DST

- Offer Profile

- DST -

Permanent Magnetic Couplings

Leakage-free transmission is essential in process technology today owing to environmental protection reasons. Highly toxic or aggressive media require hermetically sealed drives for pumps, agitators etc

Product Portfolio

DST Permanent Magnetic Systems

- • Today leakage-free transmission is essential in

process technology owing to environmental protection reasons. Highly toxic

or aggressive media require hermetically sealed drives for pumps, agitators

etc.

• DST ST permanent magnetic couplings optimally comply with the increasing environmental safety protection awareness. High torques can be safely transmitted wear-free through the vessel walls. If the maximum torque is exceeded, the torque transmission will be interrupted so that overload protection is always guaranteed.

• The well proven compact and high-performance magnetic couplings from DST apply rare earth magnets with excellent magnetic capacities.

• A significant performance advantage of the DST magnetic coupling is the freedom from wear in contrast to dynamic seals. This offers DST customers a competitive

advantage in a growing worldwide market with applications in the chemical, pharmaceutical and plastics industries.

Applications

• DST permanent magnetic couplings from DST using contact-free torque transmission are installed in the following areas:

• Chemical industry

• Pharmaceutical industry

• Food industry

• Biotechnology

• Industrial ovens

• Compressors

• Metering

• Batching

• Hydraulics

Materials

• The permanent magnetic coupling components in contact with the medium are selected from the following materials:

• 1.4571 / AISI 316 Ti

• Hastelloy

• Titanium

• 1.4435 / AISI 316 L

• 1.4539 / AISI 904

• 1.4301 / AISI 304

• 1.4462

• Plastic

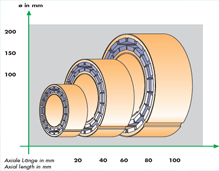

Standard Construction Ranges

- Performance spectrum

• The broad spectrum of the DST standard construction range covers centrifugal pumps, rotating piston pumps, liquid ring pumps as well as agitators with differing torque ratings.

• Individual intermediate solutions are also available.

• Customer specific special solutions further down.

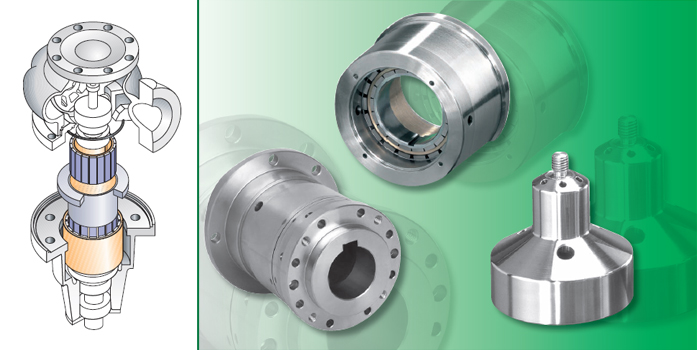

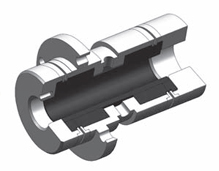

Construction of DST permanent magnetic coupling

• Outer ring

• Canister (the shell is in Hastelloy from size 75/10)

• Inner rotor completely encapsulated in AISI 316 Ti stainless steel

• Magnet material Sm² Co17*

Standard construction range

DST permanent magnetic coupling

Special Designs

- Individual Solutions

• In direct cooperation with our customers the requirements for practical and specific coupling systems are individually evaluated.

• Thereafter the optimum cost/performance design is produced by DST using CAD systems.

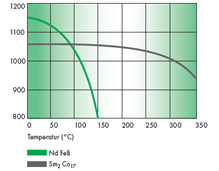

Advantages sm2Co17 vs. NdFeB

• Very high energy product

• High coercivity (resistance to demagnetization)

• Stable at high temperatures up to 350° C

• Very corrosion resistant

Magnetic coupling for pumps and agitator drives power 1 - 2000 Nm

Optimum system adaptability of DST-magnetic couplings

Demagnetization curve of Sm2 Co17 and Nd Fe B at room temperature and at 150° C. Sm2 Co17 - magnets are suitable for temperatures up to appr. 350° C.

Conversion Kits

- Application Areas

• Conversion kits can be retro-fitted in many areas, for example: PU machines, Hydraulic applications

• DST conversion kits allow a combination with all major makes of pumps and drive motors.

• We will evaluate specific applications to produce a functional combination in order to utilise the advantages of “hermetically sealed” and “wear-free” in an optimum

way.

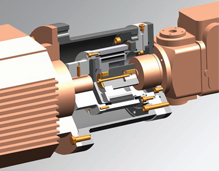

Application example

Conversion kit for hydraulic pump

with DST permanent magnetic

coupling and ABB drive motor

Application example

Conversion kit for hydraulic pump

with DST permanent magnetic

coupling and ABB drive motor

Bearings

- Silicium carbide - ceramic plain bearings

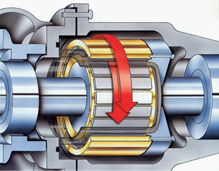

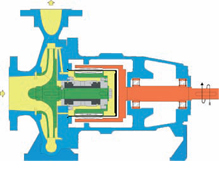

• Complete SSIC - Ceramic plain bearings are available as axial and radial types, predominantly for use in centrifugal pumps, combined with the DST standard permanent magnetic coupling.

SSIC Ceramic bearing in a

centrifugal pump

Plain bearings for diverse media and

temperature ranges

Agitator Drives

- Individual Solutions

• In direct cooperation with our customers the requirements for practical and specific coupling systems are individually evaluated.

• Thereafter the optimum cost/performance design is produced by DST using CAD systems.

Advantages sm2Co17 vs. NdFeB

• Very high energy product

• High coercivity (resistance to demagnetization)

• Stable at high temperatures up to 350° C

• Very corrosion resistant

Magnetic coupling for a plastics pump

- The wetted areas of the inner rotor are

coated with PP, PFA or PVDF for installations in critical media for the chemical industry.

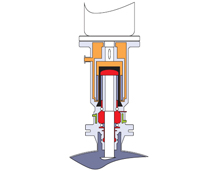

Agitator drive for the pharmaceutical

and food industry - Bottom mounted drive - hermetically sealed!- Using a bottom mounted agitator drive,

the agitator is hermetically sealed, thus

preventing any contamination of the

product.

Agitator drive for the

chemical industry - Overhead mounted drive - vapour sealed!- The overhead drive prevents the escape of any hazardous gases or the ingress of contamination during agitation.