- Offer Profile

-

The best barrier against moisture and dirt: foam sealing technology made by CeraCon

The only things which are really leakproof are those which do not contain any gaps. In order to achieve this, sealing foams with outstanding properties, reliable foam technology and plenty of experience in automation and application technology are required. In brief: CeraCon Sealing systems.

Prevents noises before they start: foam sealing technology by CeraCon

Creaking centre consoles, clattering cockpit elements – unwanted vibration and friction sounds can reduce your sense of well-being. Stop "noise vibration harshness": with CeraCon Sealing systems.

CeraCon Sealing systems: Foam Sealing Technology

- System solutions for single-component PUR foam seals for reliable sealing and noise reduction.

The best barrier against moisture and dirt: foam sealing technology made by CeraCon

- The only things which are really leakproof are those which do not contain any gaps. In order to achieve this, sealing foams with outstanding properties, reliable foam technology and plenty of experience in automation and application technology are required. In brief: CeraCon Sealing systems.

Sealing materials

-

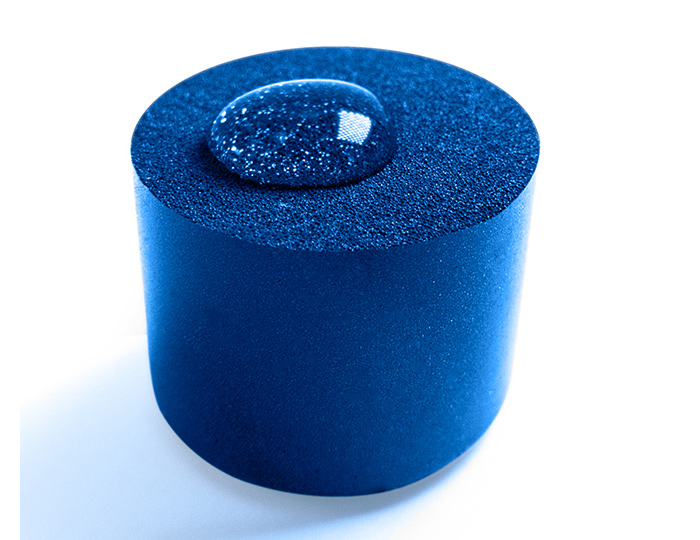

When things need to be tight: single-component polyurethane foams from CeraPUR®

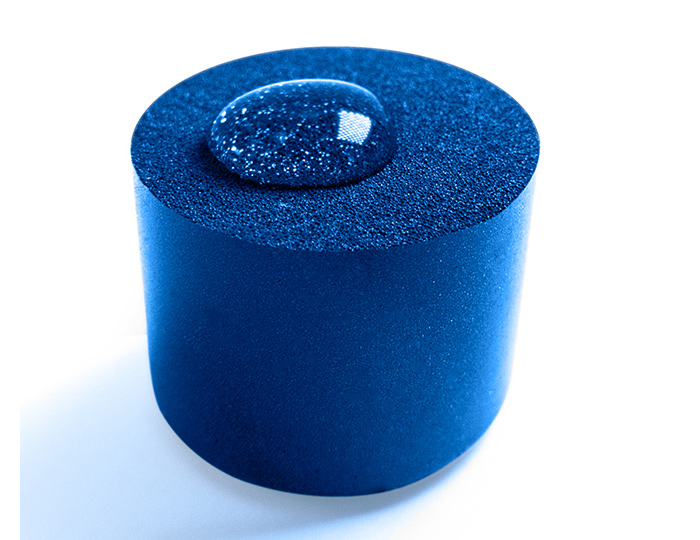

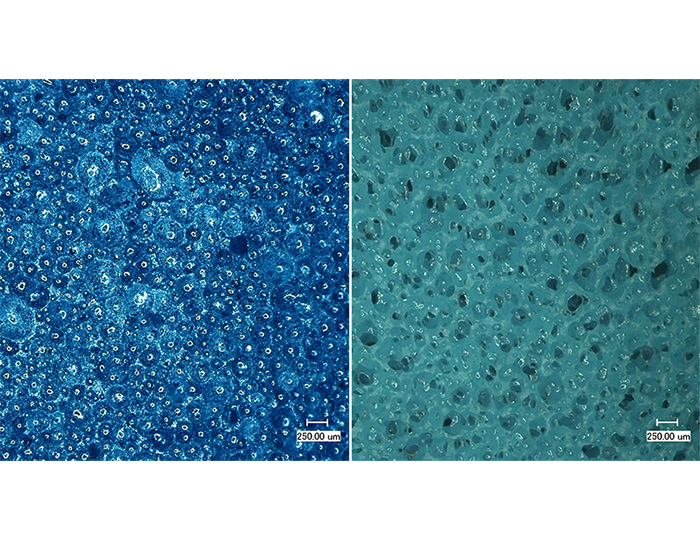

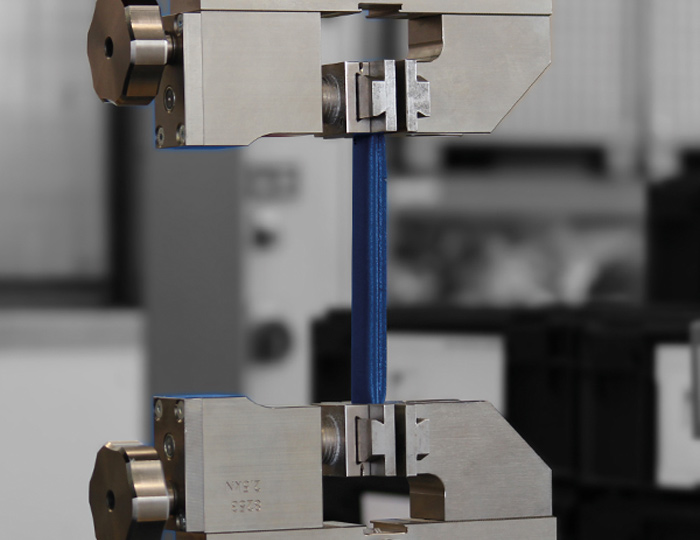

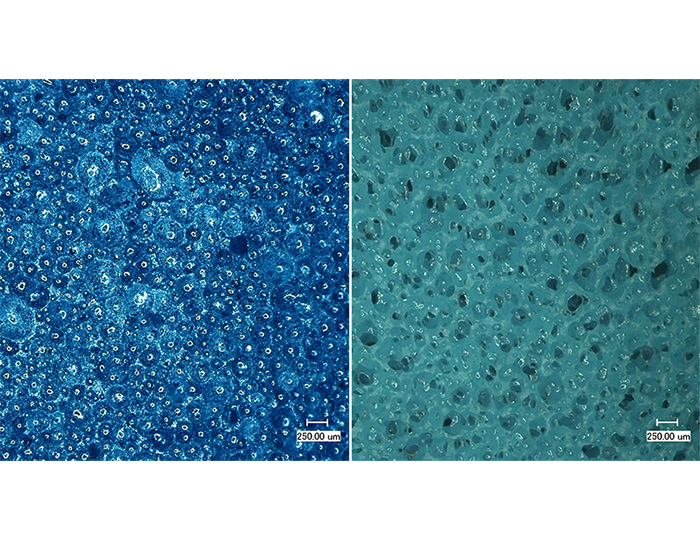

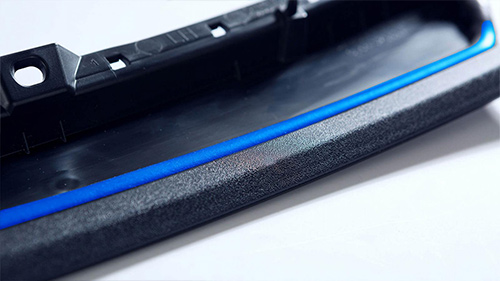

The CeraPUR® sealing materials are solvent-free and very fast cross-linking single-component elastomers. They are mechanically foamed, processed at room temperature in a standard room atmosphere and enable the efficient, environmentally friendly and reliable application of foamed seals – without the well-known problems such as the pot life, rinsing, test shots or the search for the right mixing ratio. During the foaming process, gas pores – the cells of the PUR foam – develop in the raw material. The higher the share of closed cells, the less moisture can penetrate. Due to the purely physical foaming process and clever combination of raw materials, CeraPUR® foam beads exhibit predominantly closed-cell structures and outstanding hydrolysis.

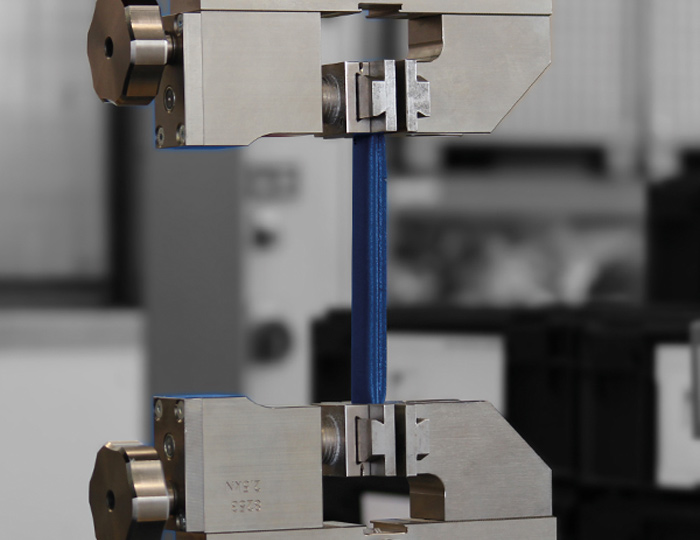

resistance after curing. CeraPUR® is also extremely tear-resistant. A decisive advantage not only during installation, but also in terms of tightness. We offer CeraPUR® in various designs, degrees of softness and colours, tailor-made to provide protection against moisture and dirt or for noise attenuation. In our laboratory and application technology department we are always working on further improvements and developing customised special solutions for specific requirements. Always in focus: certified quality, environmental compatibility and occupational safety. Simply talk to our specialists and you will receive the perfect sealing material for your demanding applications.

The most important advantages at a glance

- Mechanical foaming process without pot life, rinsing or test shots

- Predominantly closed-cell structure: extreme tightness

- Excellent resistance to hydrolysis

- Very good recovery behaviour

- Extreme tear resistance

- Fast curing: cycle times of less than 2 seconds

Flexible, simple, reliable: CeraFLOW® foam metering systems

-

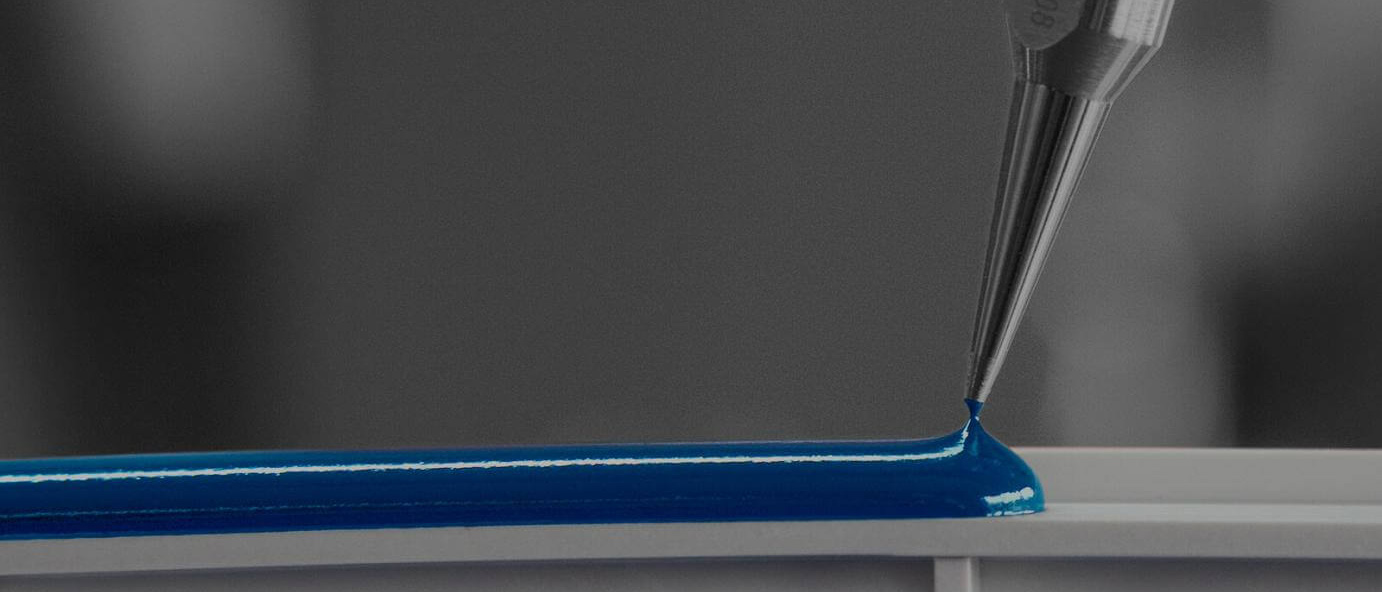

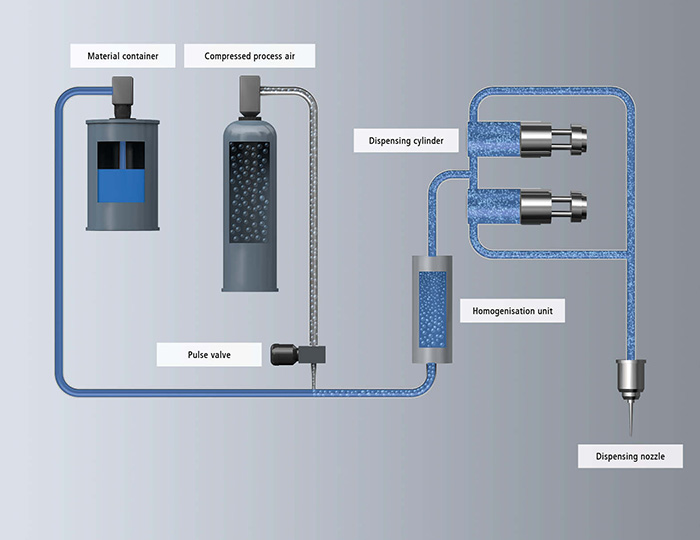

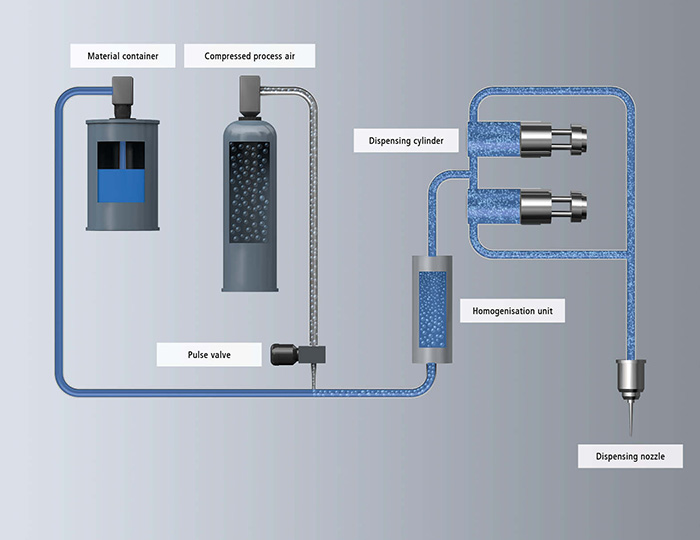

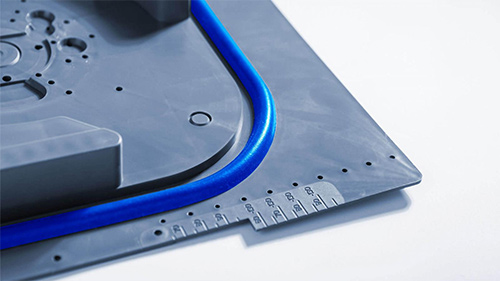

As a service provider with more than 15 years of experience in contract gasketing we know: never before has the use of foams for seals been as uncomplicated and clean as it is today – without any chemical reaction, pot life, rinsing or test shots. This is made possible by single-component sealing materials (polyurethane or silicone) and our CeraFLOW® foam technology, which is fully tailored to customer requirements. The principle (see image below): single-component sealing material is pumped directly out of the container into the CeraFLOW® system, where it is mixed with compressed air. Shearing forces cause an even, very fine foam to develop whose softness can be regulated by means of air content – fully in line with your wishes and the specific application. The foam is then precisely dispensed, for example, by means of a robot-guided valve using the FIPFG process, and applied to the component. Only now does the sealant harden. This means that it can remain in the system for a very long time without reacting. We offer you CeraFLOW® in various standardised versions, depending on whether things need to move quickly, you only want to manufacture small sealing beads, for example as a replacement for O-rings, or you would like to execute a large-volume application, for example on control cabinet doors. And of course we also develop individual automation solutions for you. Simply inform us of your requirements.

The most important advantages at a glance

- Mechanical foaming process without pot life, rinsing or test shots

- Softness of the foam is continuously adjustable

- Short start-up times

- Low maintenance requirements

- High system availability due to quick-change exchange units

For improved efficiency: automation from CeraCon

-

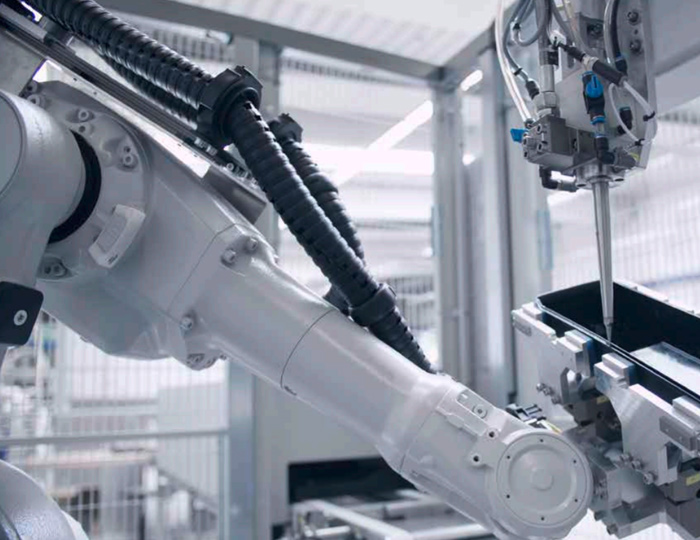

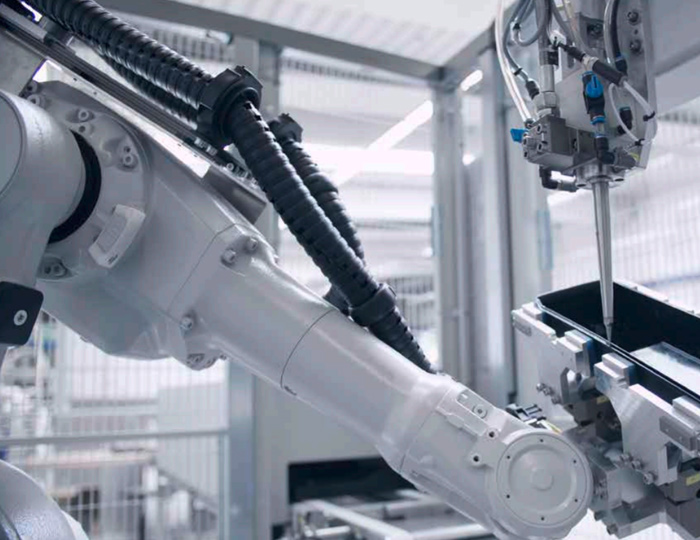

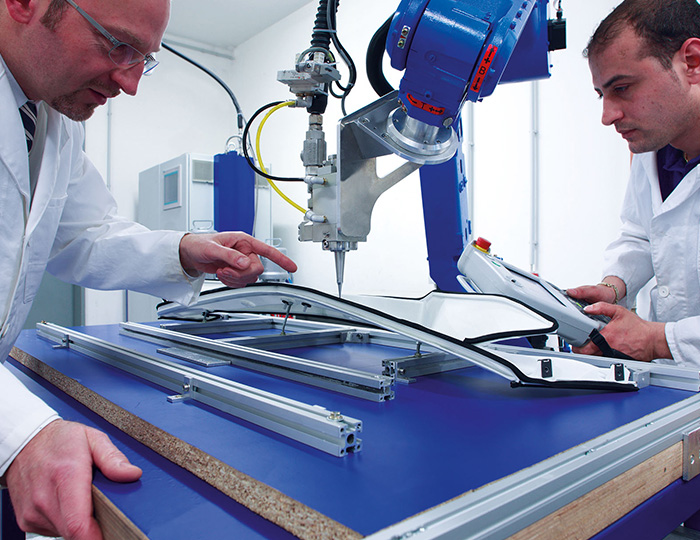

A simple foam dispensing system is not enough for the work you have to do? Maybe you need a fully automatic foaming system instead – best of all integrated into your production lines? No problem: with our extensive expertise in the fields of engineering and automation, as well as many years of experience as a mass producer, we design your individual all-round system and integrate it seamlessly into your production – for example following an injection moulding machine. On request we can also take into account your requirements for Industry 4.0.

If necessary, we insert further upstream and downstream production steps – from pre-treatment, through measuring and testing systems to laser applications (e.g. marking or separating) or curing processes. By the way: if our single-component foam sealing process is combined with heating technology, entire in-line-capable systems with cycle times of less than two seconds can be created.

The most important advantages at a glance

- Safe and quick integration into your production process

- High service-friendliness due to the modular design and standardised components

- One point of contact for sealing material, foam and plant technology

- Integration of further production steps

Let us play it safe: with CeraCon application technology

-

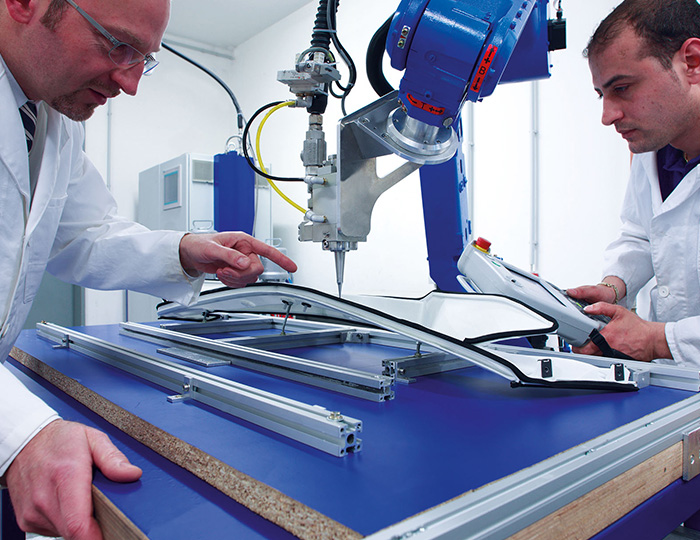

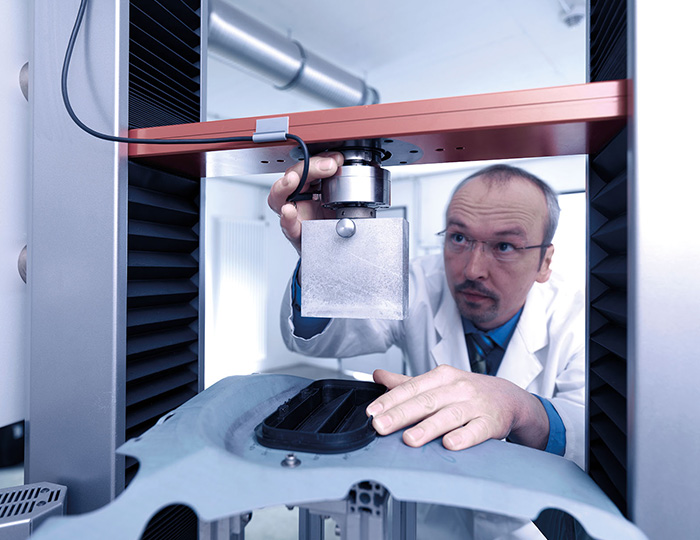

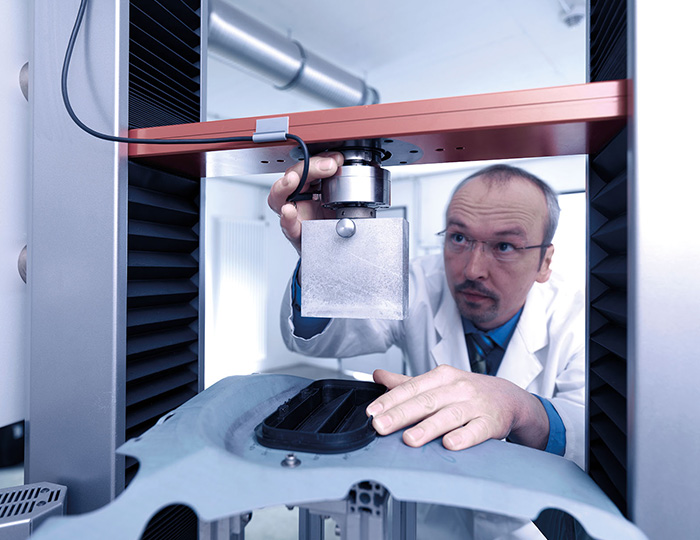

Whether sealing or noise attenuation – there are many factors that have to be considered if you want perfect results. Talk to our experts: they will provide you with assistance from the very beginning, i.e. at the design stage of your components, and provide detailed advice on sealing materials, suitable pre-treatments or the optional use of heat technology. In our technical centre they also sample your components and work out the ideal route to take in the future.

Together with the process parameters that have been established, these findings are integrated directly into the conceptual design of your production plant or contract gasketing order. On request, we also take over responsibility for foaming your prototypes or pre-series samples and carry out standardised component tests for you.

The most important advantages at a glance

- Perfect results and optimised production processes

- More safety: we assume responsibility for the component that needs to be sealed

- Create a good impression with your customers through the use of illustrative samples

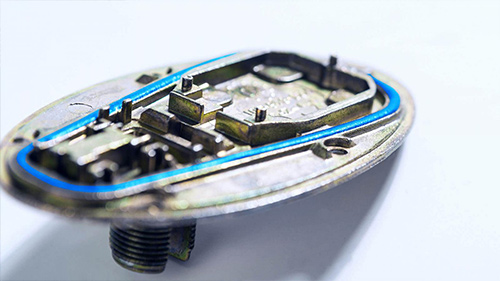

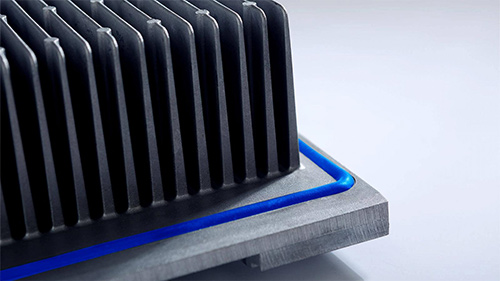

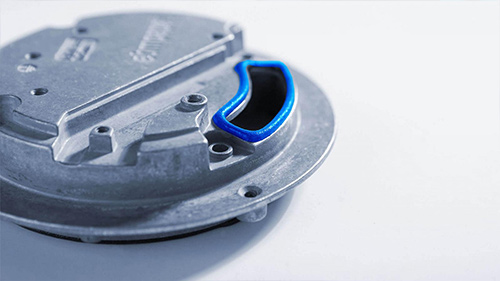

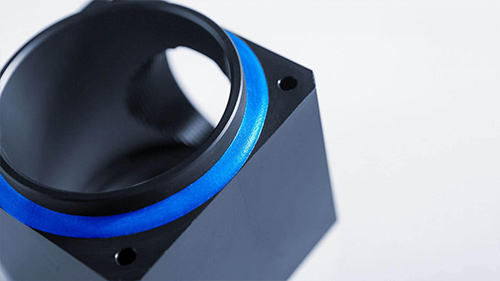

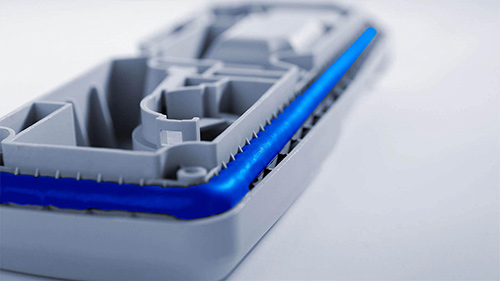

Perfectly foamed: example components from various industries

- Many customers. Countless products. One aim: perfect results when it comes to sealing or noise suppression. To achieve this, we need to know your individual requirements. However, we would be happy to provide you with a first impression.

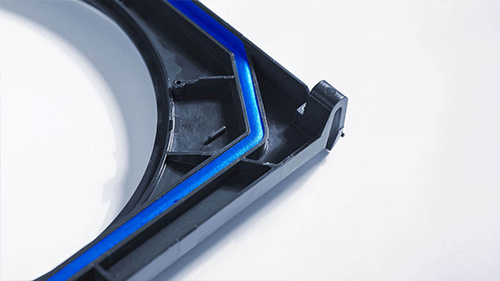

Sealing of rear lamps

Sealing of door modules

Sealing of locker cases

Sealing and cushioning of B-pillar covers

Cushioning of loudspeaker housings

Sealing of bases for roof antennas

Sealing of heat sinks for robot control systems

Sealing of fuse boxes

Sealing of housings for electronic parts

Sealing aluminium die-cast covers for electric motors

Sealing of distributor housings of cable bushings

Sealing of housing parts for traffic lights

Sealing of lint filters for tumble dryers

Sealing of faceplates for dish washers

Sealing of housings of heat pumps for tumble dryers

Sealing of housings for mowing robots

Sealing of covers of transport safety devices for household appliances

Sealing of connecting flanges for washing machines

Sealing of wheel housings for travel cases

Sealing of lids for plastics containers

Sealing of screw tops

Sealing of plugs for drives of electric bicycles

Sealing of covers for roller shutter boxes

Sealing of housings for navigation devices for bicycles