numerous applications of the customers, the units

supply the required operating pressure and flow rate. From bare shaft pumps

up to turnkey solutions and self sufficient complete systems, URACA offers

all possible variants.

Advantages of URACA pump units- tailor-made solutions

- individual adjustments

- high levels of efficiencies

- reliable technology

- spare parts supply secured over many years

- great variety of different solutions

- large selection of complementary components

- competent support in pump selection

JetPower40 hot water

- Power rating: up to 38 kW

- Operating pressure: up to 1000 bar

- Flow rate: 5-26 lpm

JetPower180

- Power rating: up to 170 kW

- Operating pressure: up to 3.000 bar

- Flow rate: 15-104 lpm

JetPower300

- Power rating: up to 330 kW

- Operating pressure: up to 3000 bar

- Flow rate: 29-224 lpm

JetPower480

- Power rating: up to 440 kW

- Operating pressure: up to 3000 bar

- Flow rate: 39-305 lpm

JetPower600

- Power rating: up to 550 kW

- Operating pressure: up to 3000 bar

- Flow rate: 48,5-381 lpm

High pressure nozzles

for high cleaning efficiency

The high-pressure nozzle is very small, but extremely important. Its design determines the efficiency of high-pressure cleaning. Optimum interaction between nozzles and the pumps used is required. URACA supplies different types of nozzles for different applications such as nozzles with round cross-sections, fan nozzles, tube cleaning nozzles, rotor nozzles or special nozzles.

Advantages of URACA high-pressure nozzles- sturdy design

- suitable materials

- nozzles in different designs

- low-wear operation

Needle jet nozzles- Operating pressure: up to 3200 bar

- Flow rate: up to 48,4 lpm

Fan jet nozzles- Operating pressure: up to 800 bar

- Flow rate: up to 568 lpm

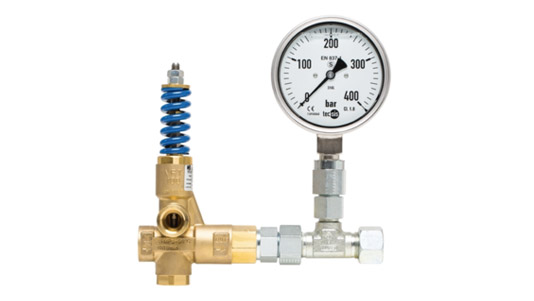

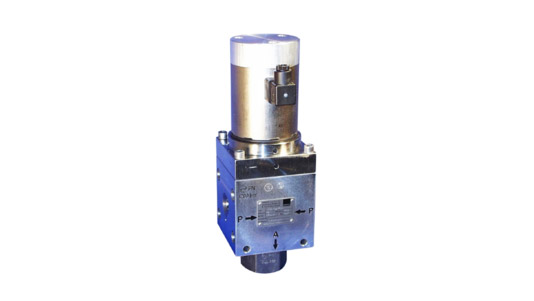

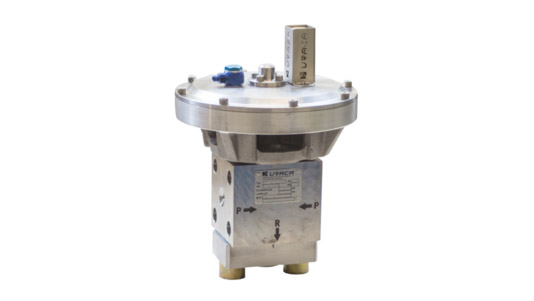

High-pressure valves

Why URACA valves?

URACA has been known for decades for the highest quality in the construction of high-pressure positive displacement pumps and high-pressure valves. In order to consistently meet this requirement, URACA in Bad Urach develops and manufactures highly reliable and durable valves for small to very large flow rates and system pressures of over 3,000 bar.

On the one hand, we can serve a multitude of necessary and meaningful individual functions, on the other hand the uniquely broad spectrum of valve types also covers many combinations of functions. This allows systems and plants to be built in a much more compact, efficient and cost-effective manner. As a further special feature, URACA valves offer maximum personal safety for the operator. Switching positions can be reliably and precisely queried and evaluated in the system control. Depending on the valve type, it can be used in potentially explosive areas up to zone 2. Highest material quality allows the use with different media and medium temperatures.

Almost all URACA switching valves can shut off a consumer line reliably against full operating pressure without auxiliary energy.

Cascadable URACA valves can be assembled extremely compactly to form a valve station.

Pressure Testing Valve DPV

- Permissible positive operating pressure: 50-1.000 bar

- Recommended flow rate: 6-150 lpm

- Dimensions: 480x360x80 mm

Pressure Testing Valve DPV

- Permissible positive operating pressure: 50-1.000 bar

- Recommended flow rate: 6-150 lpm

- Dimensions: 480x360x80 mm

Spring regulated safety valve FSV

- Permissible positive operating pressure: 400-2000 bar

- Recommended flow rate: 0-75 lpm

- Dimensions: 400x105x90 mm

Spring-Loaded Safety Overflow Valve FSUV

- Permissible positive operating pressure: 30-1200 bar

- Recommended flow rate: 0-75 lpm

- Dimensions: 870 x Ã200 mm

High-Lift Safety Valve HHV

- Permissible positive operating pressure: 5-1000 bar

- Recommended flow rate: 5-550 lpm

- Dimensions: 20 x Ã85 mm

Diaphragm Actuated Double Switching and Safety Valve MDSV

- Permissible positive operating pressure: 200-3000 bar

- Recommended flow rate: 0-350 lpm

- Dimensions: 400 x Ã250 mm

Diaphragm Actuated Unloading, Overflow Safety Valve MSUV

- Permissible positive operating pressure: 40-1200 bar

- Recommended flow rate: 0-1000 lpm

- Dimensions: 370 x Ã250 mm

Safety Valve SVL

- Permissible positive operating pressure: 80-660 bar

- Recommended flow rate: 0-250 lpm

- Dimensions: mm

Full Stroke Safety Valve VSV

- Permissible positive operating pressure: 150-300 bar

- Recommended flow rate: 100-650 lpm

- Dimensions: 460x160x110 mm

Pressure Regulating Valve DRV

- Permissible positive operating pressure: 15-630 bar

- Recommended flow rate: 15-100 lpm

- Dimensions: 250x205x56 mm

Electrically Switching Valve ESV

- Permissible positive operating pressure: 50-1200 bar

- Recommended flow rate: 50-600 lpm

- Dimensions: 321x110x110 mm

Spring-regulated overflow valve FUV

- Permissible positive operating pressure: 0-1000 bar

- Recommended flow rate: 0-75 lpm

- Dimensions: 479xÃ125 mm

Diaphragm Actuated, Water Operated Switching- and Pressure Control Valve MWSV

- Permissible positive operating pressure: 800-2000 bar

- Recommended flow rate: 0-50 lpm

- Dimensions: 268xÃ198 mm

Diaphragm Actuated Switching and Safety Valve MSSV

- Permissible positive operating pressure: 10-2800 bar

- Recommended flow rate: 0-750 lpm

- Dimensions: 450 x Ã250 mm

Check Valve RV

- Permissible positive operating pressure: 0-3200 bar

- Recommended flow rate: 0-300 lpm

- Dimensions: 185 x SW80 mm

Cone Overflow Valve KÃV

- Permissible positive operating pressure: 0-1200 bar

- Recommended flow rate: 5-150 lpm

- Dimensions: 180 x Ã54 mm

Closure Valve ZV

- Permissible positive operating pressure: 0-300 bar

- Recommended flow rate: 0-1000 lpm

- Dimensions: 126 x SW80 mm

Pneumatically Switching Valve PSV

- Permissible positive operating pressure: 0-2800 bar

- Recommended flow rate: 0-650 lpm

- Dimensions: 364x145x145 mm

Pneumatically Overflow Valve PUV

- Permissible positive operating pressure: 50-2800 bar

- Recommended flow rate: 10-500 lpm

- Dimensions: 438x92x92 mm

Pneumatic Closure Valve PZV

- Permissible positive operating pressure: 0-1200 bar

- Recommended flow rate: 0-800 lpm

- Dimensions: 175x110x105 mm

Full Stroke Holding Valve VZV

- Permissible positive operating pressure: 50-2000 bar

- Recommended flow rate: 0-1000 lpm

- Dimensions: 100x190x90 mm

Pneumatic Selector Valve (3/2-ways valve) PUSV

- Permissible positive operating pressure: 5-1200 bar

- Recommended flow rate: 10-200 lpm

- Dimensions: 389xÃ195 mm

Pneumatically Pressure Maintaining Valve PDV

- Permissible positive operating pressure: 100-2000 bar

- Recommended flow rate: 10-100 lpm

- Dimensions: 428x92x92 mm

Pneumatically Overflow Valve PUV multistage

- Permissible positive operating pressure: 50-2800 bar

- Recommended flow rate: 10-500 lpm

- Dimensions: 425xÃ166 mm

Manually Controlled Overflow Valve HÃV

- Permissible positive operating pressure: 0-1200 bar

- Recommended flow rate: lpm

- Dimensions: mm

Diaphragm Actuated Switching Valve MSV

- Permissible positive operating pressure: 0-2500 bar

- Recommended flow rate: 0-100 lpm

- Dimensions: 330xÃ250 mm

Pressure Control Valve DBV

- Permissible positive operating pressure: 15-630 bar

- Recommended flow rate: 20-100 lpm

- Dimensions: 221x205x48 mm

Tank cleaning heads

Highest flow rates for cleaning

In 1973, URACA was the first company in the world to launch a 3-D cleaning head. It revolutionized cleaning of the interior of tanks and enabled efficient and automatic cleaning of reactors, tanks and autoclaves without the need for people to get in. Downtimes of plants can be reduced thanks to the cleaning process.

The URACA tank cleaning heads can be operated with high flow rates at a high operating pressure of up to 1,600 bar. An extensive range of accessories and options completes the URACA range.

Advantages of URACA tank cleaning heads- easy assembly and disassembly

- pressure seals with a long service life

- compact exterior dimensions and low weight

- suitable for areas subject to explosion hazards

- low contamination tendency of the smooth housing surface

- high corrosion and temperature resistance

- adjustable, wear-free and encapsulated magnetic brake

- optionally available for long or compact rotors

- extremely low flow resistance

- extremely quiet even when using freely suspended on the hose

Tank cleaning head TWK125-1600

- Permissible positive operating pressure: 200-1600 bar

- Recommended flow rate: 30-150 lpm

- Interference circle: 125 mm

Tank cleaning head TWK125-1000 chemistry

- Permissible positive operating pressure: 100-1000 bar

- Recommended flow rate: 40-200 lpm

- Interference circle: 125 mm

Tank cleaning head TWK125-1000 VC gas

- Permissible positive operating pressure: 100-1000 bar

- Recommended flow rate: 40-200 lpm

- Interference circle: 125 mm

Tank cleaning head TWK150-1400

- Permissible positive operating pressure: 200-1400 bar

- Recommended flow rate: 50-250 lpm

- Interference circle: 150 mm

Tank cleaning head TWK175-800 chemistry

- Permissible positive operating pressure: 100-800 bar

- Recommended flow rate: 75-350 lpm

- Interference circle: 175 mm

Tank cleaning head TWK175-800 VC gas

- Permissible positive operating pressure: 100-800 bar

- Recommended flow rate: 75-350 lpm

- Interference circle: 175 mm

Tank cleaning head TWK185-1200

- Permissible positive operating pressure: 200-1200 bar

- Recommended flow rate: 100-400 lpm

- Interference circle: 185 mm

Tank cleaning head TWK200-600 chemistry

- Permissible positive operating pressure: 100-600 bar

- Recommended flow rate: 40-200 lpm

- Interference circle: 200 mm

Tank cleaning head TWK200-600 VC gas

- Permissible positive operating pressure: 100-600 bar

- Recommended flow rate: 150-750 lpm

- Interference circle: 200 mm

Tank cleaning head TWK185-1200

- Permissible positive operating pressure: 200-1400 bar

- Recommended flow rate: 50-250 lpm

- Interference circle: 150 mm

Tank cleaning head TWK18-500

- Permissible positive operating pressure: 50-500 bar

- Recommended flow rate: 50-550 lpm

- Interference circle: 200 mm

Tank cleaning head TWK13-1200

- Permissible positive operating pressure: 100-1200 bar

- Recommended flow rate: 25-380 lpm

- Interference circle: 150 mm

High pressure spray guns and spray lances

The right high pressure spray gun for every need

The professional high pressure tools from URACA are used where thorough cleanliness or the effective removal of materials is essential. Excellent quality, ergonomic handling and large number of available accessories make URACA the ideal partner for your daily cleaning tasks.

Benefits of the URACA high pressure tools- robust, reliable and long-lasting quality products

- low pull-off and holding forces

- light-weight construction and ergonomic design

- large volume flow, low pressure los

- consistent safety concept

- ATEX-conform design available

- individual adjustment possible by using accessories

- can be combined with units from other manufacturers

Spray guns

- Permissible positive operating pressure: 10-250 bar

- Recommended flow rate: 5-125 lpm

Spray lances

- Permissible positive operating pressure: up to 3000 bar

- Recommended flow rate: up to 60 lpm

read more

Foot valves

- Permissible positive operating pressure: up to 1200 bar

- Recommended flow rate: up to 140 lpm

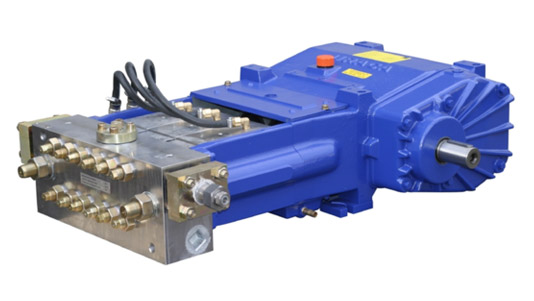

Individually manufactured process diaphragm pumps

for high-pressure applications

For years, industrial process systems have been subject to ever stricter regulations on the part of system operators and authorities. Toxic or environmentally harmful media must be handled emission-free for safety and environmental protection in the workplace. In many cases, conventional plunger pumps with stuffing box sealing no longer meet the strict requirements. URACA has developed hermetic process diaphragm pumps for these applications, which are available as individual special designs.

Advantages of the URACA process diaphragm pumps- emission-free handling of critical media

- space-saving thanks to T-arrangement of the diaphragm heads

- proven drive technology

- simple modernization of existing systems

- high operational safety through hydraulic control

- permanent monitoring of the diaphragm

- preventive maintenance of the pump system possible

- reliable prevention of medium leakage