PlanET

Videos

Loading the player ...

- Offer Profile

We are the leader in biogas solutions worldwide.

As biogas pioneers since 1998 and provider of biogas plants, we understand all aspects of biogas technology. The economic success of your plant relies on the optimized interaction of the individual processes. Our experience and competence in engineering, approval processes, plant construction, technical service, CHP service and biological service make PlanET your best choice or all of your biogas plant needs.

Product Portfolio

PlanET Biogas Plants

With our technology we have saved about 037429614 metric tons of CO2 worldwide since 1998!

Biogas pioneers since 1998. As one of the leading providers of biogas plants, we understand that the optimal interaction of processes determines the economic success of your biogas plant. We are specialists in engineering, approval, plant construction, technical plant service and CHP service. We also have an in-house laboratory for biological service and process optimisation which makes PlanET a unique brand for biogas and biogas technology.Solutions

Many possibilities that benefit you and the environment.

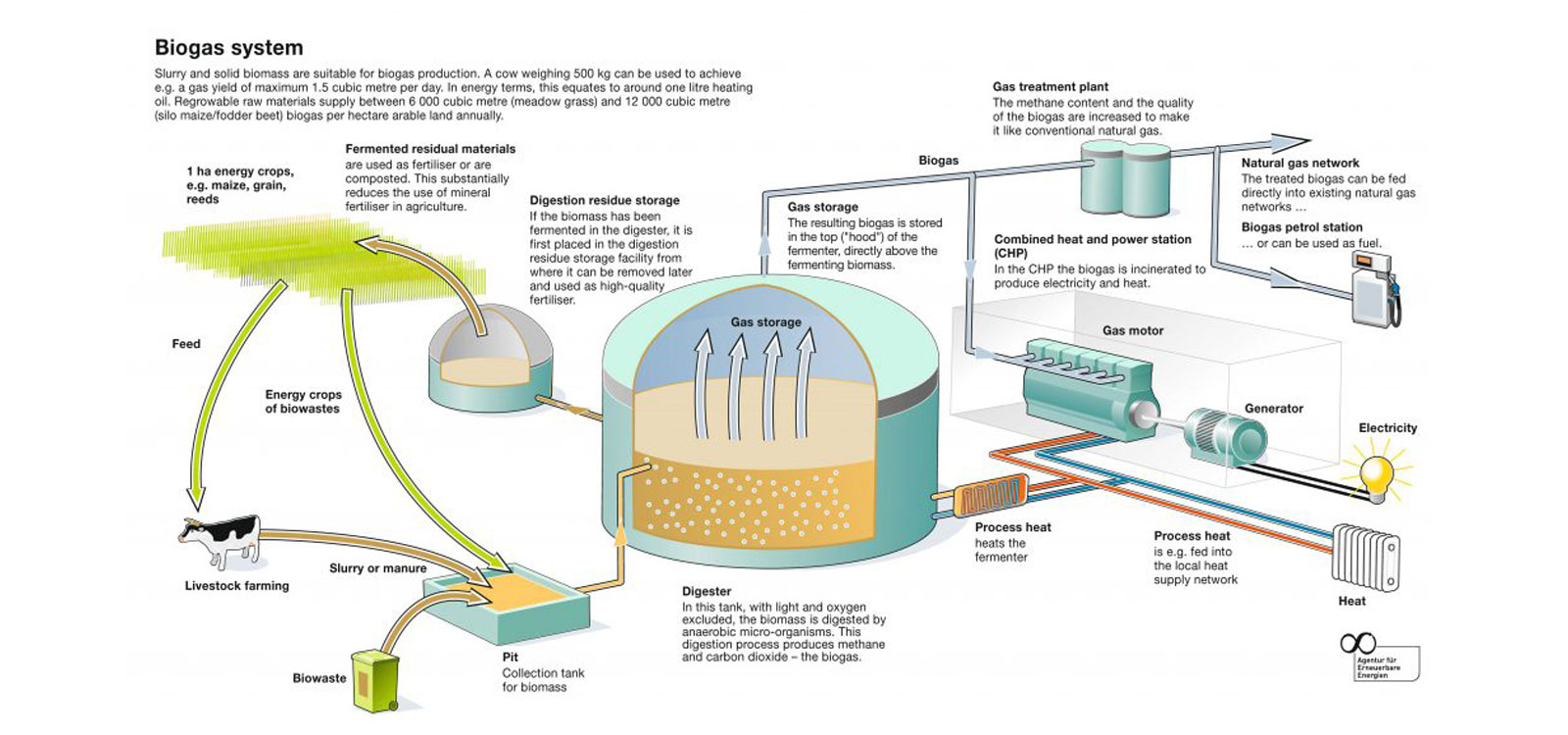

Our solutions have proven themselves hundreds of times and are continuously being further developed. PlanET Biogas products have often become benchmarks of biogas technology and are awarded regularly.Biogas

Biogas can be used for heat generation in a renewable way.Organic Waste

Everywhere around the world you find organic waste. Think about it to generate this to renewable energy.Renewable Natural Gas / Biomethane

With RNG / Biomethan, you can generate fuel or send it in a gas grid.Slurry & Manure

In agriculture you have a big potential to generate renewable energy with your substrate.Electricity & Heat

You can generate renewable electricity & heat. It can be important, to stay independent.Sugarcane Waste

Producing renewable energy from waste of the sugar industry.Functions of a Biogas Plant

Benefits of Biogas

Biogas Provides Multiple Value-Added Benefits to Society as a Whole

Agricultural

Anaerobic digestion of livestock manure and organic food residuals provides security to the agricultural/ food sector. Several benefits include:- financial diversification and risk mitigation through energy sales

- implementing strong nutrient management practices

- supporting local processing of agricultural production

- reducing commercial fertilizer requirements and costs

Economic

The green economy benefits of biogas are considerable and include:- local job creation in technical, manufacturing and construction/trades

- economic development generating billions of dollars of investment in rural communities creation of useful by-products from wastes, acting as a significant economic multiplier

Energy

As a source of renewable energy, biogas has unique characteristics and offers many energy end uses. Biogas can:- generate reliable, flexible power 24/7

- manage intermittent renewable power supply through means of storage and flexible power

- improve/support local infrastructure and power

- quality upgrade to renewable natural gas (RNG) for injection into the natural gas grid, delivering ‘green’ renewable energy through existing infrastructure

- be compressed for use as transportation fuel, or direct replacement of fossil-sourced natural gas in household heating, or industrial, commercial and institutional processes

Environmental

The environmental benefits of biogas are numerous.- capture and use of methane, a greenhouse gas 21 times worse than CO2 convert high energy waste streams into fuel, diverting them from landfill control weed seed germination, reducing herbicide use remove odour-causing compounds

Biogas

Biogas can be used for heat generation in a renewable way.

You need biogas? We can help you out!

There are many uses for biogas produced with a solution from PlanET. It is very versatile and can be used for electricity and heat production or, after a purification step, even be fed into the public gas grid. As the methane from the biogas is a natural gas equivalent, it can completely replace fossil natural gas. Of all renewable energy forms, biogas is the most variable.Your advantages!

- Replacement of process heat

by renewable energy generated on site. - Replacement of fossil gas

by directly produced renewable biogas. - Business growth

without additional space. - Reduction of emissions

in the local area.

Our PlanET technology!

- Optimize Worktime and Workflow

for a smooth process and operation. - Many years of experience

in plant construction and exclusive use of high-quality components. - Solutions for various substrates

for the generation of renewable energies such as electricity, heat and biomethane. - Common contact

for engineering, design and service. -

Biological service

with own laboratory and years of experience. - High quality process control

with named brands worldwide. - Understandable potential analysis

with evaluation of own substrates and performance.

- Replacement of process heat

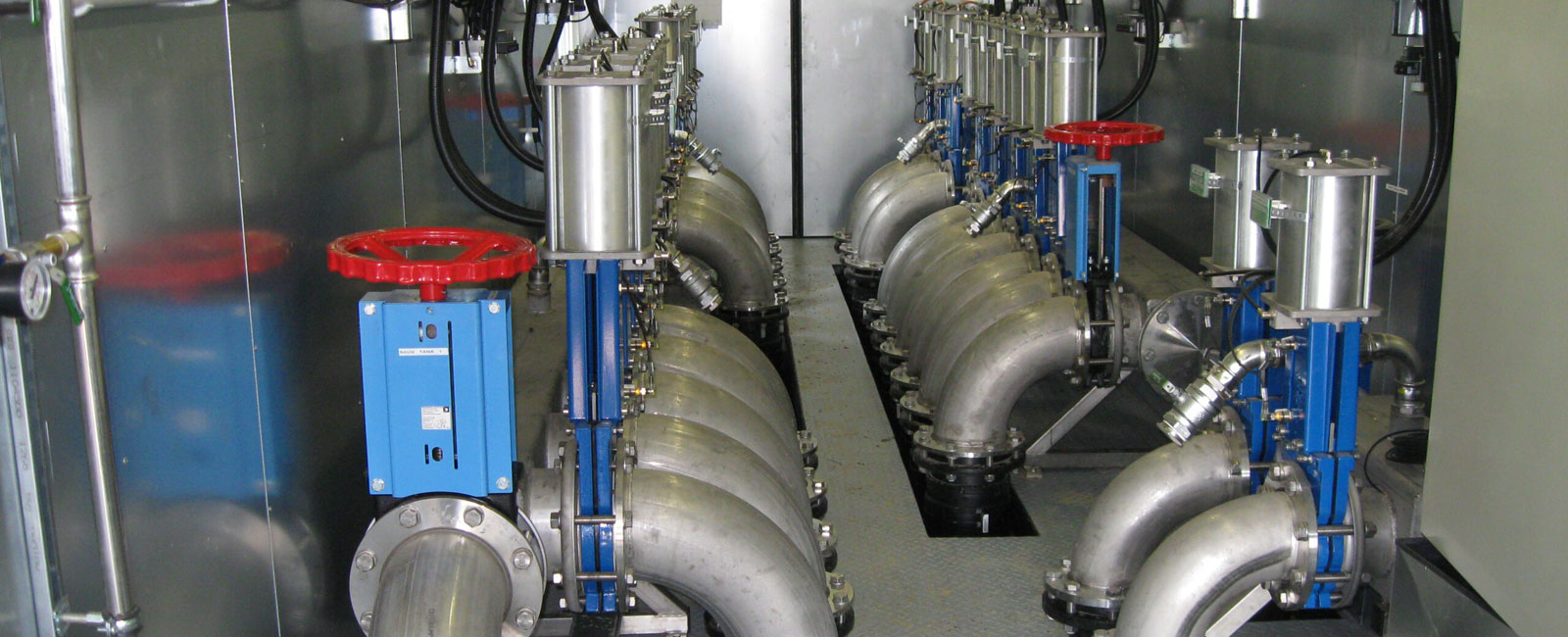

Renewable Natural Gas / Biomethane

With RNG / Biomethan, you can generate fuel or send it in a gas grid.

Biomethane can be used as fuel and injected into the gas network

PlanET has made its reputation delivering modular, energy efficient solutions that are focused on lifecycle value and customer operability. This is the same approach we took when developing the PlanET Stateron. Extending our technology offering to RNG is a natural evolution in our development as we continue to be driven by pure energy.Your advantages!

PlanET Strateron utilizes a carefully selected membrane technology which enhances the biogas output to meet the gas networks statutory requirements. This technology is delivered as a turn-key installation, taking into account specific customer requirements to ensure optimal operational efficiency.- Gas Cooling

The water-saturated raw gas enters the piping system where it is cooled in a dryer. A separator then eliminates the liquid faction of the biogas, after which the gas is reheated through a blower and the pressure is boosted. - Gas Conditioning

The biogas is then directed to the activated carbon filters which are used to eliminate pollutants such as H2S, VOC’s and siloxanes. This activated carbon pre-treatment is made up of a number of filters, installed in a lead-lag; allowing any one of the filters to be bypassed. - O2 Injection

Direct oxygen injection allows for desulphurization of the biogas while it is still inside the digester. Using only oxygen means that other impurities are not introduced into the gas stream. Injection stations can be installed into a process module or directly at the digester. - Gas Upgrading

Our containerized 3-stage membrane upgrading unit is designed for ease of installation and simple operation while allowing for seamless expansion in the future. - Secondary Compression

Packaged Compression Systems designed for the North American Market. A modular compressor package in an insulated silent ISO enclosure up to 5,000 psi for secondary compression for CNG truck filling and virtual pipeline. - Vehicle Fueling

Fueling systems for light, medium and heavy-duty fleets for time-fill, fast-fill or combined solutions.

Our PlanET technology!

- Optimize Worktime and Workflow

for a smooth process and operation. - Many years of experience

in plant construction and exclusive use of high-quality components. - Solutions for various substrates

for the generation of renewable energies such as electricity, heat and biomethane. - Common contact

for engineering, design and service. - Biological service with own laboratory and years of experience.

- High quality process control

with named brands worldwide. -

Understandable potential analysis

with evaluation of own substrates and performance.

- Gas Cooling

Electricity & Heat

You can generate renewable electricity & heat. It can be important, to stay independent.

Electricity & Heat are needed everywhere. Produce your own independent source.

Our solution gives you the opportunity to generate renewable electricity and heat. Both can be used on your own premises or sold to another company. Additionally there is the possibility to feed the electricity into an existing grid and earn money.Your advantages!

-

Generation of renewable electricity

through the use of existing substrates. -

Generation of renewable heat

Produce heat for personal use. -

Business growth

without additional space. -

Reduction of emissions

in the local area. -

Create new revenue

through the sale of renewable electricity and heat. -

Remain independent

of energy prices and availability through self-generation.

Our PlanET technology!

- Optimize Worktime and Workflow

for a smooth process and operation. - Many years of experience

in plant construction and exclusive use of high-quality components. - Solutions for various substrates

for the generation of renewable energies such as electricity, heat and biomethane. - Common contact

for engineering, design and service. - Biological service

with own laboratory and years of experience. - High quality process control

with named brands worldwide. - Understandable potential analysis

with evaluation of own substrates and performance.

-

Generation of renewable electricity

Organic Waste

Everywhere around the world you find organic waste. Think about it to generate this to renewable energy.

Want to change organic waste into power?

With anaerobic digestion, you can create value from waste. Disposed organics can be used for the production of biogas which can substitute fossil fuels. Our biogas plants can process almost all organic waste materials from the food industry as well as agricultural residues or fats and oils. Anaerobic digestion offers significant cost advantages over traditional disposal methods – both to waste management companies and producers alike. Our highly customized Waste to Energy plants provide the maximum economic benefit for your waste management challenge.Your advantages!

- Generation of renewable electricity

through the use of existing substrates. - Generation of renewable heat

through the use of existing substrates. - Generation of renewable fuel

through the use of existing substrates. - Reduce disposal costs through the fermentation of the substrates.

- Individual concepts

adapted to the operation. - Business growth

without additional space. - Reduction of emissions

in the local area. - Create new revenue

through the sale of renewable electricity and heat. - Remain independent

of energy prices and availability through self-generation.

Our PlanET technology!

- Optimize Worktime and Workflow

for a smooth process and operation. - Many years of experience

in plant construction and exclusive use of high-quality components. - Solutions for various substrates

for the generation of renewable energies such as electricity, heat and biomethane. - Common contact

for engineering, design and service. - Biological service with own laboratory and years of experience.

-

High quality process control

with named brands worldwide. - Understandable potential analysis

with evaluation of own substrates and performance.

- Generation of renewable electricity

Slurry & Manure

In agriculture you have a big potential to generate renewable energy with your substrate.

Utilization of slurry & manure in agriculture

Produce high quality fertilizer from substrate used in your digester. The AD process leaves a digestate with improved nutient availability for the soil and plant growth. Your business will be more environmentally friendly while providing many benefits.Your advantages!

- Manure improvement

through better nutrient availability. - Generation of renewable electricity

through the use of existing substrates. - Generation of renewable heat

through the use of existing substrates. - Generation of renewable fuel

through the use of existing substrates. - Business growth

without additional space. - Reduction of emissions

in the local area. - Create new revenue

through the sale of renewable electricity and heat.

Our PlanET technology!

- Optimize Worktime and Workflow

for a smooth process and operation. - Many years of experience

in plant construction and exclusive use of high-quality components. - Solutions for various substrates

for the generation of renewable energies such as electricity, heat and biomethane. - Common contact

for engineering, design and service. - Biological service

with own laboratory and years of experience. - High quality process control

with named brands worldwide. - Understandable potential analysis

with evaluation of own substrates and performance.

- Manure improvement

Sugarcane Waste

Producing renewable energy from waste of the sugar industry.

Biogas production from sugarcane waste

PlanET offers state of the art anaerobic digestion (AD) technology with expertise in the biogas production from sugarcane waste.Your advantages!

- Convert

your sugarcane waste into energy - Generate

a nutrient-rich fertilizer - Increase

your revenue - Reduce

your waste disposal costs - Mitigate

the CO2 footprint

Our PlanET technology!

- Sugarcane waste

converted efficiently into energy - Combining stirred digesters

with covered lagoons provides a lucrative cost-benefit solution for the treatment of sugarcane waste and for the biogas production during the whole year - In the compact module,

co-digestion of filter cake and bagasse is more profitable than the mono-digestion of filter cake - During the on-season,

additional biogas can be burned in boilers for heat generation

- Convert

PlanET Biogas Products

- We offer our customers numerous products to get the best out of your equipment. Here you will find a short overview.

- PlanET Vario

The insertion technique with 100% customer confidence - PlanET BIGMix

A single product for storing, dosing and mixing substrates... - PlanET PreMix

A high-performance insertion technique - Pumping technology

Safety, power and simplicity - PlanET eco® stirrers

Optimal mixing and good level of biological activity for ideal yield - CHP module

Full power for gas engines with pilot injection and gas cogeneration modules - Gas storage

PlanET Flexstore: Gas storage for the energy of tomorrow - Roof structure

For reliable and efficient desulfurization - Flare

To ensure maximum safety - PlanET hygienisation tank

Know-how at the service of optimal co-fermentation

- PlanET Vario

PlanET Vario

The insertion technique with 100% customer confidence

PlanET Vario allows chopped renewable resources, solid manure, food residues and solid co-ferments to be injected directly into the fermenter. The system is highly modular: the hopper capacity ranges from 11 to 120 m³ and can be expanded as required. Thanks to the Vario insertion technology, the system is energy-efficient and wear-resistant. The stainless steel feed belts are individually driven and equipped with side flaps so that the substrates are conveyed efficiently. A disentangling screw is mounted on the front of the box. The substrate is conveyed to the auger ensuring a good filling level. Our “Plus” package for a high proportion of grass and manure has a second disentangling screw and guarantees a smooth insertion of 100% grass and manure.

The outstanding results of our customer satisfaction surveys with a 100% probability of purchase of the PlanET Vario feeding system allow PlanET to offer a five-year guarantee on the PlanET Vario feeding belts.Advantages of PlanET Vario:

- All stainless steel and plastic substrate contact feed system

- Basic model in stainless steel, optional all models in stainless steel

- Safe and sustainable investment - Extendable and adjustable thanks to modular design

- Reliability thanks to simple and durable components

- Easy maintenance, can be disconnected individually

- Low energy consumption, depending on the model, less than 0.6 kWh/t (including control and power supply systems)

PlanET BIGMix

A single product for storing, dosing and mixing substrates...

…PlanET BIGMix is the ideal insertion technique for you! PlanET BIGMix ensures easy and energy-saving transport of sticky and long-fibre substrates such as manure or finely ground solids. The moving floor technology consists of 12 stainless steel push bars, individually driven by a hydraulic system, which transport the material to the mixing and dosing area where the substrate is decompressed, crushed and mixed by means of a vertical stainless steel mixing screw installed at the front. The substrate is fed into the fermentation pit by means of a feed screw system, which is available in several variants and can also be combined with the introduction of liquid materials.

The control cabinet for the electric motors, the mixing screw and the ultrasonic sensors are included in the basic model. PlanET BIGMix is the right product when the material is to be mixed directly in the storage and dosing system.Advantages of PlanET BIGMix:

- Moving floor technique minimizes the formation of substrate agglomerates, a slope prevents undesired adhesion of the materials before the dosing zone

- Treatment of difficult materials such as e.g. 75% grass silage with fibre lengths

- Storage capacity with different volumes up to 110 m3

- Integrated level monitoring system

- Integrated weighing system

- Numerous optional accessories available (e.g. inspection opening, hydraulic hood)

PlanET PreMix

A high-performance insertion technique

Our PlanET PreMIX system is a high-performance insertion technique that combines several important steps in the feeding process into one system. Pumpable co-ferments, such as e.g. food leftovers in the form of slurry, slurry or large volumes of dry substrates such as straw or energy plants, are reliably processed and fed into the fermentation process. The advantage of our compact and energy-saving module is that it combines the following steps of the feeding process into one system:- Automatic dosing and insertion of liquid and solid substrates

- Removal of foreign bodies before the pump unit

- Mixture of liquid and solid phase to form a homogeneous suspension free of disturbing elements and foreign bodies

- Grinding and decomposition of long-fibre substrates

- Transport of the prepared substrate to as many fermenters as desired by means of a high-performance pump (possibility of later expansion of the plant capacity)

PlanET PreMIX is the ideal solution for installations that use very heterogeneous substrates or for installation projects where a change of substrates and/or an expansion of capacity to accommodate new substrates is planned. It can be integrated as a compact element into existing systems.The advantages at a glance:

- Treatment of various coferments to form a mixed and homogeneous biosuspension

- Decompaction of the solids and grinding of the coarse elements/fibres before arrival at the pumping unit

- Compact dimensions, easy to integrate

- Feeding of several fermenters by a single system

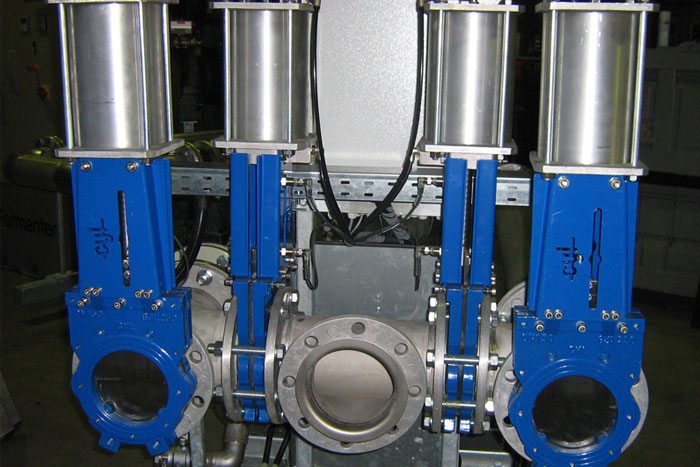

Pumping technology

Safety, power and simplicity

- Pumping liquid from one tank to another safely and odourlessly? No problem with the PlanET compact dispenser. To manage your substrates simply and efficiently, the technical module is delivered equipped with a rotary piston pump and integrated in a compact construction pre-assembled on a distributor block. The rotating lobe pump allows you to suck and discharge in a single line and to feed up to six tanks connected to the device. This makes the PlanET compact distributor ideally suited for retrofitting and expansion projects of existing plants.

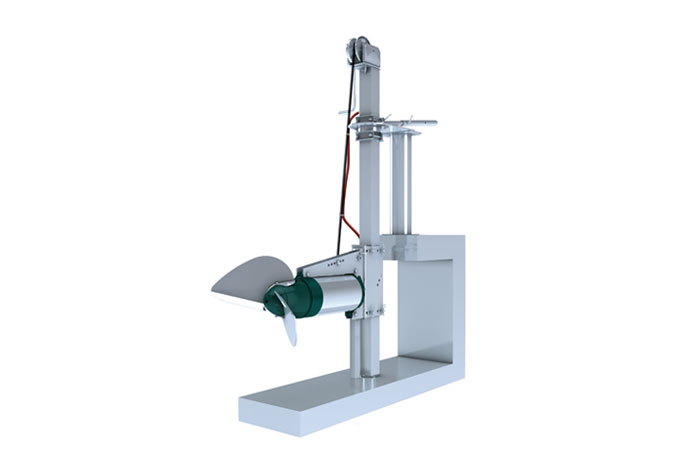

PlanET eco® stirrers

Optimal mixing and good level of biological activity for ideal yield

- The dimensioning of the agitators must be optimal to guarantee a satisfactory level of efficiency of your biomethanisation installation. Only when the agitators are adapted to the tank size and the type of substrate, the fermenting substrate is homogeneous and the yield is optimal. The patented PlanET eco® agitator series offers you a complete range of all proven mixing systems from the submersible motor to the large propeller mixer to the paddle mixer – always with minimal own power consumption, long service life and robustness. Replacing energy-intensive mixers with more energy-efficient systems reduces your plant’s power consumption.

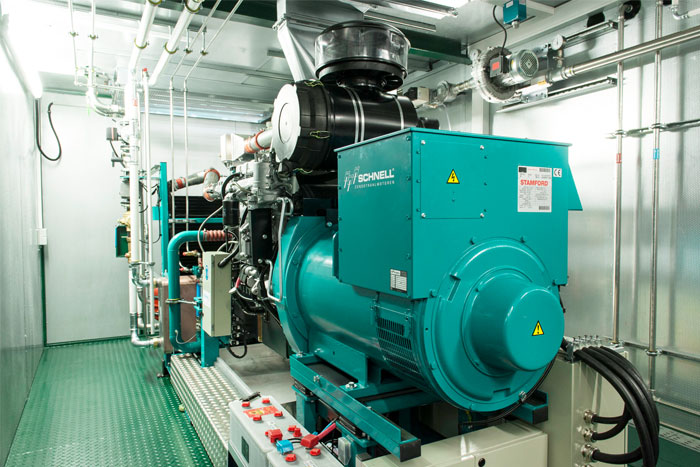

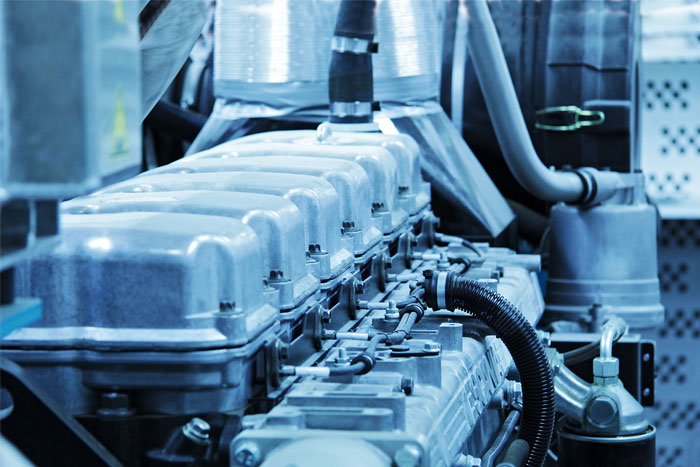

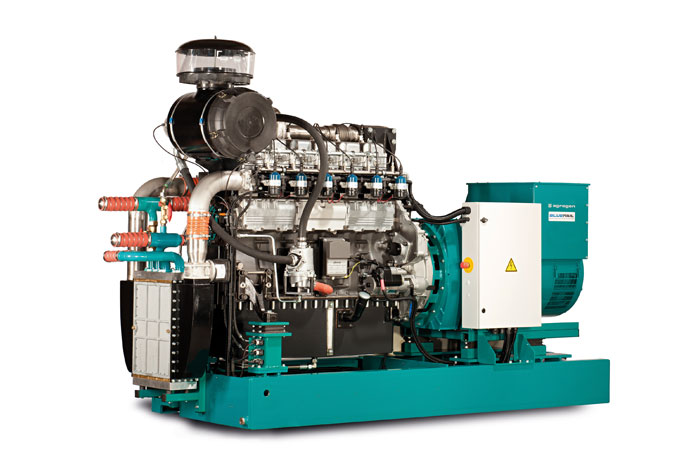

CHP Module

CHP Module

- For our cogeneration modules, we work with renowned manufacturers of gas and pilot injection engines with innovative technology and proven engines with the highest efficiency on the market. As a manufacturer of biogas plants, we install and integrate the cogeneration module into your existing plant according to your individual project. As a single partner, we offer you a complete service from the extension of the gas network to the connection to an existing heating system or the integration into your existing PlanET control system.

Depending on your individual requirements, the CHP module can be delivered in a container or integrated on site in your technical room. In order to comply with noise emission standards, we also offer soundproof containers with noise protection enclosures or “Super Silence” containers. With additional options, our units are optimally equipped for on-demand power generation in order to protect the engine and plant components and to keep wear and tear to a minimum during regular start/stop operations.

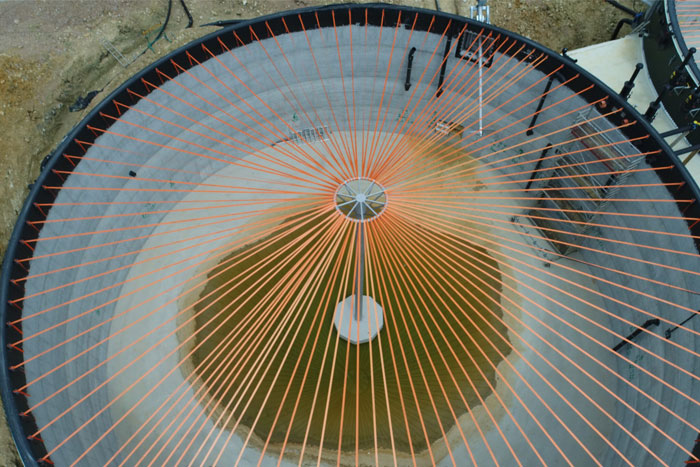

Gas storage

PlanET Flexstore: Gas storage for the energy of tomorrow

The biogas collector is the central element in the demand-responsive production of electricity. The flexible production of electricity with one or more combined heat and power modules requires in particular variable volume flows despite constant biogas production. For this reason it is necessary to use gas collectors with variable storage levels in order to participate in the electricity balancing market. PlanET offers operators two modern technical solutions: PlanET Flexstore XL or PlanET FlexStore XXL. These double membrane collectors cover your fermenter or fermentation tank hermetically and in compliance with the strictest safety standards. For existing installations that do not plan any increase in slurry storage, PlanET offers the PlanET eco® gasakku collector. This gas collector installed on the ground floor ensures a gas valorisation oriented towards financial gains thanks to an additional storage volume.

The PlanET Flexstore biogas collector has one of the largest storage volumes on the market. The special shape of the dome has been designed to increase volumes but also to fit perfectly into the landscape. Its shape is not the only advantage: the membrane material is designed to be weatherproof and reliable against odour emissions thanks to a new innovative sealing system, which is also easy to maintain.The advantages:

- Up to 35% more biogas storage volume compared to traditional dome collectors

- Compressed air circuit of the split sealing system for faster opening and intervention

- Polyethylene venting system to prevent corrosion and increase service life, gas expansion is controlled by a butterfly valve

- High wind resistance (up to force 12 - hurricane)

- Particularly thick weather protection fabric (800-1100 g/m² depending on the size of the roof membrane)

- 5-year warranty on the weather protection cover

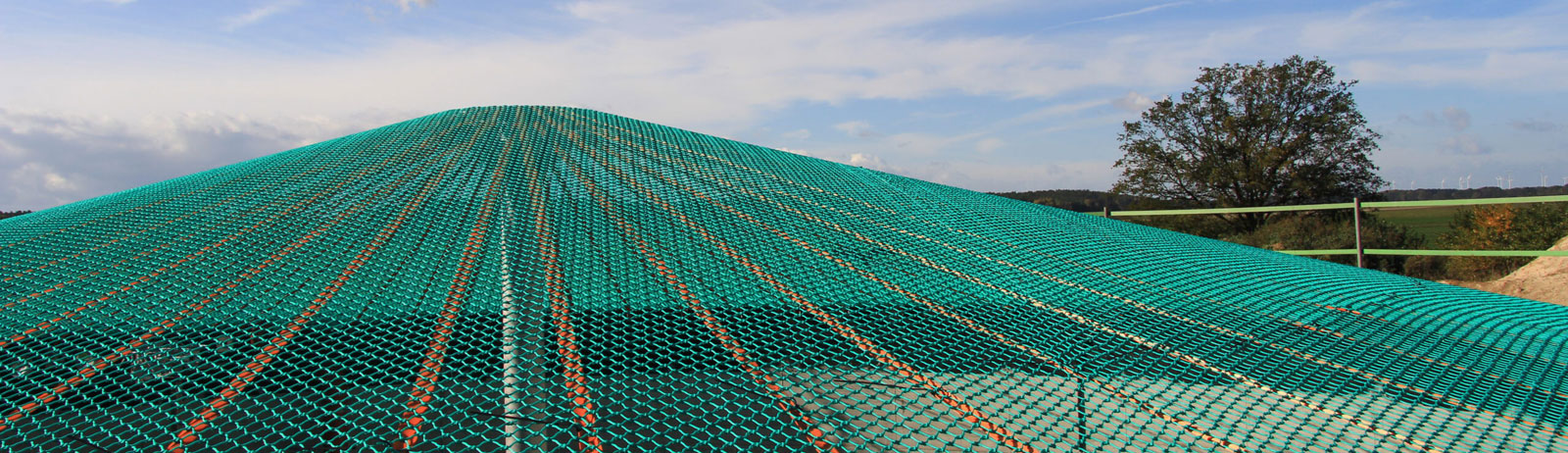

Roof structure

For reliable and efficient desulfurization

- The PlanET eco® cover G is an improved technological solution for biogas co-desulphurisation. It combines different properties for optimal operation of the biogas plant and is the result of the further development of the desulfurization fleece cover PlanET eco® cover or PlanET eco® cover plus.

The basic principle of the PlanET eco® cover roof construction remains intact, but the structure of the plastic mesh fabric has been expanded. In this way, liquids or foam can more easily penetrate through the fabric.

Thanks to its structure, it is also possible to spray liquid nutrients during the start-up phase or repeatedly during desulfurization.

Flare

To ensure maximum safety

In addition to the power-heat cogeneration module and the biomethane treatment, each installation must have an additional gas combustion device. PlanET offers manual and automatic flares in different sizes. The proven industrial quality automatic flares operate with their own compressor to ensure safe and constant combustion in case of bad weather conditions. An optionally available protective enclosure protects against frost in winter and ensures that the torch is always functional. In the event of a power failure, an emergency generator can also be connected via an EEC socket.

More economical emergency flares are available as standard as a manual version, but the shut-off valve must be opened manually.

In the manual version, to start the torch, the operator must light the flame with a propane cylinder. This also allows the torch to operate in the event of a power failure. The manual flare can be automated. Automatic flares can be ignited from an external signal from the gas tank fill level or from a pressure switch in the gas system.The advantages:

- Automatic selection and deselection

- Autonomous operation possible by connection to a separate gas sampling line

- The flare can operate even in the event of a power failure (a back-up generator is required for automatic flares).

- Underpressure switch, integral part of the safety chain of the flare stack