- AUTOMATION 21XX

- Online Exhibition presenting manufacturers of industrial factory automation, robotics and assembly

- We offer a Milling Machine with CNC used for high quality milling and engraving of surfaces of details and products.

- For 60 years we have been constantly developing new clamping solutions focusing on the essentials: your wants and needs.

- All around metal processing without a break. Matec produces state of the art All-In-OneCNC-, Millturn-, and Gantry maschines

- We are high positive machining pioneers and industry drivers. AVANTEC milling cutter solutions set the benchmark in standard tooling and customized turnkey projects. When it comes to chip volume Q, outstanding precision and cost effectiveness.

- Grinding machines used wherever productivity, performance and precision are required

- Specializing in surface, profile and creep-feed grinding machines as well as a wide range of highly efficient production systems.

- We design, manufacture and market premium high-precision tooling systems and solutions for the automotive, mil/aero, energy, and microtechnology industries.

- Microfinishing process for: Camshafts, Crankshafts and Transmission components.

Robotic automation solutions for Vision Guided Robot Systems, Machine Tending, Robotic Machining and De-burring

- Machining centres, moving column machining centres with fixed table, universal moving column 5 axis machining centres, machining solutions for big circular pieces

- We manufacture a complete line of CNC vertical as well as horizontal machine centers and also lathes and rotary products.

- Our portfolio covers form knurling tools, cut knurling tools, knurling wheels and marking tools in market-leading technology and quality.

- Machines for grinding, eroding, lasering and measuring together with the relevant software and services from a single source.

- Customized grinding machines that are characterised by precision, reliability and cost effectiveness

- provides custom-made, high-precision cylindrical, cam and universal grinding machines

- Tooling systems and application consulting for the milling of complex 2.5 and 3D geometries

- Leading suppliers of world class precision engineering products, multi-lock milling chuck, rotary table, drilling and boring tools, tool pressetters and spindle optimisation

- VARGUS is a world-leading manufacturer of high-quality cutting, grooving and deburring tools for the metals and plastics industries.

- Behringer is one of a very small number of complete suppliers in the sawing technology market. Its product range spans from bandsawing and circular sawing machines through hacksaws to plants for steel construction.

- High productivity and precision grinding machines

- Offers a broad range of turning, milling, and gear manufacturing technology with the knowhow of the machine tool brands VDF Boehringer, Hüller Hille, Hessapp, Honsberg, Modul and Witzig & Frank.

- Produces a wide range of high speed milling machines in 3 & 5 axis, turning and milling solutions dedicated to machining by chip-removal.

- The Föhrenbach Group is one of the leading manufacturer of high-precision components, units and systems for linear and rotary movements in the automation technology and precision machinery industry. Föhrenbach products solve requirements for guiding, drive, movement, control and positioning.

- For 50 years, HEDELIUS has set the standard in mechanical engineering in Germany. The vertical CNC machining centres made in Germany are valued for their high precision, efficiency and reliability.

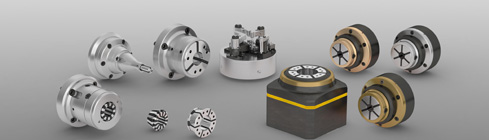

- Benefit from our synergy effects in tool clamping, workpiece clamping and drive systems.

- PRIMINER MACHINE TOOLS offers a large range of CNC machine tools from 50kg to 10,000kg max. load.

- Low energy lath, single-spindle lathe, chuck lathe, pick-up chuck lathe, twin-spindle pick-up lathe, 4-axis shaft lathe, pick-up cutting and centring machine, all-electric precision lathe

- Our product portfolio ranges from the universal machining center all the way through to highly complex production systems with individual automation, and from manual assembly stations through to fully automated assembly lines.

- Seco is one of the world’s largest providers of comprehensive metal cutting solutions for milling, stationary tools, holemaking and tooling systems.

- NICOLÁS CORREA offers the widest range of milling solutions on the market, including bed machines, gantry machines, floor type machines and machines with a T-shaped configuration.

- Hexacon Messtechnik develops precision measuring heads for diameters and chamfers. The modular PMK systems offer sub-micron accuracy, long service life, and are ideal for manual or automated quality control. Made in Germany for high-precision industrial use.