- Offer Profile

- Use our synergies

Eggersmann sets new standards in recycling with its specially developed plants, concepts and products. We excel in a wide array of competencies based on five core areas.

Have the advantage of our all-round line-up and benefit from our profound service from planning to operating your plants and components. Use our synergies for your project.

Recycling Technology - Mobile Machines

- Our machines impress with their performance, their reliability and best results – our brand with its particularly wide product range. At Eggersmann, we offer you machines for all recycling process steps. Thanks to a large selection of different sizes and additional options, you will find exactly the right solution for you.

NEW Crushers and Shredders

IMPAKTOR 250

-

Crushing and Shredding at a low Price

Product Highlights

- Crush or shred!

- Cost-effective solution

- Definable grain size

- Compact transport dimensions

The Eggersmann IMPAKTOR 250 impresses with high throughput rates at an excellent price: For just 162,500 € you can use this robust machine to crush mineral material – especially building rubble and concrete – or shred different kinds of waste.

The Eggersmann IMPAKTOR has excellent transport dimensions and is equipped as standard with tracks as well as a hook lift bracket.The Eggersmann IMPAKTOR 250 can be customised to your application and the desired results with just a few measures. This is possible via different rotor shafts, different screen baskets (alternative to the standard breaking bars) and additional attachments . Rotor Shafts Screen Baskets Attachments

ROKTEC IC 1000

-

Minerals as a Predefined End Product

Product Highlights

- Cubic end product

- Low-wear design

- Large feed area

- High throughput capacity

The Eggersmann ROKTEC IC 1000 is impressive in every respect. The impact crusher is of high quality and yet affordable. Even at high throughput rates, the crusher produces a homogeneous end product with an excellent grain shape for further marketing.

Eggersmann C 14

-

Primery Shredder

Product Highlights

- Shred waste at the source

- Reduce transport costs and CO2 emissions

- Attachment for all container types

- Safety-Box for 1,1 m3 waste containers and dumpsters

FORUS Twin Shaft Shredders

-

In Which Applications can a FORUS Shredder be Used?

The application possibilities of our twin shaft shredders are exceptionally diverse. Due to the asynchronous mode of operation typical for FORUS, even materials that can be wound can be handled without any problems. Here are some examples for which material our FORUS shredders can be used:

- Waste wood or demolition wood

- Green waste and roots

- Household and commercial waste

- Pre-shredded construction and demolition waste

- Paper, cardboard, and paperboard

- Foils

- Mattresses

- Glass

- Photovoltaic modules

- and much more.

FORUS F 25

-

Compact and Powerful

Product Highlights

- Shredding programme individually adjustable

- Asynchronous running shafts against material winding

- Hydraulically lifting and lowering hopper

- Optionally selectable secondary crushing bars for precisely fitting final grain sizes

FORUS F 38

-

The Twin Shaft Shredder for Almost Every Application

Product Highlights

- Shredding programme individually adjustable

- Asynchronous running shafts against material winding

- Hydraulically lifting and lowering hopper

- Optionally selectable secondary crushing bars for precisely fitting final grain sizes

TEUTON Single Shaft Shredders

- All About Our Mobile Single Shaft Shredders: Our TEUTON shredders are not only among the most flexible shredders on the market, they also have extraordinary economic potential. With intuitive operation, outstanding energy efficiency, minimal maintenance and maximum control when defining the final grain size, they offer the opportunity to significantly optimize work processes.

TEUTON Z 50 - The Reliable Universal Shredder

-

The Reliable Universal Shredder

Product Highlights

- Easily exchangeable and robust rotor tools with double screw connection

- Long-life "Marathon" shredding rotor (resistant to contaminants)

- Perfect material feed due to 5 m wide feed area

- Tool-free cutting gap adjustment in six stages

TEUTON Z 60 - The Shredder for Large Quantities

-

The Shredder for Large Quantities

Product Highlights

- Easily exchangeable and robust rotor tools with double screw connection

- Durable "Marathon" shredding rotor (disruptive resistant)

- Perfect material feed due to 4.5 m wide feed area

- Tool-free cutting gap adjustment in six stages

Screening

BLUE SELECT 15.44

- Affordable and Compact

Product Highlights

- Compact transport dimensions

- Adjustable trommel speed

- Quick trommel change

- Powerful drive concept

With its compact trommel from the standard 4 metre class, the BLUE SELECT 15.44 is an affordable entry-level solution for mobile screening of a wide variety of materials.

TERRA SELECT T 50

-

Excellent Screening Performance

Product Highlights

- Above-average sieve drum size

- High separation efficiency and excellent machine availability

- Doubling of the cone of discharge through long discharge belts (option)

- Profiled hopper belt for better material feed (option)

TERRA SELECT T 60

-

First Class Mobile Screening

Product Highlights

- Above-average trommel screen size

- Quick and easy trommel screen change

- Powerful drive concept with low fuel consumption

STAR SELECT S 60

-

The Mobile Solution for Three Fractions

Product Highlights

- Most precise separation accuracy for all three fractions

- Best machine availability due to innovative design

- High throughput rates

- Doubling of the bulk cone due to long discharge belts (optional)

Sifting - AIRFIX V 60

Mobile Wind Sifting Unit - AIRFIX V 60

-

- AIRFIX Wind Sifters

Product highlights

- Suction/pressure blower with 20.5 kW output

- Can be connected electrically or hydraulically

- Adds wind sifting to the screening process

- Efficient and cost-effective solution

Turning Technology

BACKHUS A 30

-

The Entry-Level Solution for Professional Composting

Product Highlights

- Self-propelled – no tractor required

- Compact transport dimensions for inter-site use

- Rotor adjustable under load; direction of rotation reversible

- Track clearer with automatic ground contour adjustment

- Rubber tracks with high traction

BACKHUS A 38

-

The Compact Turner With Many Advantages

Product Highlights

- Height-adjustable and reversible rotor

- Track clearer with ground contour adjustment

- Eggersmann TRACK Control

- Panoramic cabin

BACKHUS A 45

-

The Powerful Mid-Range Solution

Product Highlights

- Height-adjustable and reversible rotor

- Track clearer with ground contour adjustment

- Eggersmann TRACK Control

- Panoramic cabin

BACKHUS A 50 / A 55

-

The Standard Machines

Product Highlights

- Height-adjustable and reversible rotor

- Track clearer with ground contour adjustment

- Eggersmann TRACK Control

- Panoramic cabin

BACKHUS A 60 / A 65

-

Windrow Turning With Tremendous Performance

Product Highlights

- Height-adjustable and reversible rotor

- Track clearer with ground contour adjustment

- Eggersmann TRACK Control

- Panoramic cabin

BACKHUS A 75

-

The Most Powerful Compost Turner

Product Highlights

- Height-adjustable and reversible rotor

- Track clearer with ground contour adjustment

- Eggersmann TRACK Control

- Panoramic cabin

BACKHUS CON 60

-

Automated Turning With Membrane

Product Highlights

- Automated winding and unwinding

- Automated transfer

- Proven BACKHUS technology

- Virtually closed system

BACKHUS CON 80

-

Automated Turning With Membrane

Product Highlights

- Automated winding and unwinding

- Automated transfer

- Proven BACKHUS technology

- Virtually closed system

BACKHUS CON 100

-

Automated Turning With Membrane

Product Highlights

- Automated winding and unwinding

- Automated transfer

- Proven BACKHUS technology

- Virtually closed system

LANE TURNER LT 30

-

The Turner for Closed Facilities

Product Highlights

- Fully electric

- Fully automated process possible

- Safe process with aggressive material

- Designed for perfect emission control

LANE TURNER LT 45 / LT 50

-

The Turners for Closed Facilities

Product Highlights

- Fully automated process possible

- Safe process with aggressive material

- Designed for perfect emission control

- High turning capacity

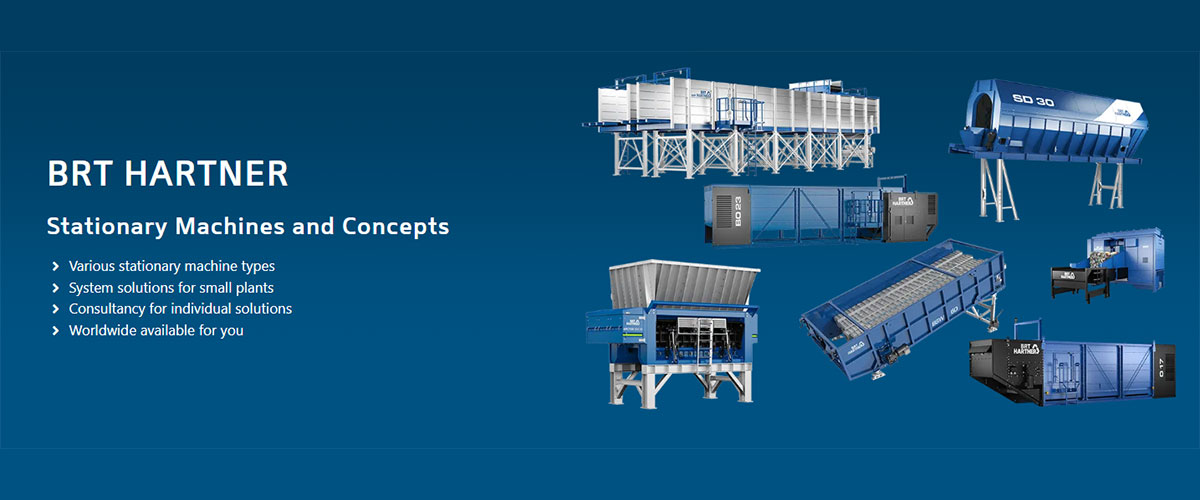

Stationary Machines and Concepts

- With over 30 years of experience, we at BRT HARTNER are your first partner stationary recycling machines for mechanical processing and material recovery.

BRT HARTNER Opening Systems

- The correct opening is the basic prerequisite for efficient processing and sorting of the input material. We offer a wide range of solutions for the most diverse applications.

BRT HARTNER BO

- Bag Opener

- The Bag Opener with integrated Feed Hopper opens and empties bags.

Product Highlights

- Virtually 100% opening and emptying of bags

- Suitable for a wide range of materials

- High opening rate of "bags within bags"

- Entangle protection against strings, wires and foils

BRT HARTNER BOS

- Bag Opener for Small Plastic Bags

- For the application with biowaste: Efficient opening of small plastic bags and sacks.

Product Highlights

- Virtually 100% opening of small bags

- Low purchase costs

- Extremely robust and wear-resistant

- Ready-to-connect design

BRT HARTNER EWD

- Electric Waste Dismantler

- The Dismantler breaks open plastic housings and casings of electric and electronic appliances.

Product Highlights

- Suitable for electrical household appliances

(vacuum cleaners, kitchen appliances, lawn mowers, etc.) - No risk of injury for sorting personnel

- Low dust generation

- Low energy consumption

BRT HARTNER BD

- Bale Dewirer

- The Bale Dewirer removes wires from pressed bales.

Product Highlights

- Mechanical dewiring of bales

- Compaction of the wires

- Replaces heavy and dangerous manual dewiring

- For bales of plastic, film, PET bottles, paper, etc.

BRT HARTNER PS/PD

- Perforator

- The PET perforator enables plastic bottles to be pressed.

Product Highlights

- Perforation rate > 95

- Throughput capacity up to 160 m³/h

- Can be used for containers from 0.5 to 5 liters

- Reduction of the material volume by > 30%

Dosing Systems

- A homogeneous material flow is crucial for the effectiveness of a recycling system. With the rigth feeding and dosing machines in the correct places, you can ensure optimum overall system efficiency.

BRT HARTNER BB

- Bale Breaker

- The Bale Breaker breaks up compressed bales of PET bottles, waste paper, residual waste, plastics and many other recyclable materials.

Product Highlights

- Efficient opening of bales and loosening up of material

- Even and continuous material discharge

- Infinitely adjustable throughput rate

- Large feed hopper for long feeding intervals

BRT HARTNER D

- Feed and Metering Hopper

- BRT HARTNER D Feed and Metering Hoppers are designed for buffering (storing) as well as for continuous and even feeding of the most different material types.

Product Highlights

- Loosened up and even material feeding to sorting and recovery units

- Minimal risk of entangling with strings, long films and tapes

- Efficiency boost of as much as 20% compared to common feeding methods

BRT HARTNER MF

- Moving Floor Conveyor

- The Moving Floor Conveyor can funnel all kinds of material, no matter if it is light, heavy, moist, sticky or abrasive.

Product Highlights

- Modular design for any size

- High load capacity and insensitive to impact loads

- Adjustable conveying speed

- Easy integration into existing material hoppers

BRT HARTNER DC

- Decompactor with Scrape Chain Conveyor

- The Decompactor with integrated Scrape Chain Conveyor DC by BRT HARTNER serves the loosening of material and its dosed discharge.

Product Highlights

- Designed for heavy, biological material with a high share of fines

- Pendulum suspension of the decompaction rollers to avoid blockages

- Breaking up bridging and intense loosening

- Exchangeable tools on the decompaction rollers

Digestate Mixer

- The BRT HARTNER DM Digestate Mixer prepares digestate, sewage sludge or similar materials for aerobic treatment or the subsequent composting process. For this purpose, these almost structureless materials are mixed with structure-forming materials such as green waste, raw compost or screen overflow.

BRT HARTNER DM

-

Mixing unit for the pre-treatment of digestate, sewage sludge, etc.

Product Highlights

- Driven swivel device for the mixing unit to increase availability

- Available in two versions - filling by belt conveyor or by wheel loader

- Easy retrofitting in existing systems

- High throughput capacity combined with high durability

Sorting Systems

- Weight, density, size, dimensionality – recycled material has a wide range of properties. With our sorting systems, you can use these properties for optimum separation into different fractions of high purity.

BRT HARTNER BS

- Ballistic Separator

- Ballistic Separator for multi-fraction separation of packaging materials, household, commercial and mixed construction waste.

Product Highlights

- Different lengths and working widths for different throughput capacities

- Three machine types for three special types of application

- Unique straight shafts with individually exchangeable eccentric bearings

- Exchangeable screen grid plates on the paddles

BRT HARTNER BPS

- Waste Paper Separator

- Ballistic Separator for separating cardboard and cardboard packaging from waste paper and for fine screening of impurities from mixed paper.

Product Highlights

- Straight shafts with eccentric bearings

- Robust, changeable bearings

- Adjustable screen holes

- Wide range of variants for every application

BRT HARTNER SD

- Screen Drum

- Screening Drums separate the material into fractions of different sizes.

Product Highlights

- Extremely sturdy construction design of tscreen drum and frame

- Screen hole size up to max. 300 mm, optionally rectangular or round

- Entanglement protection with flat bars or tube sleeves

- Screwable, exchangeable screen elements

BRT HARTNER ST

- Trommel Screen

- Trommel Screens ensure the separation of oversized particles in compost, wood chips or soil.

Product Highlights

- High throughput with optimum separation quality

- Emptying of torn bags

- Extremely easy to maintain

- Screening of fines

BRT HARTNER SC

- Disc / Rotor Screen

- The Coarse Screen separates mixtures of cardboard and waste paper into a cardboard fraction and a mixed paper fraction.

Product Highlights

- Loosened up and even material feeding to subsequent sorting

- Impervious to disruptive material

- Dynamic adjustment of the screen cut

- Easy integration into existing systems

BRT HARTNER SF

- Disc / Rotor Screen

- The Fine Screen separates cardboard and waste paper mixtures into a cleaned mixed paper fraction and a fine fraction.

Product Highlights

- For optimal subsequent treatment of mixed paper fraction

- Efficient screening of disruptive materials and small parts

- Dynamic adjustment of the screen cut

- Cost-effective and durable

BRT HARTNER STS

- Star Screen

- The Star Screens are primarily used for organic materials such as compost, wood chips or bark mulch.

Product Highlights

- Extremely high throughputs with maximum separation quality

- Split-Speed system for homogeneous material carpet

- Separation rates of up to 90% (depending on material)

- QuickChange system

BRT HARTNER BBS

- Wind Sifter

- The stationary Wind Sifter / Air Belt Separator separates the material into a light and a heavy fraction.

Product Highlights

- High recovery rate of light fraction

- Numerous adjustment parameters

- Optimal separation result with different materials

- Integrated filter unit

Stationary Shredders

- Shredding the recyclingmaterial is beneficial for you in many ways. A homogeneous material size enables a uniform material flow in your system and reduces the volume. Sorting is also simplified in many cases.

ARCTOS BM 21

- Compact High-Performance Shredder

Product Highlights

- Particularly Fine Preparation

- Compact Dimensions

- High Throughputs

- Screwed Wear Elements

BRT HARTNER ARCTOS BM 36

- Pre-Shredder

- Powerful shredder for private and municipal waste like biomass oder lightweight packaging

Product Highlights

- Particularly fine processing

- High throughputs

- Screwed wear elements

- Simple feeding

BRT HARTNER ARCTOS OM 36

- Pre-Shredder

- Powerful shredder for light metal scrap, domestic and commercial waste as well as special applications

Product Highlights

- High throughputs

- Screwed wear elements

- Resistant to impurities

- Simple feeding

Shredding

Eggersmann TEUTON ZS 50

- Single Shaft Shredder

- Universal shredder with 2 x 160 kW

Product Highlights

- Easily exchangeable and robust rotor tools with double screw connection

- Long-life "Marathon" shredding rotor (resistant to contaminants)

- Perfect material feed due to 5 m wide feed area

- Tool-free cutting gap adjustment in six stages

Eggersmann TEUTON ZS 55

- Single Shaft Shredder

- Universal shredder with 2 x 160 kW

Product Highlights

- Easily exchangeable and robust rotor tools with double screw connection

- Durable "Marathon" shredding rotor (disruptive resistant)

- Perfect material feed due to 4.5 m wide feed area

- Tool-free cutting gap adjustment in six stages

Eggersmann FORUS FS 25

- Twin Shaft Shredder

- Shredder with 186 kW for bulky, brittle and spherical material

Product Highlights

- Shredding programme individually adjustable

- Asynchronous running shafts against material winding

- Hydraulically lifting and lowering hopper

- Optionally selectable secondary crushing bars for precisely fitting final grain sizes

Recycling Plants

-

Eggersmann Anlagenbau is your expert for the implementation of complex plants for waste processing.

General Contractor for Waste Management Solutions- Planning, new construction, retrofitting, modernization and optimization

- Many years of experience

- Machines from own production

- Wide range of solutions

Mechanical Treatment

-

Mixed or pre-sorted industrial and commercial waste contains raw materials that can be recovered by means of mechanical processing. Mechanical recycling equipment supplied by Eggersmann separates recyclable waste by composition and particle size to deliver the recovered raw materials in a particularly effective and efficient way, in accordance with application and material requirements.

The Art of Correct Waste Treatment

The size of each plant system is based on a detailed analysis of the substances being handled and the required quantities of recycled raw material. High-performance components developed by us in house guarantee maximum purity, reliability and fine-tuned capacity as required.

The entire design and setup procedure is placed in the expert hands of our highly-qualified, multi-disciplinary team.- Pure recyclable fractions

- Homogeneous material flow

- High system availability

- Efficient processes

Biological Treatment

Procedure for the treatment of organic waste

Effective Utilisation of Organic Waste- Solutions for drying, composting and fermentation

- Different approaches

- High compost and biogas yields

- Highest compost purities

Aerobic Waste Treatment

According to the name, aerobic waste treatment is a process in which the biological decomposition of organic waste takes place using oxygen from the ambient air. We offer various options for this:

Processes - The Right Solution for your Requirement

Lane Composting - LANE TURNER LT

- The Turner for Closed Facilities

Product Highlights

- Low energy requirement

- Easy lane change

- Perfect odor control

- Batch or flow through process

The LANE TURNER LT are lane turners for working in open, high lanes. They are the perfect solution for turning in closed buildings.

Tunnel Composting

-

Tunnel composting is even profitable with low input quantities. By increasing the modular tunnel units it can also be used for very large throughput quantities.

Tunnel composting is suitable for aerobic treatment of bio waste and mixed household and kitchen waste as well as for composting of digestates of an upstream fermentation system. As part of the nutrient cycle of heterotrophic microorganisms, which disintegrate organic material in a controlled environment under the influence of atmospheric oxygen (aerobic) and transform it to water-soluble minerals and humus-rich compost in several intermediate steps, the composting process is significantly dependent on the process parameters oxygen, moisture content and temperature.

Windrow Composting - BACKHUSWindrow Turners

- The Choice for Professional Composting

The widest range of machine widths for every application, the most comprehensive standard equipment and the best range of optional customization options make us the first choice on the market. Coupled with almost 40 years of experience, expert advice and excellentservice, today our Eggersmann BACKHUS stand for professional turning all over the world.

Drying With Membrane

-

Biological drying stabilises the material, increases the calorific value (substitute fuel), reduces the volume and simplifies the separation of different components.

The CONVAERO drying system provides a controlled and monitored environment in which the micro-organisms decompose organic material under the specially developed CONVAERO membrane cover. An aeration system in the base provides a steady flow of air through the waste to remove moisture while maintaining sufficient heat for water evaporation. This utilises the natural process heat generated by the microorganisms present in the waste during the decomposition of the organic material. The temperature in the waste pile can thus rise to 60 to 70 °C. The water is efficiently evaporated without additional heat input. After a drying process lasting from two to four weeks, the rest of the waste is a dry (≤ 20% moisture), odourless and stable mixture that is safe to handle and easy to separate.

Membrane Composting

-

Oxygen supply, temperature, moisture - the CONVAERO system creates optimum conditions for the microorganisms required for composting.

The CONAVERO membrane creates a controlled and monitored environment in which the microorganisms decompose the organic matter. The aeration system integrated into the base provides a steady flow of air through the waste to maintain aerobic conditions, creating an ideal environment for the composting process. The temperature rises to 55 - 65°C and ensures reliable hygienisation of the compost.

Depending on the composition of the input material, the ambient temperature and humidity, the logistics on the plant and any preceding and subsequent processes, the CONVAERO process and its capacity are adjusted to the desired degree of maturity (degree of rotting). Every product stage can be achieved, from fresh compost to fully matured compost. The material is covered for the entire duration of the process. Alternatively, it is possible to remove the covers during the later stabilisation and maturing phase.

Dry Fermentation

-

Reliable Generation of Sustainable Energy

- High degree of automation

- Robust and simple processes

- Modular concept

- High biogas yields

Only a fraction of the energy generated flows into the plant's own energy consumption. Together with the high biogas yield, this makes the process particularly efficient.

- Waste always accumulates, which makes our processes reliable and constant. Consequently, energy production is not volatile, like solar or wind energy, for example.

- Biogas can be easily stored and is therefore used to cover peak loads

- As the volume of waste increases, our modular plants can easily be expanded with additional fermenters

- Free choice between conversion to electricity or upgrading to biomethane in natural gas quality or fuel (Compressed Natural Gas (CNG) or Liquefied Natural Gas (LNG))

- Power generation produces exhaust heat that can be used as local or district heating

- Regardless of the regional or seasonal ratio of biowaste and household waste, the batch process allows the batches to be processed in a way that is suitable for each other

- The energy is obtained from renewable, as organic waste – the processes are thus absolutely sustainable

- With organic waste as input, a high-quality compost is produced in a second process step

- Single-stage and highly automated work processes

BEKON is the only supplier to offer either a continuous or discontinuous process to suit customer requirements.

Discontinuous Process

-

Discontinuous fermentation is a safe and biologically stable process. All processes within the fermenter run completely automatically.

It is a single-stage process, the fermenters are filled either with a wheel loader or automatically using a tunnel feeder. All processes within the fermenter run automatically as standard. By feeding the tunnels at different times, an constant energy supply is guaranteed. To start the fermentation process immediately, the substrate is heated in an aerobic start phase and then inoculated with process liquid (percolate). No further mixing or feeding of additional substrate is necessary, as the fermenter is a closed circuit. The cell liquid that escapes during the process is collected by a drainage system, fed to the percolate fermenter and sprayed back into the fermenter from there. At the same time, wall and underfloor heating systems ensure a constant temperature so that the microorganisms involved in the process have perfect living conditions at all times. The fermenters are then emptied using a wheel loader.

Continuous Process

-

Continuous fermentation is a robust process in which particularly large quantities of biogas are constantly produced. Pre-shredded biomass is fed into the digester by means of a feeding screw, where it decomposes into a liquid slurry under anaerobic conditions.

As only the process water contained in the biomass is used for liquefaction in this process, it is a dry fermentation process – for wet fermentation, additional water must be added. In the fermenter, the material is regularly mixed by paddle agitators , thereby stimulating the exchange of substances and the release of gas. Mixing mainly takes place vertically in order to avoid the formation of layers of sinking and floating components. The substrate is optimally homogenised by the paddle agitators and uniform fermentation is achieved. The finished fermented substrate is discharged using a digestate pumping system. Exactly as much fresh biomass is added to one end of the elongated fermenter as fermentation residue is removed from the other end. As a result, the substrate automatically moves from the input to the output, creating a continuous fermentation process with a particularly high biogas yield.

Substitute FUEL

- The Superior Alternative to Landfilling

- Higher net calorific value

- Utilisation of the biomass

- Complete solution for RDF

- 80 % less landfill mass

The core of the Eggersmann FUEL process is biological drying using the CONVAERO system. This is installed before the usual mechanical treatment. The proven and robust process is designed to treat both small and very large quantities of waste. In addition, the standardised process allows affordable waste treatment also in countries, where landfilling or dumping of waste still is the main or only disposal method. The mass to be landfilled is reduced to only 20 % of the original waste and emissions from the uncontrolled decomposition of the organic fraction are avoided. Fossil fuels can also be saved.

Service for Recycling Plants and Components / General Contractor Recycling Plants