- Offer Profile

- Efficient processes in the areas of mixing and drying, reacting, evaporating, sterilizing, and granulating for any industry form the core business of the internationally active BHS-Sonthofen company.

Product portfolio

Filters

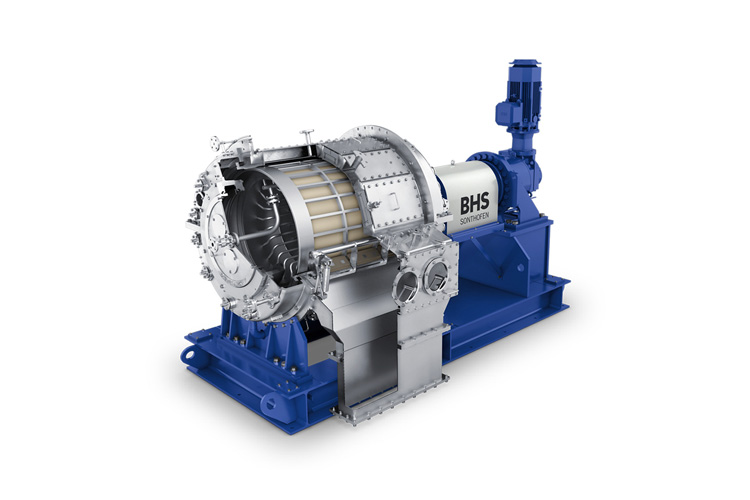

Rotary pressure filter

-

The BHS rotary pressure filter (type RPF) is a continuously operating filter for pressure filtration. It facilitates gas-tight cake handling in a series of separate process steps. Cake treatment can, for instance, comprise single- or multi-stage cake washing and subsequent cake drying. Cake discharge can take place at atmospheric pressure. Application scenarios cover a wide range of industries, including industrial chemicals, fine chemicals, the pharmaceutical industry and the food industry.

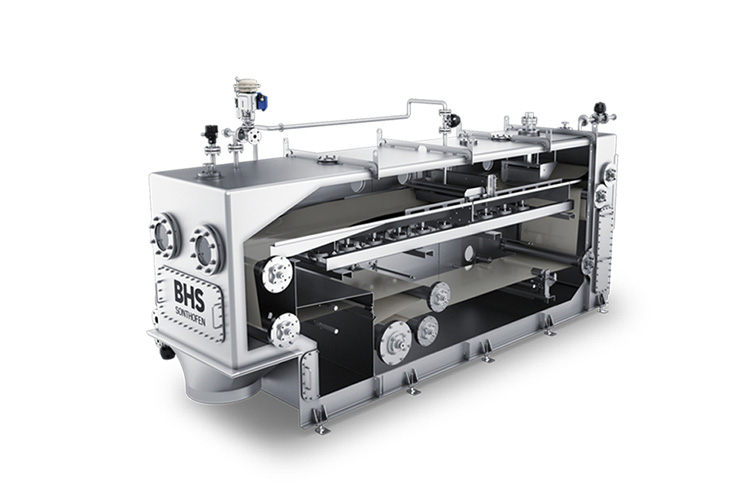

Indexing belt filter

-

The indexing belt filter of type BF is a continuously operating, horizontal vacuum filter used for the efficient and gentle separation of sedimenting solids from suspensions. The filter cake formed on the conveyor belt can be further processed in many ways, and this versatility is what makes the indexing belt filter stand out. Moreover, the individual filtrates can be recovered and processed separately.

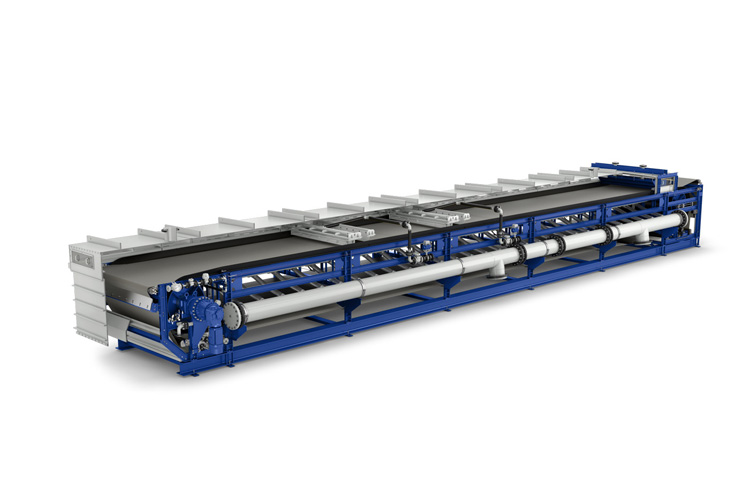

Rubber belt filter

The rubber belt filter of type BFR is a continuously operating, horizontal vacuum filter used for the reliable separation of quickly sedimenting solids from suspensions. It is characterized by high throughput rates and a robust design. Cake treatment involving one or more washing stages is possible.

Candle filter

- The candle filter of type CF is a filter that operates in a discontinuous manner. The candle-shaped filter elements are arranged vertically in a pressure vessel. The process steps typically performed with this unit are filtration, washing, drying and discharge. All these steps take place under pressure. The candle filter is used for the clarification of liquids with a low solids content. It is a compact unit, operates fully automatically and enables high throughput rates, dry cake discharge and a wide range of cake treatment options.

BHS candle filters are available in a standardized range with a variety of modules. 15 sizes with filter areas ranging from one to 87 square meters cover all common applications and market requirements - a flexible and cost-efficient solution for clarification filtration.

Pressure plate filter

-

The pressure plate filter of type PF is a filter that operates in a discontinuous manner. The plate-shaped filter elements are arranged as a plate stack in a pressure vessel. The process steps typically performed with this unit are filtration, washing, drying and discharge. All these steps take place under pressure. The filter is used primarily for cake-forming solid-liquid separation of suspensions with a low solids content that are moderately or very difficult to filter. It is also suitable for adsorptive filtration (as a deep bed or precoat filter). The pressure plate filter is frequently used for clarifying filtration. It is a compact unit, operates fully automatically and delivers high throughput rates.

Dryers

Horizontal Dryers

Horizontal Dryers

-

Many production processes generate water and/or solvent-moist intermediate products that must be dried before further processing, distribution, or disposal is possible. Drying is often carried out in two steps: an upstream, less energy-intensive mechanical method for expelling the main moisture (e.g. filter) and the subsequent thermal final drying. BHS horizontal dryers AVA HTC-T and HTK-T are used in the cellulose industry, as dryers for flame retardants in the chemical industry, and for evaporating high-boiling substances (for example, hydrocarbons) from contaminated environmental industry substances under vacuum conditions.

Benefits at a glance:

- Short drying times

- Adjustable process parameters

- Uniform temperature & product moisture

- Efficient drying of even highly viscous products

- Vacuum & high pressure operation

Short drying times in batch and continuous mode

-

The product fed into the machine comes into direct contact with the heated drying elements (drum, head ends and/or shaft, and shovels) and is continuously shifted by the rotating agitator. Half-pipe coils or double jackets are available for heating the drum. Thermal oil or steam are most commonly used as heating fluid, or an electric heater can be used for high-temperature applications.

The constant circulation along the heated surfaces leads to uniform moisture expulsion and creates a uniform temperature and product humidity in the drying mixer product chamber. Vapors are removed via vapor filter systems specially constructed by BHS. The shape and angle of the shovels ensure optimal heat exchange between product and side wall. Separately driven choppers dissolve lumps, thus resulting in a fine-grained to powdered material consistency. Benefits include very short drying times, which can be further reduced by including a vacuum dryer in the design.s

Vertical Dryers

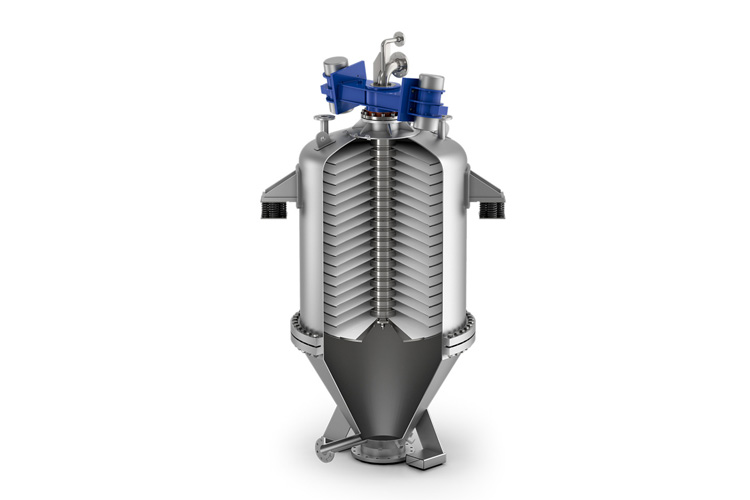

Vertical dryer AVA HVW-T

-

BHS vertical dryer application scenarios range from laboratory to large-scale production, and from highly sensitive pharmaceutical applications to rugged environmental engineering. Customers frequently chose this versatile machine type as the basis for tailored solutions. This is a tiny sample of the possible applications: drying of APIs for the pharmaceutical industry, sterilizing of spices in the food industry, drying of ion exchange resins in the chemical industry, as well as coating of iron powder with additives in metallurgic applications. A multitude of process steps can be implemented using BHS vertical dryers.

Benefits at a glance:

- Short process times with maximum product protection

- Adjustable process parameters

- Uniform temperature and product moisture

- Seal positioned outside the product chamber

- Operation under vacuum and high pressure

Short process times and gentle product handling

- BHS vertical dryers consist of a cone-shaped vessel with mixing helix installed close to the side walls. They were developed for shorter process times with maximum product protection. The mixing helix is a double-threaded (or single) conical spiral that is connected to the shaft via steps. It conveys the product upwards along the heated side wall, after which it sinks downwards again inside the process chamber. This results in a uniform temperature and product humidity across the entire product chamber. To further reduce the drying time, the helix can additionally be heated and a vacuum can be applied. In the convective heating variant, steam or hot air is applied to the mixer interior, and the drying elements can also be heated.s

Mixers

-

The breadth of our product portfolio underscores BHS-Sonthofen’s long-standing expertise in mixing-related process engineering solutions. Moreover, we offer all machines in a horizontal or vertical version, thus meeting all your application needs.

BHS-Sonthofen HTC series batch mixers are optimally suited to variable processes and frequent product changes. BHS-Sonthofen HTK series continuous mixers for continuous operation, from powder mixers to heavy-duty mixers, are ideally suited to large throughput volumes in continuous processes. Variable, multifunctional, versatile – these are the hallmarks of the BHS-Sonthofen HTL laboratory series. High peripheral speeds of up to 50 m/s form the basis of the HRM ring layer mixing system. HVM series conical mixers and conical dryers combine the advantages of a conical vessel, for example, with regard to optimal residual discharge with optimized overall height to fit in existing buildings. BHS-Sonthofen HVW vertical mixers are capable of processing a wide variety of product consistencies and are ideally suited to virtually any mixing operation. Continuous mixer

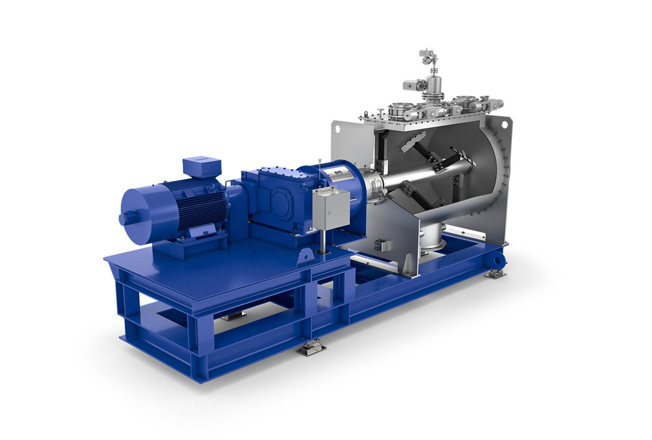

Horizontal mixer AVA HTC / HTK

- Benefits at a glance:

- Intensive continuous mixing process

- Perfect mixing quality

- Further operations such as agglomeration, granulation, coating, or moistening are possible

- Consistently reproducible product quality

- Low-maintenance operation

Vertical mixer

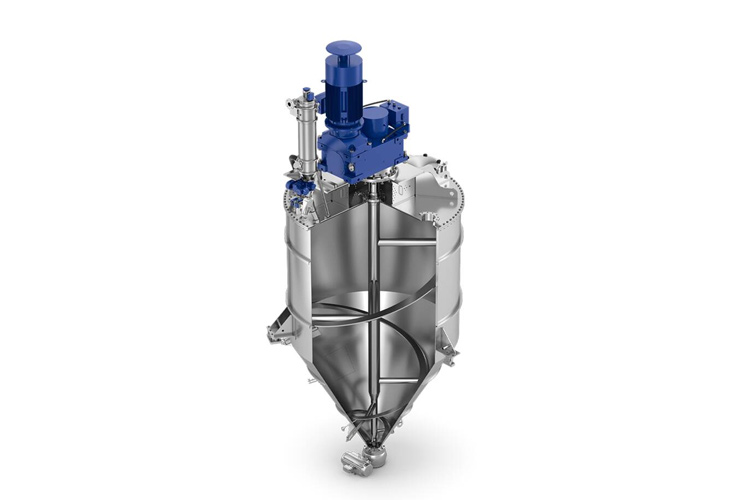

Vertical mixer AVA HVW

-

BHS vertical mixers are in operation across all industries. Depending on your application, they process dry or wet, free-flowing, or sticky products. In the food sector, the gentle production of spice blends is a classic application. In the pharmaceutical industry, BHS vertical mixers are used for the production of APIs, while the production of cellulose is the most common application in the chemical industry. The conical mixers are perfectly suited to nearly any mixing task, and the heated version can also be used as a dryer, reactor, or evaporator.

Benefits at a glance:

- Gentle mixing of delicate materials

- Complete discharge in case of frequent product changes

- Perfect mixing quality

- Easy to clean

- Consistently reproducible product quality

Gentle and thorough mixing

- BHS vertical mixers are capable of processing a wide variety of product consistencies and are ideally suited to almost any mixing operation. The rotating helix conveys the product upwards, along the vessel side wall. From here, it drops down into the center and thus once again joins the mixing process. Horizontally arranged connection bridges provide additional cross mixing. This results in greatly reduced mixing times compared to other systems. Depending on the agitator rotation speed and design, gentle folding or intensive mixing can be carried out. The bearing of the self-centering helix is mounted outside of the mixing chamber. BHS vertical mixers are ideally suited to processes where high purity and effective cleaning are required. The vessel shape also supports quick and optimal discharge.

Industries

- The trust of our customers in everything we say and do is a valuable commodity that we earn anew, every day. All industries have very specific requirements, and we account for these in our custom productions based on our experience and spirit for innovation. Whether chemical or food and feed, pharmaceutical or building materials, power plant engineering or metallurgy, starch, cellulose or environmental engineering: We combine our engineers’ technical expertise with competence in all areas of project management for tailor-made solutions from a single source.

Chemicals

CHEMICALS & BIOCHEMICALS

-

Solutions for the safe separation of substances

Separation solutions from BHS-Sonthofen are the first choice in the chemical industry. Whether in continuous production or in batch operation, our systems deliver high quality and impressive performance. The BHS experts put their decades of experience to work for you, advising you on process planning for a vast range of process steps in the production of chemical products. Together with you, we develop customized solutions for the processes of filtration, drying, mixing and reacting that best meets your application needs.

MINERAL SUBSTANCES & METAL SALTS

- High throughput and minimized resource consumption – this is a central requirement for separation solutions for the production of minerals and zeolites or for the processing of metal salts. Our durable high-performance filters have proven their worth in the chemical industry across the globe.

PLASTICS

-

Reliable production of intermediates

World leader in the production of PTA

BHS-Sonthofen leads the market in this field. A large share of the global production of terephthalic acid, better known as PTA (purified terephthalic acid), passes through BHS filters. Our high-performance filters are used for this purpose across the world.

CELLULOSE DERIVATIVES & STARCH

-

Efficiently gaining natural raw materials of high quality

Top quality

No matter which derivative you produce, such as methyl, micro or carboxymethyl cellulose – when it comes to filtration and washing, our filters offer you comprehensive advantages compared to other technologies. Highest product quality, maximum yield and efficient use of resources characterize our machines.

STARCH

-

Safe and clean functionalization

No matter which derivative you produce, such as methyl, micro or carboxymethyl cellulose – when it comes to filtration and washing, our filters offer you comprehensive advantages compared to other technologies. Highest product quality, maximum yield and efficient use of resources characterize our machines.

DYES & PIGMENTS

-

Efficiency and superior product purity

High-quality paints and pigments are used in various sectors, such as the automotive, cosmetics and pharmaceutical industries. In production, rotary pressure filters (type RPF) and indexing belt filters (type BF) support the necessary process steps of filtration, washing and dehumidification in a single system and deliver high product purity.

CATALYSTS

-

Separating and recovering catalysts

For the complete separation and recovery of catalysts from reaction solutions and suspensions, we offer various filters that enable fully automated and closed processes. Our candle filters (type CF) and pressure plate filters (type PF) have consistently proven their worth in both the chemical and pharmaceutical industries. They thus represent a more efficient alternative to manual and conventional filters.

Pharmaceuticals

ANTIBIOTICS

-

Production of antibiotics

The pharmaceutical industry has set itself the goal of increasing productivity in the production of antibiotics – while at the same time monitoring the quality of the drugs reliably and comprehensively. What was previously difficult to achieve using batch processes has now become possible by drawing on the wealth of experience and process expertise of BHS: Continuous processes offer great potential for increasing yield and improving quality assurance. Solid-liquid separation based on efficient, continuous filtration solutions is the key to achieving this.

NATURAL EXTRACTS

-

Efficient extraction of natural substances

Separation solutions from BHS-Sonthofen have a proven track record across the globe when it comes to the extraction of valuable substances from plant-based raw materials. The high-performance filter systems deliver efficient processes and ensure natural purity and consistent quality of the end product. Our machines are successfully used both in continuous production and batch operation.

PHARMACEUTICAL SUBSTANCES (APIS)

-

Continuous production of active pharmaceutical ingredients

Whether you are producing antivirals, anti-asthmatic drugs, hormone derivatives, orlistats or statins: In the production of active pharmaceutical ingredients (API), rotary pressure filters (type RPF) and indexing belt filters (type BF) are particularly suitable for solid-liquid separation. These filter systems enable continuous processes that demonstrate vast potential for increasing yields and improving quality assurance. At the same time, our filters meet the highest demands as regards product quality, purity and process reliability.

Food & feed

DIETARY SUPPLEMENTS

-

Purity and quality

Whether you’re handling amino acids, vitamins or other additives: Dietary supplements are very sensitive. Our filters ensure gentle production as well as top product purity and quality. Economical operation due to high throughput rates is guaranteed.

COFFEE; TEA AND COCOA

-

Optimal extraction using a rotary pressure filter

Extraction processes for soluble coffee can be significantly optimized by using rotary pressure filters. Manufacturers benefit from higher yields using the same or even less water – and consumers enjoy particularly rich flavors.

SPICES

-

Dynamic Steam Sterilization

Most spices such as chili, pepper, cumin, or others are heavily contaminated with microorganisms. Many sterilization processes affect product characteristics such as taste, smell or color. Since these are important quality features and selling points, effective and gentle sterilization is crucial to establishing a successful product.

Power generation

Power generation

REA GYPSUM

-

Usable building materials

In the treatment of REA gypsum and fly ash, filtration solutions from BHS-Sonthofen ensure a particularly high quality of the respective end product. The use of appropriately treated materials conserves resources and thus helps to protect the environment.

FLY ASH

-

Usable building materials

In the treatment of REA gypsum and fly ash, filtration solutions from BHS-Sonthofen ensure a particularly high quality of the respective end product. The use of appropriately treated materials conserves resources and thus helps to protect the environment.

Battery materials

BATTERY MASSES

-

Processing of anode and cathode materials

High temperature is a critical factor in the processing of high performance anode and cathode materials. BHS has developed a high-temperature reactor, which opens up new possibilities for the production of battery materials. In addition the dynamic BHS drying principle ensures high product and temperature homogeneity - an ideal basis for reaching a higher energy density.