- Offer Profile

- VOGELSANG -GERMANY'S INNVOATION LEADER

Cutting-edge technology for agricultural technology, biogas, industry, transportation and wastewater

Solutions for Agriculture, Biogas, Industry, Transportation and WastewaterVogelsang GmbH & Co. KG develops, produces and distributes highly-engineered equipment that is easy to maintain. The head office is located in Essen/Oldb. in Lower Saxony, Germany. Founded in 1929 as a manufacturer of agricultural machinery, the company has grown to become a specialist in individually configurable machines, plants and systems for the agricultural, biogas, industrial, transportation and wastewater sectors.

ENGINEERED SOLUTIONS FOR HIGHLY VISCOUS AND ABRASIVE MEDIA

-

Robust and powerful industrial pumps and macerators

Whether in the gas and oil industry, the chemical industry, the food sector, or recycling – efficient and safe pumping of abrasive, aggressive or highly viscous media remains a major challenge in the transport and disposal process. Depending on the industry, it is important to do more than just ensuring a safe, trouble-free process. The pump technology must be adapted to the respective medium. While grapes must be transported to production in the best possible condition, packaging waste must be macerated before it is forwarded to make it pumpable. Rubber solutions, paints or detergents require particularly high suction power, while contaminated media or media with high solids content can push pumps and macerators literally to breaking point.

The pump and shredding technology used in the industry must therefore not only be extremely high-performance and low-maintenance, but also flexible and equally gentle and resistant. The elastomer-coated rotary lobe pumps invented by Helmut Vogelsang in 1970 owe their excellent reputation to their compact design and low maintenance requirements. The pumps operate pulsation-free, despite their high power. This protects the mechanical components and increases their lifetime. Add to this the company's experience and history of innovation. As a solution-oriented partner, Vogelsang always manages to develop new, application-specific pumps and machine combinations that meet changing customer requirements. Equally carefully tailored shredding technology supplements a product line that covers the widest possible range of functions and economy. EFFICIENT AND RELIABLE TECHNOLOGY FOR WASTEWATER PURIFICATION

-

Reduce costs for your sewage treatment plant and sewage system using the right technology

Safe and reliable disposal of wastewater, i.e. the detection, treatment and purification of municipal and industrial wastewater, is becoming more and more important for the protection of waterwaysand the environment, but also for sustaining quality of life. Municipalities, wastewater associations and private operators of sewage treatment plants and sewage networks are being confronted with a wide range of requirements and specifications designed by legislators to ensure the drinking water of tomorrow stays clean. To avoid the entry of noxious substances, heavy rain events need to be safely handled and the reliable drainage of wastewater ensured at all times. Heavy rain incidents need to have as few effects as possible on the quality of wastewater purification and the Wastewater Ordinance needs to be observed at all times to prevent contamination of waters and the environment. In addition surface water and wastewater need to be detected and sewered separately where possible. Wastewater should be discharged via the sewage system, and wastewater treatment in the sewage treatment plant also needs to be as energy-efficient as possible while conserving resources. Organic loads need to be decomposed, with nitrogen and phosphate safely eliminated. At the same time the focus is on heavy metals and trace elements, as well as chemical and pharmaceutical residue in the wastewater. The requirement to separate microplastics in the future and recover valuable phosphates is presenting yet more, new requirements for sewage technology.

At the same time demographical changes and changes in living habits are influencing wastewater collection and purification. Above all there is the wish to keep the costs for wastewater removal and purification as low as possible, and ideally to reduce them. Consequently wastewater technology needs to be developed and adapted on a continuous basis, incorporating the latest knowledge into building new systems for wastewater treatment and purification, along with expanding and upgrading existing systems so that water is purified as best as possible, ensuring the ground is stressed as little as possible.

Vogelsang has been a reliable and innovative partner for wastewater technology for decades. We offer our customers efficient components such as wastewater pumps, slurry pumps, grinders and disintegration systems for the economically efficient operation of sewage networks and sewage treatment plants. Every single one of our products is designed for economical, reliable operation. Coupling together several machines and optimal coordination of individual components using intelligent control technology enables us to provide efficient system solutions for individual problems.

BIOGAS PLANTS: FLEXIBLE PRODUCTION OF RENEWABLE ENERGY FROM BIOMASS

-

Biogas technology uses environmentally friendly natural processes

Objectively, biogas is considered a flammable byproduct of the anaerobic fermentation of organic matter. Biogas is one of the most flexible elements in the mix of renewable energies. It can be stored in the form of heat or electricity so that the energy can be used when it is needed. This flexibility makes biogas an ideal supplement to solar or wind energy, which both fluctuate in reliability and are difficult to regulate.

Vogelsang provides reliable components for the economic production of biogas. From pump technology to maceration, disintegration technology and solid matter feeding systems, Vogelsang offers a comprehensive portfolio of biogas technology for the entire range of fermentation. This is why we see ourselves as partners in the biogas sector. Together with our customers, we are continuously developing our biogas technology, adapting it to ongoing changes in the underlying conditions to deliver solutions for the efficient production of biogas. An important aspect of this is the individual analysis of every single biogas plant. This is the only way to find and fully realize potential for optimization.

SERVICE, WATER SUPPLY, AND WASTEWATER DISPOSAL FOR BUS, RAILWAY, AND BOATS

-

Vogelsang service equipment—From pump systems and cleaning cabinets to online monitoring

In Germany alone, roughly 150 million people use long-distance trains or buses to travel from A to B every year1. Europe-wide, more than 9 billion passengers boarded trains in 20152. The logistical achievement behind this is immense—and that includes the drinking water supply to buses and trains and disposal of their wastewater. In addition to the fundamental investment in technical installations for supply and disposal, all kinds of national and international regulations need to be observed for hygienic reasons. This is a tight regulatory framework that the manufacturers of the corresponding equipment components can only master with in-depth expertise.

As a main supplier of major tran operating companies, Vogelsang is a market leader in the train car service sector in Germany, with decades of experience to look back on. Vogelsang's range encompasses not only the systems for supply and disposal of water and for interior cleaning, but also operating data management and system monitoring. We also offer corresponding systems for buses and boats as well.

LIQUID MANURE TECHNOLOGY - FROM THE ROTARY LOBE PUMP TO THE STRIP TILL DEVICE

-

Efficient liquid manure spreading and liquid manure management

Liquid manure is an important resource for agriculture. Used correctly, it brings with it distinct economic benefits. Though improved liquid manure technology comes at a price, it enables huge savings. Why? The more uniformly liquid manure is deposited on or in the ground, the better the nutrients it contains can be utilized since emissions are minimized. Farmers, corporate contractors and machine syndicates can significantly reduce outlay on mineral fertilizer using this natural source of nutrients. Using the full range of agricultural technology by Vogelsang will ensure low-emission application of liquid manure is more successful even under the most demanding conditions.

For several decades now, Vogelsang GmbH & Co. KG has been committed to liquid manure technology. Time and time again we have set new benchmarks for low-emission spreading, thereby enabling our customers to use the nutrients contained in liquid manure efficiently and hence optimize their operating costs. Consequently, we have contributed considerably to their economic success. Incorporating ongoing developments and innovations in our techniques means we are in a position to act as your professional partner – from tanking to spreading. For we know only too well that efficient liquid manure management with ground-level spreading saves costs while at the same time preserving the environment. In order to support our customers in achieving their economic goals as best as possible, we offer a broad portfolio of products in the areas of pump, shredding and spreading technology.

Pump technology for every application

-

The right pump for the right application

Whether you need to pump liquid manure loaded with foreign matter out of a pit, organic suspension into the digester, or aggressive chemicals: Vogelsang pumps are resistant to foreign matter, can convey highly abrasive media, and they are impressively easy to maintain. Thanks to their exceptional power they can convey media from 1 m3/h to more than 1,400 m3/h at differential pressures of up to 16 bar.

As one of the leading producers of positive displacement pumps, Vogelsang offers customers a variety of application-oriented solutions.

VX SERIES

-

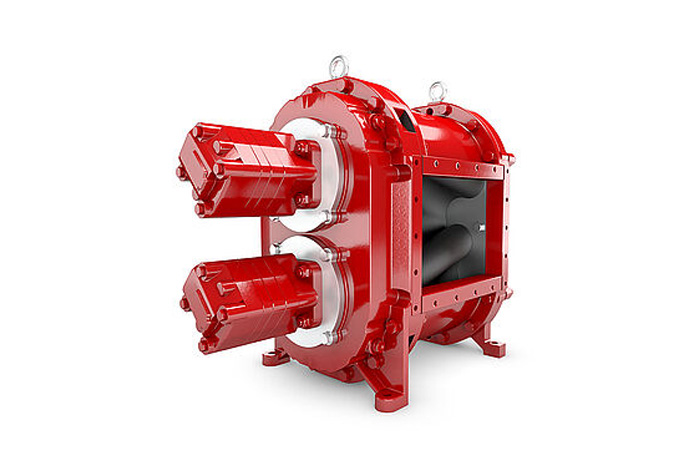

The adaptable rotary lobe pump for task-oriented pumping

The VX series- Comprehensive range of features and options

- Quick access to the pump chamber by removing the cover

- Simple service and maintenance

- Self-priming and dry-running resistant

- Shaft warranty

IQ SERIES

-

Service and handling made even easier

The IQ series- Quick and convenient access to pumping elements

- Intelligent, integrated foreign matter handling

- Excellent suction capacity and integrated dry running protection

- Significantly reduced spare parts costs

R SERIES

-

Thousandfold proven pump technology for yard and field

The R series- Keep it simple: Economic solution with all necessary functions

- Ideal for both occasional and simultaneously reliable use

- Self-priming and resistant to foreign matter

- Smooth running thanks to sophisticated rotary lobe design

- Axial wear plates for maximum protection of the pump chamber

- Flexible use thanks to different drive types

VY SERIES

-

The new design for any situation

The VY series- Keep it simple: Economic solution with all necessary functions

- Ideal for both occasional and simultaneously reliable use

- Self-priming and resistant to foreign matter

- Smooth running thanks to sophisticated rotary lobe design

- Axial wear plates for maximum protection of the pump chamber

- Flexible use thanks to different drive types

FX SERIES

-

Proven liquid manure pump that offers you more

The FX series- Comprehensive range of features and options

- Quick access to the pump chamber by removing the cover

- Simple service and maintenance

- Self-priming and dry-running resistant

- Shaft warranty

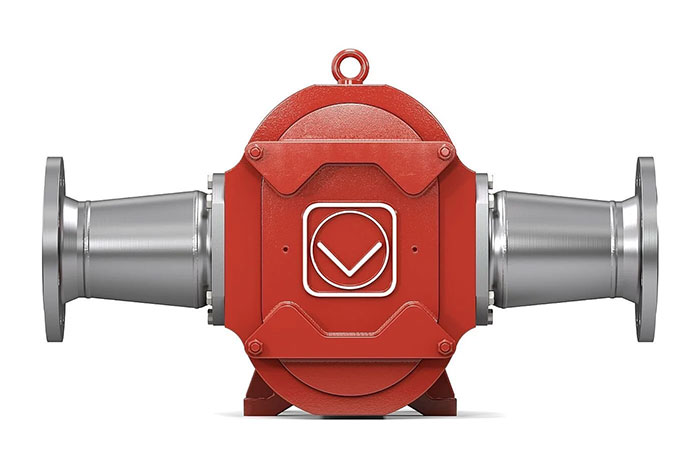

EP SERIES

-

For maximum performance under extreme conditions

The EP series:- High differential pressures of up to 18 bar are possible

- Incomparable running smoothness due to high performance gearbox

- High efficiency thanks to the one-piece housing

- AirGap to protect the gearbox in the event of leakage

- Alternative seals per industry standards and customer requirements

- Quick connection for higher flange loads and easy maintenance

LoadMaster

-

More compact and lightweight than ever before

The LoadMaster- Up to 45 % less weight

- Significant space savings thanks to compact design

- Lower power consumption and therefore lower energy requirements

- Unmatched maximum smoothness thanks to new synchronization discs

- Up to 4 times longer service life of the seal package thanks to sophisticated

- Geometry of the protective plate

Wine pump

-

Rugged, yet sensitive pumps for minimal technical impact on the grape

The wine pump- Gently moves grapes and wine without shaking and creating foam

- Reduced oxygenation of wine to maintain flavors intact

- Self-priming and able to operate under dry conditions

- Portable and stationary options

- Pulsation-free during operation

- Space-saving, flexible use

- Quick access to pump compartment by removing cover

- On-site assistance and maintenance

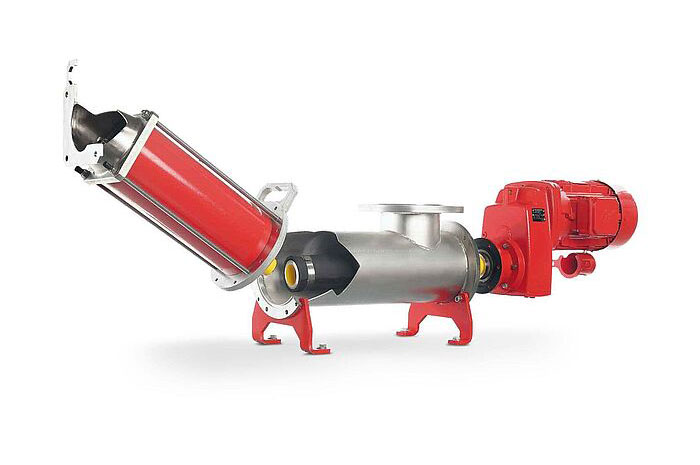

PROGRESSIVE CAVITY PUMP

CC SERIES

-

The progressive cavity pump with quick and easy service

CC series- Easy and quick to service with minimal space requirements

- No disassembly of the discharge-side and suction-side pipes necessary

- Variety of options for changing parts

- The Quality Cartridge mechanical seal can be changed without opening the pump

- Sturdy cardan shaft with protective sleeve

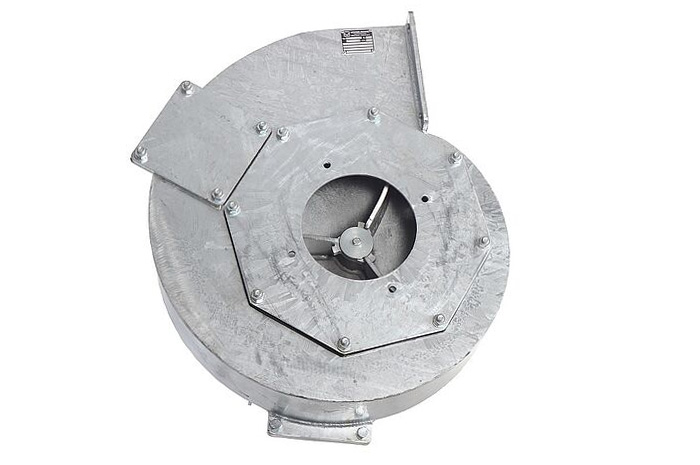

CENTRIFUGAL PUMPS

POWERFILL

-

TURBO FILLER FOR VACUUM TANKERS PowerFill

- Up to 30% less filling time of the tanker with a vacuum system

- Full utilization of the transport volume via complete filling

- More precise spreading of liquid manure due to homogenization

- Simple to retrofit

PUMP SYSTEMS FOR SPECIAL CASES

-

Innovative pump technology squared

Some pumping processes require additional functions. But generally, this leads to problems relating to issues of space, installation possibilities etc. With pump systems from Vogelsang, our customers benefit from powerful pump technology combined with that certain something extra.

- Combinations of cutter and pump: Designed specifically for the biogas sector, our pump systems consisting of a macerator and rotary lobe pump (BioCut) or progressive cavity pump (CC- Cut) can shred, pump and separate out foreign matter in a single process.

- Filling liquid manure tankers: We developed the FillMaster systems for optimum tank filling in agricultural operations, biogas plants or in liquid manure storage facilities. The effective solution for the liquid manure chain, with trouble-free filling at any location.

- Pump for the wine industry: The Vogelsang wine pump was developed specifically for the wine industry. The all-in-one system is ready for immediate use pumping grapes, must and wine very gently.

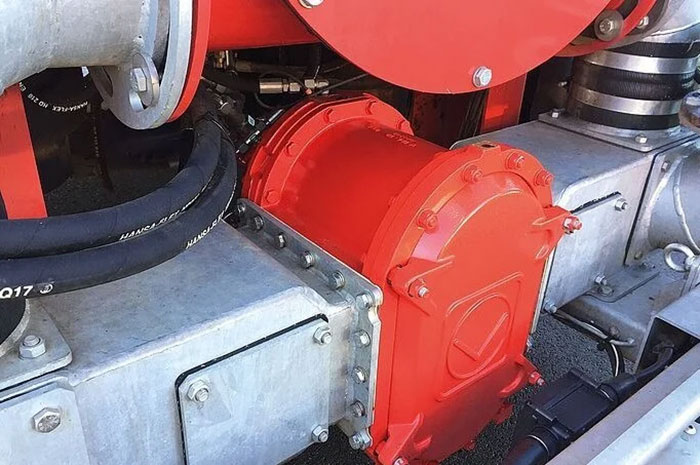

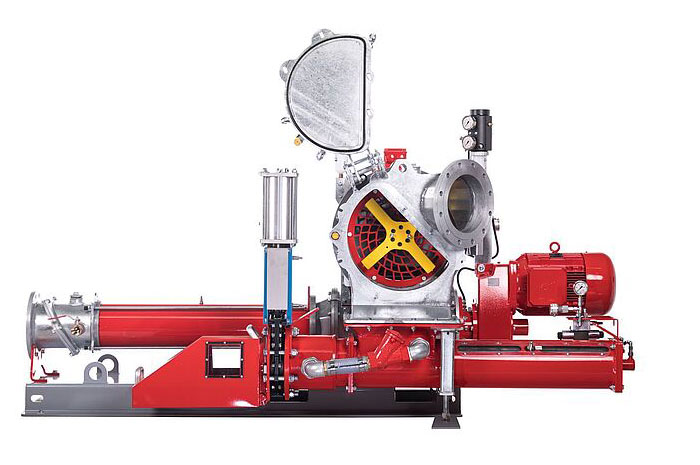

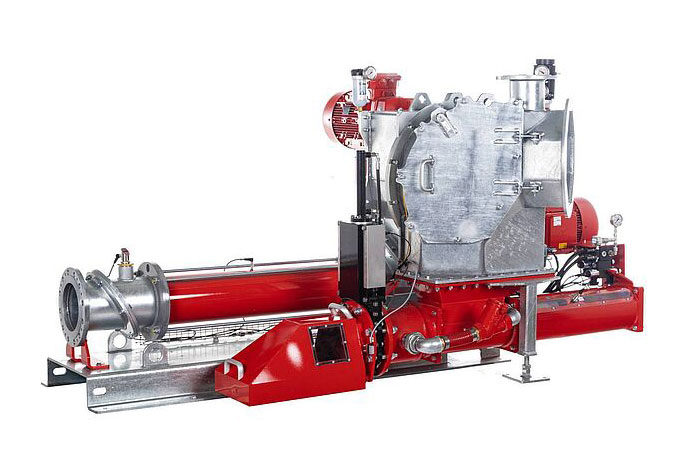

BIOCUT

-

The universal pump system

BioCut- Cost-effective pumping thanks to optimally coordinated components

- Reliable conveying of a wide range of challenging media

- Separation of heavy material and treatment of disruptive matter before the pump

- Compact design and minimal space requirements

- Service and maintenance can be performed quickly and easily on site

CC-CUT

-

The powerful pump system

CC Cut- Efficient pumping thanks to optimally coordinated pump and cutter

- Reliable, trouble-free pumping of challenging and highly viscous media

- Treatment of disruptive matter and separating out of heavy material before the pump

- Low space requirements thanks to extremely compact design

- Maintenance and changing of parts can be performed quickly and easily on site

FILLMASTER

-

Tank filling station for liquid manure

- Convenient and quick filling

- No complicated connection and disconnection of hoses

- Can be transported with any tractor

CC-CUT

-

The powerful pump system

CC-Cut- Efficient pumping thanks to optimally coordinated pump and cutter

- Reliable, trouble-free pumping of challenging and highly viscous media

- Treatment of disruptive matter and separating out of heavy material before the pump

- Low space requirements thanks to extremely compact design

- Maintenance and changing of parts can be performed quickly and easily on site

GRINDERS AND SEPARATORS FOR PROFESSIONALS

-

For protection and optimization of applications and media

When a customer is looking for a grinding technology, the only thing that usually counts is whether the technology meets the requirements, i.e. whether the grinder can handle the medium and application. The details as to whether it's a single-shaft grinder, twin-shaft grinder or a combination of grinders and pumps is usually a secondary consideration or entirely irrelevant. To protect downstream components, however, additional foreign matter separators and/or heavy material separators are often advisable.

That's why at Vogelsang, we differentiate between the following types of cutters and separators:

- Solid matter grinders: A grinding technology such as the RedUnit reduces the particle size of solid matter to enable further processing without any problems.

- Wet grinders: These grinders (RotaCut/XRipper) mainly come in contact with liquid media and shred any disruptive matter they contain.

- Separators: Active separators such as the DebrisCatcher free the liquid medium of undesired foreign matter that cannot be reduced by a grinder.

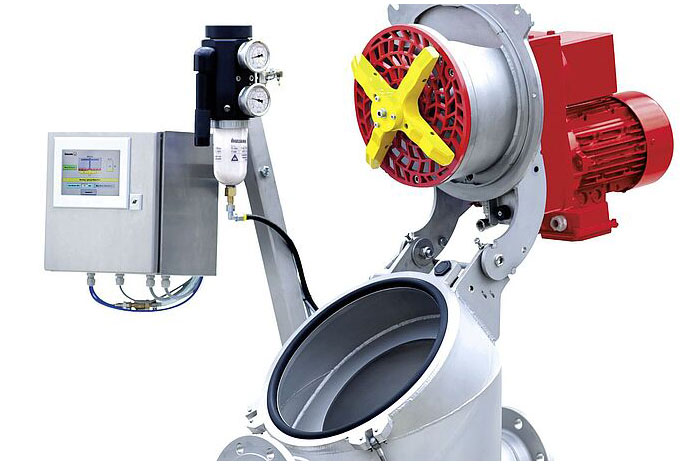

RotaCut®

-

Maximum cutting performance with reliable foreign matter separation

RotaCut®- Reliable maceration of fibrous and coarse matter in liquid media

- Foreign matter protection for all downstream components

- Lower mixer and pump power requirements thanks to more homogeneous and flowable medium

- Fully automatic, interruption-free and low-maintenance operation thanks to the optional Automatic Cut Control (ACC)

- Easy to maintain thanks to the good accessibility of all wearing parts

XRipper®

-

The ultra-robust twin-shaft shredder for major challenges

XRipper®- Economical shredding of solid and disruptive matter such as wet wipes, wood, fabric, trash and waste

- Efficient protection for pumps and system components from clogging, blockages and damage

- Long service life thanks to rugged design

- Fast access to all individual parts yet less service and maintenance work

- Added reliability thanks to cartridge mechanical seal technology

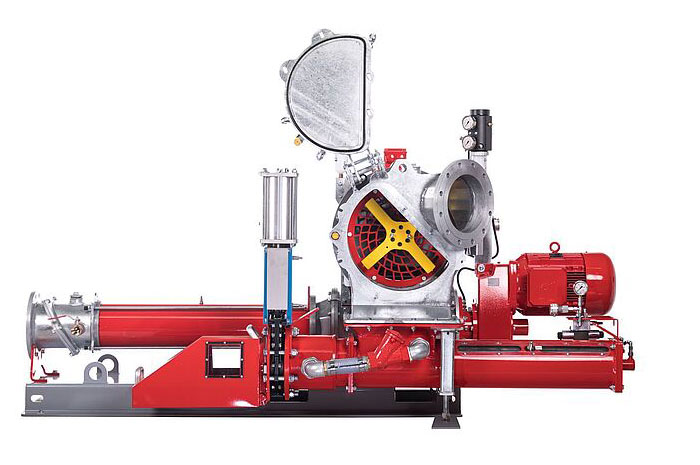

REDUNIT

-

Adaptable, heavy-duty machine mix for particle reduction and pumping

RedUnit- Individual engineered unit thanks to modular design

- Compact and sturdy

- High availability thanks to quick-and-easy service

- Added safety due to cartridge mechanical seal technology

- Low electricity consumption

DISINTEGRATION TECHNOLOGY FOR BIOGAS AND SEWAGE TREATMENT PLANTS

-

Electrokinetic or mechanical disintegration methods for optimized processes

Efficient disintegration technology reduces the costs of sewage treatment and biogas plants while improving results. By using Vogelsang technology to digest sludge or substrate, the gas yields of sewage treatment and biogas plants can be optimized. This is complemented by reduced power consumption of mixers, pumps, decanters and other components. In the waste water sector, the disintegration of sewage sludge also leads to less sludge accumulation and a lesser need for flocculants (polymers) when dewatering the sludge.

Vogelsang offers the following methods:

- Electrokinetic disintegration using the BioCrack: In this electrokinetic method, the medium flows through a high voltage field which breaks up the medium's structures.

- Mechanical disintegration using the DisRuptor: In this mechanical method, external forces reduce the size of the medium's particles and increase their surface area. In the case of the DisRuptor, this is achieved through grinding up and defibering the solid matter in the medium.

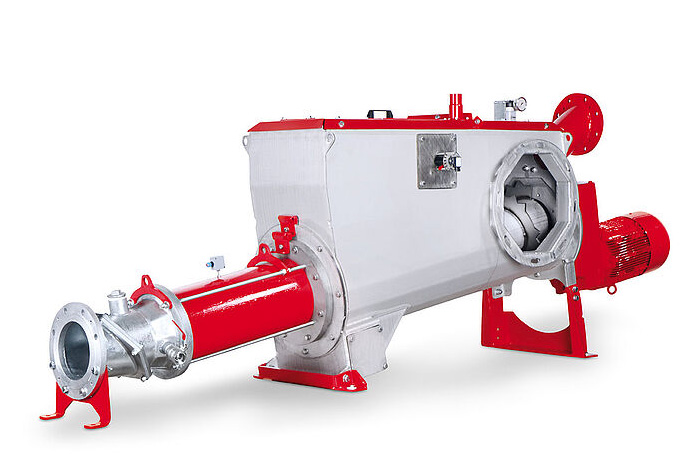

DisRuptor

-

More efficiency through mechanical disintegration

DisRuptor- Increases the surface of the biomass feed

- Homogenizes and reduces the viscosity of the organic suspension

- Accelerates and increases gas production

- Reduces the power consumption of mixers and pumps

- Easy to retrofit

INNOVATIVE, SOLID MATTER FEEDING

-

Reliable solid matter feeders for efficient biogas production

Biogas equipment must be safe and efficient to allow economic operation of the biogas system. In this respect digester feeding has a key function. This is why we have developed systems for feeding solid matter in a mashed form which is suitable for bacteria. Thanks to this feeding, which is ideal for the microorganisms, you can increase the gas yield and reduce your energy requirements for mixing, stirring and pumping. Vogelsang solid matter feeders contribute to a more efficient and profitable operation of your biogas system – and that has even been scientifically checked.

CC-MIX

-

The economical liquid feeding system for solid matter incorporation

CC-Mix- Mashes simple biomass cost-effectively to form a homogeneous organic suspension

- An integrated foreign matter separator removes heavy material before it can reach the pump unit

- Is uncomplicated to integrate thanks to its compact dimensions and simple control

- Several digesters can be fed from one CC-Mix

- Easy to change parts on site

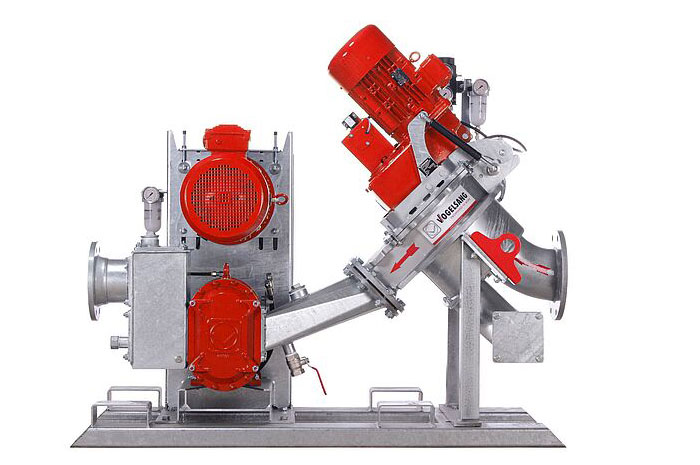

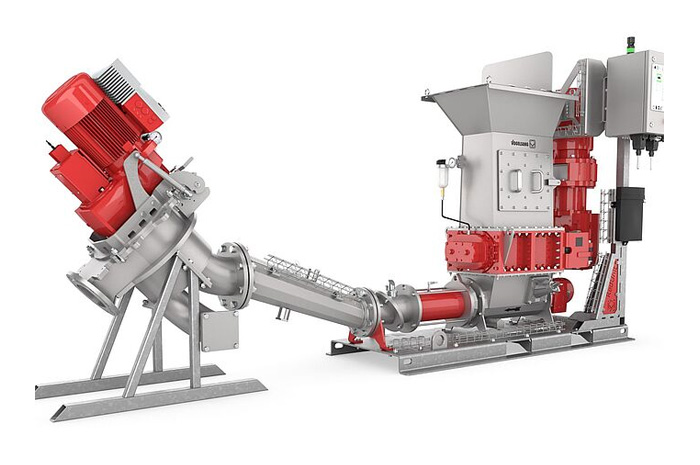

PREMIX

-

The universal 4-in-1 solid matter feeder

PreMix®- Mashes a wide variety of biomass to a homogeneous organic suspension

- Separates out heavy material and shreds the solids before the pump unit

- Compact dimensions and easy to link in so its integration is uncomplicated

- Easy to feed several digesters with just one PreMix

- Easy and quick service on site