- Offer Profile

- SOLID-LIQUID SEPARATION SYSTEMS, SINGLE-USE SOLUTIONS & VIBRATORY MIXERS

We develop, design and fabricate filtration systems for solid/liquid separation in the processing industries as well as Vibratory Mixers and Single-Use Technologies.

Single-use Systems

- Explore our single-use filter FUNDALOOP®, the ideal alternative to disposable filter cartridges for cell harvesting and clarification. Highly hygienized variants are also available to adapt for strict GMP requirements. Our single-use vibratory mixing technology FUNDAMIX® SU was also adapted for single-use applications to maintain homogeneity while avoiding high shear forces and vortices within cell cultures.

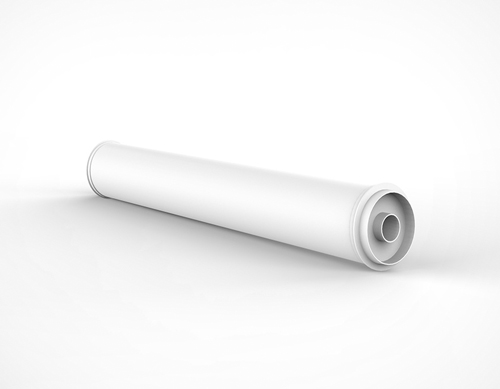

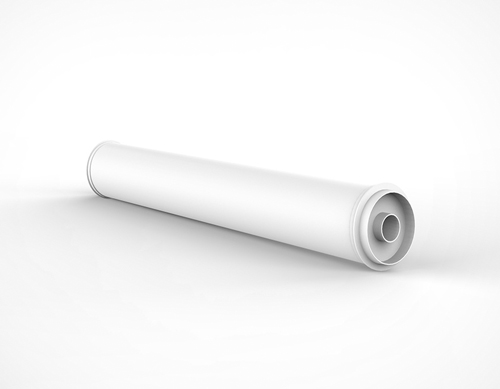

FUNDALOOP®

-

Filtration with high throughput and pre-sterilized filter enclosures.

FUNDALOOP® single-use filters are the innovative solution to disposable filter cartridges for cell harvesting and clarification in pharmaceutical processes. The filtration system consists of multiple vertically aligned filter elements packed into a fully contained FUNDALOOP® Bag that is placed inside a transparent pressure vessel.

Advantages- High throughput

- Increased yield in cell recovery and enzyme recovery operations

- Shorter reactor downtime due to reduced cleaning and validation requirements

- Pre-sterilised and validated filter enclosure available for pharma/biotech applications

- Reduced heel volume and compaction of solid waste thanks to the external pressure

- Fully enclosed containment made completely with plastics ensuring safe handling and disposal of hazardous components

- Multilayered plastic bag providing superior robustness

FUNDAMIX® SU

- Sophisticated mixing by vibration

The FUNDAMIX® SU is a sophisticated mixing device where the mixing effect is generated by high frequency vibration created by an electromagnetic drive. The vibration is transferred through the length of a shaft to a perforated mixing plate with conical bores. The oscillation of the plate causes the liquid to be pumped through the conical holes, creating a flow according to the Bernoulli effect. The membrane sealing unit options offer a low maintenance solution perfectly suited for a sterile environment. The absence of rotating parts results in the seal being guaranteed with use of a simple membrane, capable of withstanding both full vacuum and pressure up to 5 bar g or higher upon special request. The membrane seal design does not generate any friction unlike rotating devices and is well suited for both CIP & SIP processes.

Mixing devices are designed according to the customer and process requirements to guarantee optimal mixing performance, constructed according to the hygienic design principles and supplied with all supporting documentation. The flow direction can be adapted to suit the application or desired mixing effect, the mixing direction depends on the orientation of the conical bores. The oscillating mixing technique generates fast, homogenous product dispersion without a vortex and if required, with minimal surface movement.

Advantages- Low shear forces

- No baffles required in the tank

- No rotating mechanical seals

- No lubricant required

- Low installation and maintenance cost

- Low energy consumption

- No vortex

- No friction

- Long service life

- No overheating of liquid

- No damage to life cells or delicate crystals

- Simpler sterilization

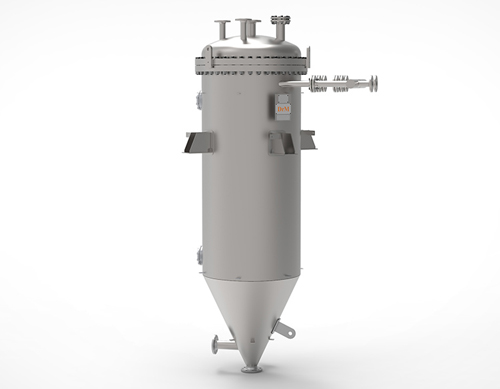

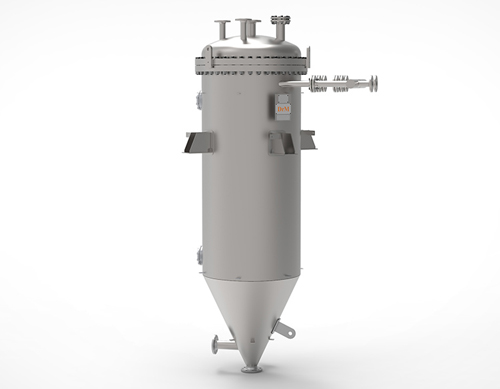

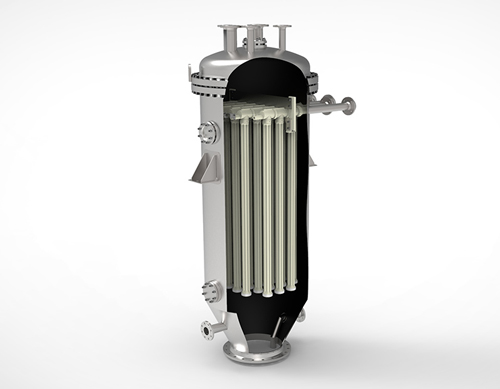

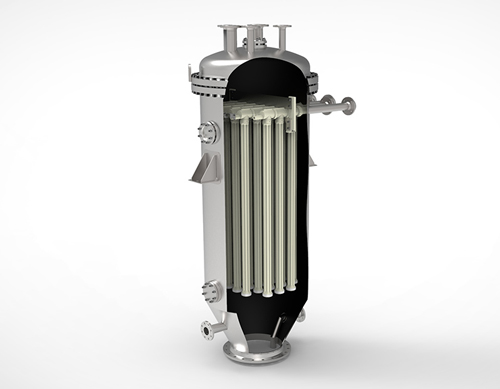

STERIBAC®

-

Candle filtration system for strict regulatory requirements STERIBAC® candle filters are a special execution of the conventional FUNDABAC® candle filter technology specifically targeted to industries where GMP standards are required. These industries have to adhere to strict regulatory agency requirements relating to particle shedding and sterility and require reliably clean and sterile solid-liquid separation steps. Our filtration system features simple modular elements, allowing easy size and volume adjustments in a contained setup. Preassembled modules enable quick product changes, while the absence of moving parts reduces maintenance and operating costs significantly. The system offers seamless automation for all filtration steps, ensuring efficient and flexible operations, even after start-up.

Benefits- A totally enclosed system for high-containment tasks devoid of mechanically moving parts

- Automation of all filtration steps

- Simple, modular construction of the filter elements

- Mobile and flexible design for short production cycles and frequent batch changes

- Dry, slurry or reslurried discharge of sterile solids into a sterilized container

- Washing liquid waste minimization due to the patented spray washing system

- Patented heel volume filtration allows for virtually 100% recovery of both solid and liquid heel and assures batch integrity

- Cake washing allows for recovery of valuable mother liquor and/or discharge of solids without undesired liquid impurities

- Easy SIP, CIP and disassembly of all components for inspection

- Easy handling of filter cake for washing, drying and discharge

- Filter media that are fully compatible with the product

- Used in the production of particulate free injectables

- All connections of the sanitary tubing to meet O-ring sealed GMP flange requirements

- Selection of process-focussed sterile pump and instruments

SU Pinch Valve

- Simple installation with the possibility for multiple valves

A newly developed design allows for on/off control of pressurized single-use tubings in a compact package. The tubing firmly sits in a well-defined, hose size adaptable bed which guarantees uninterrupted operation for many cycles. The valve can easily be installed within a cabinet with only the actuated part being visible.

The valves are perfectly suited to be panel mounted into a control panel. This OEM version is delivered without an enclosure. If required, the valve can also be delivered as a stand alone version with a plastic enclosure. The entire valve component can be easily installed in any direction desired without losing any pinching ability.

Candle filters

CONTIBAC®

-

Clear filtrate at a high flow-rate The CONTIBAC® is a slightly modified FUNDABAC® candle filter used as a continuous filter thickener, producing concentrated slurries. Clear filtrate at a high flow-rate is achieved. As a self cleaning filter, a CONTIBAC® features back-washable filter elements that are flushed back with compressed gas or clear filtrate so that solids get freed into the liquid and the resulting thickened slurry is drawn off intermittently or continuously from the bottom outlet of the filter. This solid-liquid separation process mainly applies when a continuous or semi-continuous flow is required and inlet suspended solids are minimal.

Advantages- Semi-continuous thickening operation

- Clear filtrate at a high throughput rate

- Concentrated slurries without flow interruption

- Unique cloverleaf shaped candle element design

- High solids capture efficiency

- Sub-micron particle retention capability

- Can be designed to work by using filter aid (precoat, body feed) according the needs

- Uniform filter cakes dependably adhere to the filter cloths

- Can be designed to recovery valuable precious metals/catalysts

- Fully enclosed design and automatic operation means virtually no operator intervention or materials contact

- Very low operating costs

- Lab and pilot units readily available for testing under the supervision of trained field service representative

CONTIBAC® RX

-

Clear filtrate at a high flow-rate

In solid-liquid separation processes fine particles are often suspended in large volumes of liquid having a low solids concentration. The large filtration area required to handle such streams is in turn resulting in large filter housings, structures, plant footprints and corresponding high CAPEX and OPEX. The CONTIBAC® RX slurry thickener technology offers a smart solution for these specific cases. The self cleaning filter elements in the CONTIBAC® RX automatic filter is grouping of multiple long and narrow cores in metal or plastic, surrounded by flat synthetic media cloths; elements are positioned in parallel, collectively providing a large filtration surface area in a compact space: roughly speaking, a certain vessel equipped with CONTIBAC® RX internals can fit up to 3-4 times the filter area with respect to the conventional design. Cake is typically only few mm thick, which matches well with the low inlet solid concentration. Both the inner core and the cloths are available in a variety of materials, enabling this technology to fit for a wide range of process conditions (e.g. temperature, chemical composition), which is the distinctive sign of DrM separation systems. During backwashing, the cloth expands similarly to what happens with the traditional FUNDABAC® and CONTIBAC® design, thus resulting in the same, thorough cleaning typical of DrM filters in conventional execution. Suitable applications include any solid-liquid separation process involving high flows, low solids concentration and no requirement for dry discharge.

Advantages- Fully automatic slurry discharge filter

- Small physical footprint due to large media surface area

- Long service life

- Minimal maintenance requirements

- Minimal spare parts and energy requirements

FUNDABAC® Candle Filter

- Efficient solid-liquid separation

The unique cloverleaf shaped candle element design of this tubular pressure filter is at the heart of the self cleaning filter system. This design allows for efficient solid-liquid separation resulting in a polishing grade filtrate while guaranteeing adherence of the filter cake to the cloth throughout the entire filtration cycle, as well as effective and automatic cake discharge. Once the clean filtrate has passed through the filter cloth, it flows into the perforated peripheral tubes and then down to the bottom of the candle, before rising in the central tube toward the registers.

Regardless whether the solids discharge is in slurry or a dry cake form, it is achieved by a rapid counter-current flow and pressure from the inside of the candle. The patented candle structure accentuates the effect of this counter-current flow. A quick-pulse air or nitrogen (gas) blowback results in a rapid flexing of the filter media away from the candle. This breaks the cake away from the filter media, causing it to fall from the candle to the bottom of the filter vessel.

It is perfectly suited for automatic operation via PLC or DCS. This ensures reliable product quality and reproducible batch filtration. It is designed to operate in the absence of any moving parts. As a result, maintenance requirements and costs are extremely low. The use of new synthetic materials, particularly filter internals, contributes to reliable operation and long life of the filters.

Advantages- Unique cloverleaf shaped candle element design

- High solids capture efficiency

- Sub-micron particle retention capability

- Can be designed to work by using filter aid (precoat, body feed) according the needs

- Uniform filter cakes dependably adhere to the filter cloths

- Slurry or dry cake discharge

- Patented heel volume filtration ensures minimal liquid loss

- Can be designed to recovery valuable precious metals/catalysts

- Effective cake washing can be implemented as an additional process step

- Fully enclosed design and automatic operation means virtually no operator intervention of materials contact

- Virtually no operating costs

- Lab and pilot units readily available for testing under the supervision of trained field service representatives

Oscillating Technologies

FUNDAMIX® Vibratory mixer

- Sophisticated mixing by vibration

The FUNDAMIX® mixing system revolutionises conventional mixing methods with its innovative oscillating mixing plate. Unlike traditional rotating mixers, our system employs precise oscillation to achieve thorough blending of ingredients. This unique approach offers several advantages, including reduced shear forces and gentler handling of sensitive materials.

With the ability to customize oscillation patterns and flow direction, the FUNDAMIX® mixer provides unparalleled flexibility and control over the mixing process. Whether used in pharmaceutical, food, or chemical applications, this cutting-edge system ensures uniform mixing while minimizing energy consumption and maintenance requirements. Upgrade to the FUNDAMIX® mixing system today for efficient, precise, and reliable mixing performance.

Advantages- Low shear forces

- No baffles required in the tank

- No rotating mechanical seals

- No lubricant required

- Low installation and maintenance cost

- Low energy consumption

- No vortex

- No friction

- Long service life

- No overheating of liquid

- No damage to life cells or delicate crystals

- Simpler sterilization

FUNDAMIX® Amplitude Monitor

- Precise amplitude readings for FUNDAMIX® Vibratory Mixers

The FUNDAMIX® Amplitude monitor marks a new generation of amplitude monitoring instruments. It measures the distance to an oscillating plate fixed on the shaft of the mixer every 1.5 ms. These values are algorithmically converted into an analog reading shown on an integrated display.

As we are measuring an absolute distance there is no requirement for additional calibration. This allows the instrument to be applied to any FUNDAMIX® Vibratory Mixer equally, irrespective to other influencing factors such as frequency. As the sensor is not fixed to the oscillating part of the equipment it can be applied as a handheld battery-operated device to be easily carried around. This marks a new generation of amplitude monitoring instruments and we are proud to offer this to our clients.

Advantages- Compact size for easy handling

- Lightweight and robust body

- Intuitive Oled display for quick readings

Services

Lab Scale Single-use Systems

- Small tests for big applications

Lab scale tests are a must to investigate basic parameters before scaling up to a full industrial unit, these parameters can include homogenization efficiency, possibility to achieve a shear-free mixing, capability of suspending settling or floating solids, etc.

These smaller systems are also ideal to simulate whole processes such as crystallization, fermentation, heat transfer, or pH control. Our laboratory accessories are available in compact ready-to-use demo sets or can also be custom-made to fit exact application requirements.

Select accessories and units are available in stainless steel, glass or PP, PVDF or similar, adaptable according to the material being processed.

Lab Scale Filtration Systems

- Small tests for big applications

Lab scale tests are a must to investigate basic parameters before scaling up to a full industrial unit, these parameters can include homogenization efficiency, possibility to achieve a shear-free mixing, capability of suspending settling or floating solids, etc.

These smaller systems are also ideal to simulate whole processes such as crystallization, fermentation, heat transfer, or pH control. Our laboratory accessories are available in compact ready-to-use demo sets or can also be custom-made to fit exact application requirements.

Select accessories and units are available in stainless steel, glass or PP, PVDF or similar, adaptable according to the material being processed.

Pilot Scale Filtration Systems

- Compact on-site testing units for compatibility control

Following lab scale testing, some of our clients wish to conduct pilot scale testing at their site to ensure compatibility with actual process conditions. The pilot scale candle filter units are connected directly to the client’s filtration process.

A wide range of pilot filters is offered to meet all possible process requirements. Cake washing, slurry or dry cake discharge and Heel Volume Filtration are available as process possibilities.

The available filter area range of these units is from 0.16 m2 to 50 m2 in surface area. Our pilot filters are available in a wide array of materials of construction and are fully equipped, self-standing units either with manual or fully automatic operation with control system. Most are available from our inventory on short notice.

Lab Scale Mixing Systems

- Small tests for big applications

Lab scale tests are a must to investigate basic parameters before scaling up to a full industrial unit, these parameters can include homogenization efficiency, possibility to achieve a shear-free mixing, capability of suspending settling or floating solids, etc.

These smaller systems are also ideal to simulate whole processes such as crystallization, fermentation, heat transfer, or pH control. Our laboratory accessories are available in compact ready-to-use demo sets or can also be custom-made to fit exact application requirements.

Select accessories and units are available in stainless steel, glass or PP, PVDF or similar, adaptable according to the material being processed.