- Offer Profile

We develop high-end X-ray and CT system solutions that enable non-destructive testing in the semiconductor/electronics, automotive, and aerospace industries – from R and D labs to production settings.

Led by experience. Driven by curiosity.

Good solutions start with good questions. At Comet Yxlon, our curiosity and passion for technology are the drivers behind our collaborative approach to product development. Based on customer feedback we create inspection systems for all types of cast parts, new materials, electronic components, batteries, welded joints, and a lot more.

Technologies

Comet Yxlon industrial X-ray and CT inspection systems help manufacturers and developers stay in control of product quality – with technologies like CT metrology, laminography, image software solutions, and data analytics.

Getting the most out of industrial X-ray and CT

While the term "industrial X-ray" often refers to classic 2D radiographic inspection, it is also the basis for many other non-destructive testing (NDT) technologies, such as industrial computed tomography (CT) or computed laminography. Inspection data from Comet Yxlon systems allow users to examine material samples, analyze defects or perform dimensional measurements. Powerful image software solutions and data analysis tools enable the easy and fast evaluation of inspection data and help optimize production processes.

Industrial X-ray

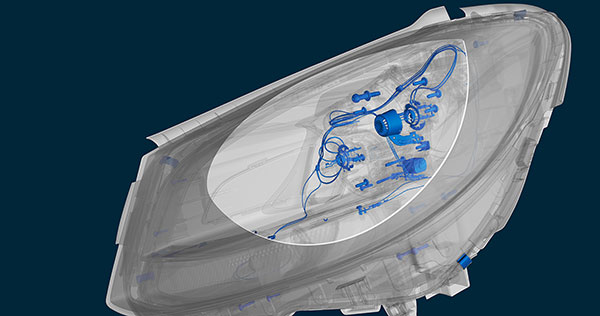

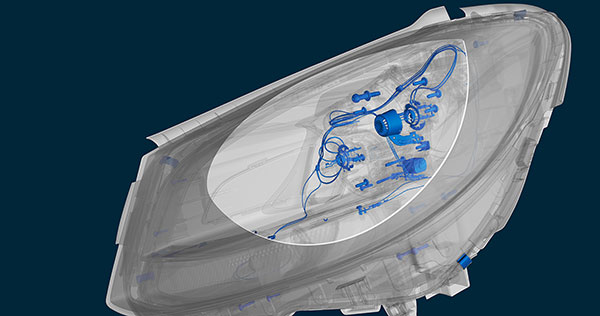

2D digital radioscopy with Comet Yxlon inspection systems gives operators insight into the internal structures of components – from microchips to massive engines.

Industrial X-ray is applied in

- First article inspection

- Quality assurance and material analyses

- Failure analyses, e.g., flaws, porosities, cracks, inclusions

- Assembly checking

- Measurements of outer and inner structures

- Inspection of samples, small serial productions, and 100% inspection

- Process control

Industrial CT

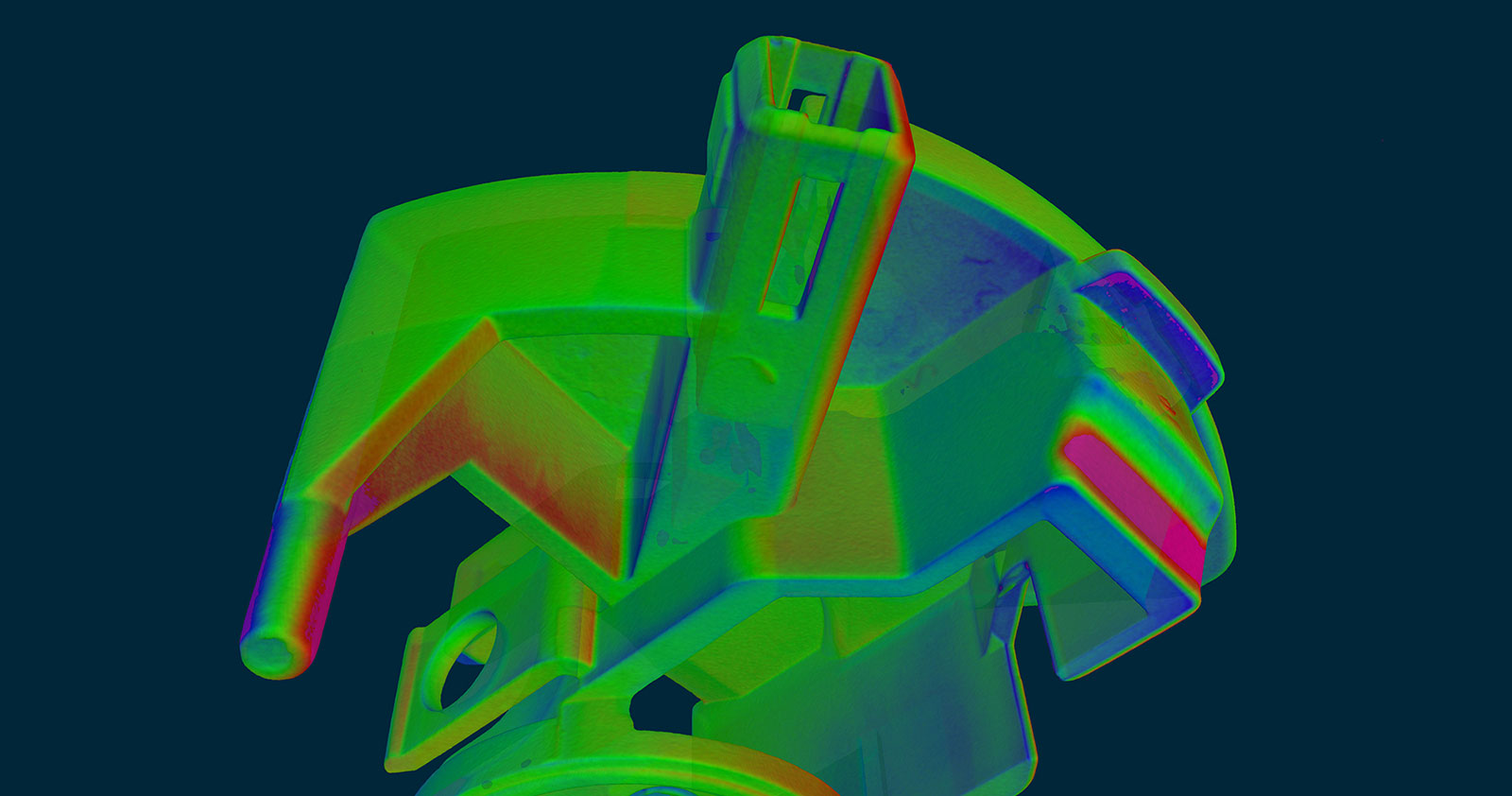

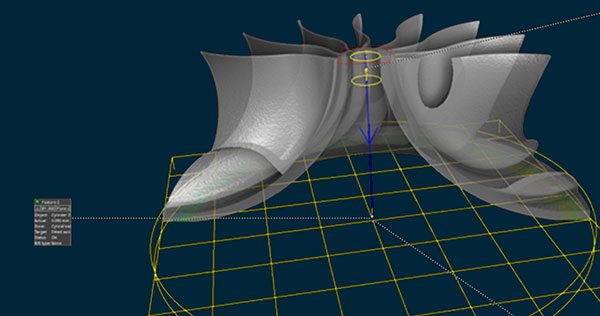

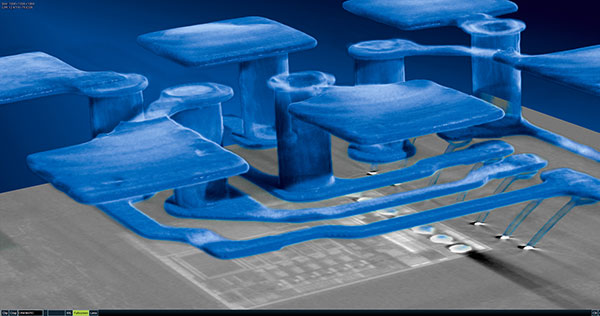

3D computed tomography (CT) visualizes the inner structures of a scanned object and lets operators identify the exact spatial position of defects.

Computed tomography is one of the most important and powerful non-destructive testing methods in quality assurance and quality control. Comet Yxlon CT inspection systems support manufacturers and scientists, e.g., in the electronics, automotive, and aerospace industries, in their pursuit of maximum product quality, and efficient production processes – with fewer rejects and recalls, less waste, and less downtime.

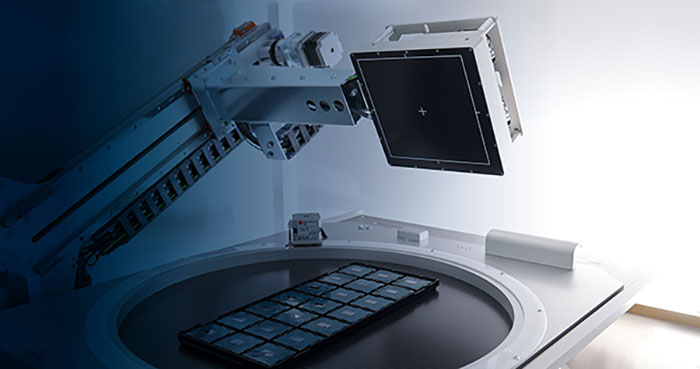

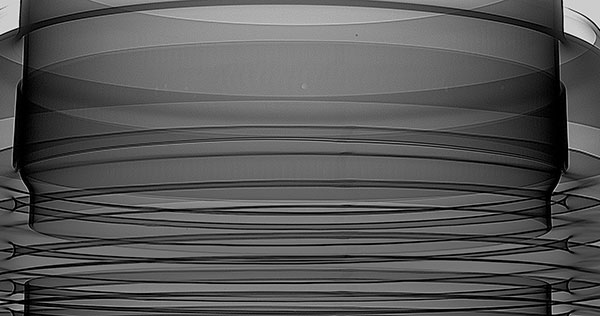

Computed Iaminography

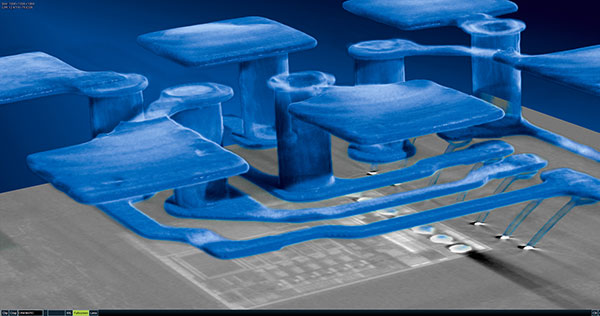

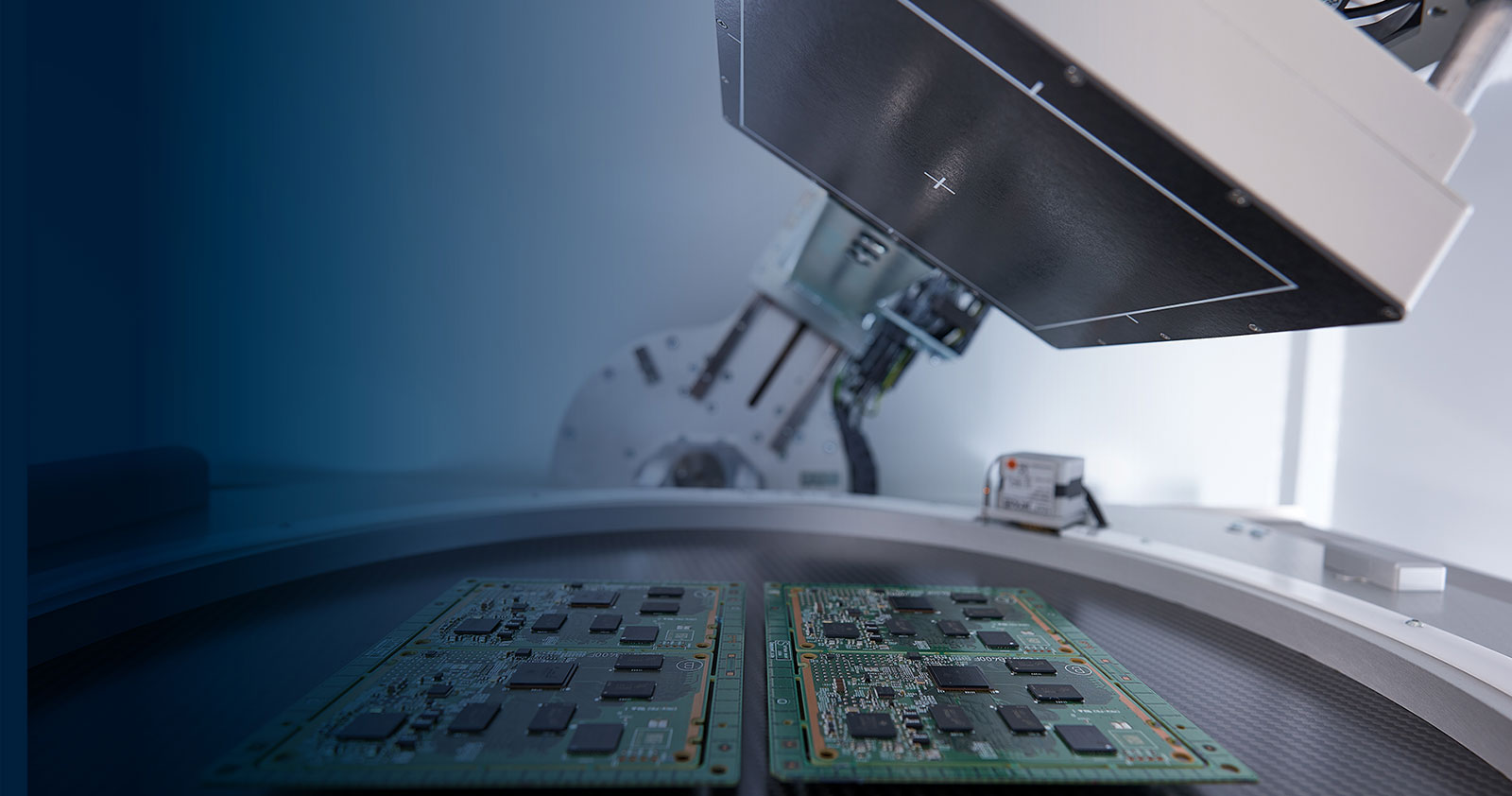

- Comet Yxlon systems use computed laminography to inspect flat components like microchips, PCBs, phones, and tablets, or EV batteries.

Computed laminography is sometimes referred to as “2.5D inspection” because it is a technological intermediate between 2D X-ray radioscopy and 3D computed tomography (CT). Laminography addresses the specific challenges of inspecting flat components, such as printed circuit boards (PCB), microchips (IC), entire cell phones, tablets, laptops, or even scripts on papyrus. While a 2D X-ray inspection provides high resolution but does not give spatial information, 3D CT supplies good spatial information but can lack resolution. A case for laminography: It adds depth information to high-resolution 2D images, so defects can be reliably detected and spatially located in a plane object.

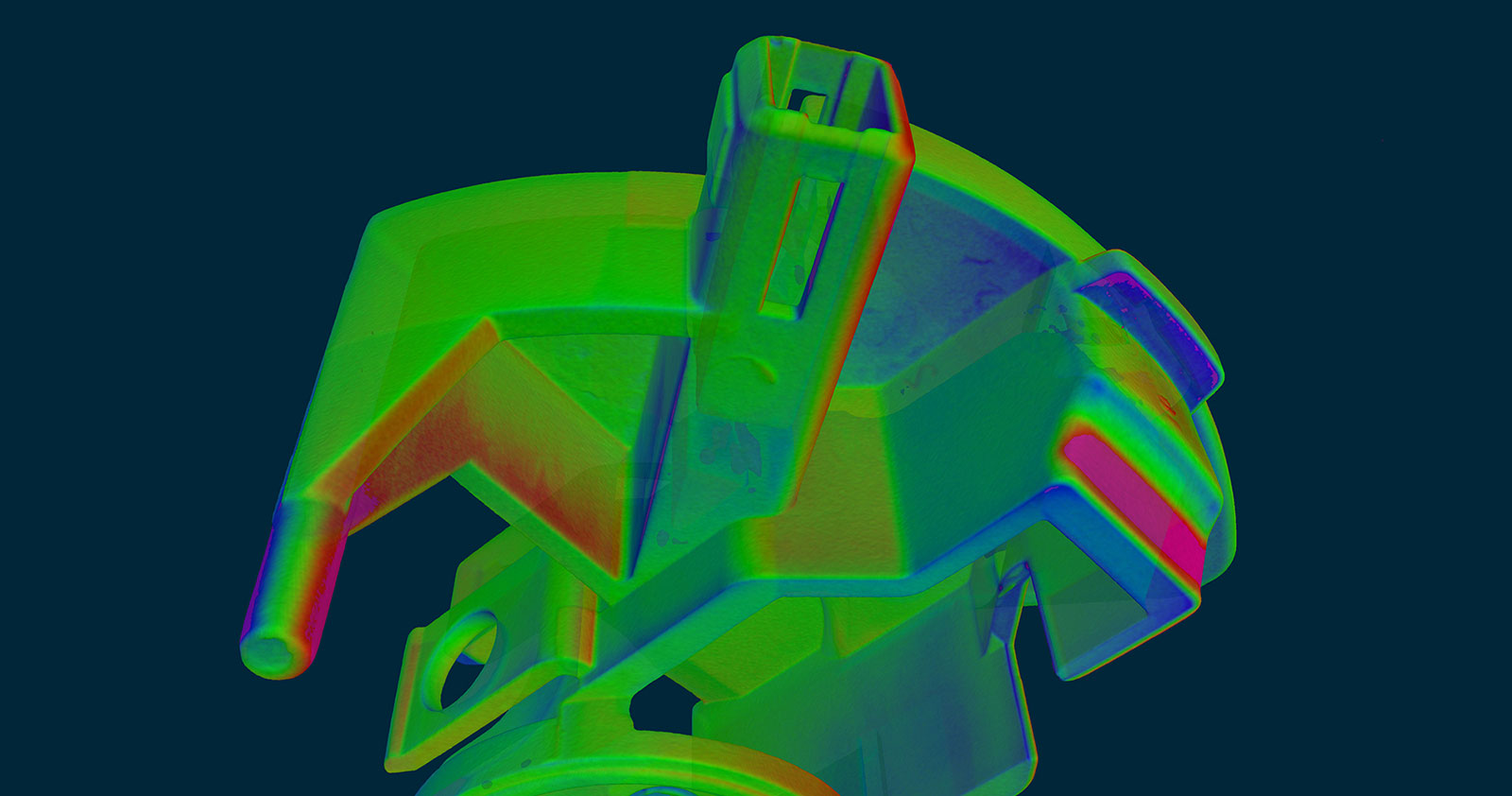

CT metrology

- Comet Yxlon high-resolution CT systems for dimensional measurement deliver precise and accurate data for use in quality assurance, science, and research.

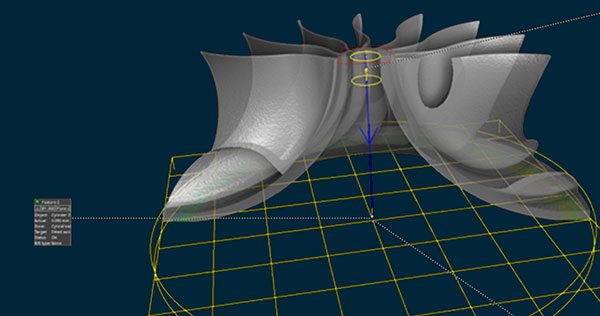

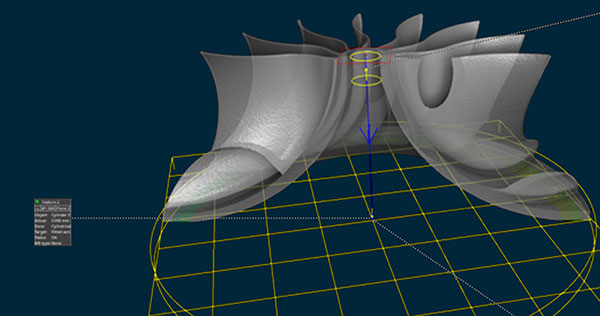

Analyses and measurements of the internal structures of objects have become very important, especially in the context of new additive manufacturing methods. Non-destructive testing with Comet Yxlon CT metrology scanners produces volume data containing comprehensive geometrical information. With an almost unlimited number of reference points, a complete part can be measured, while internal measurements of cavities and material interfaces in hybrids and assemblies can be added later.

Image software solutions

- Thanks to smart software solutions like Comet Yxlon’s user interface Geminy, X-ray and CT inspections are as easy as never before.

Traditionally, X-ray systems were designed by experts for experts and were usually complex to operate. But the new working environment of Industry 4.0 has changed priorities: today, workers need to have a broad knowledge of various tasks and systems instead of specialized knowledge for just one. Therefore, Comet Yxlon consistently pursues its path towards software products with a clear focus on user-friendliness. The simple, intuitive operation with Geminy, the customer-focused software platform for all our modern Comet Yxlon CT systems , eliminates the need for time-consuming and costly training and quickly guides any operator to the best test results.

Data Analytics

- A wide range of smart data analytics solutions supplies manufacturers with valuable data for process optimization and predictive maintenance.

X-ray and CT systems are sensors that provide rich data. While many manufacturers use the image data that the systems generate solely for quality assurance and product analytics applications, the raw data material itself can serve a lot of additional purposes. Comet Yxlon offers a wide range of smart data analytics solutions that allow manufacturers to tap into their valuable data lake and use the information smartly for process optimization and predictive maintenance.

Powerful X-ray and CT inspection systems

Comet Yxlon industrial X-ray and CT inspection systems help manufacturers and developers stay in control of product quality – with technologies like CT metrology, laminography, image software solutions, and data analytics.

Comet Yxlon offers a wide range of cutting-edge X-ray and CT systems designed to support manufacturers in all their industrial inspection needs. The specialized systems are used in the most diverse areas such as aerospace, automotive, electronics, science and research, and many more. Whether a component is measured in micrometers or meters, ounces, or pounds – there’s a Comet Yxlon system to match. Many systems can be integrated right into the production line, optimizing production time and processes.

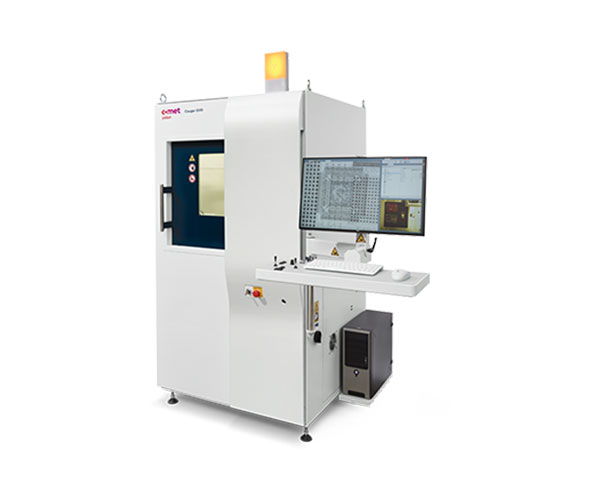

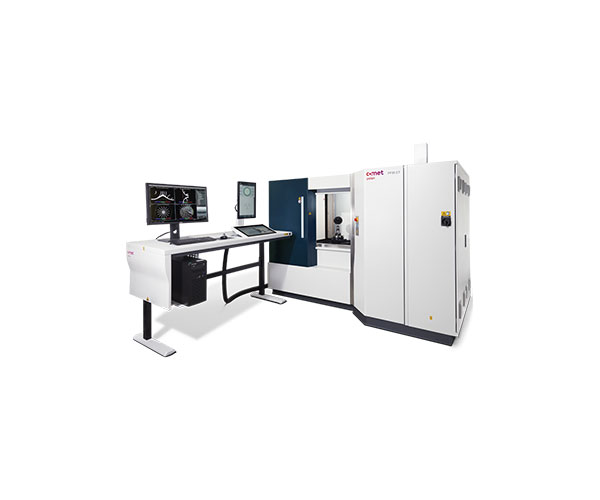

CC product line - Cheetah EVO and Cougar EVO

-

Future-ready to meet the demands of Industry 4.0

In today’s smart factory, everything revolves around connectivity and self-optimizing processes. Industry 4.0 demands for quality control systems that offer improved automated inspections and can become an integral part of the production line. Based on customer input, Comet Yxlon upgraded the Cheetah EVO system with advanced features that help manufacturers reach new heights in speed, image quality, reliability, and repeatability.

Cheetah EVO

-

Cheetah EVO highlights

- Reliable, fast, and repeatable inspections – manually and automatically

- Automatic void calculation with VoidInspect

- Easy-to-use, dynamic enhancing filters, e.g., eHDR

- Best available laminography with micro3Dslice and FF CT software

- Dose reduction kit and low dose detector mode for sensitive components

- Optional high load capacity

Cheetah EVO responds to the need for improved, automated operation with integrated workflows in the FGUI operating software. The Comet Yxlon FF CT software is designed to start automatically for faster reconstruction and visualization. It has a unique ability to render 3D cinematic images with a preset selection of transfer functions (TF), resulting in the most realistic, vivid visualization available today.

Technical Data

- Attribute: Respective Value

- Sample Size: 800 x 500 [mm] (31'' x 19'')

- Max. Radiographic Area: 460 x 410 [mm] (18'' x 16'')

- System Dimensions (W/D/H): 1650 x 1400 x 2050 [mm]

- System Weight: 2200 kg

- FeinFocus X-ray Tube: FXT-160.50 Microfocus or FXT-160.51 Multifocus, 20 - 160 kV voltage range

- Detector Active Area: 1004 x 620 px (Y.Panel 1308), 1004 x 1004 px (Y.Panel 1313), 1276 x 1276 px (ORYX 1616)

- Pixel Pitch: 127 µm

- Bit Depth: 16 bit

- Oblique Viewing: +/- 70° (140°)

- 3D Modes: Laminography (micro3Dslice), CT Quick Scan, Quality Scan

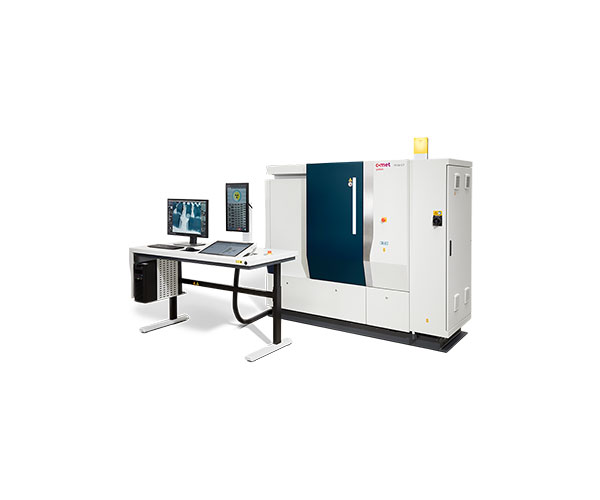

Cougar EVO

Cougar EVO highlights:

- Reliable, fast, and repeatable inspections – manually and automatically

- Automatic void calculation with VoidInspect

- Easy to use, dynamic enhancing filters, e.g., eHDR

- Best available laminography with micro3Dslice and FF CT software

- Dose reduction kit and low dose detector mode for sensitive components

- Smallest footprint available on the market

Cougar EVO responds to the need for improved, automated operation with integrated workflows in the FGUI operating software. The Comet Yxlon FF CT software is designed to start automatically for faster reconstruction and visualization. Due to its unique ability to render 3D cinematic images with a preset selection of transfer functions (TF), the software produces the most realistic, vivid visualization available today.

Technical Data

- Attribute: Respective Value

- Sample Size: 440 x 550 [mm] (17'' x 21'')

- Max. Radiographic Area: 310 x 310 [mm] (12'' x 12'')

- System Dimensions (W/D/H): 1000 x 1050 x 2200 [mm]

- System Weight: 1450 kg

- FeinFocus X-ray Tube: FXT-160.50 Microfocus or FXT-160.51 Multifocus, 20 - 160 kV voltage range

- Detector Active Area: 1004 x 620 px (Y.Panel 1308), 1004 x 1004 px (Y.Panel 1313), 1276 x 1276 px (ORYX 1616)

- Pixel Pitch: 127 µm

- Bit Depth: 16 bit

- Oblique Viewing: +/- 70° (140°)

- 3D Modes: Laminography (micro3Dslice), CT Quick Scan, Quality Scan

UX product line - UX50 and UX20

Which items can be inspected with the UX50/UX20?

UX50

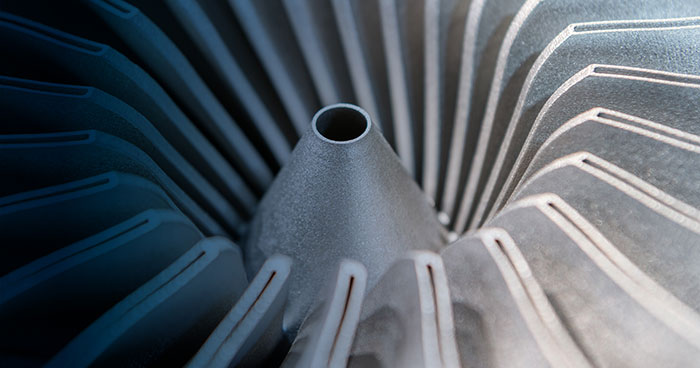

- Components made of aluminum, steel, and superalloys

- Mechatronic assemblies

- Electromobility drive components and batteries

- Geological samples

- Fossils for paleontological research

The UX50’s powerful CT techniques facilitate the optimum part size spectrum, speed, and image quality.

- Special techniques for cone-beam CT with the DDA

- Special techniques for fan-beam CT with the LDA

- Image quality optimizations

UX20

Which parts can be inspected with the UX20?- Automotive and aerospace castings

- Welded structures

- Multi-material components

- Additive manufactured parts

- Special alloys

- Plastics and fiber-reinforced composites

- Ceramics

Which applications is it designed for?

- Quality assurance and material analyses

- Failure analyses e.g., flaws, porosities, cracks, inclusions

- Assembly checking

- Measurements of inner structures

- First inspections

- Small series inspections

- Spot-check inspections

- Process control

UX50

With its large inspection envelope, multiple field-of-view extensions, and a powerful 450 kV X-ray tube, the UX50 takes the inspection of complex, dense parts to the next level.

UX50 highlights:

- Wide application range: 450 kV and large inspection envelope

- Choice of line and/or flat-panel detectors for maximum flexibility

- CT techniques for extended field of view and image processing

- Simple creation of inspection sequences with Geminy

- Automated detector calibration and image sharpness measurements

- For applications e.g., in automotive, metal casting, and additive manufacturing

Whether its massive motor blocks, larger steel parts, or complex e-mobility components – the Comet Yxlon UX50 CT system scans the most challenging items in record time. Fast switching between line and flat-panel detectors, intuitive operation with the user interface Geminy, and a comprehensive set of image processing tools make the UX50 ideal for an unlimited range of X-ray and CT applications in the industrial environment.Technical data

- Attribute: Respective Value

- Sample Diameter: 600 [mm]

- Sample Height: 850 [mm] Flat-Panel Detector / 800 [mm] Line Detector

- Maximum Sample Weight: 100 [kg]

- X-ray Tube Y.TU450-D11

- Detector Type: Y.Panel 4343 N Flat-Panel Detector and/or YXLON CTScan 3-0780 Line Detector

- CT Modes: Cone-beam CT, Helical CT, FoV extension, Volume Crop, QualityScan, QuickScan®, Fan-beam CT

- Voxel Size: Down to 55 [µm]

- Inspection Envelope CT (3D) with Flat-Panel Detector: 570 x 850 [mm]

- Inspection Envelope CT (3D) with Line Detector: 600 x 800 [mm]

- Inspection Envelope DR (2D): 520 x 850 [mm]

UX20

Designed to provide intuitive operation, the UX20 system makes it easy for users of all expertise levels to conduct highly efficient X-ray and CT inspections in record time.

UX20 highlights:

- Intuitive operation with Geminy

- Benchmark image quality

- Fast results in 2D and 3D

- Compact footprint

- Robust design

Due to the transformation to electric mobility, foundries are increasingly producing larger and more complex components. With its exceptional inspection envelope and the smart Geminy software, the UX20 facilitates fast and precise inspections of cast parts and helps increase overall production efficiency.Technical Data

- Attribute: Y.Panel 2323 HB/ Y.Panel 4343 DXi

- Maximum Sample Weight: 100 [kg]/ 100 [kg]

- System Dimensions: 2250 x 1770 x 2350 [mm]/ 2250 x 1770 x 2350 [mm]

- X-ray Tube: 160-225 [kV]/ 160-225 [kV]

- Detector Active Area: 1280 x 1280 [px]/ 3072 x 3072 [px]

- Pixel Pitch: 179 [µm]/ 139 [µm]

- Bit Depth: 16 bit/ 16 bit

- Oblique Viewing: +/-55 (45° in central beam)/ +/-55 (45° in central beam)

- CT Modes: QuickScan, QualityScan, Cone beam CT, virtual axis, FoV extension/ QuickScan, QualityScan, Cone beam CT, virtual axis, FoV extension

- Inspection Envelope DR (2D): 710 x 1090 [mm]/ 800 x 1100 [mm]

- Inspection Envelope CT (3D): 190 x 165 [mm]/ 340 x 280 [mm]

- Inspection Envelope CT (3D) with ScanExtend: 315 x 1085 [mm]/ 540 x 1100 [mm]

FF product line

-

High energy. High resolution. High versatility. Small parts or large parts, the optional combination of two X-ray tubes with a spacious flat-panel detector (DDA – digital detector array) and a linear detector array (LDA) caters to the broadest application range. While the mini-focus tube, with its high energy of up to 600 kV, is the right solution for large and dense parts, the directional micro-focus tube (up to 300 kV) provides detailed insights into the inner structures of small components. Seamless switches between 2D radioscopy, 3D cone-beam, and fan-beam CT provide outstanding flexibility and the creation of individual inspection processes.

Which applications is the FF85 CT designed for?

- Material and structural analysis in research and development

- First article inspection

- Dimensional measurement

- Small series inspection

- Failure analysis

- Assembly checks

- Digitization Segmentation

- Quality assurance, material analysis, and research

- Failure and structure analysis

- Assembly checking

- Inspection of small serial productions

- Process control

- Digitization Segmentation

- Quality assurance, material analysis, material research

- Failure and structure analysis

- Assembly checking

- Inspection of small serial productions

- Process control

- Digitization Segmentation

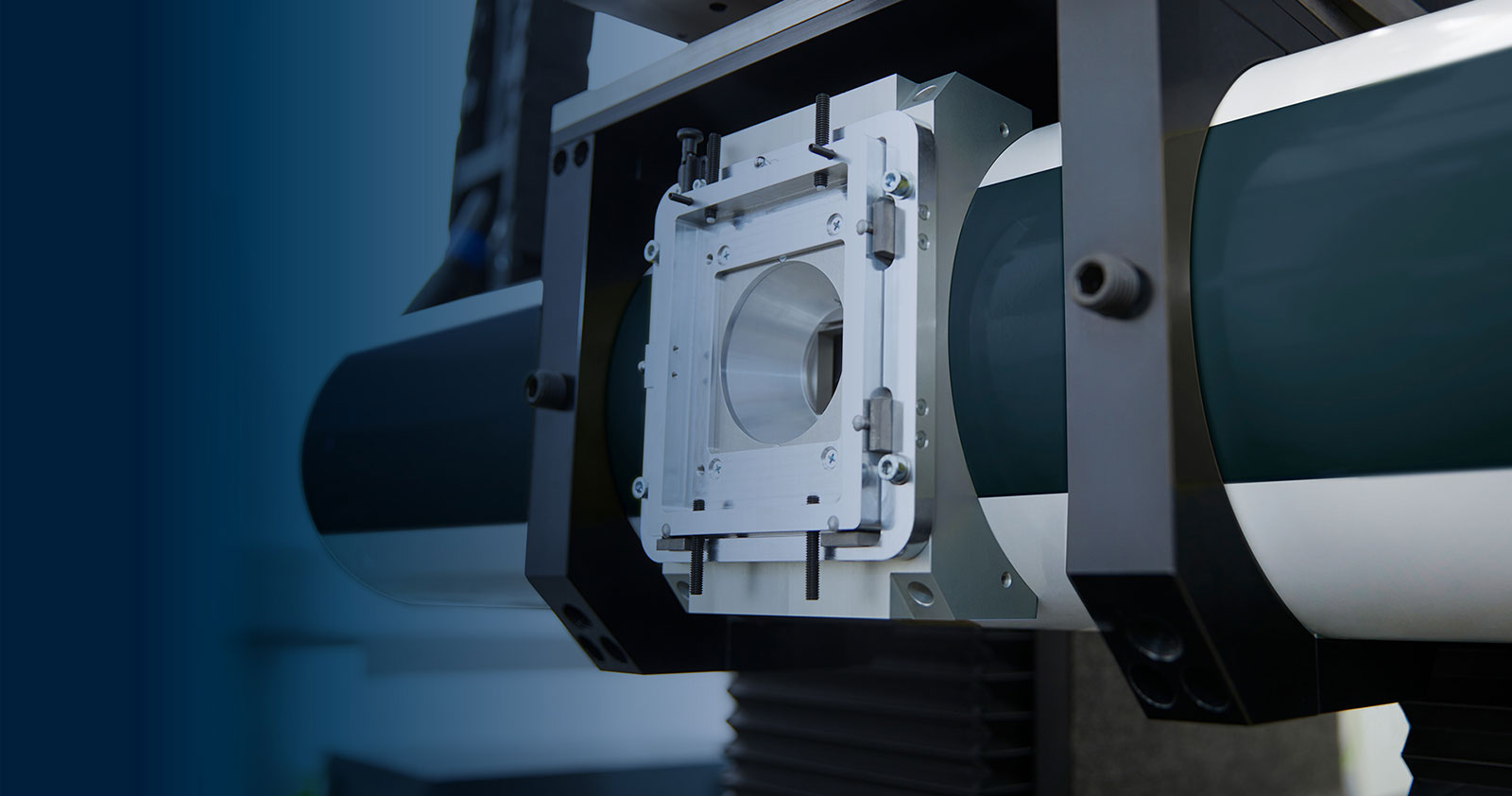

FF85 CT

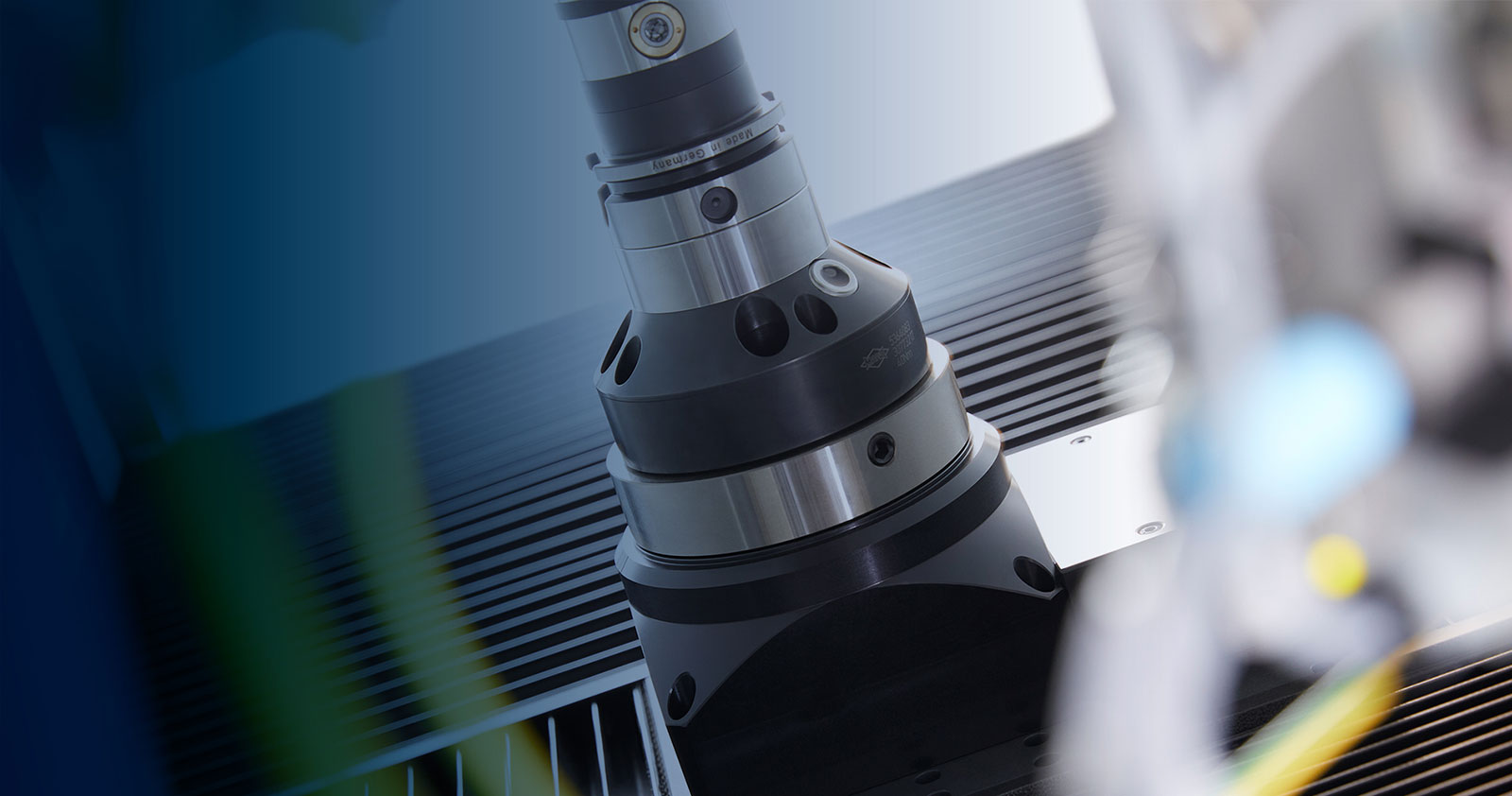

With its dual-tube configuration, the high-energy, high-resolution FF85 CT achieves extremely precise inspection results for a wide variety of material types and part sizes.

FF85 CT highlights:- Extensive range of applications from microCT to high-energy CT due to dual tube configuration and both flat-panel and line detector

- Large inspection envelope by diverse field-of-view extensions, helical and dual-helical CT techniques

- Granite base for temperature stability and precise manipulation

- Maximum versatility through up to 7 manipulation axes

- Intuitive Geminy user interface with touchscreens for easy system operation

Small parts or large parts, the optional combination of two X-ray tubes with a spacious flat-panel detector (DDA – digital detector array) and a linear detector array (LDA) caters to the broadest application range. While the mini-focus tube, with its high energy of up to 600 kV, is the right solution for large and dense parts, the directional micro-focus tube (up to 300 kV) provides detailed insights into the inner structures of small components. Seamless switches between 2D radioscopy, 3D cone-beam, and fan-beam CT provide outstanding flexibility and the creation of individual inspection processes.

Technical Details

- Attribute: Respective Value

- Sample Diameter: 1000 [mm]

- Sample Height: up to 1840 [mm]

- Maximum Sample Weight: 400 [kg]

- Focus-Detector-Distance (FDD): up to 2050 [mm]

- X-ray Tube: Y.TU450 mini-focus Y.TU600 mini-focus 300kV directional beam tube Y.FXT 225.48 directional beam tube

- CT Modes: Cone beam CT, Helical CT, virtual axis, FoV extension, Volume Crop, QualityScan, QuickScan®

- Manipulation: 7 axes, granite based

FF35 CT

With its optional dual-tube set-up, the FF35 CT combines unprecedented CT data quality with the highest versatility when inspecting small and medium-sized parts.

FF35 CT highlights:

- Single or dual tube configuration for highest versatility in laboratory micro-CT applications

- Switch between 225 kV micro-focus and 190 kV nano-focus tubes in seconds with the touch of a single button

- Accurate results due to granite-based manipulation and air conditioning

- Application flexibility due to various CT trajectories and FoV extensions via software platform Geminy

- Optional metrology version with an MPESD = 5.9 µm + L/75 [L in mm]

- Available as FF35 CT SEMI version in compliance with semiconductor market standards

Flexible inspection of very small to medium-sized parts: The Comet Yxlon FF35 CT, FF35 CT Metrology, and FF35 CT SEMI cover an extraordinary range of applications. Capabilities include improved material testing in the R and D department, optimization of process control and small series inspection as well as various scientific applications. The dual X-ray tube set-up enables the high-resolution CT system to significantly expand quality assurance and research possibilities in the automotive, electronics, aviation, and material science industries.

Technical Data

- Attribute: Respective Value

- Sample Diameter: 530 [mm] (20.9")

- Sample Height: 800 [mm] (31.5")

- Maximum Sample Weight: 27 [kg]

- System Dimension: 2960 x 1590 x 2120 [mm]

- X-ray Tube Y.FXT 225.48 directional beam tube, additional optional Y.FXT 190.61 transmission tube

- CT Modes: QuickScan®, QualityScan, cone-beam CT, helical CT, virtual rotation axis, FoV extensions, volume crop

- Manipulation: granite-based, active air damping, 6 to 8 axes, wide FDD range

FF20 CT

The FF20 CT is the expert microCT system for R and D, defect analysis, or CT metrology. It is designed for inspections of very small components and objects in the electronics industry, material science, and other research areas.

FF20 CT highlights

- Accurate material analyses in laboratory applications

- 2D detail visibility of down to 150 nm with 190 kV transmission tube

- Precise manipulation and temperature stability through granite base

- Intuitive Geminy graphical user interface with touchscreens

- Optional metrology version with an MPESD = 3.9 µm + L/75 [L in mm]

The smaller components become, the more important it is to achieve highly accurate, reliable X-ray and CT scans for quality assurance, process control, and small series inspections. The extremely compact high-resolution systems Comet Yxlon FF20 CT and FF20 CT Metrology are designed specifically for the inspection of very fine parts and internal structures. With comparatively high energy of 190 kV, even dense items can be analyzed to the smallest detail.

Technical Details

- Attribute: Respective Value

- Sample Diameter: 280 [mm] (11.02")

- Sample Height: 700 [mm] (27.6")

- Maximum Sample Weight: 17 [kg]

- System Dimension: 2380 x 945 x 2180 [mm]

- X-ray Tube: Y.FXT 190.61 transmission tube

- CT Modes: QuickScan®, QualityScan, cone-beam CT, helical CT, virtual rotation axis, FoV extensions, volume crop

- Manipulation: granite-based, active air damping, 6 axes, wide FDD range

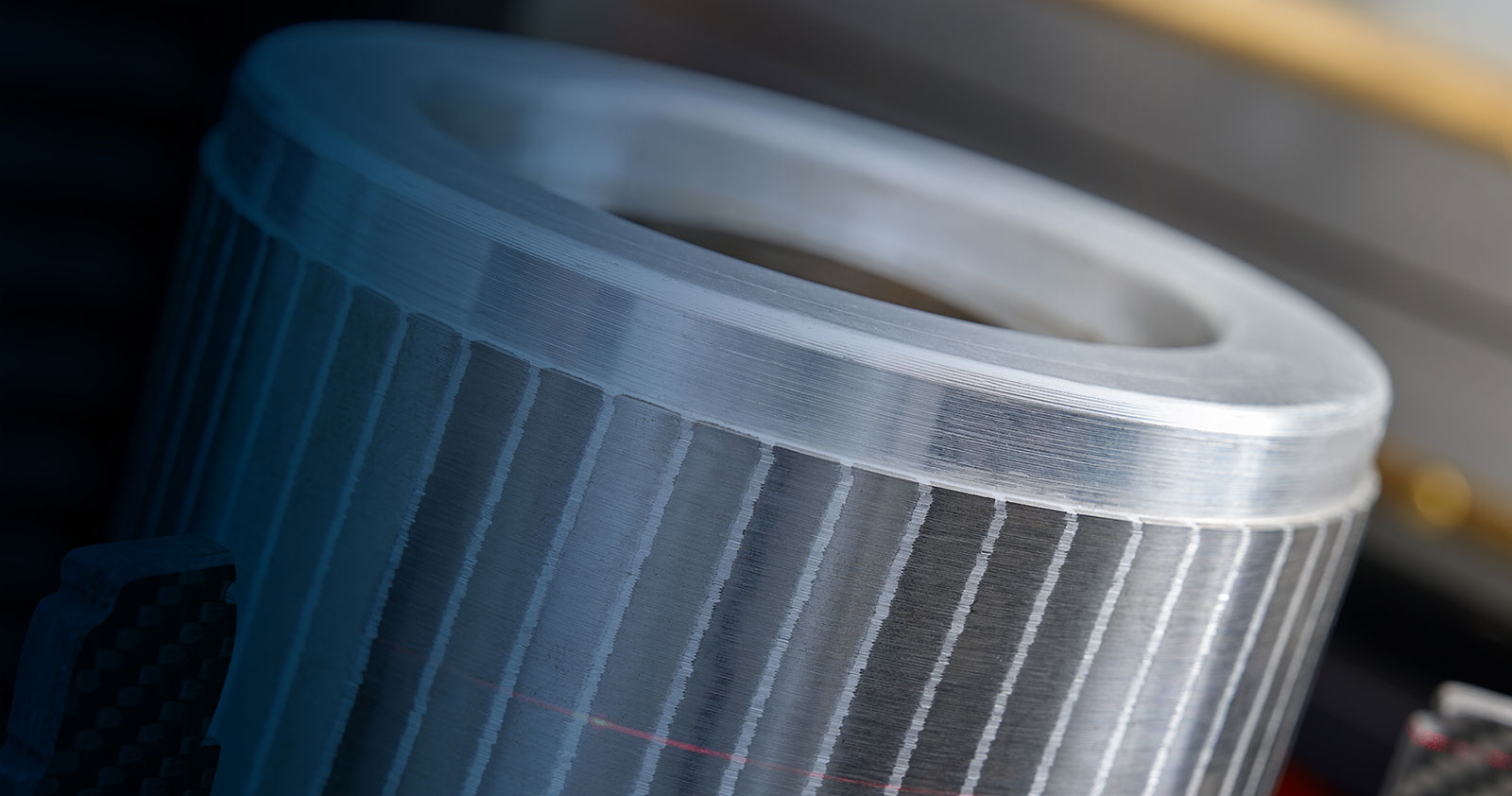

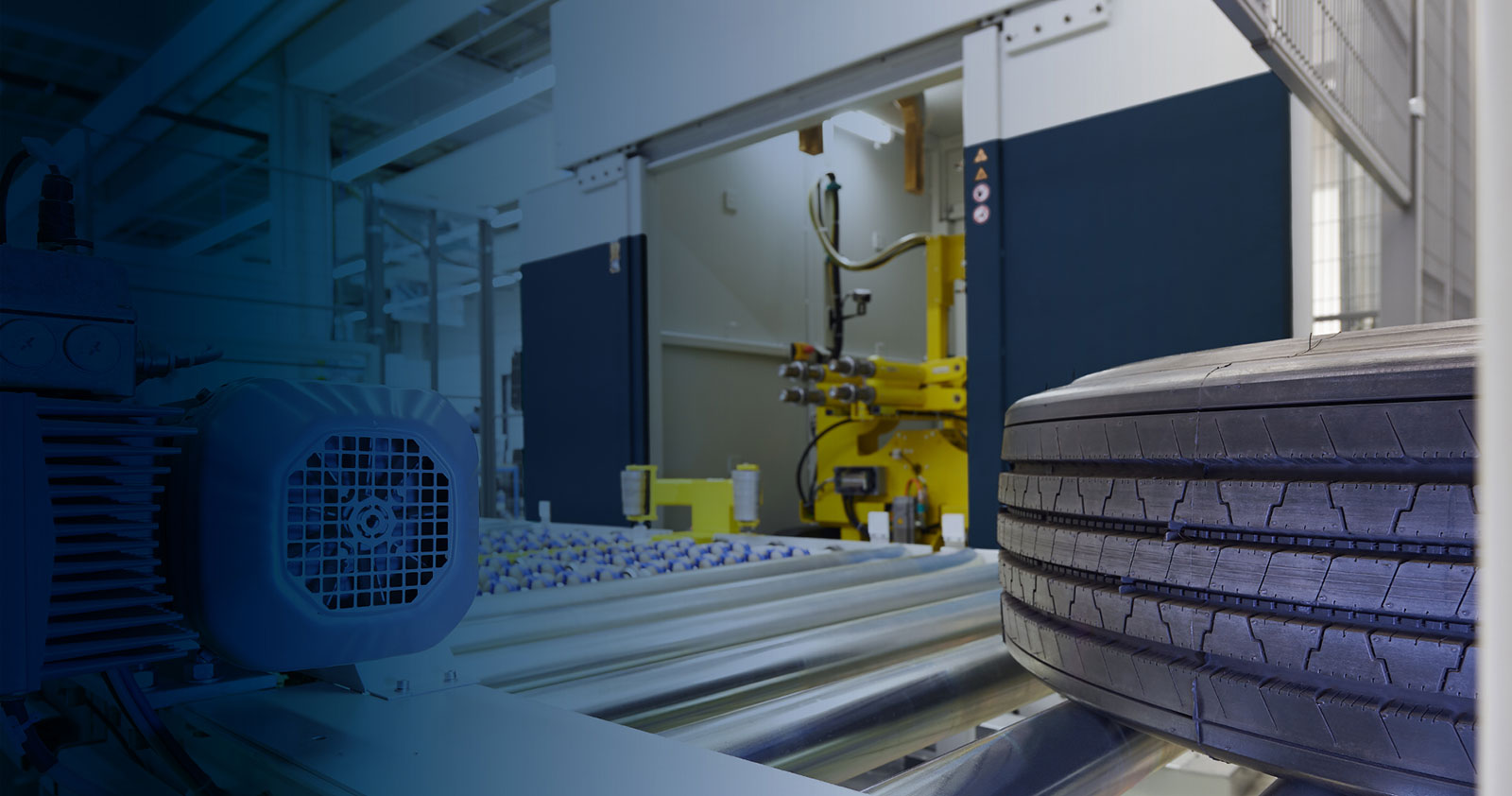

MTIS-The world's leading X-ray system for radial tire inspection.

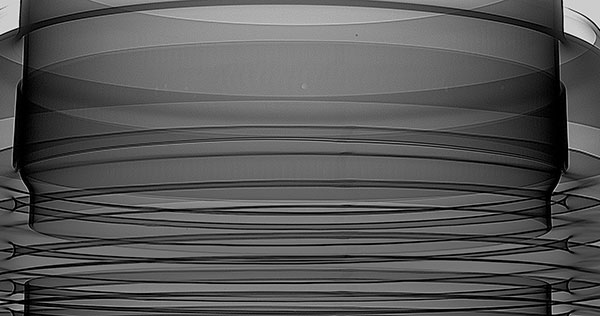

To produce radial truck, bus, and passenger car tires, non-destructive material testing with the help of digital radioscopy has become an indispensable tool. Whether directly integrated into the production process or for product development: Industrial X-ray inspection systems support the operator during quality assurance or perform the final evaluation of the X-ray image fully automated.

Finding tire anomalies with the market leader

With more than 375 units sold worldwide and a reliable uptime of more than 95%, Comet Yxlon’s MTIS is the gold standard for 24/7 inline quality assessment of radial tires. The MTIS system reliably identifies defects and irregularities such as- Inaccurate positioning of structural steel components

- Defects of the components, i.e., loose wires or dog ears

- Separated cords or irregular cord spacing in the sidewall

- Inclusions of foreign material or defects in the rubber compound

- Defects in the bead core areas

- Irregular cut belt edges

- Asymmetrical tire structure in the tread area

MTIS

-

From quality assurance to process optimization: the MTIS provides the highest image quality and inspection accuracy while gathering valuable statistical process control data.

MTIS highlights

- The most popular solution, more than 375 units sold worldwide

- High uptime for reliable 24/7 inline operation

- Leading image quality for dependable inspection decisions

- Outstanding accuracy and reproducible inspection results due to 4-spindle manipulation

- Automatic defect recognition (ADR) for objective and efficient inspection

- Data acquisition from each tire enabling statistical process control

Technical Details

- Attribute: Respective Value (TBR)/ Respective Value (PCR)

- Tire Width: 100 - 508 mm / 4" - 20"/ 100 - 400 mm / 4" - 15.5" (with UScan 3-L) 100 - 350 mm / 4" - 13.5" (with UScan 3-M)

- Tire Inner Diameter: 13" to 26" tires 13" to 26" tires/ 12" on request

- Maximum Sample Weight: 160 [kg] / 352 [lbs]/60 [kg] / 132 [lbs]

- System Dimension: ~5400 x 5100 x 2700 [mm]/ ~4800 x 5100 x 2700 [mm]

- X-ray Tube: 100 kV / 300 W 100 kV / 300 W

- Detector Active Area: 2469 [px] (with UScan 3-L)/ 2469 [px] (with UScan 3-L) 1819 [px] (with UScan 3-M)

- Pixel Pitch: 500 [µm]/ 500 [µm]

- Bit Depth: 16 [bit]/ 16 [bit]

Industries-Reliable inspection systems for every industry

Different industries have different needs: With a comprehensive range of industrial X-ray and CT systems, Comet Yxlon offers solutions for their specific challenges

Diverse inspection systems for manifold challenges

Close collaboration with manufacturers and science institutes is at the heart of Comet Yxlon’s customer-centric product development. Understanding the individual challenges of various industries, applications and businesses enable the creation of innovation and relevant solutions that help customers shape future markets. Comet Yxlon X-ray and CT inspection systems serve a wide range of traditional as well as new industries – from metal casting to e-mobility, from additive manufacturing to semiconductors, and many more.- Semiconducters

- Electronics

- Automotive

- Metal casting

- E-Mobility

- Additive Manufacturing

- Science and Research

- Aerospace

Semiconductors

From single die traditional packages to wafers and advanced packaging devices – Comet Yxlon supplies manufacturers with X-ray inspection systems that meet the high standards of semiconductor quality control.

Electronics

- Comet Yxlon X-ray inspection systems are designed for the safe and reliable, non-destructive testing of electronic, microelectronic, and electromechanical products.

Automotive

- Multi-material design, e-mobility, autonomous driving: In the fast-changing automotive sector, quality assurance must keep up with the new challenges. Just like the industry, Comet Yxlon systems are evolving constantly.

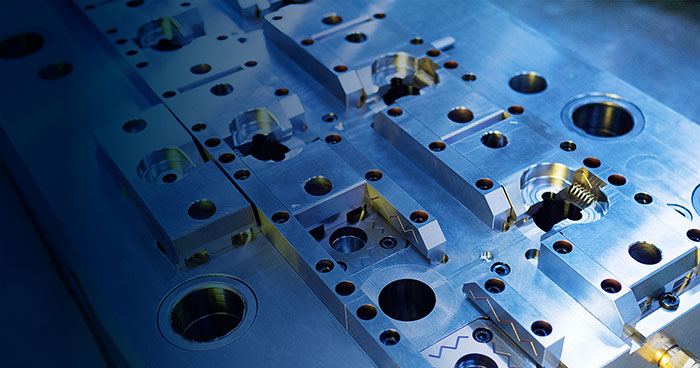

Metal Casting

- Porosities, pores, blisters, thermal cracking, dimensional changes, or inclusions – non-destructive testing (NDT) with Comet Yxlon industrial X-ray and CT systems enables high-volume inspection of typical casting flaws.

E-Mobility

- Highly complex, sensitive, and costly components used in electric vehicles (EVs) such as battery cells demand modern test methods like CT to ensure safety and performance.

Additive manufacturing

- Since the early days of additive manufacturing, computed tomography has been the quality assurance tool of choice. Now CT validates its strengths as an informational tool in R and D.

Science and Research

- From Megalodon teeth to carbon bikes, from soil samples to medical implants – Comet Yxlon supports science and research with cutting-edge X-ray and CT inspection systems.

Aerospace

- Comet Yxlon X-ray and CT systems are designed to meet the most critical aerospace and defense standards and ensure the safe, reliable inspection of aircraft parts and materials.

Technologies

Comet Yxlon industrial X-ray and CT inspection systems help manufacturers and developers stay in control of product quality – with technologies like CT metrology, laminography, image software solutions, and data analytics.

Getting the most out of industrial X-ray and CT

While the term "industrial X-ray" often refers to classic 2D radiographic inspection, it is also the basis for many other non-destructive testing (NDT) technologies, such as industrial computed tomography (CT) or computed laminography. Inspection data from Comet Yxlon systems allow users to examine material samples, analyze defects or perform dimensional measurements. Powerful image software solutions and data analysis tools enable the easy and fast evaluation of inspection data and help optimize production processes.

Industrial X-ray

2D digital radioscopy with Comet Yxlon inspection systems gives operators insight into the internal structures of components – from microchips to massive engines.

Industrial X-ray is applied in

- First article inspection

- Quality assurance and material analyses

- Failure analyses, e.g., flaws, porosities, cracks, inclusions

- Assembly checking

- Measurements of outer and inner structures

- Inspection of samples, small serial productions, and 100% inspection

- Process control

Industrial CT

3D computed tomography (CT) visualizes the inner structures of a scanned object and lets operators identify the exact spatial position of defects.

Computed tomography is one of the most important and powerful non-destructive testing methods in quality assurance and quality control. Comet Yxlon CT inspection systems support manufacturers and scientists, e.g., in the electronics, automotive, and aerospace industries, in their pursuit of maximum product quality, and efficient production processes – with fewer rejects and recalls, less waste, and less downtime.

Computed Iaminography

- Comet Yxlon systems use computed laminography to inspect flat components like microchips, PCBs, phones, and tablets, or EV batteries.

Computed laminography is sometimes referred to as “2.5D inspection” because it is a technological intermediate between 2D X-ray radioscopy and 3D computed tomography (CT). Laminography addresses the specific challenges of inspecting flat components, such as printed circuit boards (PCB), microchips (IC), entire cell phones, tablets, laptops, or even scripts on papyrus. While a 2D X-ray inspection provides high resolution but does not give spatial information, 3D CT supplies good spatial information but can lack resolution. A case for laminography: It adds depth information to high-resolution 2D images, so defects can be reliably detected and spatially located in a plane object.

CT metrology

- Comet Yxlon high-resolution CT systems for dimensional measurement deliver precise and accurate data for use in quality assurance, science, and research.

Analyses and measurements of the internal structures of objects have become very important, especially in the context of new additive manufacturing methods. Non-destructive testing with Comet Yxlon CT metrology scanners produces volume data containing comprehensive geometrical information. With an almost unlimited number of reference points, a complete part can be measured, while internal measurements of cavities and material interfaces in hybrids and assemblies can be added later.

Image software solutions

- Thanks to smart software solutions like Comet Yxlon’s user interface Geminy, X-ray and CT inspections are as easy as never before.

Traditionally, X-ray systems were designed by experts for experts and were usually complex to operate. But the new working environment of Industry 4.0 has changed priorities: today, workers need to have a broad knowledge of various tasks and systems instead of specialized knowledge for just one. Therefore, Comet Yxlon consistently pursues its path towards software products with a clear focus on user-friendliness. The simple, intuitive operation with Geminy, the customer-focused software platform for all our modern Comet Yxlon CT systems , eliminates the need for time-consuming and costly training and quickly guides any operator to the best test results.

Data Analytics

- A wide range of smart data analytics solutions supplies manufacturers with valuable data for process optimization and predictive maintenance.

X-ray and CT systems are sensors that provide rich data. While many manufacturers use the image data that the systems generate solely for quality assurance and product analytics applications, the raw data material itself can serve a lot of additional purposes. Comet Yxlon offers a wide range of smart data analytics solutions that allow manufacturers to tap into their valuable data lake and use the information smartly for process optimization and predictive maintenance.

Quality Assurance

-

Non-destructive testing with industrial X-ray and CT systems from Comet Yxlon helps manufacturers monitor and optimize both product and process quality.

Fast, convenient, and cost-efficient inspections

In the diverse field of quality assurance and quality control, Comet Yxlon stands for X-ray and CT inspection systems with easy operability for all types of cast parts, tires, electrical and electronic components, additively manufactured parts, welded joints, composites, ceramics, and a lot more. By minimizing rejects and downtimes and using inspection data to optimize the production process, Comet Yxlon X-ray and CT scanners help manufacturers produce the highest quality – and save time and money at the same time.

Control and assurance

Failure analysis, characterization, or process optimization – Comet Yxlon X-ray and CT systems take quality control and assurance to the next level.

Non-destructive testing

Deep insights into a component’s structure without altering the object: X-ray-based NDT methods are making the difference, in particular in combination with computed tomography.

CT metrology

Comet Yxlon CT metrology systems for quality assurance deliver premium dimensional measurements of internal and hard-to-access areas of industrial products.

Life Cycle Service

- Supporting you every step on the way

At Comet Yxlon, service is not an add-on, but an integral part of every product. We support you through the entire lifecycle of your system – to keep it running at peak performance for the long term.

Tailor-made services for a long-term partnership

Offline applications, at-line scenarios, or in-line implementation – Comet Yxlon supplies tailored service solutions for a wide range of production environments. We use a 360° customer perspective to find out how we can help you best: Whether you are an X-ray beginner or a CT expert, our service team is here to support you. In addition to our full-service support, we also offer our customers self-service collaboration on demand.

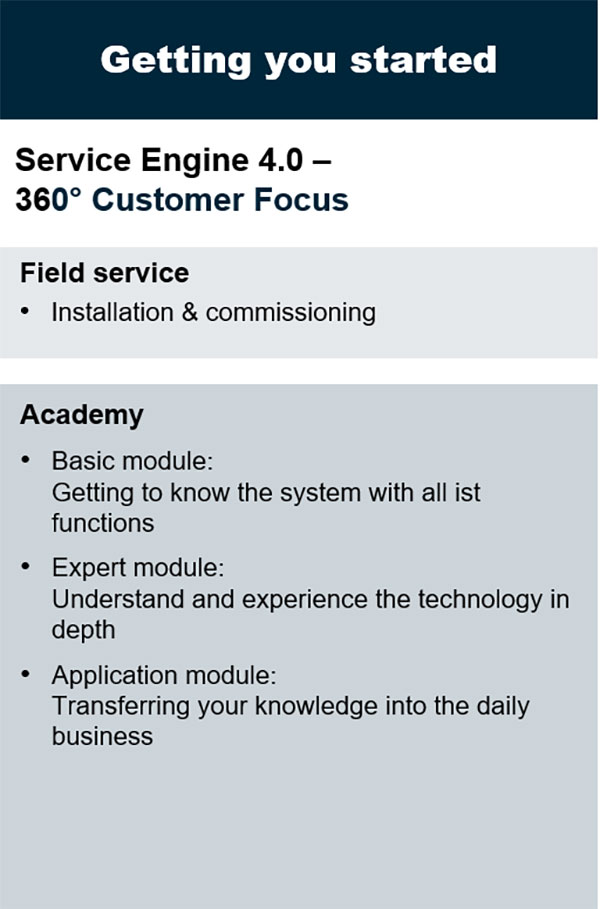

Getting you started

- All’s well that starts well: Our professional installation and trainings will ease your way into working with your new inspection system.

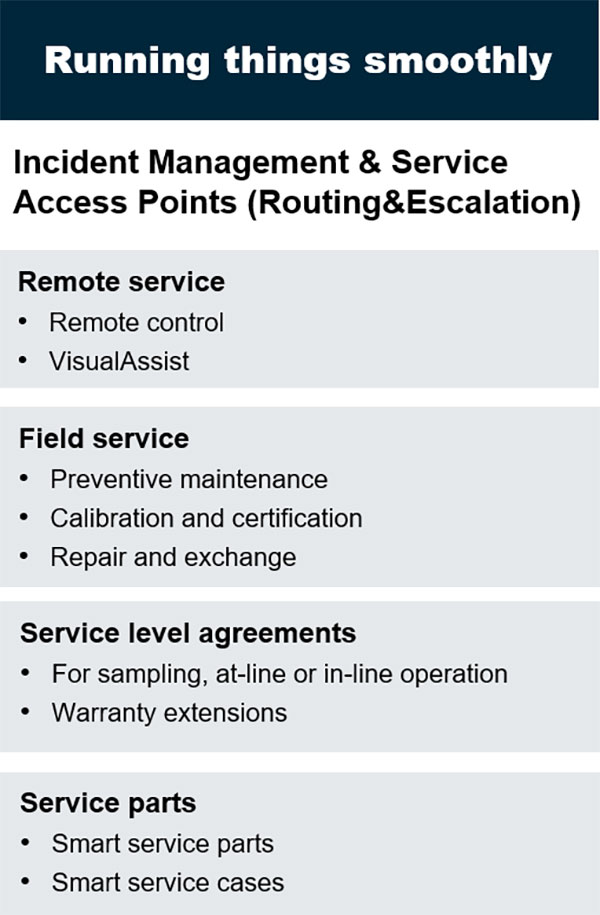

Running things smoothly

- Is there an issue? No problem. Our skilled service technician team helps with troubleshooting, maintenance, and part exchange for an easy operation of your Comet Yxlon system.

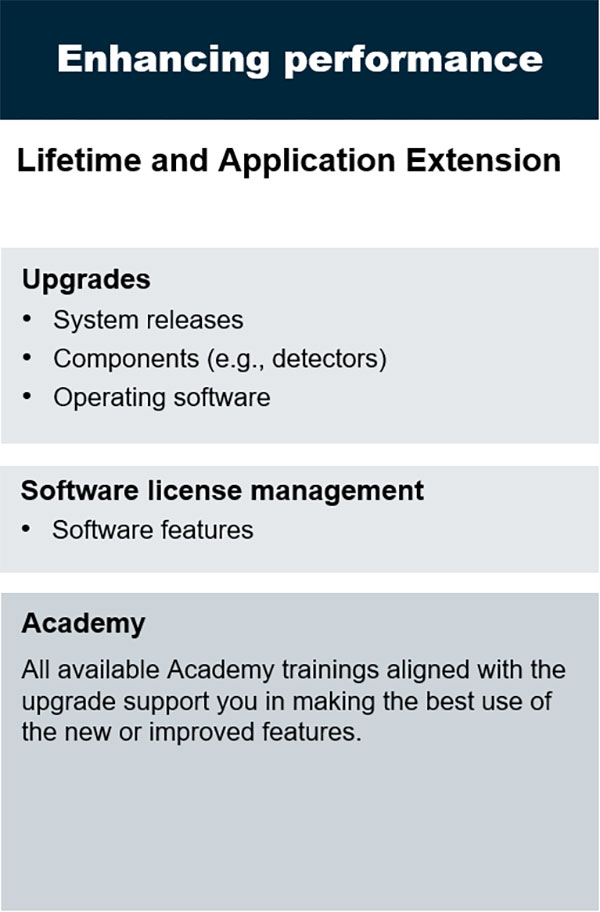

Enhancing performance

Let’s keep your investment safe: With our Upgrades and Conversion Kits, your Comet Yxlon system remains in top-notch condition and keeps its value as market demands change.

The Comet Yxlon FF35 CT SEMI X-ray system is an innovative, versatile high-resolution CT system for use in research and development and quality assurance. It was developed specifically for inspections in semiconductor-related industries. The FF35 CT SEMI meets the high SEMI® standards, including the hazard and safety standards SEMI® S2-0818 and SEMI® S8-0218, and is certified accordingly.

Which applications is the FF35 CT designed for?

The smaller components become, the more important it is to achieve highly accurate, reliable X-ray and CT scans for quality assurance, process control, and small series inspections. The extremely compact high-resolution systems Comet Yxlon FF20 CT and FF20 CT Metrology are designed specifically for the inspection of very fine parts and internal structures. With comparatively high energy of 190 kV, even dense items can be analyzed to the smallest detail.

Which applications is the FF20 CT designed for?