- Offer Profile

-

With the development of our first high-performance industrial robots in the 1960's, NACHI proved its high innovative abilities in the field of automation. Since then, NACHI has continuously increased its range of industrial robots.

Today, NACHI provides customized automation solutions with robots for all application areas. Whether loading/unloading of machine tools and injection molders or spot and seam welding in the automotive and steel construction industries, picking, packaging, and palletizing of all kinds of components, as well as positioning and assembling small components in electronics manufacturing.

Robots

Collaborative robot CZ

-

Nachi's new robot, CZ10, has several people-friendly functions and structures.

Makes it easier to install a robot with various applications.Collaborative people-friendly design

Nachi's new robot, CZ10, has several people-friendly functions and structures.

Makes it easier to install a robot with various applications.Stops safely when contact is made with person.

Stops when collision is detected.

Easy Programming

Pinch Points Eliminated.

All specifications subject to change without notice.

CZ10

-

Max. reach: 1300mm Payload: 10kg Axes: 6 Repeatability: ±0.1mm Protection Rating Body: IP54

Pick-and-place robot EZ

-

Space-saving thanks to overhead drive with vertical movement of the first axis. Requires no floor space. Highly dynamic axis movements for productive and efficient mounting and installing in electric and electronics manufacturing. Simple and collision-free programming thanks to internal cable and hose runs and hollow wrists.

KEY FACTS:

- Four and six-axis versions

- 2 and 3kg payload

- up to 550mm reach

- up to 0.014mm repeatability

EZ02-V6-02-4515

-

Max. reach: 450mm Payload: 2kg (1kg rated) Axes: 6 Repeatability: ±0.02mm Protection Rating Body: IP20

EZ02-V6-02-4525

-

Max. reach: 450mm Payload: 2kg (1kg rated) Axes: 6 Repeatability: ±0.02mm Protection Rating Body: IP20

EZ03V4-02-4515

-

Max. reach: 450mm Payload: 3kg (2kg Rated) Axes: 4 Repeatability: ±0.014mm Protection Rating Body: IP20

EZ03V4-02-4525

-

Max. reach: 450mm Payload: 3kg (2kg Rated) Axes: 4 Repeatability: ±0.014mm Protection Rating Body: IP20

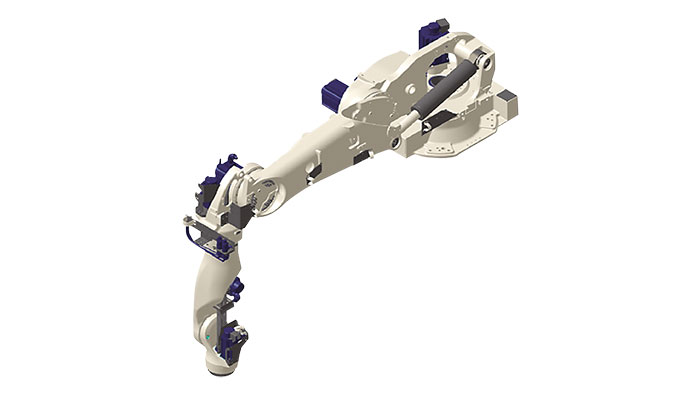

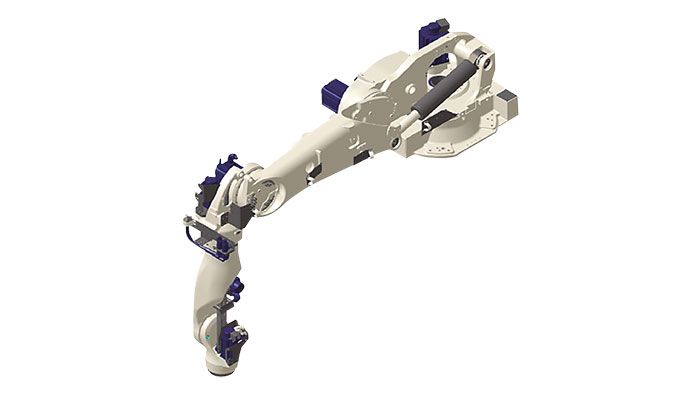

7-axis Robot - MR-Series (20-50kg) for handling

-

MR series

Flexible and complex positioning and motion can be available by 7-axes structure.

Minimizing installation space.7-axes structure

Flexible and complex positioning and motion can be available by 7-axes structure.

Compact body, powerful arm

Minimizing installation space.

Payload 20kg MAX 30kg

MR20

-

Max. reach: 1260mm Payload: 20kg Axes: 7 Repeatability: ±0.06mm Protection Rating Body: IP65

MR20L

-

Max. reach: 1398mm Payload: 20kg Axes: 7 Repeatability: ±0.06mm Protection Rating Body: IP65

MR35

-

Max. reach: 2050mm Payload: 35kg Axes: 7 Repeatability: ±0.07mm Protection Rating Body: IP67

MR50

-

Max. reach: 2050mm Payload: 50kg Axes: 7 Repeatability: ±0.07mm Protection Rating Body: IP67

6-axis robots

Six-axis robots of the MZ series (1-25 kg)

World’s fastest lightweight compact robot The MZ series are the world’s fastest lightweight compact robots. These robots are available in dust-proof and drip-proof specifications, with multiple installation orientations that provide flexibility to automate a variety of processes for an all-round compact high-performance robot.

The hollow wrist construction for the MZ series includes an internal path for wiring, which provides a streamlined profile for working in confined spaces.The MZ25, which has a vast workspace, is the latest addition to the MZ series.

This high-speed and precise robot was designed with advanced CAD tools for a very lightweight, but strong, rigid structure, which helps improve cycle time by 12%

MZ01

-

Max. reach: 350mm Payload: 1kg Axes: 6 Repeatability: ±0.02mm Protection Rating Body: IP40

MZ03EL

-

Max. reach: 1102mm Payload: 3.5kg Axes: 6 Repeatability: ±0.03mm Protection Rating Body: IP67

MZ04 (MZ04D)

-

Max. reach: 541mm Payload: 4kg Axes: 6 Repeatability: ±0.02mm Protection Rating Body: IP40 (IP67)

MZ07

-

Max. reach: 723mm Payload: 7kg Axes: 6 Repeatability: ±0.02mm Protection Rating Body: IP67

MZ07F

-

Max. reach: 723mm Payload: 7kg Axes: 6 Repeatability: ±0.015mm Protection Rating Body: IP67

MZ07L

-

Max. reach: 912mm Payload: 7kg Axes: 6 Repeatability: ±0.03mm Protection Rating Body: IP67

MZ07LF

-

Max. reach: 912mm Payload: 7kg Axes: 6 Repeatability: ±0.02mm Protection Rating Body: IP67

MZ10

-

Max. reach: 723mm Payload: 10kg Axes: 6 Repeatability: ±0.03mm Protection Rating Body: IP67

MZ10LF

-

Max. reach: 1202mm Payload: 10kg Axes: 6 Repeatability: ±0.025mm Protection Rating Body: IP67

MZ12

-

Max. reach: 1454mm Payload: 12kg Axes: 6 Repeatability: ±0.04mm Protection Rating Body: IP67

MZ12H

-

Max. reach: 1454mm Payload: 12kg Axes: 6 Repeatability: ±0.04mm Protection Rating Body: IP67

MZ25

-

Max. reach: 1882mm Payload: 25kg Axes: 6 Repeatability: ±0.05mm Protection Rating Body: IP67

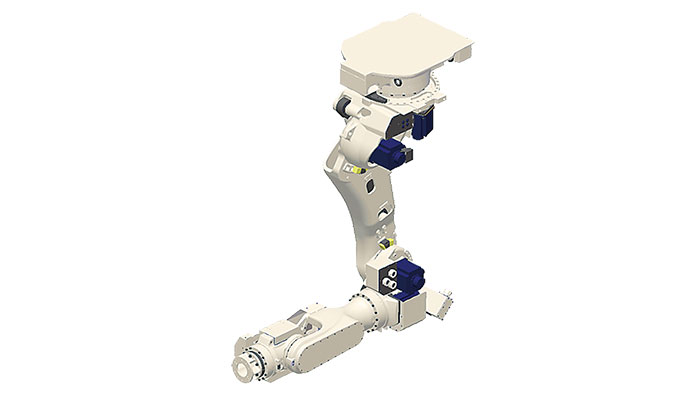

6-axis robot - MC-Series for handling (20-70 kg)

-

Wide envelope and environment protection makes the MC-series a valuable robot for various kind of manufacturing processes.

Easy installation by compact design, and powerful wrist supports to transfer large or heavy works.Suitable for various purpose.

Wide envelope and environment protection makes MC-series a valuable robot for various kind of manufacturing processes.

Compact design

Easy installation by compact design, and powerful wrist supports to transfer large or heavy works.

MC20

-

Max. reach: 1722mm Payload: 20 (max. 22) kg Axes: 6 Repeatability: ±0.06mm Protection Rating Body: IP65

MC35

-

Max. reach: 2050mm Payload: 35kg Axes: 6 Repeatability: ±0.07mm Protection Rating Body: IP54 (Option: IP65/67)

MC50

-

Max. reach: 2050mm Payload: 50kg Axes: 6 Repeatability: ±0.07mm Protection Rating Body: IP54 (Option: IP65/67)

MC70

-

Max. reach: 2050mm Payload: 70kg Axes: 6 Repeatability: ±0.07mm Protection Rating Body: IP54 (Option: IP65/67)

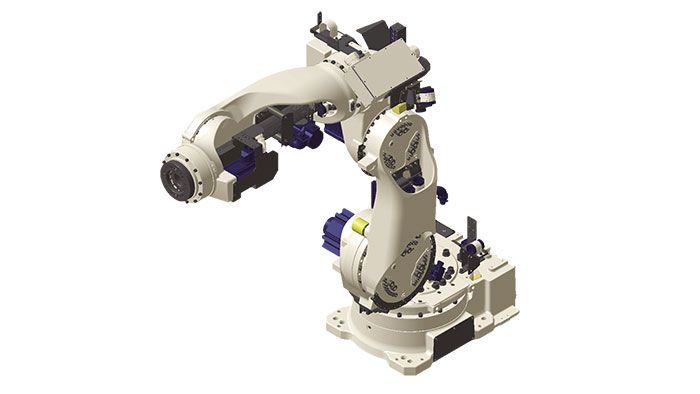

6-axis robot - Spot Welding SRA-Series (100-250 kg)

-

SRA Series

Ultra-fast spot welding robotThe ultimate spot welding robot. Using higher speeds and vibration damping properties, we greatly improved productivity by shortening cycle times by 30% (compared with our existing models). Improvements were made in three areas, weight reduction, higher rigidity, and faster controls.

The compact design allows for high-density installation layouts, and maintenance is streamlined, making periodic inspections and parts replacement easy. The lighter weight and latest in motor drive controls have reduced power consumption by 15% over existing models, reducing environmental impact.The hollow arm version of the shelf mount for the 166kg and 210kg are now available.

SRA100

-

Max. reach: 2654mm Payload: 100kg Axes: 6 Repeatability: ±0.1mm Protection Rating Body: IP54

SRA100B

-

Max. reach: 2071mm Payload: 100kg Axes: 6 Repeatability: ±0.1mm Protection Rating Body: IP5

SRA100H

-

Max. reach: 2654mm Payload: 100kg Axes: 6 Repeatability: ±0.1mm Protection Rating Body: IP54

SRA100HB

-

Max. reach: 2044mm Payload: 100kg Axes: 6 Repeatability: ±0.1mm Protection Rating Body: IP54

SRA100HS

-

Max. reach: 1634mm Payload: 100kg Axes: 6 Repeatability: ±0.1mm Protection Rating Body: IP54

SRA100J

-

Max. reach: 1634mm Payload: 100kg Axes: 6 Repeatability: ±0.1mm Protection Rating Body: IP54

SRA120EL

-

Max. reach: 3099mm Payload: 120kg Axes: 6 Repeatability: ±0.15mm Protection Rating Body: IP54

SRA133H

-

Max. reach: 2654mm Payload: 133kg Axes: 6 Repeatability: ±0.1mm Protection Rating Body: IP54

SRA133HL

-

Max. reach: 2951mm Payload: 133kg Axes: 6 Repeatability: ±0.15mm Protection Rating Body: IP54

SRA133L

-

Max. reach: 2951mm Payload: 133kg Axes: 6 Repeatability: ±0.15mm Protection Rating Body: IP54

SRA166

-

Max. reach: 2654mm Payload: 166kg Axes: 6 Repeatability: ±0.15mm Protection Rating Body: IP54

SRA166H

-

Max. reach: 2654mm Payload: 166kg Axes: 6 Repeatability: ±0.1mm Protection Rating Body: IP54

SRA166HT

-

Max. reach: 3087mm Payload: 166kg Axes: 6 Repeatability: ±0.1mm Protection Rating Body: IP54

SRA166L

-

Max. reach: 2951mm Payload: 166kg Axes: 6 Repeatability: ±0.15mm Protection Rating Body: IP54

SRA166T

-

Max. reach: 3086mm Payload: 166kg Axes: 6 Repeatability: ±0.1mm Protection Rating Body: IP54

SRA166TL

-

Max. reach: 3383mm Payload: 166kg Axes: 6 Repeatability: ±0.15mm Protection Rating Body: IP54

SRA210

-

Max. reach: 2674mm Payload: 210kg Axes: 6 Repeatability: ±0.15mm Protection Rating Body: IP54

SRA210H

-

Max. reach: 2654mm Payload: 210kg Axes: 6 Repeatability: ±0.15mm Protection Rating Body: IP54

SRA210HT

-

Max. reach: 3087mm Payload: 210kg Axes: 6 Repeatability: ±0.15mm Protection Rating Body: IP54

SRA210T

-

Max. reach: 3106mm Payload: 210kg Axes: 6 Repeatability: ±0.15mm Protection Rating Body: IP54

SRA210V

- Description

SRA220H

-

Max. reach: 2575mm Payload: 220kg Axes: 6 Repeatability: ±0.15mm Protection Rating Body: IP54

SRA220HV

-

Max. reach: 2575mm Payload: 220kg Axes: 6 Repeatability: ±0.15mm Protection Rating Body: IP54

SRA240

-

Max. reach: 2674mm Payload: 240kg Axes: 6 Repeatability: ±0.2mm Protection Rating Body: IP54

SRA250

-

Max. reach: 2792mm Payload: 250kg Axes: 6 Repeatability: ±0.2mm Protection Rating Body: IP54

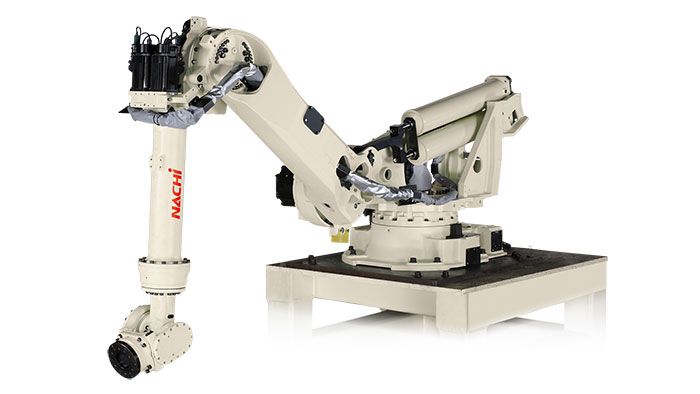

6-axis robot - MC-Series (280-1000 kg)

MC1000DL

-

Max. reach: 3972mm Payload: 1000kg Axes: 6 Repeatability: ±0.3mm Protection Rating Body: IP54

MC280L

-

Max. reach: 3101mm Payload: 280kg Axes: 6 Repeatability: ±0.2mm Protection Rating Body: IP54

MC350

-

Max. reach: 2771mm Payload: 350kg Axes: 6 Repeatability: ±0.2mm Protection Rating Body: IP54

MC400L

-

Max. reach: 3756mm Payload: 400kg Axes: 6 Repeatability: ±0.3mm Protection Rating Body: IP54

MC600

-

Max. reach: 2890mm Payload: 600kg Axes: 6 Repeatability: ±0.3mm Protection Rating Body: IP54

MC700

-

Max. reach: 2890mm Payload: 700kg Axes: 6 Repeatability: ±0.3mm Protection Rating Body: IP54

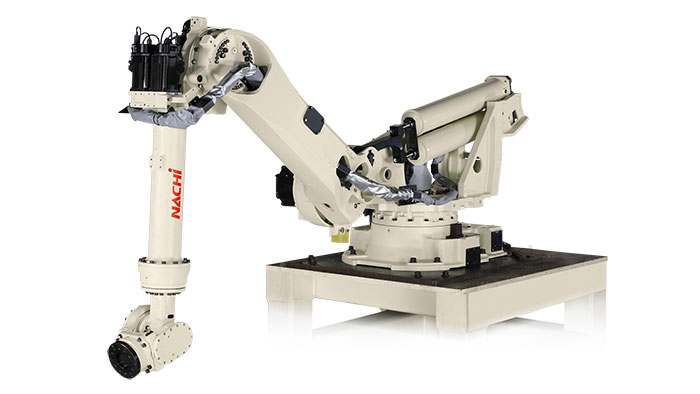

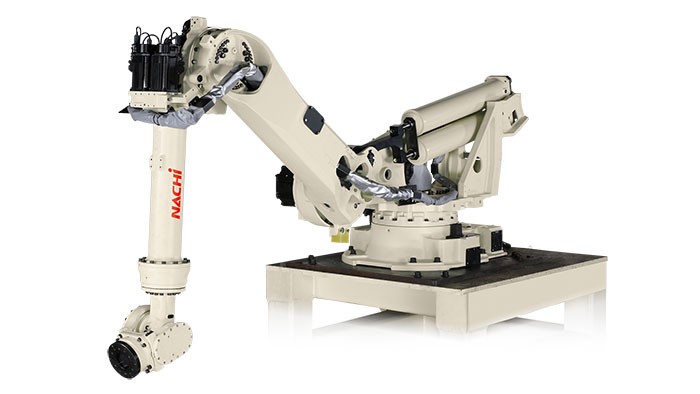

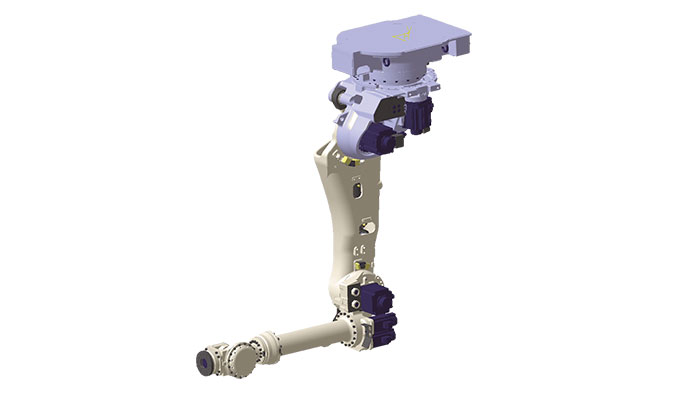

Palletizing-LP and MC-Series

-

LP series

High performance based on the large capacity motor and the enhanced optimized motion control.

Improvement of 20% compared with the conventional model.High-speed handling

1,800 packages per hour at maximum. (for 130kg loads)

(Improvement of 20% compared with the conventional model.

High performance based on the large capacity motor and the enhanced optimized motion control

* Motion pattern: 400mm in vertical direction, 2,000mm in horizontal direction and 60 degree in swivel movement.Flexible palletizing

Flexible layout of work-piece of various shapes/sizes due to the wide operation range (Pallet area size: 1,600mm squares and the hight is up to 2,212mm)

Hadling with suitable hand (option) for the work-piece is availableCompact layout

The large motion range and the space saving design reducing the interference amount realize the compact and flexible design of the equipments.

Easy operation

Easy setup due to an interactive interface.

Easy programming by interactive program generator.

LP130F

-

Max. reach: 3210mm Payload: 130kg Axes: 4 Repeatability: ±0.3mm Protection Rating Body: IP54

LP180

-

Max. reach: 3210mm Payload: 180kg Axes: 4 Repeatability: ±0.4mm Protection Rating Body: IP54

LP210

-

Max. reach: 3210mm Payload: 210kg Axes: 4 Repeatability: ±0.4mm Protection Rating Body: IP54

MC-Series for palletizing

MC palletizing series

High speed Heavy payload by the Hollow wrist structure.

Heavy loader palletizing

High speed Heavy payload by the Hollow wrist structure

This robot has enough lifting power to handle jobs loading and stacking beverages, bricks, plastic resins, concrete and other heavy goods.

MC470P

-

Max. reach: 2771mm Payload: 470kg Axes: 6 Repeatability: ±0.2mm Protection Rating Body: IP54

MC500P

-

Max. reach: 3756mm Payload: 500kg Axes: 5 Repeatability: ±0.3mm Protection Rating Body: IP54

Heavy Duty- MC-Series

-

MC Heavy Loader Series

Heavy loader robotWith high wrist torque and large operating envelope, these robots are opening up a new era of heavy loading robots.Simple construction has no counterweights or parallel linkage on MC350 and MC280L models.

Compact arm design requires minimal installation space for a heavy payload robot. Welding cables and hoses routed inside hollow arms provide excellent life.

MC280L

-

Max. reach: 3101mm Payload: 280kg Axes: 6 Repeatability: ±0.2mm Protection Rating Body: IP54

MC350

-

Max. reach: 2771mm Payload: 350kg Axes: 6 Repeatability: ±0.2mm Protection Rating Body: IP54

MC400L

-

Max. reach: 3756mm Payload: 400kg Axes: 6 Repeatability: ±0.3mm Protection Rating Body: IP54

MC470P

-

Max. reach: 2771mm Payload: 470kg Axes: 6 Repeatability: ±0.2mm Protection Rating Body: IP54

MC500P

-

Max. reach: 3756mm Payload: 500kg Axes: 5 Repeatability: ±0.3mm Protection Rating Body: IP54

MC600

-

Max. reach: 2890mm Payload: 600kg Axes: 6 Repeatability: ±0.3mm Protection Rating Body: IP54

Controller

Introducing the intelligent robot controller based on Windows.

Robots and additional axis are easy to operate by using the teach pendant.

Vision and force sensors, as well as networks, are managed in one place.

CONTROLLER FD18

-

Basic specifications for controller

Item Specifications Controllable axes 6 Maximum controllable axes 8 External dimensions [mm] 300 (W) × 600 (D) × 1050 (H) Max. I/O 2048 Maximum programmes 9999 Position reader Absolute encoder Protection rating IP54 Power supply three-phase 400 V, AC Ambient temperature/humidity 0 to 40°C (50/60Hz) / 20 to 85% (without condensation) Robot monitoring function PL d (Cat. 3), optional: PL e

CONTROLLER FD11

-

Basic specifications for controller

Item Specifications Controllable axes 6 Maximum controllable axes 8 External dimensions [mm] 580 (W) × 542 (D) × 1180 (H) Max. I/O 2048 Maximum programmes 9999 Position reader Absolute encoder Protection rating IP54 Power supply three-phase 400 V, AC Ambient temperature/humidity 0 to 40°C/20 to 85% (without condensation) Robot monitoring function PL d (Cat. 3), optional: PL e

CONTROLLER CFD (FOR MZ-SERIES ONLY)

-

Basic specifications for controller

Item Specifications Controllable axes 6 Maximum controllable axes 7 External dimensions [mm] 369 (W) × 490 (D) × 250 (H) Max. I/O 2048 Maximum programmes 9999 Protection rating IP20 Power supply one-phase 230 V, AC Ambient temperature/humidity 0 bis 40°C/20 bis 85% (without condensation) Robot monitoring function PL d (Cat. 3), optional: PL e

CONTROLLER CFDL (FOR EZ-SERIES ONLY)

-

Basic specifications for controller

Item Specifications Model CFDL1-0000 CFDL2-0000 CFDL4-0000 Maximum controllable units 1 2 4 Maximum controllable axes 6 axes/unit External dimensions [mm] 369 (W) × 490 (D) × 250 (H) 369 (W) × 560 (D) × 327 (H) Protection rating IP20 Power supply one-phase 230 V, AC Ambient temperature/humidity 0 to 40°C (50/60 Hz) / 20 to 85% (without condensation)