Alphafluid

- Offer Profile

- AlphaFluid Hydrauliksysteme

Müller GmbH was established in 1990 as part of the Müller Group.

We aim our company and organisational structure at offering our customers optimal solutions for their fluid-technical problems – from design and developing up to mass production.

At the moment our valves control thrusts from 0.1 up to 500 bars and thereby handle flows of fluid from 0.002 up to about 400 l/min

Product Portfolio

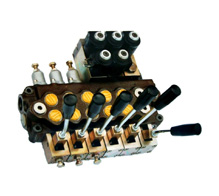

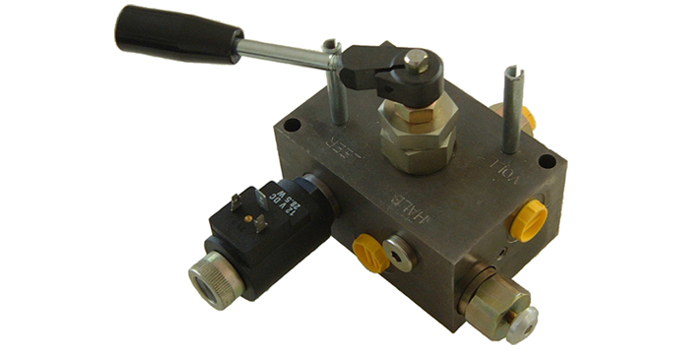

Directional Valves

- Distributing valves are used in an open circulation.

They provide various consumer loads with the delivery flow of the pump. The

distributing valves of ALPHAFLUID are available in mono design or modular

circuit board. The valves with electrical resp. electronically proportional

control don’t need any additional control pressure supply. The hydraulic

auxiliary energy for the build on input unit is taken from the main oil

circulation and will be lead towards the triggered consumer load via the

moved distributor valve.

Advantages:- Solid construction

- Low weight

- No additional control pressure supply

- Parallel operation possible

- Shock absorbing action of the distributor valve that is smooth switching on and switching off of the consumer loads

- Flexible modular design (modular circuit board)

- Excellent sensitivity due to electronic proportional operation

- Add-on kit for directional valves

- Manually operated

- Electrical (S/W)

- Electronically proportional

- Manually/electrical combined

- Manually/electronically proportional

- Construction equipment

- Agricultural machinery

- Forest machinery

- Fork lift-truck

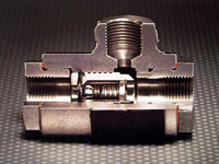

3-Way-Switch

- The hydraulic 3-way-switch is a logic valve which

works automatically. It solves with little energy the problems of long

hydraulics pipe lines, works as a return flow relief or as a rapid traverse

valve. In the usage of hydraulics the 3-way-switch is also called

3/2-way-switch, however without any external operating units. Shown is the

simple construction including a few components. The automatical control can

be clearly seen and the two switching positions will always be attained.

Advantages:- Installation of pipes or cartridge available

- Direct installation in the cylinder base or -head possible

- Oil replacement in long pipes

- Rapid traverse circuit

- Return flow relieve

NG 6 Valves (heavy series)

- These control valves basically correspond to the

well-known industrial valves for disc construction with the

mechanically-hydraulic adapter hole pattern according to DIN 24 340 – A6 and

the common switching function as 4/2- or 4/3-way-switch with electric and

hydraulic operating units.

The expression "heavy series" comes from the robust design of the whole valve which is especially designed for the use in rough and dirty environmental conditions.

Further features are the high pressure capability also for the tank connections and the very robust manual operating units in self-contained design with or without mechanical locking device.- Tank connection capable with high pressure of 315 bar

- Very robust, self-contained emergency manual override

- Hand lever lockable in final position

- Special slide valve with leak oil release of the operating connectors (Type SE 418)

- Impulse control valve with hydraulically detent final positions (Type RAV)

- Also possible with ex-magnet

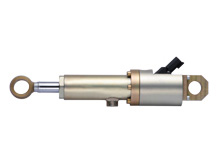

Linear Unit

- The linear unit is a proportional cylinder including

integral position control which means any position may be achieved.

Advantages:- No additional control valves needed

- No electronics needed

- Very solid construction

- very high steady-state

Fine Filters

- Through the oil fine filters very small particles up

to 0.5 µm² are filtered and water is adhered. By using the filter, the

purity level according to ISO 4406: 12/5- NAS 1638: 3 is achieved. As a

result the oil change intervals can be extended many times.

Advantages:- Little abrasion of machines and power units

- Reducing of the operating expenses

- Reducing of downtimes

- Environmental- and resource friendly

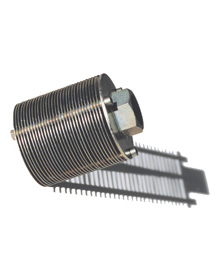

Filters

- This filter design is very robust and insensitive. The

pile construction allows a fine graduation of the filter sizes and thus an

exact customization.

Built

The disc filters made by ALPHAFLUID consist of several double-beveled filter discs with a close meshed wire gauze having a mesh size of 100 µm. They are particularly suitable for using them as an air strainer being the pump’s full flow protector against abrasive impurities inside the tank.

One advantage of the disc filters is the fact that they can be cleaned and reused after dismantling.

Filters

- Half the fitting space or longer maintenance rates

The Filter discs made by ALPHAFLUID need only about half the fitting space (or even less) compaired to common filter discs - based on the same filter surface. Thus, the the size of the hydraulic tank can be reduced as well as the oil filling capacity.

Using the same fitting space as for the star-shaped screen filters, the doubled filter surface leads to a bigger soil retainer capacity - the filter maintenance rates can be extended accordingly.

Diffusers

- Various aspects have to be taken into consideration

when dealing with the dimensioning of containers of fluidity circuits. As a

result there will be no failures or problems during later operation. An

important factor is the rotate time of the medium. Problems concerning the

air- and dirt precipitation will occur should the rotate time be too short

or the size of the tank too small. This will result in frothing, dirt

dispersion, stream flow murmur and cavitation of the pump exhaust.

The diffuser of AlphaFluid enables you to use smaller containers by avoiding the mentioned problems. The diffuser enormously decelerates the oil speed of the return flow pipe. As a result the marginal exit speed of the tank leads to a smooth mixture of the return flow medium with the medium contained in the container.

Diffusers

-

Function:

The medium of the return flow pipe is split up in a lot of component currents. It will be radially decelerated within each of the component currents. The practical construction allows an exact adjustment to the requirements. Only by changing the screens, can the number of the component currents be determined. The diffusers made of steel or stainless steel are hard- wearing against mechanical loads and maintenance-free.

Advantages:- Smaller tank possible

- No return pressure

- No cavitations any more

- Improved air- and dirt precipitation

- No dispersion of dirt in the tank

- Noise reduction

- Maintenance-free

- No oil foam formation

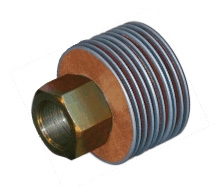

Fittings

- A familiar problem occurs - most common are inches or

metric threads. The design engineer or mechanic of hydraulic systems always

faces the same problem. He has to connect the equipment with different

threads safe and water-tight. If he tries to solve this problem with the

usual standard screwing, combinations of different screwing will occur. Thus

the costs will be raised and the reliability of the system is diminished.

Therefore AlphaFluid offers a variety of more than 250 special purpose screwing. It includes metric and inch threads in different designs. All screwing is designed at the screw in side with a metal water- tight edge. Thus a lot of common problems can be avoided such as seal tolerance, too high or too low operating temperature, sealing service life regarding the surface roughness of the thread counter sink. This variety of screwing will be constantly enlarged and adjusted to the arising requirements

Fittings

- Advantages:

- Sealing edge out of metal - Standard

- Conversion from inches into metric and vice versa

- Reducing Available from stockof leaking points

- Customer specific sizes

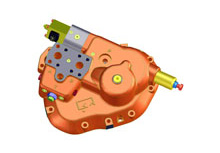

Customer Specific Solutions

- We are specialised on customer specific production. Please take note of the following examples

Valve Units

- Advantages:

- Function according to customer demand

- Design and improvement in 3D-CAD

- Self-made, self-installed and self-tested

- Miniature up to big size possible

- Material: steel, cast, aluminium

Adjustment Units

- Advantages:

- Up to 500 bar of pressure

- Hydraulic or electronically proportional controlled

- • Internal bearing regulation (mechanical-hydraulic)

- Integrated power regulation