- Offer Profile

-

Competence with integrity

Triptiser Edelstahl GmbH is a medium-sized company founded in 1993 with its headquarters in Triptis and another production facility in Greiz. We are a well-respected company in pipeline and plant construction with a focus on environmental and supply engineering. We construct piping systems, manufacture stainless steel tanks and heat exchangers, and integrate these products into functional plants.

Everything from a single source.

Biogas technology

-

Your competent partner for all tasks in pipeline and plant construction

Thanks to our many years of experience in the field of biogas technology, we are able to plan and implement even complex tasks in pipeline and plant construction. We have specialised in customised design using standard and special solutions. In our projects, we rely exclusively on high-quality and tried-and-tested components that guarantee long-lasting and trouble-free operation. Our team consists of experienced professionals who are always ready to answer your questions and help you plan the project in question. We look forward to your enquiry! Pipeline construction for biogas plants

-

For everything that needs to be moved

We are a specialist company certified in accordance with WHG/AwSV for pipeline and plant construction on biogas plants. Our core competence lies in the comprehensive processing of tasks, starting with consultation and planning, through manufacturing, to assembly, insulation and commissioning. Everything from a single source. We construct above-ground as well as underground pipelines and piping systems for a wide range of applications on biogas plants, individually and specifically tailored to the respective task. Thanks to our many years of experience in pipeline construction, we know the critical details and bring this know-how specifically to every project.

Our services in pipeline construction at a glance

- Gas pipelines above ground and buried in accordance with TRAS 120 [technical rules for plant safety] made of stainless steel and plastic

- Substrate pipelines above ground and buried in accordance with AwSV [ordinance on facilities handling substances that are hazardous to water] made of steel, stainless steel and plastic

- Heating pipelines above ground and buried made of steel and plastic

- Waste gas pipelines made of stainless steel

- Connection work for CHP and ORC systems as well as the integration of these into the existing systems

- Retrofitting of SCR and oxidation catalytic converters

- Construction of centralised heating systems and heating networks with and without heat buffer storage

- Installation of waste gas heat exchangers as well as the integration of these into the existing systems

- Execution of all necessary thermal and refrigeration insulation for pipelines, containers and other components

- Leak tests of above-ground and underground pipelines and piping systems

Gas treatment

-

For clean biogas and efficient further processing

Our biogas purification and treatment plants reliably complete an important and necessary process to make the unpurified and moist biogas available for further use, for example for combustion in a CHP unit or for further treatment to natural gas quality.

Biogas treatment begins with the dehumidification of the biogas, which is achieved by cooling it in a gas cooler. By using a demister, even the smallest water droplets are separated out of the biogas stream, and then a sophisticated system is used to drain the precipitated condensate water from the process in a gas-tight system. For further purification of the biogas, it is necessary to heat the biogas with a gas heater, resulting in an increase in its relative humidity. With the parameters now optimally set, the biogas is passed through one or more activated carbon filters, which clean the biogas of hydrogen sulphide, siloxanes and VOCs. The biogas is now cleaned and treated and can be made available for further processes.

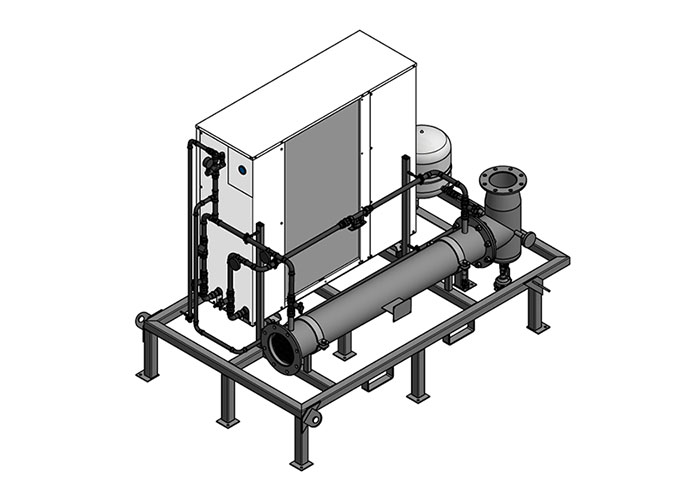

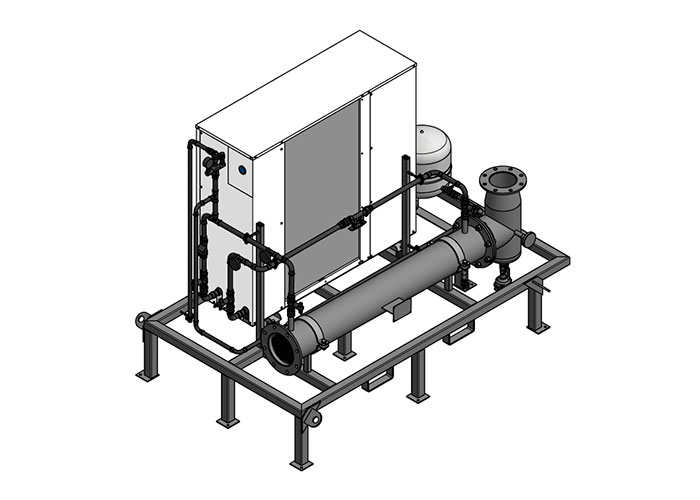

TE – Gas Drying

By cooling biogas or sewage gas in a gas cooler, the gas is dehumidified and dried. The built-in demister ensures that even the smallest water droplets in the gas stream are separated. Subsequently, a sophisticated system collects the separated condensate water and discharges it from the process in a gas-tight manner. Depending on the application, heating and the associated increase in the relative humidity of the gas can take place in a gas heater.

Facts:

- Flow rates from 30 - 2000 m³/h

- Manufacture of all gas-carrying components entirely from stainless steel

- All components mounted on a base frame as standard

- Condensate collector with demister insert and condensate drain

- Ready-to-operate piping

- Insulation for gas cooler, condensate collector and chilled water piping

- Trace heating for condensate collector and condensate drain

- Energy-efficient chilled water units

- Simple control/operation

- Operating pressures up to 2 bar

- Individual and tailor-made solutions

- Customer-specific design

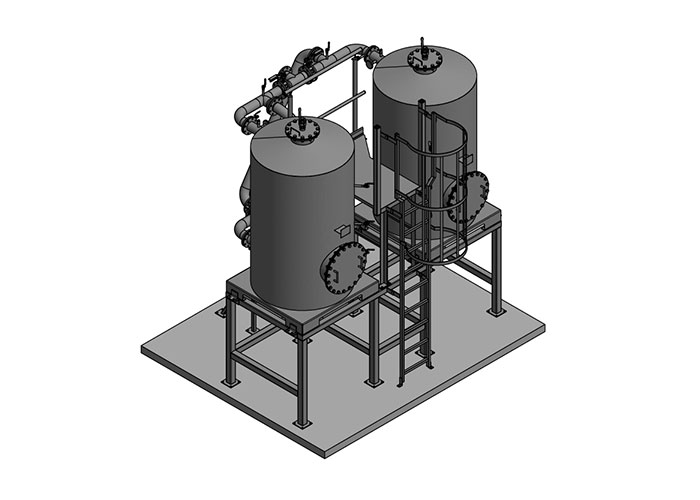

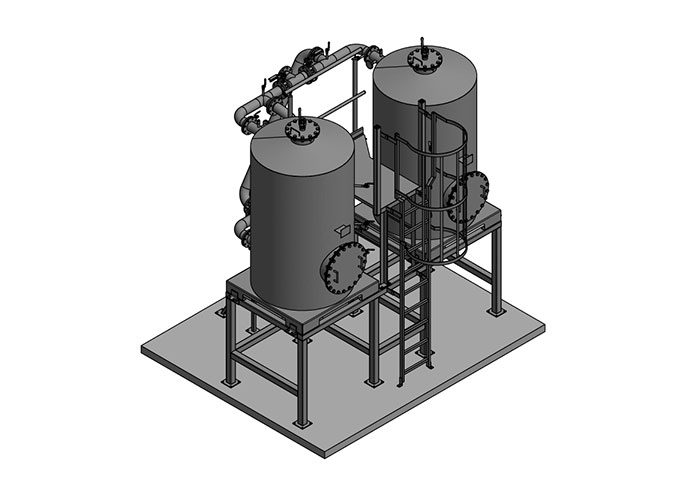

TE – Activated Carbon Filter

To remove hydrogen sulfide, siloxanes, and VOCs from biogas or sewage gas, it must be passed through one or more activated carbon filters. The purified gas can then be made available for further use, for example for combustion in a CHP unit or for further upgrading to natural gas quality.

Facts

- Flow rates from 30 - 2000 m³/h

- Vessels made entirely of stainless steel

- Compliant with TRAS 120

- Operating pressures up to 2 bar

- Individual and tailor-made solutions

- Customer-specific design

Stainless steel heat exchanger

-

for all heat extraction or heat transfer processes

We manufacture heat exchangers for a wide range of applications in the field of biogas technology and environmental technology. Our heat exchangers are distinguished by their high corrosion resistance, which is achieved by manufacturing them from stainless steel, ensuring a long service life. Each heat exchanger is designed, constructed and manufactured in accordance with the customer's specific requirements, at our factory in Triptis. To round everything off, we naturally carry out the necessary installation work with our installation teams. Everything from a single source.

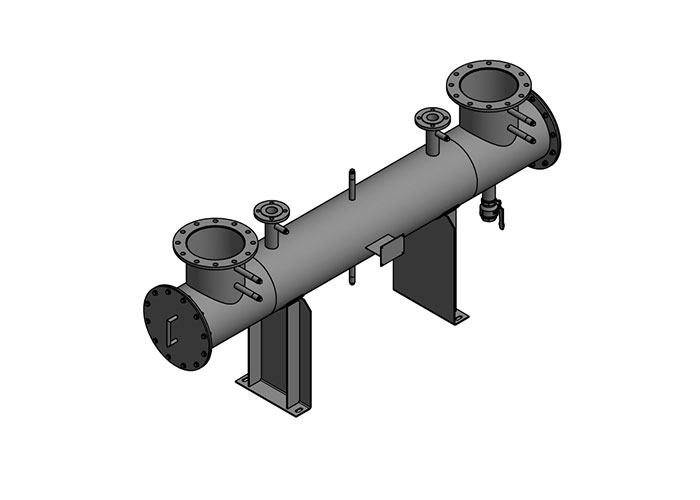

TE – Exhaust Gas Heat Exchanger

We manufacture shell and tube heat exchangers for use as exhaust gas heat exchangers, suitable for all CHP models. Our shell and tube heat exchangers are also used as gas coolers or gas heaters, as well as for all other processes for heat extraction or heat transfer in the field of environmental and supply engineering.

Facts- Manufactured entirely from stainless steel

- Standard sizes up to DN 700

- Suitable for all CHP models & micro gas turbines

- Operating pressures up to 16 bar

- Operating temperatures up to 550°C, up to 1000°C in high-temperature range

- Individual and tailor-made solutions

- Customer-specific design

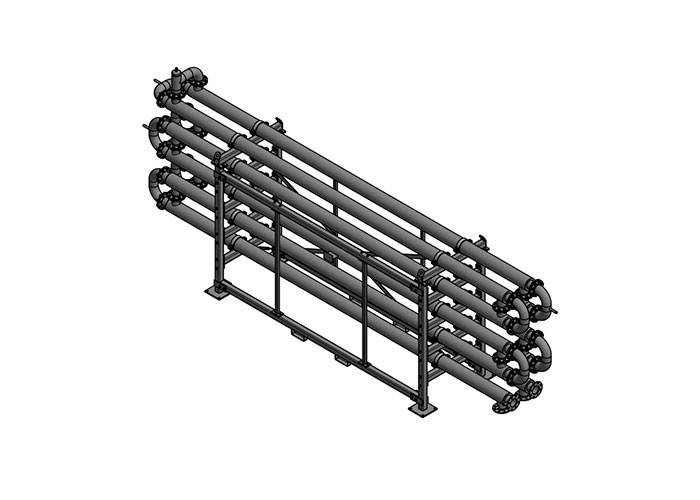

TE – Substrate Heat Exchanger

We manufacture double-pipe heat exchangers for use as substrate heat exchangers or sludge heat exchangers. Our substrate heat exchangers are used for heating or cooling substrates or in plants for the hygienisation of input or output materials in biogas plants.

Facts- Manufactured entirely from stainless steel

- Standard mounting on a base frame

- Ready-to-operate piping

- Standard sizes up to DN 200

- Operating pressures up to 16 bar

- Individual and tailor-made solutions

- Customer-specific design

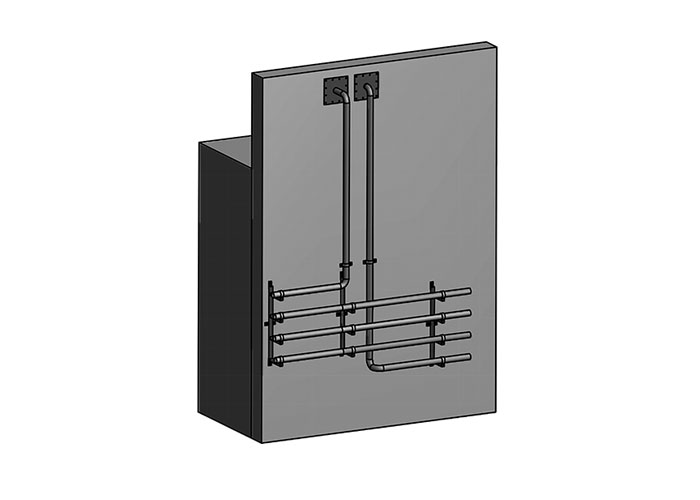

TE – Tank Heater

Our tank heaters are installed internally in fermentation tanks. With our proven mounting system, we guarantee stability and safety in all operating modes and ensure a constant heat input into the fermentation process.

Facts- Manufactured entirely from stainless steel

- Standard sizes up to DN 150

- Operating pressures up to 16 bar

- Wall penetrations compliant with AwSV

- Proven mounting system

- Robust and durable design

- Individual and tailor-made solutions

- Customer-specific design

Component production | Assembly production

-

Your partner for stainless steel components and welded assemblies

We are your competent partner for the production of pressure vessels, pipelines and tube bundle heat exchangers as well as for many other components and special designs made of stainless steel. As a certified welding company specialising in the machining and processing of stainless steel, we offer you customised solutions for your individual tasks. Thanks to our in-house production with our own pickling shop, we have direct influence on the quality of our products right up to the end. With years of experience and our know-how, we guarantee the highest quality and reliability.Our certifications

- Specialist company in accordance with WHG/ AwSV

- Pressure Equipment Directive AD 2000 HP0

- DIN EN ISO 3834-2

- DIN EN 13445-4

Custom-made products

Your customised stainless steel solutions

Custom-made products to meet individual customer requirements are our strength. We manufacture all components such as piping, containers and racks precisely in accordance with your specifications and requirements. It doesn't matter whether they are tubular, sheet metal or profile constructions. Our highly qualified team is standing by to assist you right from the planning stage and will then accompany you through the implementation to the completion of your project.Our team will be happy to answer your questions and support you in planning the respective project. We look forward to your enquiry!

Component production | Assembly production

- Vacuum test stand, drum dryer

- Stainless steel agitated tank

- Piping construction for hydrogen production plants / hydrogen pipelines

- Pilot plant for liquid tin

- Stainless steel sun protection facade

- Filter head plates for cement plants

- Stainless steel pressure vessel

- Nickel tank

- Stainless steel trolley

- Piping for ORC plants

- Stainless steel storage tank

- Double-pipe heat exchanger

- Stainless steel tank with working platform

- Stainless steel pipe fittings up to DN 1000

- Autoclave / vacuum vessel

- Hygienisation tank

- Base frames

- Shell and tube heat exchanger

- Stainless steel stairs, railings, platforms

Water technology | Waste water technology

-

Your competent partner for all tasks in pipeline and plant construction

As a specialist company in pipeline and plant construction, we have the necessary experience and know-how to equip a wide range of water engineering plants, such as elevated tanks, waterworks, rainwater retention basins and sewage treatment plants. The necessary metal construction work, the piping systems, the equipment parts or the stainless steel linings of water chambers are among our strengths. We manufacture individual staircases and platform structures, railings, windows, doors and façade constructions made of stainless steel for specific projects and install them with our installation teams.Our many years of experience in the field of water technology and wastewater technology enable us to plan and implement even complex tasks in pipeline and plant construction. We have specialised in customised design using standard and special solutions. Our piping and metal construction work is high-quality and durable and meets the highest quality standards. Our experienced professionals will be happy to help you and answer your questions.

TE – Activated Carbon Filter

To remove hydrogen sulfide, siloxanes, and VOCs from biogas or sewage gas, it must be passed through one or more activated carbon filters. The purified gas can then be made available for further use, for example for combustion in a CHP unit or for further upgrading to natural gas quality.

Facts- Flow rates from 30 - 2000 m³/h

- Vessels made entirely of stainless steel

- Compliant with TRAS 120

- Operating pressures up to 2 bar

- Individual and tailor-made solutions

- Customer-specific design

TE – Gas Drying

By cooling biogas or sewage gas in a gas cooler, the gas is dehumidified and dried. The built-in demister ensures that even the smallest water droplets in the gas stream are separated. Subsequently, a sophisticated system collects the separated condensate water and discharges it from the process in a gas-tight manner. Depending on the application, heating and the associated increase in the relative humidity of the gas can take place in a gas heater.

Facts- Flow rates from 30 - 2000 m³/h

- All gas-carrying components manufactured entirely from stainless steel

- All components mounted on a base frame as standard

- Condensate collector with demister insert and condensate drain

- Ready-to-operate piping

- Insulation for gas cooler, condensate collector, and chilled water piping

- Trace heating for condensate collector and condensate drain

- Energy-efficient chilled water units

- Simple control/operation

- Operating pressures up to 2 bar

- Individual and tailor-made solutions

- Customer-specific design

More products

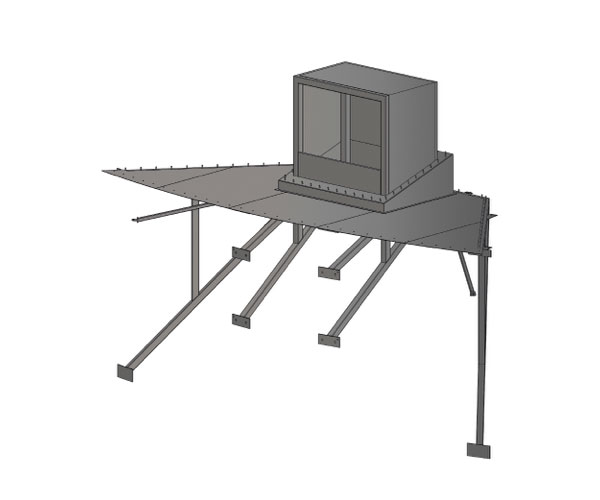

TE - Service Platforms for Double Membrane Roofs

-

Service platforms for double membrane roofs are planned and manufactured individually and depending on the task. Service platforms are attached to the tank wall, making it easy to retrofit pipe connections and sensor mounts when converting tank covers or retrofitting double membrane roofs on concrete tanks. Service platforms can also be designed and used for service work on submersible mixers.

Facts

- Made entirely of stainless steel

- Enables pipe connections and sensor mounts to be retrofitted

- Enables accessibility to submersible mixers for service work

- Robust and durable design Individual and tailor-made solution

- Customer-specific planning and design

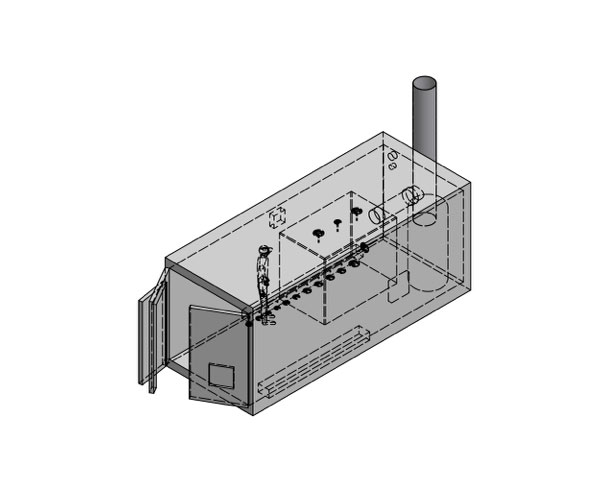

TE-Heizkessel

-

Boilers are used to generate heat in biogas plants, in industrial enterprises or for connected district heating networks and are planned and designed individually according to heat requirements. The installation can take place in a building or in a shipping container.

Facts

- Low-temperature boiler for producing hot water at 95°C

- Subsequent integration into existing heating systems possible

- Output range from 120 – 1200 kW thermal in standard sizes

- Simple regulation/control Individual and tailor-made solution

- Customer-specific planning and design

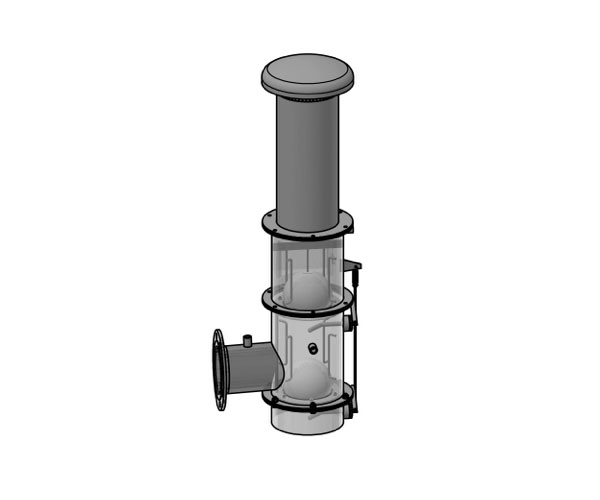

TE - Over/negative pressure protection valves

-

An overpressure/ underpressure safety device is used on biogas plants to protect roof systems and gas-tight tanks against overpressure or underpressure. Our mode of operation without sealing liquid enables safe and low-maintenance operation.

Facts

- Operation without water or sealing liquid

- Made entirely of stainless steel

- TRAS 120 conform

- Simple function control

- Low maintenance eff ort

- Overpressure protection variably adjustable

Services

-

Here's where we really impress:

With over 30 years of experience in handling and processing stainless steel, we are highly specialised in pipeline and plant construction for environmental and supply engineering. We place particular value on close and trusting cooperation with our customers. Thanks to many years of experience and our extensive know-how, we can offer individual solutions and thus meet our customers' expectations.