Product Portfolio

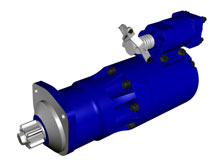

Hydraulic Motors

- Düsterloh hydro motors have been in successful use in

industry for decades. Their well though-out design and sturdiness guarantee

top reliability even under difficult operating conditions. In connection

with downstream brakes and gears, drive solutions in a wide range of

variants are available. The rotary speed and capacity of Düsterloh hydro

motors can be set quickly, precisely and in infinite settings, which makes

the motors particularly suitable for regulating tasks on machines with

greatly varying capacity requirements. As actuating drives, stepper motors

or self-regulating run-on motors – triggered directly through servo units –

they have proved their suitability as precision drives over and over again,

even in the field of extremely small rotary speeds. The areas of application

range from mining to tooling machines and vehicle engineering through to a

wide range of applications in plant engineering.

- Displacement 11-5278 cm³/rev

- Operating pressure -315 bar

- Capacity - 190 kW

- Torque 0.15-24343 Nm

- Speed range 2-3000 rpm

Type series AE10 – AE45

- Precision drives with constant displacement

Vg = 11,4 cm³/rev - 45,0 cm³/rev

Type series KM11 - KM110

- Precision drives with constant displacement

Vg = 11,1 cm³/rev - 109,5 cm³/rev

Type series RM80N - RM250N

- Precision drives with constant displacement

Vg = 80,4 cm³/rev - 251,3 cm³/rev

Type series RM250X - RM900X

- Precision drives with constant displacement

Vg = 255 cm²/rev - 904 cm³/rev

Type series RM1000X - RM5000X

- Precision drives with constant displacement

Vg = 1047 cm³/rev - 5278 cm³/rev

Gears + brakes

- Single and multiple-stage coaxial and angular gears for increasing torque, as well as spring pressure disc brakes for holding static loads.

Flow distributors

Type series RM22 - RM1250X- Arrangement of several coupled radial piston motors for the precise distribution of the hydraulic oil flow.

Accessories

- For use in a wide range of application variants with hydraulic motors.

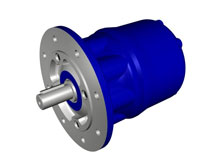

Pneumatic Motors

- Düsterloh pneumatic motors have been designed for

permanent operation and rough operating conditions. They also work reliably

in a humid atmosphere and under extreme climatic conditions. The motors can

be operated using air, nitrogen or gas. As standard, they are equipped with

protective strainer seals, differential pressure oilers and adjustable rev

limiters. Special versions for operation with unoiled air are available.

Good sound absorption is guaranteed by long exhaust gas routing, additional

downstream sound absorbers can also be delivered. Hardened and ground rotors

ensure a long service life.

- Geometrical displacement 155-6116 cm³/rev

- Operating pressure -10 bar

- Capacity 2,8-66 kW

- Torque 9-420 Nm

- Speed range – 3000 rpm

- Air consumption 3,9-66 Nm³/min

Type series PMW160 – PMW530

- Precision drives for problematical environments

Vg = 160 cm³/rev - 530 cm³/rev

Type series DMO Toothed wheel motors

- Precision drives for problematical environments

Vg = 883 cm³/rev - 2394 cm³/rev

Type series DMO Gear motors

- Precision drives for problematical environments

Vg = 1695 cm³/rev - 6585 cm³/rev

Accessories

- For a wide range of uses for pneumatic motors.

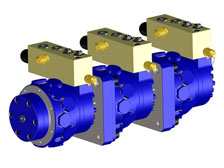

Pneumatic Starters

- Düsterloh pneumatic starters are used to start up

diesel engines and turbines. They mainly comprise a toothed wheel motor, a

single-track pinion with reduction gear and a valve combination. Since the

toothed wheel motor develops its greatest torque when breaking out, it is

particularly suitable for starting diesel engines. Düsterloh pneumatic

starters can be operated using air or gas. They are independent of

electrical energy systems, maintenance-free and explosion-safe. Their

reliable operating behaviour guarantees safe starting of the diesel engine

even under extreme environmental conditions, i.e. they can even be used for

applications in the tropics, in the Arctic circle, in deserts or off-shore.

- Geometrical displacement 265-2360 cm³/U

- Operating pressure -15 bar

- Capacity 4.7-70 kW

- Start-up torque -510 Nm (Increase possible through design as a double starter)

- Air consumption 5.6-62 Nm³/min

- Weight 12,5-52 kg

Type series DLA

- Starters for problematical environments with manual start

valve

Vg = 500 cm³/rev - 710 cm³/rev

Type series PS

- Starters for problematical environments with electrical

or pneumatic start valve

Vg = 500 cm³/rev - 2360 cm³/rev

Accessories

- For use in numerous application variants of pneumatic starters.

Power Units

- Düsterloh Fluidtechnik GmbH specialises in project

planning, designing, manufacturing and commissioning customer-specific fluid

technology systems such as

hydraulic systems

- Tank sizes up to 8,000 dm³

- Tank materials steel and stainless steel

- Operating media mineral oil, gear oil, flame-resistant hydraulic fluids

- Pipes with cutting ring or welding taper screw connections

- Required power up to 110 kW motor-pump assembly

- Noise protection encapsulation for motor-pump units and complete power units

and

pneumatic control units- Pneumatic switching systems in compact design

- Control units for pneumatic emergency drives for e.g. rotary furnaces, converters etc.

- Installation in stainless steel switch cabinet systems for use in aggressive environments

We supply systems "from a single source", including motors and cylinders as well as electronic controls with wiring, including documentation in several languages.

Our systems are used in all areas of mechanical and plant engineering.

Certification of Düsterloh Fluidtechnik GmbH according to EN ISO 9001 : 2000 ensures that the highest quality standards are observed.