- Offer Profile

-

NON FERROUS RECYCLING

FOR HIGH METAL RECOVERY PROFITSAs a specialist in the recovery of non-ferrous metals from slags, or bottom ash (IBA), Recco facilitates a state-of-the-art system that separates the aluminium and heavy metals in 3 grading sizes from residue aggregates.

The process of recovering non ferrous metals from incinerator bottom ash is described on the following pages of our website, as well as our services:

- on-site bottom ash processing plant

- non ferrous metal separation

- IBA processing plant engineering,

- maintenance, and repairs

NON-FERROUS RECYCLING

-

FOR HIGH METAL RECOVERY PROFITS

Separating ferrous and nonferrous materials from waste incineration provides not only a benefit to the environment but also serves a financial gain. Both slag and ash are the non-combustible residues from the incineration of various waste streams in the energy industry. This slag, or bottom ash, is processed in a designated IBA processing plant dividing the valuable materials into:

- 90% slag residues for valuable aggregates in, e.g., construction

- 7% ferrous materials for reuse in various industries

- 3% non ferrous materials

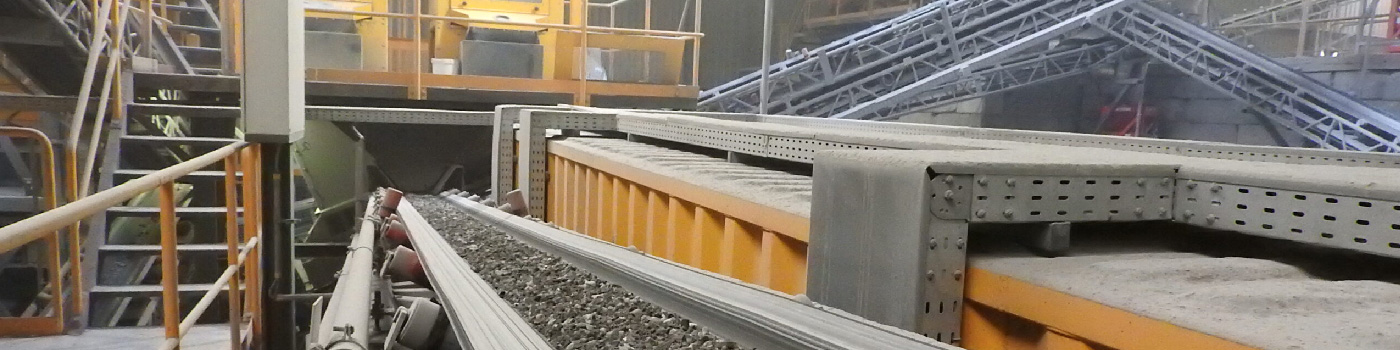

RECCO NON FERROUS RECYCLING INSTALLATION

The non ferrous metal mix that is separated from the bottom ash in the IBA processing plant contains valuable materials that can be further recycled in our stationery plant. The sophisticated separation system Recco has designed, divides the non ferrous materials stream into:

- 15% heavy metals

- 43% aluminium

- 42% residue

Example valuable heavy metals include zinc, brass, bronze, copper, lead, silver and gold. The residual materials such as stones, glass, plastics, paper, and wood are processed into reusable construction materials, for instance, concrete products, asphalt, and earthworks.

ON SITE SLAG RECYCLING

-

ON-SITE SLAG RECYCLING

Slag processing, or also referred to as bottom ash recycling or IBA recycling, and metal recovery on your site are the first steps in the range of services that Recco offers.

We engineer and manufacture a customized installation for temporary processing built up and installed from modular machinery or install a permanent system. At your choice, the operational management of the bottom ash recycling system, as well as the maintenance, can be carried out by Recco or by your staff.

The advantages of Recco slag processing installations comprise:

- optimal recycling of waste-reducing the environmental footprint

- fewer metal concentrations in surface waters

- maximum metal recovery from IBA

- higher revenues from retrieved metals

- reduced landfills thanks to 10% further compressed residue aggregates

The configuration of the installation varies and depends on the storage location and facility of your bottom ash. Overall, we succeed in achieving 1,5 % higher non ferrous metal recovery than conventional systems.

IBA REPROCESSING

For some customers, Recco reprocesses slag material. It is our experience that many valuable materials are discarded due to inadequate sorting. Thanks to our state of the art units and machinery configuration, we yield additional metal streams from previously processed IBA.

IBA PROCESSING PLANT ENGINEERING

-

ENGINEERING, PRODUCTION, AND INSTALLATION

For processing slag or bottom ash (IBA) and retrieving valuable ferrous and non ferrous materials, Recco engineers, manufactures, and installs a system that achieves maximum yields. Thanks to the Heilig group-wide knowledge in plant engineering, Recco offers customized mechanical engineering for a fully operational plant design according to your requirements and location parameters.

EXPLOITATION AND OPERATION

Also, Recco can exploit and/or operate an IBA processing installation on your site. For the purpose of installing and exploiting a system, we gladly discuss optional financial and investment structures to cooperate in a long-term partnership.

REPAIRS AND MAINTENANCE

Besides the installation and operations, Recco maintenance engineers can inspect, maintain and repair slag processing installations for our customers throughout Europe, regardless of the make or brand of your plant. Periodic maintenance guarantees continuous operation and reduces unexpected repairs. Our experts are experienced in both technical and mechanical inspections and repairs.

METAL SEPARATION PLANT

-

AT RECCO EMMELOORD

In our facility in Emmeloord, we have engineered a unique dry metal separation installation with a capacity of 600 tons per week. For our relations, we recycle the non ferrous mixed streams into single streams of heavy metals and aluminium with extremely high purity rates.

Our unique sorting and recycling method utilizes various separation techniques such as magnetic separation, screening, and metal sensors. The installation includes crushers, separators, eddy current separators, screening machinery, and magnets.

The advantages of our dry metal recycling comprise:

- maximum recovery of heavy metals

- no oxidations

- higher recovery of aluminium fines

- high purity rates of heavy metals

Needless to say, these advantages result in higher sales profits to smelters.

PROCUREMENT AND PROCEDURES

-

METAL RECYCLING WITH HIGH REVENUES

At Recco, we strive for high-quality metal recycling from incinerator bottom ash (IBA), generating the largest possible non ferrous metal recoveries. Because bigger yields sold at the best possible precious metal prices account for higher profits.

We also believe in investing in long-term relationships by operating transparently and flexibly enabling our partners to benefit similarly from the high revenues. For that reason, we offer our procurement and metal recycling procedure services in one of the following mutual determined and beneficiary manners:

- Recco purchases mixed non ferrous materials generated from IBA processing at a price based on an Open Calculation Model which covers the costs of processing, waste discharge, transport, and includes a predetermined margin on the metal revenues.

- Recco purchases mixed non ferrous materials generated from IBA processing at a price based on a Quotation upon Analysis which covers the costs of processing, waste discharge, transport, and includes a quotation for current metal prices.

- Recco supplies a stationery or temporary IBA processing installation, and purchases the mixed non ferrous materials generated from IBA processing at a price based on a Quotation upon Analysis or Open Calculation Model