- Offer Profile

-

Expert in mechanical seals

At LIDERING we have an extensive range of mechanical seals for all types of pumps: from seals for domestic pumps to seals for process pumps, specific in complex applications in the chemical and petrochemical industry. In addition, we offer a wide range of spare parts compatible with the originals of the main manufacturers of pumps (RMS). Our catalog also includes cartridge seals for more demanding industrial processes, and our extensive range of products is ever-growing in order to adapt to the requirements of our customers.

Expert in mechanical seals

-

To select the appropriate mechanical seal, it is necessary to know the operating conditions of the application that is to be sealed: shaft diameter and rotation speed, dimensions of the seal housing, physical characteristics of the fluids to be sealed, and in order to determine chemical compatibility; existence of abrasive suspended solids or permitted lubrication and the working temperature and pressure.

Industrial sectors are all subject to increasingly strict regulations. It is very important to prevent the contamination of the processed products and ensure the safety of both the working staff and the equipment in all facilities. To that end, all used materials comply with the different sector-based regulations.Description

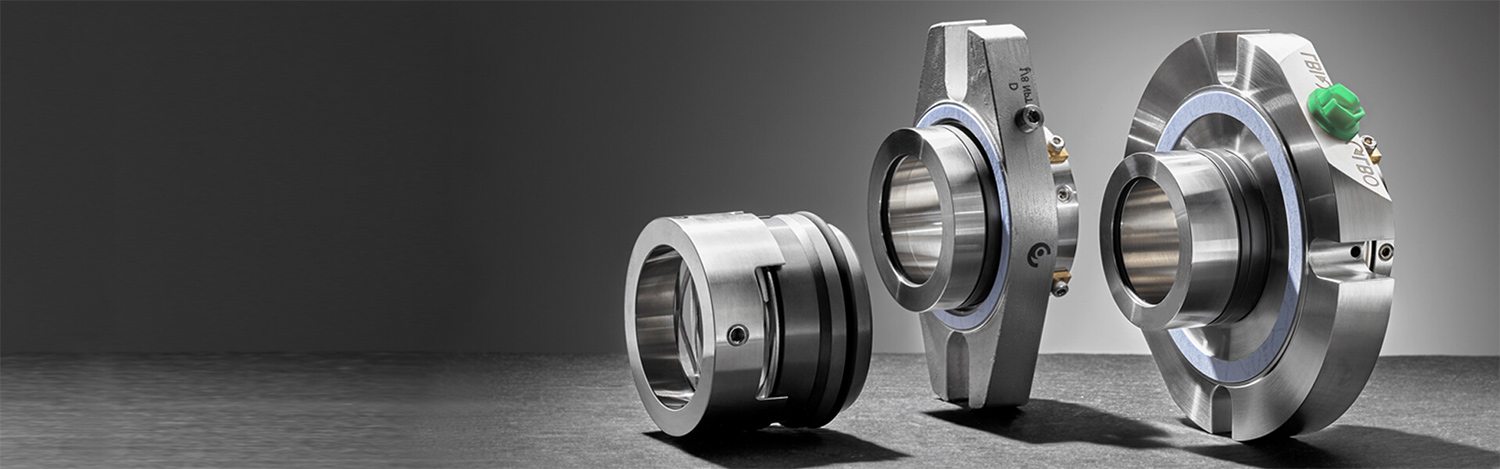

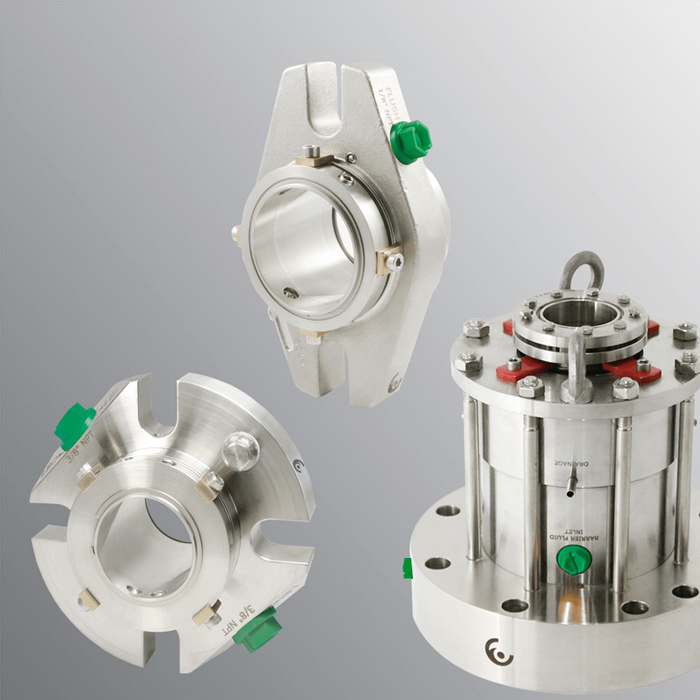

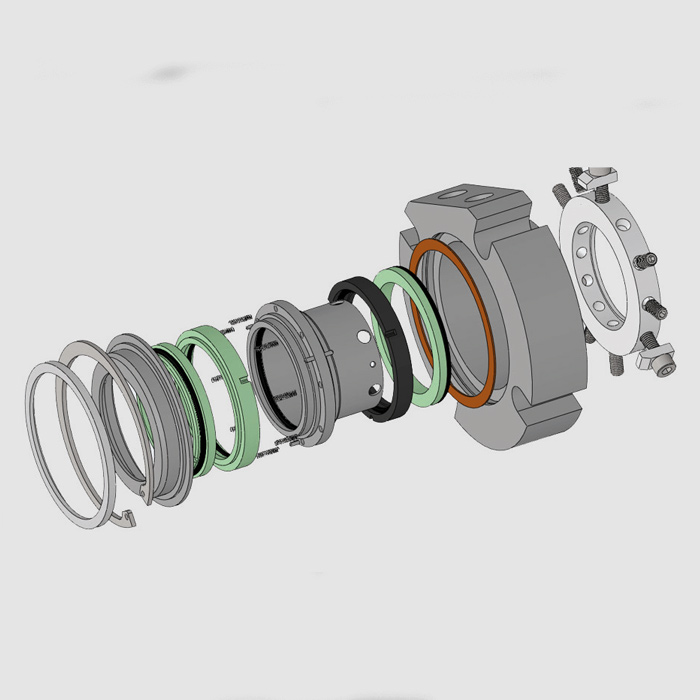

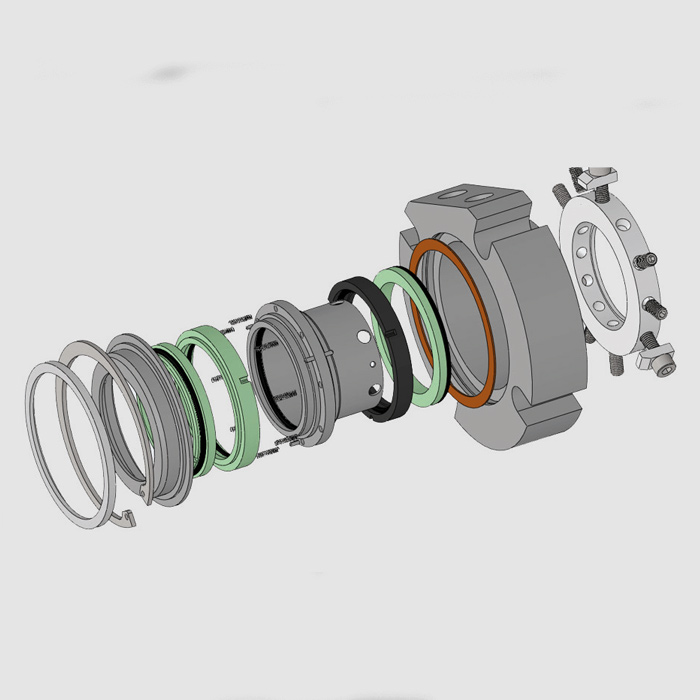

Cartridge seals

-

Cartridge seals have been designed to prevent errors in installation, reduce stopping times, prevent damage to other pump elements and reduce energy consumption. All our cartridge seals have been tested and can be installed easily and quickly. They require no maintenance or re-tightening.

Applications

- Industrial varnishes and paints

- Petrochemical industry

- Pulp and paper industry

- Food industry: in the production of sauces, candies and chocolates

- Pharmaceutical and cosmetic industry: production of creams, ointments, cosmetics and gels

- Waste water treatment: in de-sanding, de-greasing and decanting processes

- Sump pumps in the naval industry, etc.

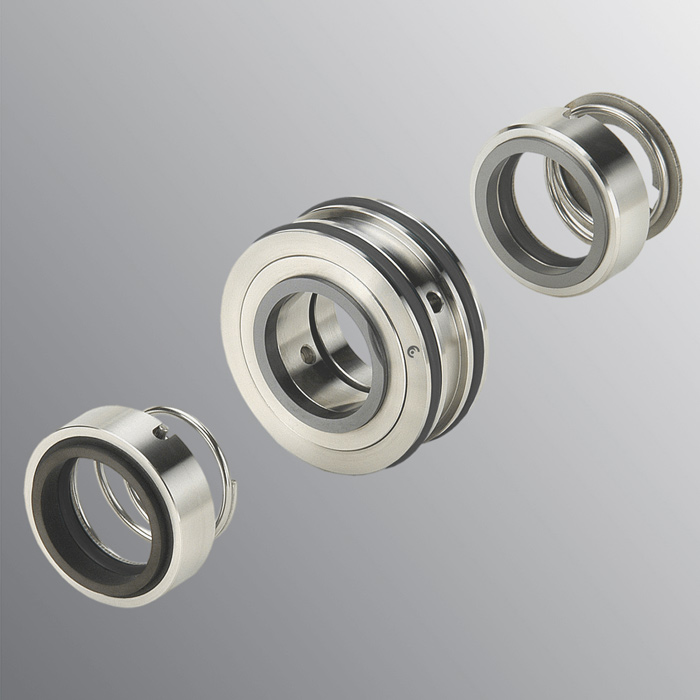

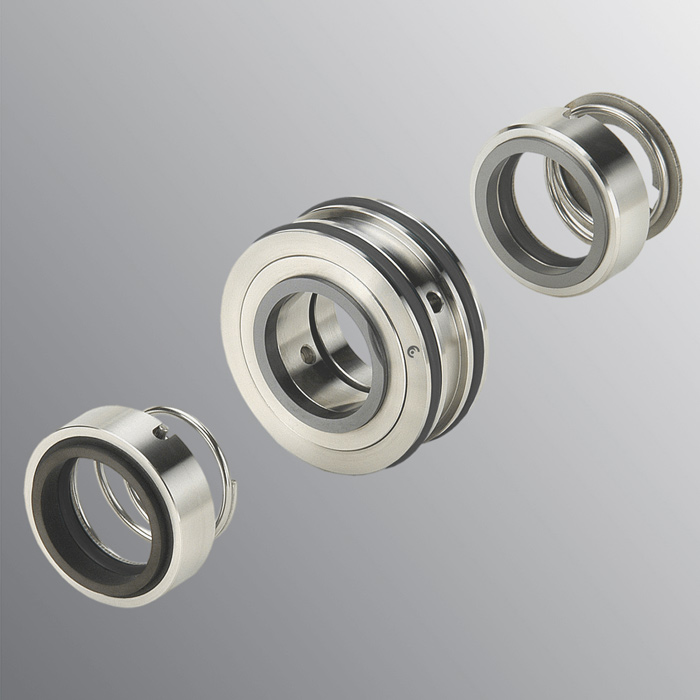

Mechanical seals for process pumps

-

Mechanical component seals, formed by a rotary contact surface, a fixed contact surface, secondary seals and springs. Depending on their hydraulic compensation, they may be balanced or non-balanced. Based on their construction, they are divided into: mechanical conical spring seals, mechanical bellow seals (elastomer bellow seals, metal bellow seals or PTFE bellow seals), mechanical multi spring seals and mechanical wave spring seals.

We have an extensive range of designs, which depend on specific working conditions.

Applications

- Chlorine and similar sub-products, acid and caustic products, detergents and fertilisers in the chemical industry

- Dairy products: milk, yogurt, butter, cheese, fats, etc. in the food industry

- Beer and soft drinks in the beverages industry

- Water treatment plants, in deodorising processes

- Salt water transfer pumps in the naval industry

Mechanical seals for domestic pumps

-

Mechanical seals for domestic pumps are mechanical component seals with a simple, economical and versatile design for applications with a low degree of complexity. Mechanical seals for domestic pumps have a single spring or rubber bellow, non-balanced design. We have a wide range of designs and elastomer materials for secondary seals.

Applications

- Pumping of industrial waste water

- Domestic pumps

- Spa and hydromassage pumps

- Drinking water pumps

RMS mechanical seals

-

The RMS mechanical seals range is compatible with the spare parts of the most popular industrial pump brands, such as Flygt®, Grundfos-Sarlin®, ABS®, Alfa Laval®, Hilge®, APV®, Fristam®, etc.

We also supply kits that contain mechanical seals and other replacement elements, like gaskets, O-rings, etc.

Applications

- Waste water transfer pumps

- Heating pumps

- Food product transfer pumps

- Pumps and agitators for pharmaceutical products

- Naval pumps

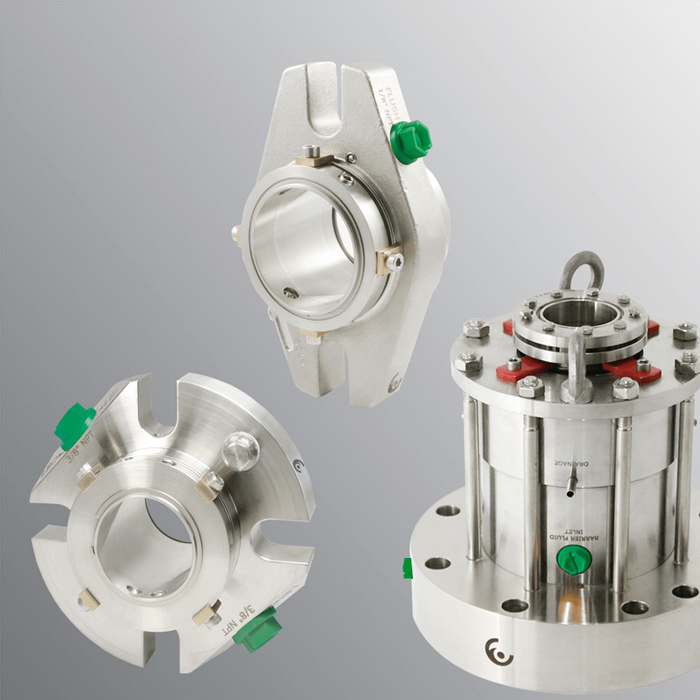

Auxiliary mechanical seal products

-

Auxiliary mechanical seals consist of a set of elements which assist in ensuring the proper functioning of mechanical seals and other customer equipment. These include cyclone seals which prevent particles, or other waste that could damage the mechanical seal, from entering the system, tanks that create barrier or quench fluids with instruments that permit automatic level control, checking of circuit pressure and temperature, and manual pumps for placing in the tank.

Applications

- Chemical and petrochemical products

- Food products

- Pulp and paper industry

- HVAC industry

- Waste water treatment

Associated product

-

Seals for static and dynamic applications, and elements for the correct lubrication of machinery:

Applications

Braided packing: to seal alternative or helical movements. The operating principle is achieved through the interference obtained by external tightening.

Rotary joints: to facilitate the passage of the fluid between a rotary and another fixed element.

Mechanical face seals: used to seal rotary applications, in extremely difficult working conditions in which high abrasion resistance is needed.

Services

-

A referential company in design, manufacture, and repair of mechanical seals

Our over 45 years’ experience in the market positions us as experts in solutions for the pumping and fluid transfer industry. Our active presence and knowledge of processes and applications in critical sectors such as the chemical, pharmaceutical, food, energy, petrochemical and waste processing industries allows us to offer our customers reliable, high quality products.

We apply our experience and technology to repairing and commissioning mechanical seals for pumping and stirring equipment, compressors or propulsion systems for the naval industry, implementing improvements that lengthen the life of the equipment and improve its reliability and performance.

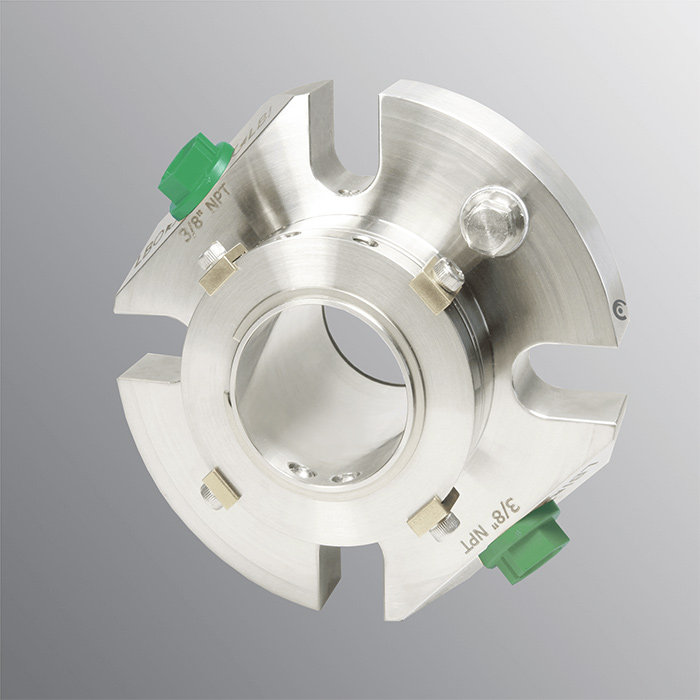

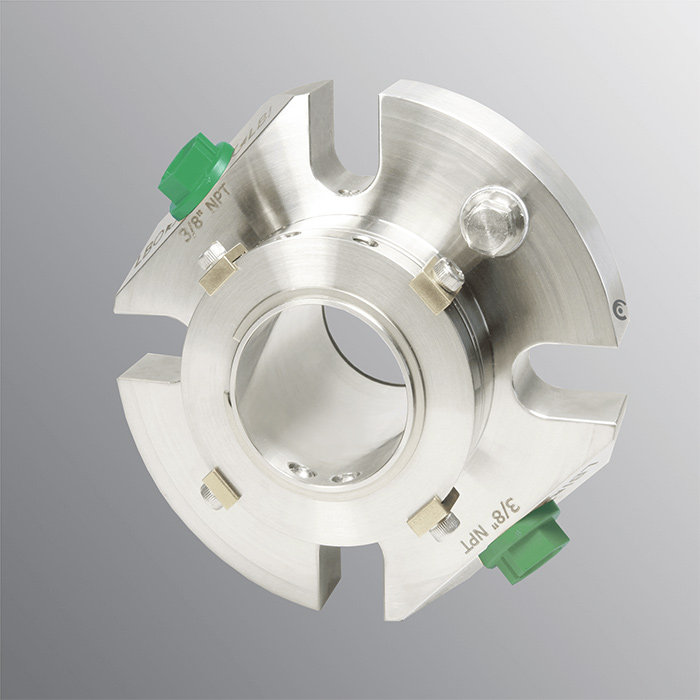

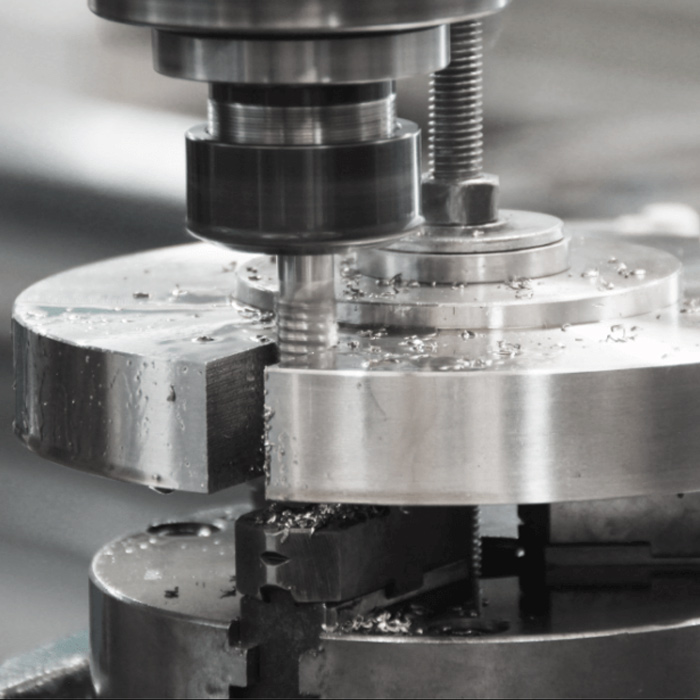

Manufacture of custom-engineered mechanical seals

-

At our production centre in Reus (Tarragona) we are able to manufacture any type of mechanical seal, including standard market solutions and special custom-engineered seals for our customers.

- Manufacture of mechanical seals for different industry sectors.

- Cartridge seals in simple or double versions for centrifugal pumps, screw pumps and others.

- Cartridge seals for agitators and reactors for horizontal and vertical installation.

- Shafts, jackets, sleeves and other components for pumps and agitators

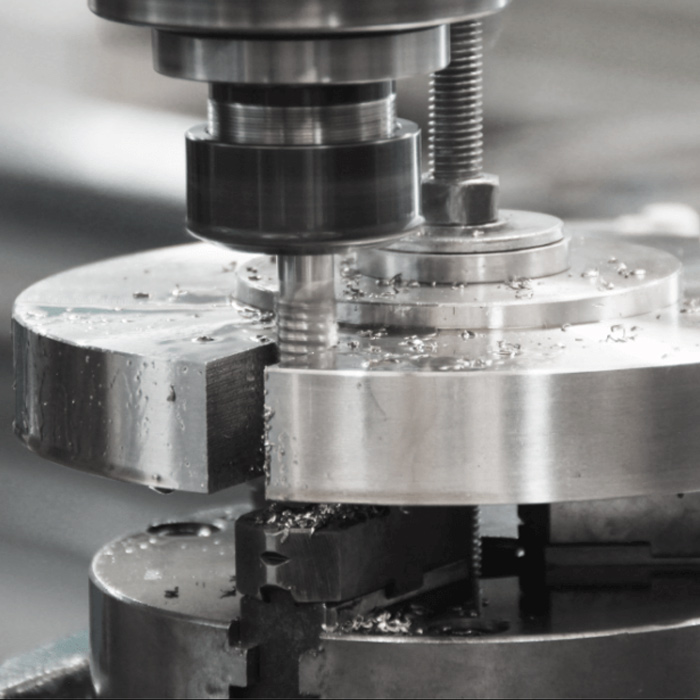

Repairing of mechanical seals

-

Thanks to the capacity of our facilities and our technical staff, we can provide the following services:

- Repair and improvement of mechanical seals

- Modification of components and equipment housings

- Machining operations on different types of steel (carbon, stainless), special alloys (chromium-nickel), other metals such as brass and bronze, plastic materials (PTFE, polypropylene) and carbon (impregnated with resin or antimony)

- Welding and coatings operations on jackets and other metal parts

- Sealing tests

- Assembly and dismantling of customer equipment in our facilities

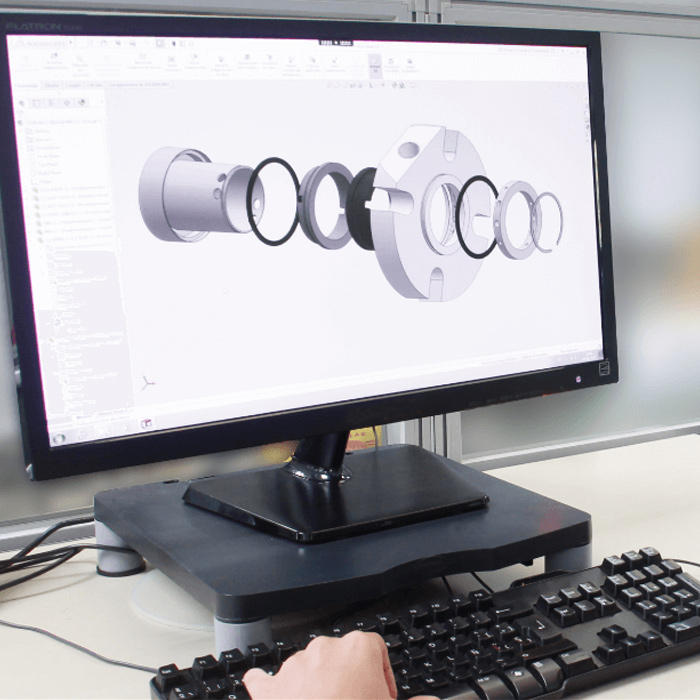

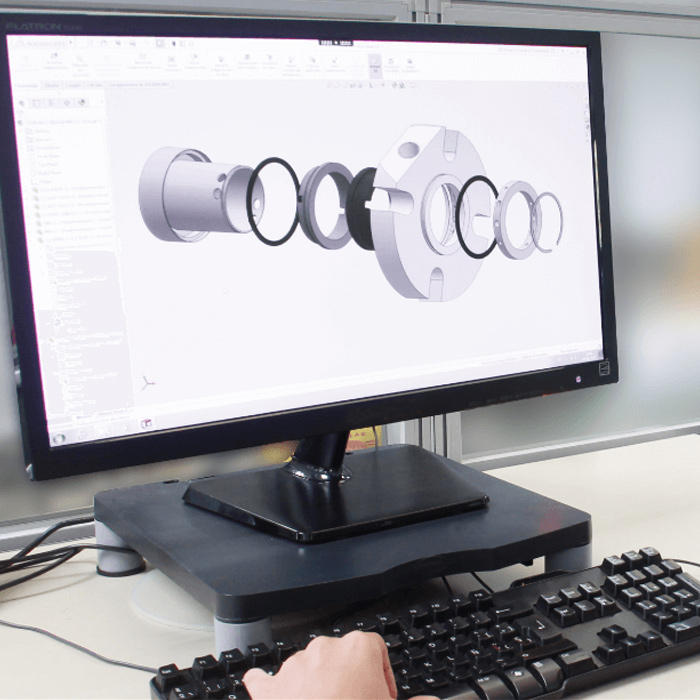

Design of solutions with 3D software

-

Our Engineering Department has the means and capacity to provide solutions to sealing problems in pumping and stirring equipment, no matter how complex the application or the working environment. We offer you:

- Design of solutions with 3D software

- Advice and assistance in assembling highly complex mechanical seals

- Custom sealing solutions

- Quality certificates

- Technical assessments

Advice and assistance

- We have a team of engineers and technicians who are product specialists and visit the premises of our customers to assist them in assembling mechanical seals in their agitators and pumping equipment, give them advice on the best solutions for their applications and help them in their preventive or predictive maintenance procedures.s

We contribute to the success of strategic sectors

-

LIDERING helps build infrastructures and facilities that are more robust and reliable. We bring safety to industrial processes and are present in companies and sectors that make our lives easier and safer.

Furthermore, through our products we cooperate in protecting and caring for the environment. In this regard, LIDERING has a wide range of mechanical seals, cartridge seals and auxiliary products for the most complex industrial processes.

We currently operate in different sectors like food and beverages, pharmaceutical, chemical, water treatment, maritime, petrochemical, renewable energies, pump and agitator manufacturers and industrial maintenance.

Food and Beverages

-

The food sector has extremely strict regulations regarding the safety of its processes. It is important to use products made of materials that are chemically resistant (CIP or SIP processes) and which also comply with the different food sector regulations: FDA, CE 1935, NSF, etc.

Pharmaceutical

-

This sector requires automated, reliable processes to guarantee a standard product that has not been altered during any of the production phases. Using elements that ensure perfect sealing during all the manufacturing phase steps is of vital importance. The most appropriate mechanical seal design is a hygienic one, since it reduces the possibility of product remains being deposited and not eliminated during CIP/SIP processes, which could give rise to sources of contamination.

Chemical

- In the chemical industry, the usual processes require sealing elements for materials with high chemical resistance. In order to transfer very aggressive or corrosive chemical fluids that are clean or that contain particles and have high viscosities, along with high temperatures and pressures, the mechanical seal materials and the type of assembly must be correctly defined: single, double, external or based on other API plans.

Furthermore, the applications require sealing systems that guarantee safety, preventing the leakage of corrosive or flammable products that could escape the atmosphere.

Waste recycling

- Waste disposal means applying chemical treatments that can affect the mechanical seal materials. An adequate selection of materials will increase the life of the pumps and prevent unforeseen repairs and uncontrolled leaks that could harm the environment and endanger people.

Water treatment

-

During the different treatments to which water is subjected, the mechanical seals may come into contact with sediments, organic matter, dissolved substances such as calcium and magnesium (hard water), sulphate and carbon dioxide (acid water), manganese (sewage water), nitrates (water contaminated by fertilisers), etc.

Maritime sector

-

A wide range of mechanical seal designs exist for this type of marine pumps, which operate in especially difficult conditions with high salt concentrations (this parameter varies, depending on the sea), at high pressures, etc.

Within this scope, not only is it important to locate spare parts to make the repair, but it is also essential to select the right materials for the contact surfaces and metal parts of the seal. It is vital to determine a structure that permits easy mounting, increases the pump’s useful life and reduces maintenance costs.

Oil + gas + energy

-

In oil and gas plants, pumps, agitators and compressors are required to transport gases and liquids in a reliable manner. For this reason, mechanical seals that can withstand the extremely severe working conditions, high pressure and speed, are necessary. These must also have high durability, to prevent stoppages caused by unforeseen repairs.

Pulp and paper

-

To make paper, cellulose fibres are mixed with water, which gives rise to paste-like mixtures and products. This is why special assemblies are recommended:

- API plan with a double cartridge and tank (API 52, 54) to ensure the permanent lubrication of the contact surfaces.

- External assembly to prevent the blocking of springs and to make sure they are not blocked by paper or pulp paste.

- Internal assembly, with metal wave spring seals that, due to the geometry of their bellows, have a self-cleaning effect, thus preventing them from becoming blocked.

Member of EPI INDUSTRIES

- EPI INDUSTRIES Family of Companies is an industrial service provider specialized in a wide range of high-quality mechanical engineering components and associated technical and logistics services that bring value-added solutions to our customers looking for their satisfaction and trust.