- Offer Profile

- LK is the oldest CMM manufacturer in the world.

LK Metrology is renowned for innovative metrology solutions and services. The company’s products, including coordinate measuring machines (CMM), portable measuring arms and metrology software, are used worldwide to control and improve the quality of manufactured components. Its precision technology underpins the process chain from design, development, production and assembly through to quality assurance in global industries such as automotive, aerospace, defence, motorsport, energy, medical and contract inspection.

Coordinate Measuring Machines

-

Coordinate Measuring Machines Precise & reliable metrology solutions

At LK Metrology, we understand that no two measurement challenges are the same. That’s why our portfolio of Coordinate Measuring Machines (CMMs) is built to cover every scale, complexity and environment – from compact labs to aircraft hangars. Explore our categories and discover the right CMM for your precision needs.

Bridge CMM

Altera C - Standard Passive Mounts

-

The LK Metrology ALTERA C Series stands as the epitome of innovation in the compact, entry-level coordinate measuring machine (CMM) category. Designed to meet the diverse and demanding needs of quality laboratories and shopfloor environments, the ALTERA C leverages advanced metrology software, multi-sensor technology, and a ceramic-bridge design to deliver unparalleled accuracy and efficient throughput.

Featuring a surprisingly compact footprint, the ALTERA C Series is the perfect solution for spaces where floor area is at a premium, without compromising on measurement capabilities.

Alterca C - Pneumatic Anti-Vibration Mounts

-

The LK Metrology ALTO Series emerges as a tailored solution for the evolving challenges of dimensional quality control, where the demand for measuring smaller parts, navigating more complex designs, and adhering to tighter design limits is ever-increasing. ALTO is the go-to CMM for quality professionals embarking on the journey towards automated inspection, offering user-friendly software and a range of versatile options to streamline the inspection process.

- The ALTO Series showcases an aluminium half-gantry design, optimizing structural stiffness while minimizing the system’s overall mass for rapid, high-precision measurements.

- Micro-machined guideways, hard anodized for wear and corrosion resistance, ensure enduring accuracy and reliability.

- Equipped with air bearings and a large bearing spread, the ALTO Series achieves dynamic stability and low maintenance through a self-cleaning design.

- Friction drives provide smooth, exact motion control, complemented by zero hysteresis for seamless operation with minimal upkeep.

- The ALTO Series showcases an aluminium half-gantry design, optimizing structural stiffness while minimizing the system’s overall mass for rapid, high-precision measurements.

ALTERA C – HA

-

The ALTERA C HA Series represents a significant leap in the precision capabilities of the already impressive ALTERA C range from LK Metrology. Designed for applications where accuracy is non-negotiable, the HA (High Accuracy) version boasts substantial improvements in volumetric accuracy, repeatability, and tactile scanning performance.

Elevated accuracy for demanding applications

- The ALTERA C HA version offers a 16% higher volumetric accuracy compared to the standard ALTERA C, with figures starting at 1.3+L/350.

- Repeatability has been enhanced by 13%, starting from an exceptional 0.0013 mm.

- Tactile scanning accuracy sees a 50% improvement, beginning at 0.002 mm, setting a new standard for precision in compact CMMs.

- The ALTERA C HA version offers a 16% higher volumetric accuracy compared to the standard ALTERA C, with figures starting at 1.3+L/350.

Altera S - Bridge CMM (up to 1m)

-

The ALTERA S Series by LK Metrology represents the zenith of small, multipurpose coordinate measuring machines (CMMs), offering unparalleled capabilities within the small compact class. Designed with the future in mind, this series is equipped with advanced multi-sensor ready technology, allowing for seamless adaptation to changing customer needs and applications without the need for additional wiring or controllers.

- The ALTERA S Series features a superior ceramic construction, achieving an almost perfect stiffness-to-weight ratio. This, combined with exceptional resistance to temperature variations, ensures reliable performance in any manufacturing environment.

- An innovative folding guideway panels design enhances the machine’s durability and performance efficiency.

- The ALTERA S Series features a superior ceramic construction, achieving an almost perfect stiffness-to-weight ratio. This, combined with exceptional resistance to temperature variations, ensures reliable performance in any manufacturing environment.

Altera M - Mid-Size Bridge CMM (1m-2m)

-

The ALTERA M Series by LK Metrology sets a new benchmark in the realm of very high accuracy, multipurpose coordinate measuring machines (CMMs). It represents the pinnacle of available CMM classes today, combining advanced capabilities with unparalleled flexibility. Equipped with cutting-edge multi-sensor ready technology, the ALTERA M Series adapts to evolving customer needs, allowing for an extensive range of applications without the necessity for additional wiring or controllers.

- The series boasts a superior ceramic construction that ensures an almost perfect stiffness-to-weight ratio, greatly enhancing measurement reliability.

- Exceptional resistance to temperature variations guarantees enduring performance in any manufacturing setting, supported by an innovative folding guideway panels design.

- Larger sections are also available (on request) in the Rail version.

ALTERA SCANTEK5 - 5-axis Multisensor CMM for Speed & Flexibility

-

The ALTERA SCANtek5 Series from LK Metrology redefines the landscape of 5-axis multisensor coordinate measuring machines (CMMs) with its unparalleled accuracy and flexibility. This series stands as the most comprehensive solution in the very high accuracy 5-axis multisensor CMM category, designed to meet the dynamic needs of today’s manufacturing landscape, especially in the automotive and aerospace sectors.

- Equipped with REVO, MODUS, and a suite of dedicated sensors for contact, non-contact, and surface finish scanning, the ALTERA SCANtek5 delivers exceptional throughput and versatility.

- This multifaceted approach allows for detailed and efficient inspection of complex automotive and aerospace components, among others.

- Equipped with REVO, MODUS, and a suite of dedicated sensors for contact, non-contact, and surface finish scanning, the ALTERA SCANtek5 delivers exceptional throughput and versatility.

Altera SL - Reference for Sub-micron Accuracy

-

The ALTERA SL Series from LK Metrology represents the pinnacle of high-accuracy coordinate measuring machine (CMM) technology available today. With its High Accuracy and Very High Accuracy versions, the ALTERA SL Series stands at the forefront of the market, offering levels of precision that compete with and challenge the sector’s leading solutions.

- Incorporating advanced multi-sensor ready technology, the ALTERA SL Series maximizes throughput and adapts seamlessly to changing customer needs, accommodating a wide array of materials and components.

- Noteworthy for its exceptional features, including the raised shoulder of the X-axis guideway for ultrafast dynamics and the S-axis 0.1-micron scale, the series achieves unparalleled accuracy.

- Incorporating advanced multi-sensor ready technology, the ALTERA SL Series maximizes throughput and adapts seamlessly to changing customer needs, accommodating a wide array of materials and components.

ALTERA SF

- ALTERA SF is designed to operate in a manufacturing environment, where conditions are often more variable and challenging than those of a controlled metrology lab. To ensure consistent accuracy, reliability, safety, and user-friendly operation, ALTERA SF incorporates a range of advanced features tailored to maintain performance and integrate seamlessly into production workflows.

Large Volume CMM

Aeros

-

The AEROS Series represents a significant advancement in metrology, featuring a mechanical design engineered for sustained metrological performance. This series offers long-term measurement data stability, thereby minimizing the frequency and costs associated with maintenance and calibration.

Central to the AEROS design is the utilization of an aluminum alloy for the Z-axis spindle, paired with a proprietary “Single Read” scale system on the X-axis, to ensure precision and reliability.

- The Y-axis employs a cross-beam constructed from light aluminum alloy, designed for maximum rigidity with minimal mass, optimizing movement efficiency.

- A multi-sensor system automatically compensates for errors attributed to thermal expansion of the machine’s structural components, maintaining accuracy under variable temperature conditions.

- An optional “Dual Read” scale system can be implemented on both X-axis beams to enhance metrological performance further.

- The Y-axis employs a cross-beam constructed from light aluminum alloy, designed for maximum rigidity with minimal mass, optimizing movement efficiency.

Aeros S

-

The AEROS S Series is distinguished by its medium to large Gantry CMMs, celebrated for their exceptional structural stability and adaptability. This series is designed to meet the diverse needs of measurement applications, offering versatility through a broad range of sizes and customizable configurations.

Central to the AEROS S design is the incorporation of a light aluminum alloy Z-axis spindle and a “Single Read” scale system on the X-axis, ensuring both precision and durability.

- Optimal mechanical rigidity is achieved through generous dimensioning of the distance between the air bearings.

- The Y-axis cross-beam features a high rigidity with a proprietary steel tubular frame design, enhancing structural integrity.

- A Z-spindle made from extruded aluminum alloy provides rigidity while minimizing the moment of inertia for improved dynamics.

- Optimal mechanical rigidity is achieved through generous dimensioning of the distance between the air bearings.

Aeros P

-

The AEROS P Series encompasses a range of large gantry coordinate measuring machines (CMMs), engineered specifically for high-stakes industrial metrology applications. This series is ideally suited for sectors such as aerospace, strategic defense, and energy, where precision in the measurement of large components is paramount.

A distinct build strategy for the structural design, coupled with “Dual Drive” motion and “Dual Read” positioning systems on the X-axis beams, significantly minimizes structural deformations during operation. This advanced engineering ensures the AEROS P series maintains exceptional metrological performance, even under the stress of measuring large, geometrically complex components. Its capabilities make it highly valued for inspecting large, accurately dimensioned parts like marine engines, transmissions, substantial transportation vehicles, and tools with free-form or sculptured surfaces.

- Optimal mechanical rigidity is achieved through generous spacing between the air bearings.

- The rack & pinion drive system on the X and Y axes ensures precise and efficient movement, crucial for the accuracy of large-scale measurements.

- X-axis beams feature a wide cross-section made of stabilized steel, equipped with a support system allowing for linear expansion without inducing stress or deformation.

- Optimal mechanical rigidity is achieved through generous spacing between the air bearings.

MAXIMA

-

With measuring volumes from 12m³ to 72m³, the MAXIMA range offers the largest measurement capacity of any table bridge-type CMM available today. Its high-capacity granite table provides outstanding stability, supporting even the heaviest components without compromising performance.

Developed to meet the growing demand for precise measurement of oversized and complex components, MAXIMA is ideally suited to industries such as aerospace, energy, automotive and heavy engineering.

By combining advanced LK ceramic technology with a robust structural design, MAXIMA delivers consistent accuracy, long-term stability and dependable results.

- Advanced Material Construction: Utilizes bonded ceramic materials for beam and spindle, providing near-perfect stiffness-to-weight ratio.

- Environmental Resistance: Offers exceptional durability and performance consistency in varying manufacturing environments.

- Modular Design: Based on a modular concept for ease of maintenance and reliability.

- Advanced Material Construction: Utilizes bonded ceramic materials for beam and spindle, providing near-perfect stiffness-to-weight ratio.

Maxima R

-

Designed for the measurement of the heaviest workpieces manufactured to precise tolerances, MAXIMA R is ideal for applications where consistent measurement integrity is essential – from aerospace and power generation to transportation and industrial machinery.

With its innovative twin-rail design, MAXIMA R enables safe, streamlined loading of heavy workpieces, including integration with automated floor-level transfer systems. This advanced approach also eliminates the need for specialized CMM foundations, delivering exceptional stability, simplified installation and outstanding cost efficiency.

- Twin Runway Configuration: Facilitates easier loading and unloading of lengthy components, optimizing workflow efficiency.

- Bonded Ceramic Construction: Retains the series’ hallmark stiffness-to-weight ratio and resistance to environmental factors.

- Twin Runway Configuration: Facilitates easier loading and unloading of lengthy components, optimizing workflow efficiency.

Horizontal CMMs

HC-90

-

The HC-90 Series represents a revolutionary step in the evolution of coordinate measuring machines (CMMs), merging the precision typically associated with bridge CMMs with unparalleled horizontal flexibility. Engineered for performance in the most demanding environments, the HC-90 Series leverages LK Metrology’s proprietary air bearing design along with a ceramic column construction to offer accuracy for larger components that was once thought unachievable.

- Utilizing high-quality Alumina Ceramic, the HC-90 Series boasts optimal speed, stiffness, and enduring measurement accuracy.

- Alumina Ceramic is chosen for its exceptional stiffness and thermal properties, being 330% stiffer and four times more thermally stable than aluminum, providing unmatched rigidity critical for high-accuracy measurements.

- Utilizing high-quality Alumina Ceramic, the HC-90 Series boasts optimal speed, stiffness, and enduring measurement accuracy.

HD-90

-

The HD-90 is a heavy-duty, ultra-reliable CMM crafted for the rigorous demands of production and shop-floor environments, tailored specifically for car-body and sub-assembly quality control applications. With a robust design to withstand harsh conditions, the HD-90 excels in delivering precision measurements for large components.

Designed with a flexible Runway configuration, the HD-90 accommodates both single and double arm setups, enhancing its versatility. The entire system is shielded with protective covers for thermal insulation and to guard against contaminants typical in workshop settings. This comprehensive encapsulation ensures the system’s integrity and operational reliability.

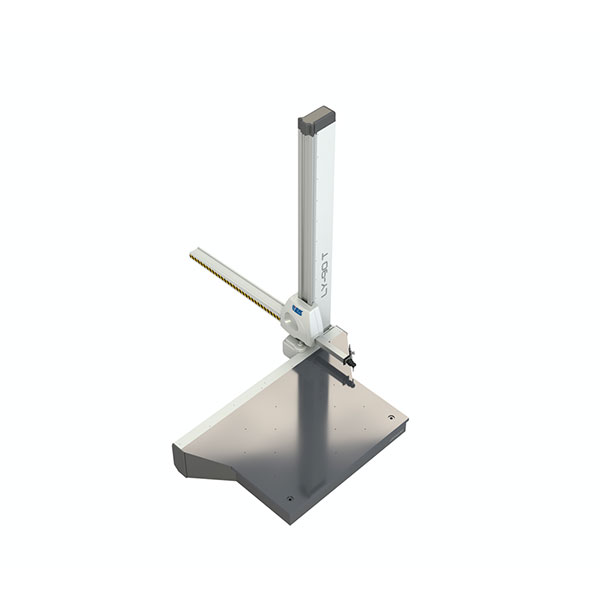

LY-90T

-

The LY-90T Console Design Series redefines the standards of precision measurement with its innovative horizontal arm configuration, designed for the accurate inspection of small to large sheet-metal and plastic components. Mounted on guideways and anchored to either granite or cast-iron plates, this series brings unmatched precision to a variety of industrial applications.

By incorporating a rotary table, the LY-90T Series extends its capabilities to inspect cubic and complex geometry parts, serving a broad spectrum of industries with ease. This feature underscores the series’ adaptability in handling diverse measurement tasks with the precision and reliability expected from top-tier CMMs.

LY-90R

-

The LY-90R Series stands out as a technologically sophisticated yet cost-effective solution for measuring large components, particularly suited for the automotive, land transport, and heavy industries. This series boasts air bearings on both the Y and Z axes, ensuring top-tier performance, precision, and reliability in dimensional control tasks.

Constructed from light aluminum alloy, the LY-90R’s mobile carriage combines lightweight design with heavy-duty performance. The double mechanical guideway and recirculating ball bearings system emphasize the series’ commitment to measurement accuracy and speed. Additionally, heavy-duty walkable guideways enhance safety for operators and the system itself, making the LY-90R ideal for shop-floor environments.

Portable Measuring Arms

LK Metrology launches the FREEDOM ARM range of 6 axis and 7 axis portable measuring arms – for quality control, on-machine verification, reverse engineering or 3D modelling. Available in three models, three accuracy levels and several sizes in different portable arm configurations with touch probe and laser scanner options.

Touch Probe 6-axis / Laser Scanner & Touch Probe 7-axis

-

Introducing the FREEDOM ARM Series by LK Metrology: Your ultimate solution for portable measuring arms, offering unmatched quality control, on-machine verification, reverse engineering, and 3D modeling capabilities. Designed with versatility in mind, the FREEDOM ARM series is available in 6-axis and 7-axis configurations, featuring touch probe and laser scanner options, tailored to meet the diverse needs of today’s dynamic manufacturing environments.

- Portability and Precision: The FREEDOM ARM range, comprising three models with three accuracy levels and various sizes, ensures precision measurements anywhere on the production floor. Its lightweight design and wireless connectivity provide unparalleled ease of use and flexibility.

- Multi-Functional for Enhanced Productivity: Designed for productivity, practicality, and flexibility, the FREEDOM ARM allows for immediate start-up with no warm-up time or calibration needed, ensuring manufacturing processes remain uninterrupted.

- Advanced Technology for Efficiency: The series boasts the Ultra-Fast H120 Laser Scanner, with next-generation blue-light technology, real-time power optimization, and the ability to scan all materials and finishes without pre-coating.

- Portability and Precision: The FREEDOM ARM range, comprising three models with three accuracy levels and various sizes, ensures precision measurements anywhere on the production floor. Its lightweight design and wireless connectivity provide unparalleled ease of use and flexibility.

Software

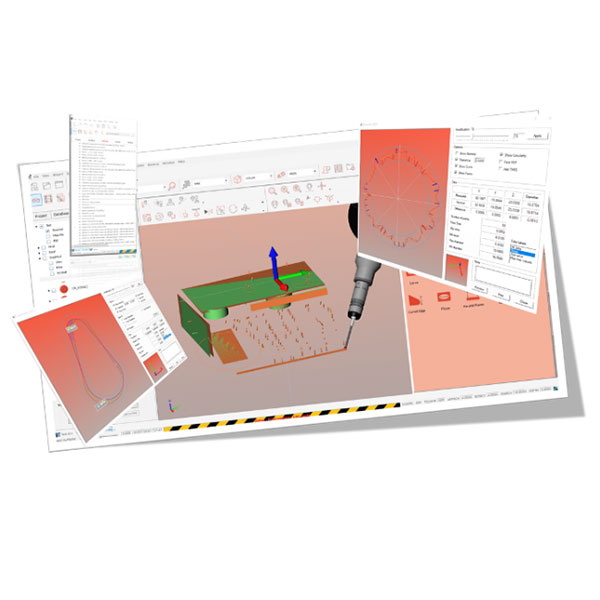

ARCOCAD

- The ultimate choice for metrology

LK Metrology offers the ultimate choice of CMM multi-sensor metrology softwares. The CAMIO software fits all solutions, especially those high-end industries, such as the aerospace industry, point cloud measurements and for offline solutions while the ARCOCAD software suits standard application, manual CMMs and portable measuring arms.

- CAMIO

- ARCOCAD

- FOCUS

Accessories

ECOAIR

-

EcoAir is an energy saving device that automatically stops the flow of compressed air to the CMM after a period of inactivity, resulting in a 95% saving* in air consumption when the CMM is idle.

Traditional CMMs can consume large amounts of compressed air, which is necessary for maintaining accuracy and precision.

Energy saving devices help manufacturers to meet regulatory requirements for energy efficiency, and support corporate social responsibility initiatives, while reaping the financial and operational benefits of reduced energy consumption.

By integrating the EcoAir energy saving device, manufacturers can optimise the use of compressed air, ensuring it is only used when necessary. This reduction in air consumption directly translates to lower energy bills, providing a cost-effective solution for high precision manufacturing.

RACKS

-

Measurement tasks often require the use of multiple styli or sensor technologies, however manually swapping components is an inefficient process. LK RACKS provide more ports than other systems and enable automated changing, ensuring uninterrupted measurements. This improves efficiency, especially for complex tasks that require frequent changes, and guarantees the right tool is available for every task.

Measurement tasks often require the use of multiple styli or sensor technologies, however manually swapping components is an inefficient process. LK racks provide more ports than other systems and enable automated changing, ensuring uninterrupted measurements. This improves efficiency, especially for complex tasks that require frequent changes, and guarantees the right tool is available for every task.

SURFACER (SRP)

-

SURFACER SRP integrates automated surface roughness analysis within your CMM measurement, for more efficient metrology in a single setup. The probe is powered through the CMM probe head autojoint, while a Bluetooth® adapter enables wireless communication with the CMM computer.

SURFACER SRP is a plug-and-play surface roughness probe designed for any CMM with a compatible industry-standard probe head, and requires no additional third-party hardware or software.

The probe is powered through the CMM probe head autojoint, while a Bluetooth® adapter enables wireless communication with the CMM computer.

For automated tool changing, the probe is fully compatible with heads and racks that support the Renishaw autojoint.

Optical Sensors

-

Our advanced optical sensor solutions bring high-speed, non-contact measurement to your metrology workflow. Designed for complex geometries, delicate surfaces and high-throughput environments, LK optical sensors deliver reliable 3D data with exceptional accuracy. Whether you’re inspecting stamped parts, molded components, or additive-manufactured surfaces, our optical sensors help you capture the full picture – quickly and precisely.

Explore our sensor lineup and discover how optical technology can elevate your quality control.

Laser Scanner

L100NX

-

Experience a new standard in 3D scanning with the L100NX CMM Laser Scanner – where exceptional accuracy meets high-speed efficiency.

Designed for modern manufacturing demands, the L100NX delivers precise surface and feature measurements at unmatched speeds, even on reflective or multi-material parts. Whether you’re working with complex surfaces or intricate features – the L100NX delivers precise results every time!

Building on the proven success of the L100, the L100NX introduces advanced blue laser technology for cleaner, more reliable scan data – especially valuable in high-precision industries like aerospace, automotive, and general manufacturing.

-

Blue Laser Precision

Reduces noise in scan data for superior measurement quality compared to traditional red laser systems. -

High-Speed Scanning

Captures up to 420,000 points per second with a wide 110mm stripe width, ideal for inspecting large components efficiently. -

Enhanced Sensor Performance (ESP)

Automatically adjusts laser power for every point, enabling seamless scanning of multi-material and reflective surfaces without manual tuning.

-

LC15DX

- The high accuracy laser scanner LC15Dx features a small laser line, and a higher number of points along said line for a higher resolution, to make it the most accurate laser scanner available on the market today. The LC15Dx perfectly suits digitizing compact or detailed objects with higher point density and tighter tolerances, both suited for surfaces and features. Considering this, the LC15Dx is often used for the inspection of high precision parts. The LC15Dx closes the gap between laser scanner and tactile probe accuracy, making it a viable alternative to a tactile probe for an increasing number of high precision CMM applications. In tests, the LC15Dx achieved the accuracy associated with using a tactile probe on a CMM. The probing error of 1.9 µm mirrors the accuracy expected when using a CMM fitted with a tactile probe. Unlike a tactile probe though, the LC15Dx uses non-contact 3D laser triangulation to measure the surface directly and eliminate probe compensation errors.

XC65DX

- The XC65Dx Cross Scanner utilizes three laser stripe scanners in one sensor. The three lasers are spaced 120 degrees apart and observe the part in question from three angles. By doing this, the XC65Dx can acquire the same amount of data with just one scan than a line scanner would do in three scans. This feature makes the XC65Dx well suited to feature inspection of slots, holes and grooves in sheet metals or items with a large complex surface area. It is often used in automotive BIW (Body-in-White) inspection, gap & flush and driveline casting inspection. Whilst the long standoff Cross Scanner retains the many advantages of the original XC65Dx, it also excels in dealing with accessing difficult-to-reach or obscured areas. By capturing geometries up to a distance of 170 mm (7.1”), the scanner gains optimum access to cavity surfaces of body-in-white structures or can scan over the clamps that hold components in position. For these reasons, the XC65Dx is used a lot on horizontal-arm CMM in the automotive industry.

SLK25

- Thanks to VIVID laser scanner technology from LK, the SLK25 provides quality professionals with an opportunity to maximise efficiency when measuring complex surfaces, small details and fragile parts. The SLK25 VIVID CMM laser scanner is a high accuracy, high resolution blue laser CMM scanner and viable alternative to tactile metrology. SLK25 offers manufacturers a smarter metrology solution, with the productivity, accuracy and versatility required for a vast range of parts, processes and materials. More surfaces, including the most challenging dark, transparent or highly reflective materials can be measured efficiently in a single pass of the laser scanner. VIVID multiple exposure technology quadruples the dynamic range of the SLK25 laser scanner. Phasing the laser scanner exposure time during scanning to match the part surface, optimises acquisition speeds and data quality. Exposure settings are provided for typical applications, with fully configurable user settings for more specialist requirements.

H120

- The H120 laser scanner is a class-leading, handheld 3D laser scanner capable of extremely detailed, precise, high speed measurement of almost any material or part. The H120 is driven by a single advanced software embedded within industry leading platforms. It provides many users with immediate familiarity, fast adoption and minimal training needs. For simple and intuitive scanner positioning, the center and limits of this laser scanner’s field of view are projected in red on the part surfaces during measurement. Repeatability mount or dismount the scanner safely, quickly and easily with just one hand, providing additional clearance for tactile probing or for use on other portable CMM device.

Industry 4.0 The Future of Manufacturing

- Industry 4.0 represents a transformative wave in the manufacturing sector, characterized by the deep integration of digitization with traditional manufacturing processes. This new industrial revolution combines advanced computers and automation with innovative technologies like cyber-physical systems, the Internet of Things (IoT), and the Internet of Systems to create highly interconnected and information-intensive environments.

Metrology Gate

- Metrology Gate represents the pinnacle of statistical software tailored for quality assurance in the Industry 4.0 era. This sophisticated web-based application manages dimensional metrology data, monitors the operation of measuring instruments, runs statistical process control (SPC), and provides a real-time view of all connected devices, including CMMs, portable arms, roughness meters, and 3D laser scanners. Metrology Gate is designed to transform your company’s performance monitoring and environmental control within the metrology room.

NC Measure

- As the need for precise machine tool measurements grows, NC Measure provides crucial support by offering advanced probing techniques and metrology software integration. This innovative approach not only supports part alignment and provides vital statistical information for large-scale production but also offers crucial feedback on tool offsets and part alignment to minimize deviations and reduce scrap.

Automation

- Automation in metrology represents a significant leap towards achieving unparalleled productivity in manufacturing. By integrating automated control of multiple systems within a single cell, companies experience marked improvements in production consistency, which directly enhances product quality. Automation reduces labor, energy, and material costs, delivering a potent combination of efficiency and precision.

Solutions

- LK Metrology serves companies in all Industrial Segments, providing products, solutions and services worldwide. Discover our solutions to learn how we’ve helped our Customers with the right choice and which benefits were achieved.

Aerospace

Just over 50 years ago, LK Metrology delivered its first coordinate measuring system into the aircraft engine industry. The system featured several firsts in the metrology industry. Not only was the CMM the state-of-the-art technology for 1969, the system also featured a mini-computer with in-house written inspection software. Together with the Customer, LK Metrology went on to develop the first ever touch-trigger probe. In the years following, it went on to become the industry standard. These innovation are still being marketed worldwide today. Today, LK Metrology is one of the foremost suppliers to the Aircraft and Aerospace industries, providing efficient and absolute accuracy at all the major OEMs for propulsion systems as well as critical structural components and panels.

Biomedical

Medical devices are extremely critical to produce to exacting standards. Reproducible, traceable examination and dimensional measurement of key items to specified tolerances play a major role in ensuring the reliable and repeatable performance required. Due to the high item cost, it is imperative to avoid rejection of lots or batches. The quality of raw material and components also needs to be certified prior to release from incoming inspection in order to provide a complete audit trail for regulatory purposes. Among the main customer requirements, we have experienced the need to avoid destructive testing of expensive prototypes and unique implants, reduction of lengthy dimensional inspection processes of complex shapes with comparison to CAD and the performance of automated measurements for high volume production. Another added benefit from the LK Metrology product portfolio is high performance reverse engineering supported by the application of non-contact laser scanning. For some medical components, such as knee or hip implants and hearing aids, the shape of the component is crucial for fast patient recovery and maximum comfort. LK Metrology‘s software and sensor solutions are a well established benchmark in this specialty segment.

Energy And Power

In a time when power and energy are of crucial necessity to the development of the current level of technology, this segment has become of strategic interest to both the developed and devloping nations. Quality and efficiency are of extreme interest where in most cases this sector involves the production of extremely critical components in terms of precision and cost. Other than the well tested traditional ways of generating energy and power, interest has grown in renewable energy projects where the accurate dimensional inspection of components ensure these products are produced to the high-quality standards desired. Windpower generation towers, turbine blades, turbo chargers, impellers, hydraulic pumps, compressor screws and numerous other components require dimensional verification using technologies such as those provided by LK Metrology.

Electronic

-

Electronics have had a major impact on the development of modern society since the identification of the electron in 1897. Fast forward to 1959 with the launch of the MOSFET, the first truly compact MOS transistor which could be miniaturized and mass-produced for a wide range of applications, revolutionizing industry and launching the Microelectronics and Digital Revolutions. Today, most electronic devices use semiconductor components.

Consumer electronics are analog or digital devices that are intended for everyday use such as entertainment, communication and recreational purposes. Today, most consumer electronics are based on digital technologies and have largely merged with the computer industry in what is increasingly referred to as the consumerization of information technology and digitalization. In turn, the driving force behind the electronic industry will always be the semiconductor industry.

Automotive

-

Just over 45 years ago, LK Metrology delivered the world’s largest moving bridge CMM to the automotive industry, and in the same year, designed, developed and delivered the world’s first horizontal arm CMM. During these early stages of CMM development, these “state-of-the-art” systems featured a mini-computer to include the in-house written inspection software package called LK CMES.

Today, LK Metrology is one of the foremost suppliers to the automotive and land transportation industries, providing absolute accuracy in time to all major OEMs, with dedicated solutions from powertrain to sheet-metal applications.

Automation

- Automation in metrology represents a significant leap towards achieving unparalleled productivity in manufacturing. By integrating automated control of multiple systems within a single cell, companies experience marked improvements in production consistency, which directly enhances product quality. Automation reduces labor, energy, and material costs, delivering a potent combination of efficiency and precision.