- Offer Profile

- Liebherr develops, designs

and manufactures high-performance components for mechanical, hydraulic and

electrical drives and control technology. The emphasis is on complete system

solutions. For this reason individual components are optimally matched to

work together.

The comprehensive range of Liebherr components includes diesel and gas engines, fuel injection systems, hydraulic pumps and motors, hydraulic cylinders, large diameter bearings, gearboxes and rope winches, electric machines and electric and electronic control technology and components.

Diesel and gas engines

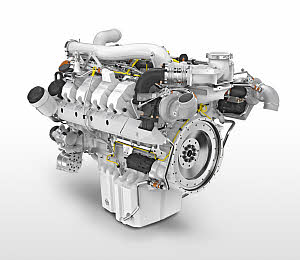

Diesel engines

- Liebherr diesel engines are designed and manufactured in Bulle (Switzerland). Liebherr also manufactures hydraulic components and splitter boxes in the same plant. Liebherr engines are designed for specific applications and are extremely robust with their high-quality technical components.

Exhaust emission standard Tier 3

Design R-engine Rated speed [rpm] 1,800 - 2,100 Number of cylinders 4 - 6 Displacement [dm³] 7 - 10.51 Power max. [kW] 200 - 300 Exhaust emission as per 97/68 EC and EPA CARB Stage IIIA/TIER 3

Exhaust emission standard Tier 4i with DPF

Design In-line engine Rated speed [rpm] 1,800 - 2,100 Number of cylinders 4 - 6 Displacement [dm³] 7 - 11.9 Power max. [kW] 200 - 340 Exhaust emission as per 97/68 EC and EPA CARB Stage IIIA/TIER 4/4i

Exhaust emission standard Tier 4i with SCR

Design R-engine Rated speed [rpm] 1,800 - 2,100 Number of cylinders 4 - 8 Displacement [dm³] 7 -16.2 Power max. [kW] 200 - 505 Exhaust emission as per 97/68 EC and EPA CARB Stage IIIA/TIER 4i

Exhaust emission standard Tier 2

Design R-engine Rated speed [rpm] 1,800 - 2,100 Number of cylinders 12 Displacement [dm³] 24.2 Power max. [kW] 750 Exhaust emission as per 97/68 EC and EPA CARB _ _ / TIER 2

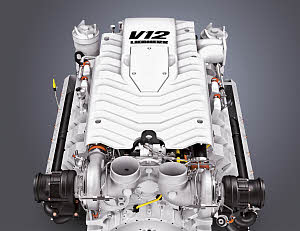

Gas engines

-

The range of Liebherr gas engines is similar to that of Liebherr diesel engines. The series based on the diesel engines of emission standard 3B is noted for being a closed system. The compressor inlet and turbine exit for the gas form the interfaces for the respective application. The charge air cooler, control flap and spark plugs are therefore already included in the standard equipment. The customer receives a compact complete system which is ready to install. Gas-specific components such as gas mixer, ignition system and controller are not integrated into the engine.

Many features of the successful Liebherr diesel engines have been adopted for the gas engines. These include, for example, the steel pistons and the use of four valves per cylinder which increase air volume flow and minimise pressure losses. This allows high ignition pressures and, as a result, yields a high engine power density as well as a high efficiency of over 42%.

Application areas for the Liebherr gas engines are primarily small combined heat and power units, pump stations, gen sets and other stationary applications which are powered by natural gas, biogas, landfill gas or other gases.

G944

Design In-line engine Rated speed [rpm] 1,500 / 1,800 Number of cylinders 4 Displacement [dm³] 8

G946

Design In-line engine Rated speed [rpm] 1,500 / 1,800 Number of cylinders 6 Displacement [dm³] 12

G9508

Design V-engine Rated speed [rpm] 1,500 / 1,800 Number of cylinders 8 Displacement [dm³] 16.7

G9512

Design V-engine Rated speed [rpm] 1,500 / 1,800 Number of cylinders 12 Displacement [dm³] 25

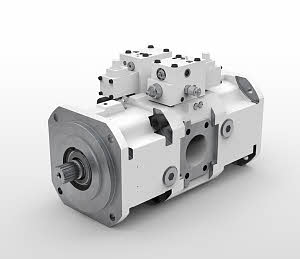

Hydraulic pumps and motors

Axial piston pumps

- The Liebherr axial piston pumps, designed as a swashplate unit, offer a wide range of combinations of pump components and control systems. With their high flexibility they offer an optimum solution for many mobile applications. Liebherr axial piston pumps are also quiet and have high efficiencies.

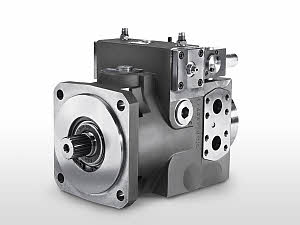

DPVO variable displacement pump, open circulation

- The Liebherr DPVO pump is designed as a high pressure pump up to max. 400 bar with a displacement volume between 108 cm³ and 215 cm³ and is suitable for all mobile drive tasks in open circulation. It can be fitted with different controllers in a modular system, e.g. load sensing (LS), performance regulator (PR) and electrical proportional controller (EPC). Different controllers can of course also be combined. As a single pump the DPVO can be attached directly to Liebherr diesel engines or splitter boxes. A 100% through-drive option is also available.

DPVD variable displacement double pump, open circulation

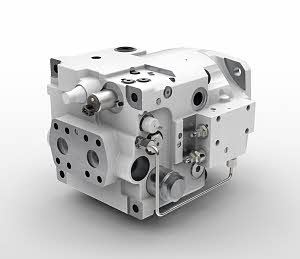

- The Liebherr DPVD pump is available as a variable displacement double pump for the 300 kW class in the nominal size of 216 cm³ (2x108 cm³) for open circulation. The tandem or so-called back-to-back arrangement gives a compact size. The DPVD pump is available with an electric proportional controller (EL) with integrated pressure cut-off (DA).

DPVP parallel pump adjustable, open circulation

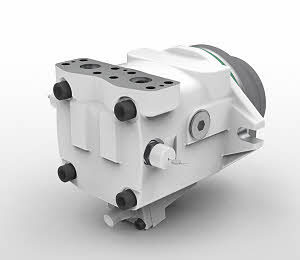

- The Liebherr DPVP pump is available as an adjustable double parallel pump with integrated splitter box for open circulation in rated sizes of 216 cm³ (2x108 cm³) and 330 cm³ (2x165 cm³). The DPVP pump is very compact with the parallel layout of the engines. The housing, designed for confined installation spaces, allows direct attachment to the Liebherr diesel engine. Different ratios, an optional third output and different through drive options provide a high degree of flexibility. Standard control functions such as electrical proportional controller (EL), performance regulator (LR), load-sensing controller (LS), control pressure proportional controller (CP) and combinations of the above are available.

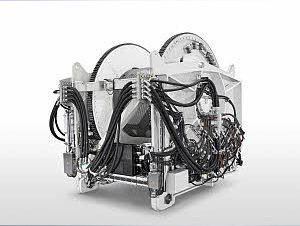

DPVG variable displacement pump, closed circulation

- The Liebherr DPVG pump, specially designed for closed circulation, meets all requirements placed on hydraulic components for closed hydrostatic circulation, such as a reversing-regenerating drive. The DPVG pump is fitted with all components required for closed circulation, such as an auxiliary pump for feed and control oil supply and with valves. The reversible DPVG pump also offers good through-drive options. The DPVG pump is available in power classes between 132 kW and 431 kW in rated sizes from 108 cm³ to 250 cm³. The pump is fitted with an electrical proportional controller (EPC), but it can also be supplied with other control functions.

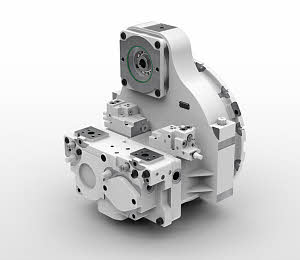

Axial piston motors

- The axial piston motors in swashplate design are an optimum solution for every hydrostatic drive output. The engines are designed for both open and closed circulation. The high degree of modularity makes them suitable for many mobile applications.

DMVA flange-mounted motor, adjustable

- The Liebherr DMVA motor, designed as a flange-mounted motor, is designed for power outputs from 259 kW to 512 kW. The displacements range from 108 cm³ to 355 cm³. The motor can optionally be fitted with an integrated valve brake for operation in open circulation. Other options, such as flushing, controller and sensor technology for closed circulation, can also be integrated into the motor. The specialised design gives the DMVA motor good starting performance.

DMFA flange-mounted motor, fixed displacement

- The fixed displacement Liebherr DMFA flange-mounted motor is designed for operation in slewing mechanisms in closed circulation or also in other types of drives in open circulation. An external Liebherr multi-disk brake or an external valve brake can be attached to the SAE connection.

CMVE plug-in motor for open circulation, adjustable

- The CMVE variable displacement motor by Liebherr is suitable for applications in open circulation. With integrated valve brake and integrated multi-disk brake this motor is an ideal solution for tracked drives. As a swashplate motor the CMVE motor offers an economical solution for drive powers between 225 kW and 299 kW (rated size 108 cm³ to 165 cm³) with high efficiency and low noise emissions.

LMF flange-mounted motor, fixed displacement

- The LMF variable displacement motor by Liebherr was designed for applications with open or closed circulation. As a swashplate motor the LMF offers an economical solution for drive powers between 208 kW and 227 kW (rated size 107 cm³ to 125 cm³) with high efficiency and low noise emissions.

FMF plug-in motor, fixed displacement

- The FMF plug-in motors by Liebherr can be operated in open and closed circulation. They are best suited for travel drives, slewing and swivelling drives and fan drives.

FMV plug-in motor for open circulation, adjustable

- The Liebherr FMV motor, designed as a plug-in motor, has been designed for power outputs from 161 kW to 367 kW. Displacements from 75 cm³ to 250 cm³ are possible. The motor with two switching positions (maximum and minimum volume flow) is an economical alternative to the continuously adjustable motors. The FMV motor can be operated in both open and closed circulation. It is primarily used with travel drives with two speeds.

Hydraulic cylinders

- Liebherr has been developing, designing and manufacturing hydraulic cylinders at Kirchdorf, Germany, for more than 50 years. Around 50,000 hydraulic cylinders are delivered every year for the complete Liebherr construction machinery range as well as for a large number of external customers. The result is a wide range of different hydraulic cylinders for all types of applications. The product range extends from standardised series cylinders to durable heavy duty cylinders through to lightweight cylinders that can take extremely high static loads. Continuous investment in machinery ensures that the latest technology is always available. State-of-the-art test technology ensures 100% functional and high-pressure testing and process-oriented quality management with numerous certifications.

Series cylinders

- Series cylinders are available in single-acting and double-acting models. They are used primarily in construction machinery. With their high degree of standardisation great economies can be achieved in the field of series cylinders.

Lightweight cylinders

- Lightweight cylinders are available in single-acting and double-acting models. With a design optimised for weight, they are particularly suitable for cranes and lifting equipment.

Suspensions

- Suspensions are used in dumper trucks. They are noted for high performance and are extremely low maintenance.

Special cylinders

- Special cylinders are available in single-acting and double-acting models, optionally with length measuring system, limit and proximity switches, adapted sealing systems along with application-specific piston rod coatings

Heavy duty cylinders

- Heavy duty cylinders are available in single-acting and double-acting models. They are particularly designed for applications in mining equipment and are designed for a particularly long service life.

Hydraulic control technology

Pilot control devices

- As a system supplier for hydraulics Liebherr also offers in-house designed and manufactured pilot control devices. The product range includes both hand and foot-operated hydraulic pilot control devices. These components have been proven over many years under severe operating conditions in mobile machinery.

VG7 1/1 single pilot control device

Consumer number 1 Input pressure [bar] up to 50 Control fluid flow [l/min] up to 16

VG7 2/2 double pilot control device

Consumer number 2 Input pressure [bar] up to 50 Control fluid flow [l/min] up to 16

VG7 2/3 double and accelerator pedal

Consumer number 2 Input pressure [bar] up to 50 Control fluid flow [l/min] up to 16

VG7 4/4 manual pilot control device

Consumer number 4 Input pressure [bar] up to 50 Control fluid flow [l/min] up to 16

VG7 4/5 manual pilot control device

Consumer number 4 Input pressure [bar] up to 50 Control fluid flow [l/min] up to 16

VG7 4/7 manual pilot control device

Consumer number 4 Input pressure [bar] up to 50 Control fluid flow [l/min] up to 16

Hydraulic valves

- The valves, which are designed primarily for mobile applications, offer various functions for open and closed hydrostatic circulation. The product range includes pressure limiting valves (DBV) and also pressure relief valves (DMV) and flushing valves. Check valves (RSV) and quantity regulators (MR) are also included.

DBV15 feed pressure valve

Rated size 15 Pressure range [bar] 35 Delivery rate [l/min] 100

MR10 quantity regulator

Rated size 10 Pressure range [bar] 420 Delivery rate [l/min] 20

WV10 shuttle valve

Rated size 10 Pressure range [bar] 420 Delivery rate [l/min] 20

RVH10 unlockable check valve

Rated size 10 Pressure range [bar] 420 Delivery rate [l/min] 12

DBE10 flushing valve

Rated size 10 Pressure range [bar] 420 Delivery rate [l/min] 20

DBV22/F pressure limiting valve

Rated size 22 Pressure range [bar] 420 Delivery rate [l/min] 400

DBV22/V

Rated size 22 Pressure range [bar] 420 Delivery rate [l/min] 400

DBVZ22

Rated size 22 Pressure range [bar] 420 Delivery rate [l/min] 400

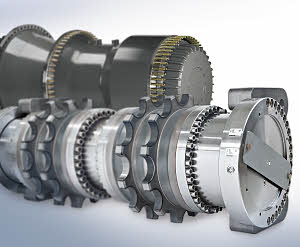

Gearboxes and rope winches

Splitter boxes

- Liebherr manufactures splitter boxes with two to four outputs in various power classes that are perfectly matched to the range of diesel engines. Different ratios are available depending on the requirements.

Slewing drives

- Liebherr designs and manufactures high-performance slewing drives with an output torque from 2000 to 620,000 Nm for a wide range of applications, such as slewing mechanisms for construction, mobile and offshore cranes or rotor blade and yaw adjustment in wind turbines.

Swivelling drives

- Swivelling drives are used in swivelling mechanisms in excavators and are very robustly designed for high dynamic loads. They are available with output torques from 4000 to 65,000 Nm.

Travel drives

- Travel drives by Liebherr have been proven in harsh conditions in crawler tractors and crawler loaders, and also in road construction vehicles. They offer output torques from 24,000 Nm up to 2,300,000 Nm and weights up to 16,000 kg.

Planetary plug-in gearboxes

- Planetary plug-in gearboxes are intended for installation in rope winches, and specifically suit customers who require rope winch drums and frames separately, or manufacture them themselves. The standard gearboxes designed for horizontal installation can be adapted for drives powered by both electric and hydraulic motors. The torque is transmitted to the rope drum by the internal gear wheels.

Compact and heavy duty rope winches

- Compact and heavy duty rope winches are mainly used for small to medium loads. A planetary gearbox integrated into the rope drum transfers a torque of between 6000 and 800,000 Nm via the internal gear wheel onto the rope drum.

Gear ring rope winches

- Gear ring rope winches are used for high to extremely high rope pull forces, such as those that occur with heavy-duty crawler cranes, deep-sea winches and other specialist applications. Output torques of up to 2500 Nm are handled most economically by using a gear ring with several external slewing drives, which can be driven electrically or hydraulically. The redundancy of the slewing drives offers high operational safety for the rope winch.

Special gearboxes

- Liebherr has always offered gearboxes designed for specific applications. Over time, many drive variations have been developed, for example specialist drives for drilling rigs, stationary concrete mixing plants, chain drives and other designs.

Electric motors

- Liebherr electric motors are compact, robust and

maintenance-free three-phase squirrel cage motors with high power density.

Down to the smallest size - round model BG 132 - all motors are designed

with a self-supporting stator core, which supports the housing in addition

to the electrical functions.

The engines have been specially designed for operation in variable-speed drives with frequency converters and also for highly dynamic applications. They are designed for a constant rated torque from standstill to the rated speed and in addition for constant power.

The electrical design and the construction principle offers a low volume-performance ratio in combination with the effective cooling. The compact design means low noise level and very quiet operation. All models can be fitted with the required attachment components (external fan, tachogenerator, incremental encoder, rotary encoder, centrifugal switch) in a modular system and are suitable for a wide range of applications.

BG 132 electric motor - round model

Design Asynchronous squirrel cage motor Power [kW] 4 - 6 (6-pole)7.5 - 11 (4-pole)

BG 132 electric motor - rectangular model

Design Asynchronous squirrel cage motor, caseless design Power [kW] 7.5 - 37 (4-pole)

BG 180 electric motor

Design Asynchronous squirrel cage motor, caseless design Power [kW] 24 - 230 (4-pole)

BG 450 electric motor

Design Asynchronous squirrel cage motor, caseless design Power [kW] 750 - 1,500 (4-pole)1,100 (6-pole)

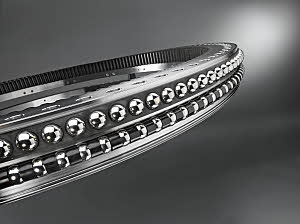

Large diameter bearings

- The Liebherr group is one of the leading global

manufacturers of large diameter bearings and has almost 60 years experience

in the development, design and manufacture of ball bearing and roller

bearing slewing rings. Since company founder Hans Liebherr developed the

first ball bearing slewing ring for cranes in 1955, approximately 300,000

large diameter bearings have been produced for use worldwide in various

applications.

Customers particularly value the large product range, the application-specific engineering and the outstanding quality of large diameter bearings by Liebherr. The large diameter bearings are produced in the factories at Biberach an der Riss, Germany, and Monterrey, Mexico, in various dimensions and models in accordance with customer specifications.

Ball bearing slewing rings

- Ball bearing slewing rings by Liebherr are available in

single- and double-row models, both with external or internal gear as well

as without gearing. The ball bearing slewing rings are designed as

four-point bearings which are characterised by four defined points of

contact per rolling element, through which bilateral axial and radial forces

and thus also a tilting moment can be transferred. Thanks to their simple

construction, four-point bearings are an efficient solution for various

applications with small to medium-sized loads.

Polymer spacers are conventionally used as intermediate pieces between the rolling elements, however there are bearing models with steel or brass cages.

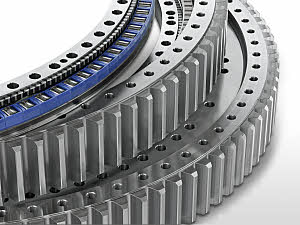

Roller bearing slewing rings

- Liebherr roller bearing slewing rings are suitable for

medium to high loads. They are designed in a triple-row model with two axial

and one radial roller raceway as standard, but other variations are also

possible depending on the application. The linear load transfer allows them

to transfer much higher forces in the same installation space compared to

four-point bearings and makes them particularly suitable for larger

diameters. Roller bearing slewing rings have a high power density, but tend

to place higher demands on the stiffness of the adjacent structure.

Roller bearing slewing rings by Liebherr can be supplied in all gearing versions. Typical applications are mining excavators or large crawler cranes, offshore and mobile harbour cranes. Roller bearings by Liebherr have also been tried and tested in drilling rigs and deep foundation machines.

Special rings

- Four-point and roller bearing slewing rings with special

adjacent structures are included in the category of special rings. Roller

bearing slewing rings with bolt connections or bayonet connections are

available for simplified disassembly of uppercarriage and undercarriage of

construction machines and cranes.

The raceway systems of ball and roller bearing slewing rings can also be designed for specific applications. For example, combined roller-ball bearing slewing rings can be supplied. Slewing connections are also available as ball bearings with adjusted contact angle for large radial loads. Angular contact roller bearings, which act as bogie wheels for a heavy duty crane, have also been manufactured in Biberach.

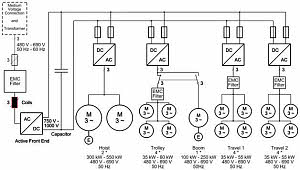

Electric control technology

- In the field of control technology Liebherr designs and manufactures items such as control systems for diesel-electric dumper trucks and controls and switchgear for construction, container and gantry cranes. The assemblies manufactured in-house include power stacks (IGBT power modules) with modular control systems and displays.

Electric drive systems

- Liebherr develops a wide range of application-specific

drive systems, such as for construction and container cranes.

The range of services includes the following controllers and systems:- Safety-related control systems (central and decentralized)

- Controls for limiting working range and patented load torque monitoring in construction cranes

- Control system for automatic adjustment of mobile cranes

- Special frequency converter controls for hoisting and slewing mechanisms

- Simulations of complex electromechanical systems

- GPS-based control systems

- Accurate positioning systems (e.g. positioning trucks under container cranes)

- Energy storage systems with double-coated capacitors

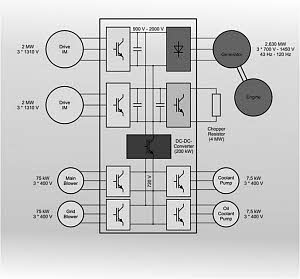

Electric vehicle control systems

- Liebherr designs and manufactures the complete control

system for the drive train for large diesel-electric dumper trucks. The

switch cabinet and its components have been designed for the most adverse

operating conditions such as vibrations, dust and extreme temperatures.

Components of this control system are:- Controls for optimisation of energy consumption and production output

- Control for turning motion support, ABS and ASR

Switchgear

- Liebherr not only develops complex electrical control

systems but also manufactures the required switchgear in house. Liebherr-Components

Biberach GmbH also produces a range of application-specific high-performance

electrical components.

The performance range includes:- Complete switchgear

In-house frequency converters for special applications - IGBT power modules for medium-voltage applications (rectifiers, inverters and (brake) chopper modules)

- Complete switchgear

Power Modules

-

Liebherr offers inverter modules for DC bus systems in various voltage categories and performances. The module of the 380-500 VAC voltage category is suitable for outputs of 100, 160, 200, 250 and 315 kW. Its external dimensions are 765 x 150 x 410 mm and it weighs 35 kg.

In the 500-690 VAC voltage category, a model with the same dimensions and weight is available. This is configured for outputs from 160, 200 and 250 kW. A second module in the voltage category is aimed at outputs of 500, 710 and 1000 kW. It weighs 50 kg and has slightly larger dimensions of 950 x 260 x 370 mm.

All inverter modules have the following features:

- output frequency of 0 to 500 Hz

- liquid-cooled

- temperature range from -20°C to +50°C

- protection class IP21

- installation for switch cabinet

Industrial Electronics

- In the plant in Lindau, Germany, the Liebherr Group

components division designs and manufactures high-quality electronic

components and systems. They are successfully used in all types of

applications, such as construction machinery, aerospace industry or

transportation systems. Development, manufacture and service are fully

oriented to project-specific and business requirements. Liebherr offers

customised electronics solutions at the highest technical level - and

guarantees customers a future-proof partnership.

Including customers in the development process allows the development of customised solutions for electronic components and complete systems.

Display and operation units

- Display and operation units supplied by

Liebherr-Elektronik GmbH combine a wide range of functions in one device.

They are the central information system and are used for both structured

visualisation and also diagnostics systems.

An important aspect of the design of these assemblies is their absolute reliability and robustness during daily operation in a harsh working environment. They must also be easy for users to operate.

Control and regulation electronics

- Electronic modules with high performance and computing

power are required for control and regulation of complex sequences, such as

in mobile machinery, aircraft and vehicles.

These devices must be absolutely reliable under the most extreme external conditions, such as mechanical stresses, high temperature variations, humidity and dirt or subject to electrical interference.

To meet all these requirements in daily use, the requirements posed by an expanded temperature range along with impact and dirt resistance are considered during the design and development phase.

Measuring technology

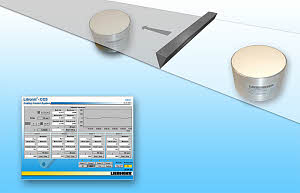

Moisture measurement - Litronic-FMS

-

The Moisture Measurement System type Liebherr Litronic-FMS II is installed successfully in different industry fields for the determination of the moisture/water content of many different kind of materials. The sensors could be installed on conveyor belts, in material chutes, silo outlets, dryers as well as in tanks and pipes and many other installation places. Also we are using the FMS II for a detection of water content in emulsions, installed in tanks and tubes (without Ex protection).

The moisture measurement system has been developed and made by our company especially to improve quality and to ensure a high-grade quality standard. With just one calibration of the sensor according to the local data and conditions we guarantee exact and replicable results.

For more information or if you have any questions, please send us an e-mail to: thomas.maier@liebherr.com

Operational areas of moisture measurement:

- Agriculture

- Automotive

- Building Materials

- Cement Industry

- Chemistry and Pharma Industry

- Food and Beverage

- Glass and Ceramic

- Mills and Concentrated feed stuff

- Paper, Cardboard and Foil

- Petrochemical

- Pet food

- Wood Industry

- Other industries

Water content determination - Litronic-WMS

-

The Water Content Measurement System type Liebherr Litronic-WMS is installed successfully in oil tanks and pipes as well as in oil separators for the exact determination of the water content. Of course, the sensors can be used in color, paint, lubrication oil and other emulsions also.

The WMS has been developed and made by our company especially to improve quality and to ensure a high-grade quality standard. With just one calibration of the sensor according to the local data and conditions we guarantee exact and replicable results.

Coating Control System - Litronic-FMS III / CCS

-

A reliable online measurement of the coating thickness or weight per unit area and the correction of the measured values are crucial for quality assurance and the improvement of the final product. The measurements detected by the sensors are collected in the signal averager of the sensor electronics and transferred for correction to the higher-level control system. The wide range of interfaces mean that the measurement can easily be directly integrated into production systems. Sensor installations are placed, for example, before and after the coating knife to achieve precise compliance with the order. For more information or if you have any questions, please e-mail: thomas.maier@liebherr.com

Operational areas of coating thickness or weight per unit area:

- Paper webs

- Cardboard webs

- Plastic film webs

- Fleece mats

- Fabric webs