- Offer Profile

-

GATHER Industrie GmbH is premium manufacturer of process and dosing pumps, flow meters, metering systems and quick connect couplings for pipes and hoses.

As a premium manufacturer of magnetically coupled gear pumps, metering systems and quick connect couplings for pipes and hoses, the company serves numerous industries and customers, e.g. the chemical, pharmaceutical, medical and food industries. With their expert knowledge in handling non-lubricating liquids, GATHER offers solutions which enable the customer to work with process reliability and durability.

NEW at Gather Industrie - Flow Meter

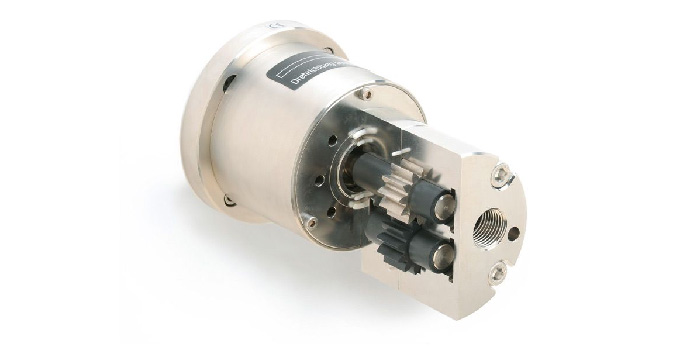

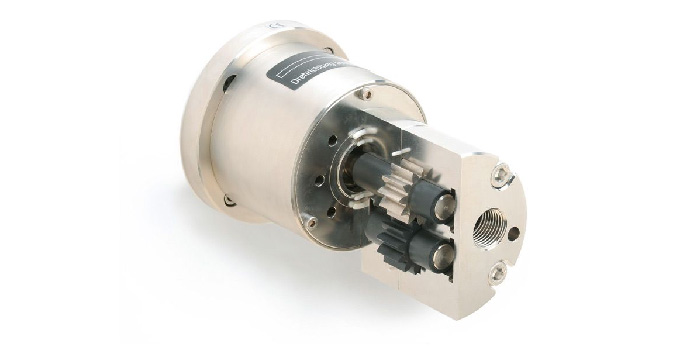

The GATHER gear flow meter (ZDM) is a volumetric flow meter based on the gearwheel meter principle for particularly non-lubricating, low-viscosity and chemically aggressive liquids. The movement of the gears is detected by a sensor via the individual gear teeth, in the form of pulses, contactless and hermetically decoupled. The GATHER ZDM is based on the same technology as the GATHER gear pumps which have seen decades of use in a wide variety of industries (including chemicals, pharmaceuticals, food, medicine, etc.).

At a glance:

- Measurement of non-lubricating liquids

- High measuring accuracy

- Large measuring range

- Universal output signals

- Robust design and long service life

- CIP-capable

GATHER pumps

Gear pump

-

The magnetically coupled GATHER Gear pump is a hermetically sealed dosing and process pump. In numerous industrial sectors (chemicals, pharmaceuticals, food, medicine, cosmetics, etc.) it is mainly used for the pulsation-free delivery or metering of non-lubricating liquids (e.g. water, salt solutions, acids, alkalis, solvents, etc.).

- Magnetic coupling – hermetically sealed

- Pulsation-free delivery & dosing

- Non-lubricating liquids

- Cooling magnetic system & slide bearings

- Robust design and long service life

- CIP- and SIP capable, if desired

Multi-purpose labotary pump

-

As already explained under „Magnetically coupled gear pump“, the GATHER gear pump is a hermetically sealed pump. This pump was designed multifunctionally in its materials in order to be able to pump many different liquids used in the laboratory.

In addition, a drive with integrated speed control is used which is a „plug and play“ solution ready for conncetion and available from stock.

Turbine pump

-

The magnetically coupled process pump

GATHER Industrie GmbH’s magnetically coupled mini turbine pump is a modern process pump for the pulsation-free metering, conveying and circulating of water, salt solutions, acids, alkalis and solvents, amongst other things.

With four different geometrical variants, flow rates ranging from 20 l up to 3600 l per hour can be attained at differential pressures up to 5 bar (see also operating data and flow rate characteristic diagram). Similar to the gear pump, it has internal wash borings and channels for efficient cooling and fluid circulation.

The magnetic coupling ensures a contactless torque transmission from the drive to the pump shaft. It is not subject to wear and tear and is absolutely maintenance-free. Together with its established slide bearings technology and simple design, the GATHER turbine pump represents a cost-effective, robust multi-purpose pump which is extremely quiet in operation.

- Magnetic coupling – hermetically sealed

- Pulsation-free delivery & dosing

- Non-lubricating liquids

- Cooling magnetic system & slide bearings

- Robust design and long service-life

- Low-noise operation

Special Solutions

GATHER Gear pump

-

Special solution for pharmaceutical applications

The SIP version was the first in-line sterilisable gear pump and has proven itself since 1998 in many pharmaceutical applications where the piping system has to be sterilised in-line with steam.

It has the same properties as the standard series of GATHER gear pumps and can additionally be sterilised with steam.

Characteristics:

- Pharmaceutically compliant connections (e.g. TriClamps or dairy pipe)

- Hygiene class H3 (Ra ≤ 0,8 µm)

- Steam sterilisation at 135°C

GATHER Gear pump and centrifugal pump

-

Robust up to 300 bar and 450°C

It has the same properties as the standard series of GATHER series 2 magnetically coupled pumps and has been modified with regard to system pressure and maximum operating temperature.

Characteristics:

- Maximum operating temperature +450°C

- Maximum system pressure 300 bar abs.

- Special magnet system

- Special slide bearings materials

Accessories

Inline filter „Mini“

-

The GATHER filter with drain plug is a universal filter designed even for extreme process conditions. Operating temperatures of up to 350°C at system pressures of up to 500 bar are possible. The stainless steel and Hastelloy® versions qualify this filter for use with aggressive media. Through using “pleated” filter elements, a compact design with a large filter surface is created, which causes only low pressure losses. The filter is optimally suited for use as a pre-filter in suction lines.

Technical Data

- Max system pressure: 500 bar

- Max temperature: +350°C

- Standard fineness: 10 µm

- Housing:

- Stainless steel: Nitronic® 60 / 1.4404

- Alternative: Hastelloy® C-276

- Filter:

- Stainless steel: 1.4401

- Alternative: Hastelloy® C-22®

- Connection: G 3/8 Female thread

Overflow valves for liquids, gases and vapours

-

The GATHER overflow valves are simply designed and compact pressure limiters which offer accurate inlet pressure adjustment with easy installation and maintenance. In operation, the inlet pressure is in balance with the spring-loaded valve as soon as the preset opening pressure (in the pipeline) is reached and exceeded. The preload of the valve spring – and thus the opening pressure – can easily be adjusted from the outside. As connections, standard pipe fittings or individual connections according to customer specifications are available.

- TÜV-certified

- Compliant with the German Clean Air Act

- FDA compliant

- ATEX compliant

- Compact straight-line construction

- Freely selectable optimal installation location

- Low pressure loss (adjustment range 1:35)

Non-return valves for liquids, gases and vapours

- GATHER Non-return valves can be used for liquids, gases and vapours. The proven accessories for our magnetically coupled pumps ensure constant flow resistance. They are used under vacuum in various pump applications. The non-return valve is available in stainless steel or Hastelloy®.

Technical Data

- Material: Stainless steel (1.4404)

- Seals:

- FKM (Viton®) (-20 up to +200°C)

- EPDM (-40°C up to +150°C)

- Response pressure: 1.0 barg (± 10%)

Heating jacket – use in the high temperature range

-

The GATHER heating jacket system ensures an even heating of the pump head by the flow of a heating medium. The heating jacket can be easily plugged and installed onto the pump head. Due to the appropriate design and material selection – especially in the area of the magnetic pot and the seals – the stainless steel pump can be used up to a system pressure of 300 bar and at a simultaneous temperature of +450°C. The heat transfer to the drive is reduced by special connecting parts.

Specification- Heating connections: G1/4

- Housing: stainless steel 1.4571

- Pressure in the heating jacket: up to 20 bar

- Heating / cooling medium: brine, steam, thermal oil, etc.

- Heating temperature: up to +450°C

Flow Meter

- Precise measurement technology for non-lubricating liquids

Gear Flow Meter

-

The GATHER gear flow meter (ZDM) is a volumetric flow meter based on the gearwheel meter principle for particularly non-lubricating, low-viscosity and chemically aggressive liquids. The movement of the gears is detected by a sensor via the individual gear teeth, in the form of pulses, contactless and hermetically decoupled. The GATHER ZDM is based on the same technology as the GATHER gear pumps which have seen decades of use in a wide variety of industries (including chemicals, pharmaceuticals, food, medicine, etc.).

Features:

- Measurement of non-lubricating liquids

- High measuring accuracy

- Large measuring range

- Universal output signals

- Robust design and long service life

- CIP-capable

Couplings

-

Why GATHER Couplings?

Our offer includes quick disconnect couplings for pipe and hose lines for almost every application and industry. With the correct design of the coupling as well as the selection of materials and seals according to the medium and requirements, we provide our customers with safe, fast and durable solutions. As a globally positioned supplier of standardized products (GATHER series DBG, HANSEN original), we also develop individual special solutions according to customer requirements, e.g. multicouplings, interconnecting logic, colour coding, handles, use of special materials Hastelloy®/Titanium, etc. Our sales engineers and partners have extensive expertise and application knowledge and are your contacts. Either at your premises or at our headquarters in Wülfrath.

GATHER series DBG

Flat-face quick disconnect coupling

-

GATHER’s flat-face quick disconnect couplings of the DBG series shut off on both sides and can be operated with one hand. They are designed in such a way that no liquids escape when disconnected and no air pockets enter the pipe system when connected. The design of their internal structure allows inline cleaning CIP (Cleaning in Place).

All components are sufficiently washed around, product adhesions are completely removed. The pressure drop in the quick disconnect coupling is very low, as the flushability is achieved by its inner contour which ensures a favourable flow. All seals are located on the inside, which means increased operational safety.

Dry-break, Robust and Safe for Every Application- DBG series, DN 4 to DN 65

- Over 500,000 coupling cycles

- The price cutter made of simple, alloyed steel

Flat-face sterile coupling

-

Principle: First seal, then release the flow! During the coupling process, the ring valve of the socket and the flat valve of the nipple push against each other. Before the valves release the flow, the interior is shut-off against the environment. The dead space-free design prevents air inclusions when connecting and drip losses when disconnecting.

The robust DBG series represents the top model in its market with over ½ million coupling cycles.

Flat-face tank coupling

-

Shut-off design in both sides, dry-break and capable of connecting under residual pressure

The hose couplings of the DBG SV series have self-closing shut-off valves. When disconnecting, there are no liquid leakages from the hose and container, no air or dirt enters the line system when connecting. These dry-break hose couplings offer a high degree of safety during refuelling, filling and decanting, because despite frequent coupling, environmental damage or hazards to persons due to leaking liquids are excluded. The liquids do not come into contact with the ambient air. Coupling and uncoupling is very easy and smooth, even if the lines are under residual pressure.

Hansen original

HIG Series

-

Beverage-dispense coupling

The beverage-dispense coupling is used for the water supply in kitchens, but also for the product pipes of beverages, such as lemonades and concentrates. They make in-line cleaning (CIP) and a fast connection process possible.

HK Series

-

Double shut-off design

(single shut-off or in both halves possible)The quick disconnect couplings of the HK series are single shut-off, double shut-off or straight-through. The double shut-off version is to be earmarked for hazardous media such as acids, alkalis, hot water or steam. Single shut-off couplings can be equipped with a non-return valve in the socket or nipple, depending on the application.

During connecting the valves do not push against each other until the coupling is shut off to the outside. Conversely, they are only separated when the valves are closed. This type of quick disconnect coupling works splash-free.

ST Series

-

Straight-through hydraulic and pharmaceutical coupling

The ST coupling series is characterized by its extremely robust design. It is particularly eligible for applications where the flow must be guaranteed even with highly viscous media such as greases and a shut-off can be dispensed with.

Metering systems according to customer specifications

-

GATHER also supplies complete metering systems as solution according to ATEX for zone 1 or 2. This includes the conceptual design and selection of all components of the pump control loop according to customer specifications.

Possible Conceptual Designs- Both “stand-alone systems” and integration into existing process systems

- Control electronics in pressure-capsulated design according to EN 60079-1

- ATEX zone 1 and 2

- Integration of safety monitoring, e.g. dry-running, overpressure, overheating, etc.

- Universal controller (GATHER Metering box 5000) for continuous metering or batch filling

- Compact Metering station GDS (“Plug and Play”)

- Modular rack design according to customer specifications

- Engineering advice on site

Metering station GDS

- Pump, controling, sensor technology – All in one station

Proven pump technology, integrated controling and regulation as well as flow and pressure measurement in one station. This is what GATHER delivers in the new compact GDS metering station. All components are integrated in a stainless steel housing to save space. As a “plug-and-play solution”, the lightweight and mobile metering station is suitable for many applications. With the integrated control software and the user-friendly interface, any metering and conveying task can be implemented quickly and easily.

Metering box 5000

-

The universal controller for all pump and control loops

GATHER’s Metering box 5000 with integrated, universal PLC enables exact conveying, metering or filling at the touch of a button. It is suitable for all applications where pumps are operated in a loop system.

Your Advantages at a Glance- Easy to use interface and handling (“Plug and Play”)

- No programming skills required

- Automated tuning for determining the control parameters (PID)

- Easy integration into any control circuits, applicable to all dosage tasks and measuring systems

- Both continuous metering and batch filling possible

- Functionality independent of liquid viscosity

- Integrated “master-slave” function

- Applicable to all pumps (with pulsation-free delivery characteristics)

- Special interfaces on request

Modular rack design

-

Development, assembly and manufacturing from a single source

With decades of experience in the chemical, pharmaceutical, medical and food industries, we can offer complete system solutions from a single source and supply individually modular systems. These solutions include transfer, measuring and monitoring as well as process control with our GATHER Metering box 5000.

The profiles used are variable, modular and can be used in a wide variety of configurations. With this flexibility, we are able to respond to the respective application in a cost-sensitive manner and provide the customer with the best possible system configuration in terms of installation space as well as selection of materials. Due to the modular approach, we can offer high-quality and expandable racks quickly and at a reasonable price.

Development, Assembly, and Manufacturing from a Single Source

- Grooved profile systems in stainless steel or aluminium

- Modularly expandable

- Customised welded constructions in stainless steel design

- Engineering advice on site